Comprehensive Allis Chalmers B Parts Diagram Guide

Understanding the intricacies of older machinery can often be a daunting task. Each element plays a crucial role in the overall function, and a clear representation of these elements is essential for efficient maintenance and repair. By examining detailed schematics, enthusiasts and professionals alike can gain insights into how different parts interact and contribute to the machine’s performance.

In this section, we will delve into the various components of classic equipment, providing an ultimate guide to their configurations. This resource aims to facilitate a deeper comprehension of each element, allowing users to navigate the complexities with ease. Whether you are a seasoned technician or a passionate hobbyist, familiarizing yourself with these layouts can enhance your understanding and skills.

Equipped with this knowledge, you will be better prepared to tackle challenges related to restoration and upkeep. From identifying individual components to understanding their assembly, the information provided here is invaluable for anyone working with vintage machinery.

Understanding Allis Chalmers B Parts

Grasping the components of vintage machinery can significantly enhance maintenance and repair efforts. A clear comprehension of each element ensures optimal performance and longevity. Recognizing the various sections and their functions is crucial for any enthusiast or operator.

Key Components: This machinery consists of several essential units, each playing a vital role. Familiarizing oneself with these parts aids in identifying issues and streamlining repairs.

Maintenance Tips: Regular checks and understanding of wear patterns can prevent larger problems down the line. Keeping an eye on these details will help maintain functionality and efficiency.

In summary, delving into the intricacies of these components is the ultimate way to ensure your equipment operates at peak performance.

Importance of Parts Diagrams

Visual representations of components are essential tools in any maintenance or repair process. They provide clarity and enhance understanding of complex machinery, enabling technicians to identify and source necessary elements efficiently.

Facilitating Efficient Repairs

Using these visual guides streamlines the repair process. Benefits include:

- Quick identification of needed components

- Reduced risk of errors during assembly

- Enhanced troubleshooting capabilities

Supporting Maintenance and Upgrades

These illustrations also play a vital role in ongoing maintenance and upgrades:

- Help in planning preventive maintenance tasks

- Assist in modifying or improving existing systems

- Provide a reference for compatibility when replacing elements

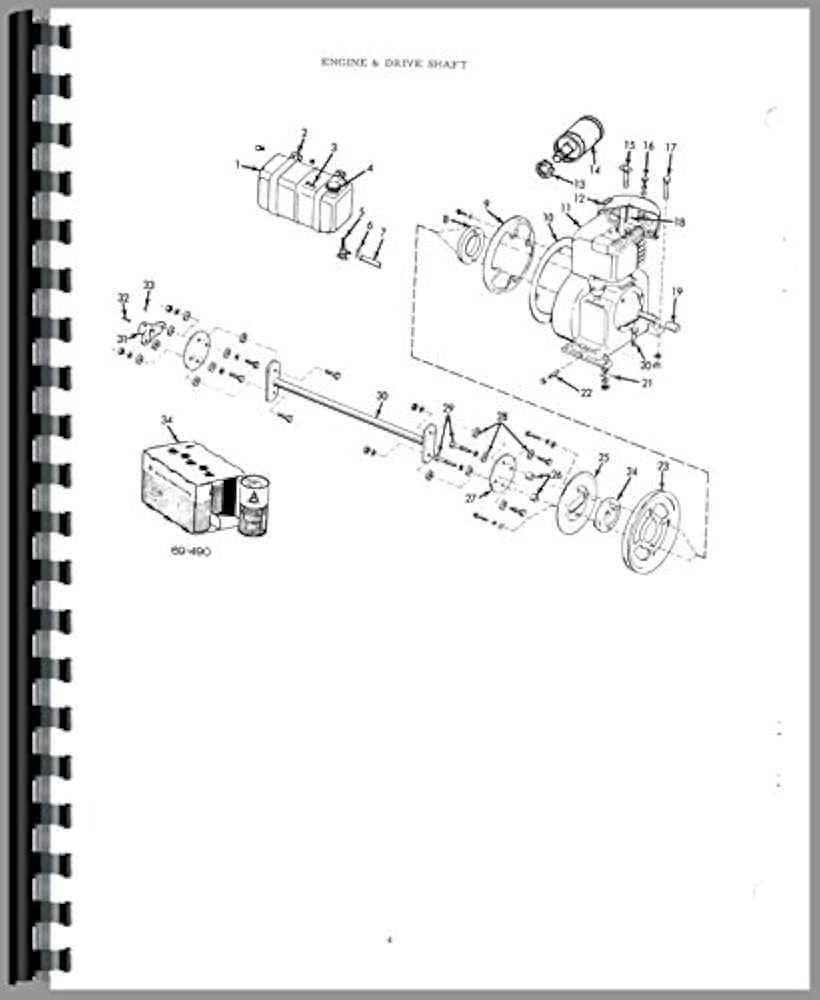

Key Components of the Allis Chalmers B

The efficient operation of any machinery relies heavily on its essential elements. Understanding these fundamental components allows users to maintain, repair, and optimize performance effectively. This section highlights the significant aspects of this particular model, emphasizing their roles and interactions.

| Component | Description |

|---|---|

| Engine | The powerhouse that converts fuel into mechanical energy, driving the entire system. |

| Transmission | This unit transfers power from the engine to the wheels, allowing for speed regulation and torque management. |

| Hydraulic System | Facilitates movement and operation of implements through pressurized fluid, enhancing versatility. |

| Steering Mechanism | Enables precise navigation and control, ensuring effective maneuverability in various conditions. |

| Chassis | The framework that supports all components, providing stability and durability under operational stress. |

Each of these elements plays a vital role in the overall functionality, contributing to a cohesive and reliable machine that meets user demands in various agricultural applications.

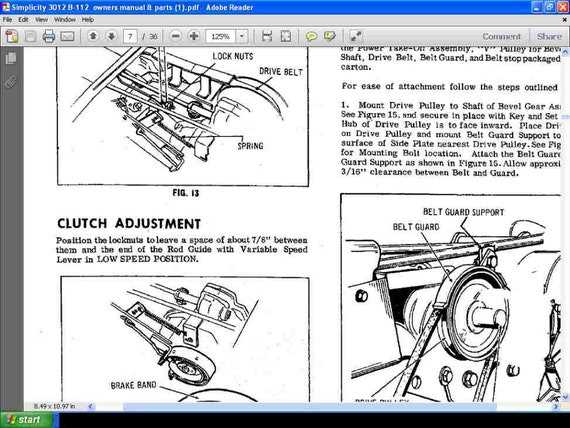

How to Read a Parts Diagram

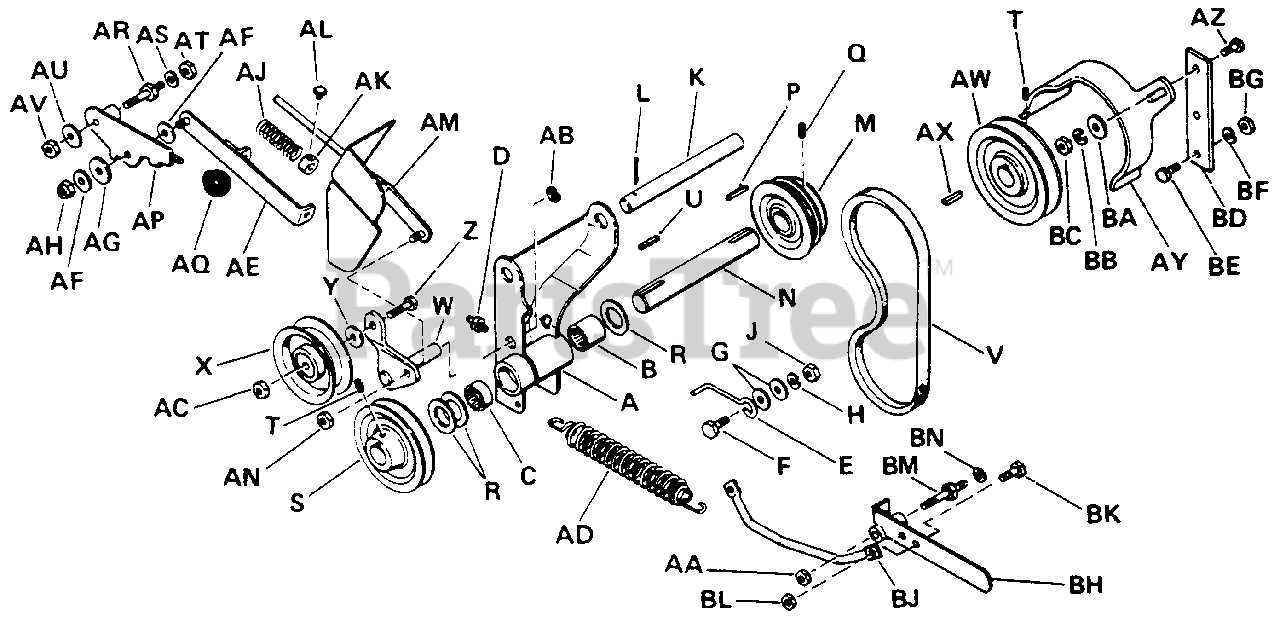

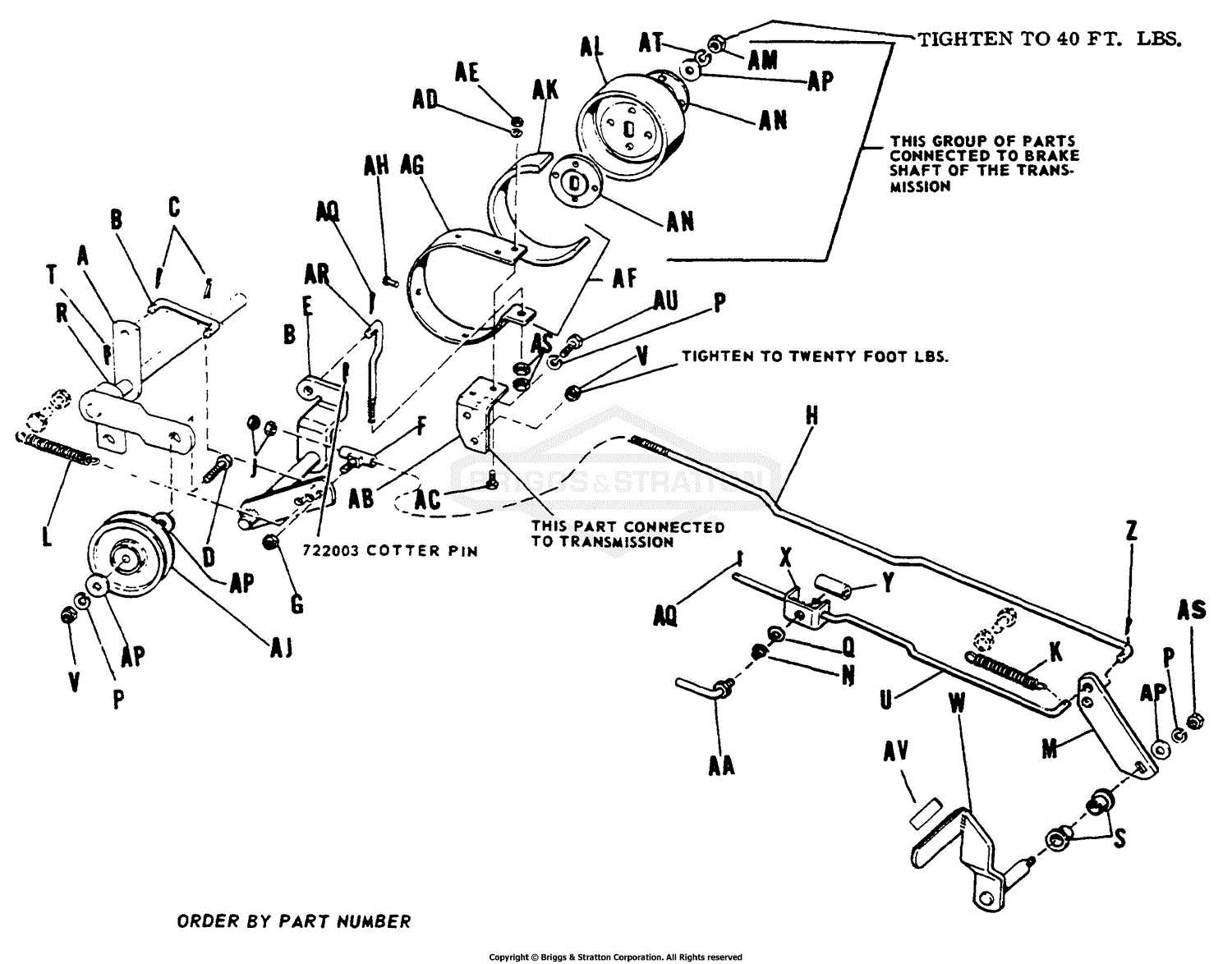

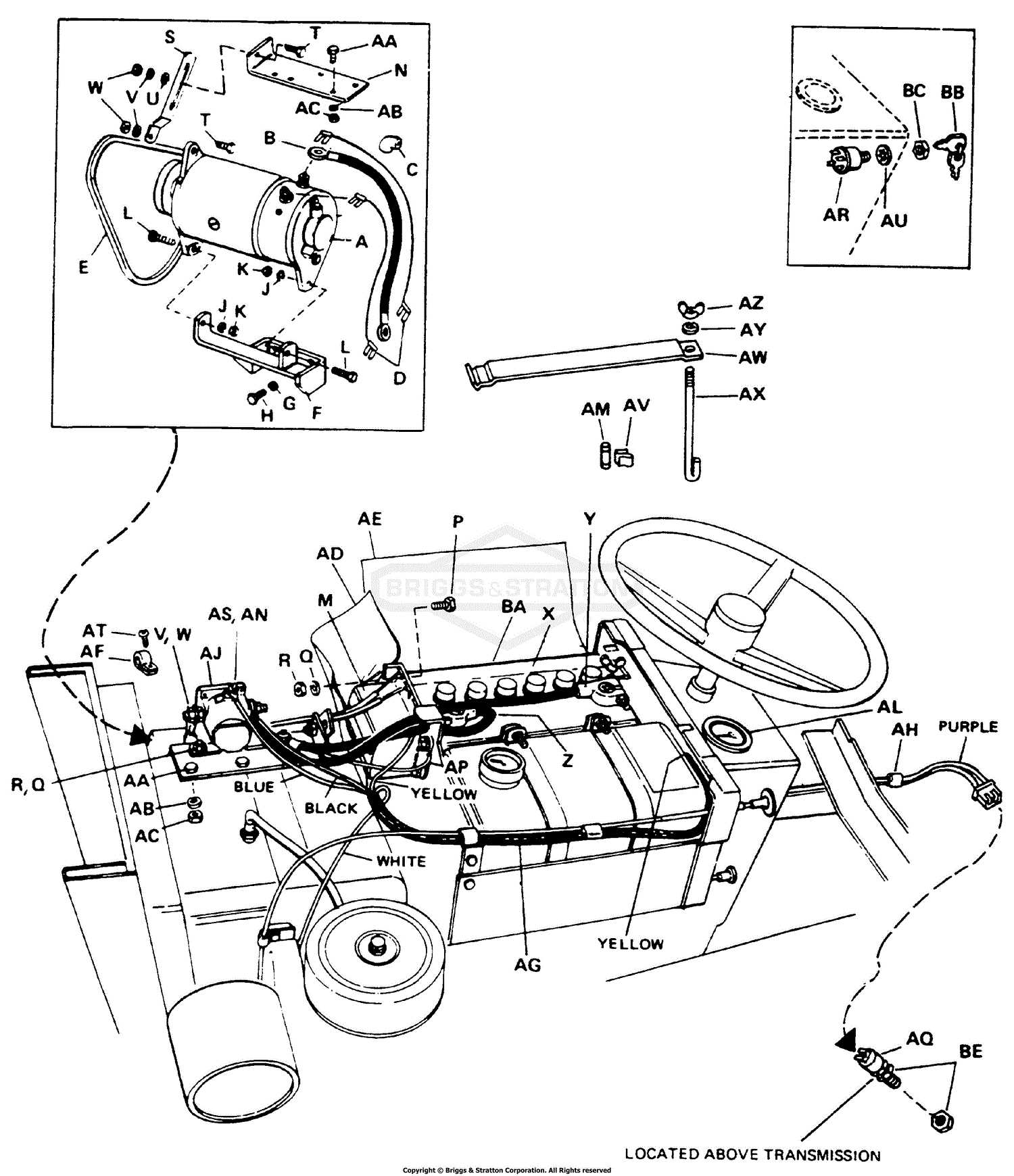

Understanding a schematic representation of components can greatly enhance your ability to identify and manage various elements within machinery. This visual tool serves as a guide, allowing users to locate specific sections and understand the relationships between different parts. Familiarity with symbols and notations is essential for effective interpretation.

Start by examining the legend, which explains the symbols used throughout the illustration. Next, focus on the layout, as it typically follows a logical sequence that mirrors the physical arrangement of components. Highlighted areas may indicate key sections that require special attention, while arrows often depict movement or connections between elements.

Pay close attention to numbers or codes that correspond to a list or table, providing additional details such as specifications or quantities. This information is crucial for ordering replacements or planning maintenance. By developing a keen eye for these details, you’ll enhance your understanding and efficiency in working with machinery.

Common Issues with Allis Chalmers B

This section explores frequent problems encountered with this particular vintage machinery, highlighting key areas that may require attention or maintenance. Understanding these common challenges can aid in effective troubleshooting and prolong the lifespan of the equipment.

Engine Performance

Engine-related issues are among the most prevalent concerns. These can range from starting difficulties to inconsistent power delivery, often attributed to fuel system complications or ignition failures.

Hydraulic System Failures

The hydraulic system is crucial for optimal operation. Problems such as leaks or insufficient pressure can lead to diminished performance, requiring prompt diagnosis and repair.

| Issue | Description |

|---|---|

| Starting Problems | Difficulty in igniting the engine due to fuel or electrical issues. |

| Power Loss | Inconsistent engine output that affects overall functionality. |

| Hydraulic Leaks | Fluid loss that can impede lifting and lowering operations. |

| Poor Steering | Difficulty in maneuvering, often linked to hydraulic malfunctions. |

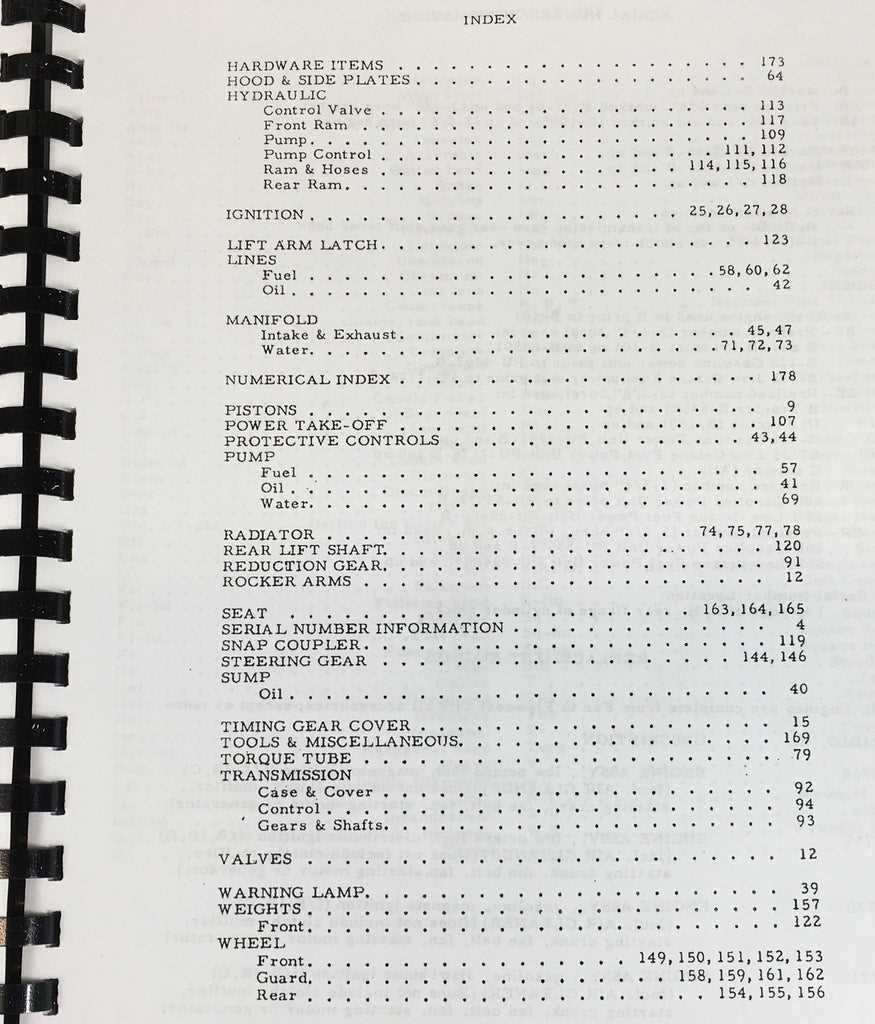

Where to Find Parts Diagrams

Locating visual guides for machinery components can greatly enhance your repair and maintenance efforts. These illustrations not only aid in understanding the assembly but also streamline the process of identifying specific pieces needed for replacement or repair. With various resources available, enthusiasts and professionals alike can easily access these valuable references.

Online Resources: Numerous websites provide extensive collections of visual references for different models. Manufacturer sites often host detailed catalogs, while dedicated forums and community groups can offer user-shared materials that may not be available elsewhere.

Service Manuals: Many manufacturers publish comprehensive manuals that include visual aids. These documents can often be purchased or downloaded, and they usually contain essential information alongside the illustrations, making them a reliable choice for anyone working on machinery.

Local Dealers: Visiting a local dealer or distributor can be beneficial. They frequently have access to original resources and can provide assistance in finding specific illustrations relevant to your needs.

Library and Archives: Don’t overlook public libraries or online archives, which may have historical manuals or reference books that include diagrams. This can be especially useful for vintage equipment where newer online resources might be scarce.

By exploring these avenues, you can efficiently find the visual references necessary for effective maintenance and repair of your machinery.

Types of Parts Available

This section explores the various components essential for maintaining and enhancing machinery performance. Each item plays a vital role in ensuring efficiency and longevity.

Engine Components: These elements include items such as cylinders, pistons, and crankshafts, crucial for the internal workings and power generation.

Transmission Elements: This category encompasses gears, clutches, and belts, all necessary for smooth operation and power transfer.

Hydraulic Systems: Essential for controlling movement and force, these parts include pumps, valves, and hoses, enabling precision in operation.

Electrical Components: This includes wiring, starters, and alternators, which are vital for ignition and electrical systems.

Frames and Chassis: These structural elements provide stability and support, ensuring that all other components function effectively.

Understanding the variety of components available is key to optimal maintenance and performance enhancement.

Repair Tips for Allis Chalmers B

Maintaining and restoring vintage machinery requires attention to detail and a systematic approach. Understanding common issues and how to address them can significantly enhance performance and longevity.

Routine Maintenance

Regular checks on oil levels, coolant, and air filters are crucial. Always replace fluids at recommended intervals to ensure optimal functioning.

Common Issues

Engine overheating can often be traced back to clogged radiators or faulty thermostats. Inspect these components regularly. Additionally, ignition problems may arise from worn spark plugs or faulty wiring, which should be examined and replaced as necessary.

Lastly, keep your equipment clean to prevent dirt buildup, which can lead to further complications down the line.

Maintenance Best Practices

Effective upkeep is crucial for ensuring longevity and optimal performance of machinery. Adopting systematic approaches can prevent potential issues and enhance efficiency. Regular attention to details and adherence to schedules are key components of a successful maintenance routine.

Regular Inspections

Conducting routine evaluations of equipment allows for early detection of wear and tear. Visual checks can reveal irregularities, while more in-depth assessments may require specialized tools. Implementing a checklist can help maintain consistency during these inspections.

Proper Lubrication

Ensuring that moving parts are adequately lubricated is essential for minimizing friction and reducing wear. Using the correct type of lubricant can significantly impact performance. Follow manufacturer guidelines to determine the appropriate intervals and products for lubrication.

Aftermarket vs. OEM Parts

The choice between replacement components from original manufacturers and those produced by third parties is a crucial consideration for many. Each option presents its own set of advantages and drawbacks that can significantly impact performance, longevity, and cost-effectiveness.

Benefits of OEM Components

Original components are designed to meet the specific standards set by the manufacturer, ensuring compatibility and reliability. They often come with warranties and are tested rigorously, providing peace of mind for the user.

Advantages of Aftermarket Alternatives

Third-party options frequently offer more competitive pricing and a wider variety of choices. They can enhance performance and may provide features not available in original designs, appealing to those looking to customize their equipment.

Upgrading Your Allis Chalmers B

Enhancing your vintage machinery can significantly improve its performance and efficiency. By making thoughtful modifications, you can breathe new life into your equipment, ensuring it meets modern demands while maintaining its classic charm.

Key Areas for Improvement

- Engine Performance

- Transmission Upgrades

- Hydraulic System Enhancements

- Electrical System Revamps

Steps to Consider

- Research compatible aftermarket components.

- Evaluate the current condition and identify weaknesses.

- Consult with experts or forums for advice.

- Plan and budget for necessary upgrades.

Resources for Allis Chalmers Owners

For those who own classic machinery, finding reliable information and support is essential. A wealth of resources is available to help enthusiasts maintain and restore their equipment, ensuring optimal performance and longevity. Whether you are a seasoned operator or a newcomer, these tools and communities can greatly enhance your experience.

Online Communities and Forums

Engaging with fellow enthusiasts can provide invaluable insights. Numerous online platforms host forums where owners can share experiences, troubleshoot issues, and exchange tips. These communities often feature sections dedicated to specific models, allowing for targeted advice and discussions.

Manuals and Technical Resources

Access to user manuals and technical guides is crucial for proper upkeep. Many websites offer downloadable resources that cover maintenance schedules, operation instructions, and repair guidelines. Utilizing these documents can save time and ensure that machinery remains in peak condition.