Comprehensive Parts Diagram for Belarus 825

The intricacies of agricultural machinery are fundamental to their efficient operation. A comprehensive understanding of how various elements interconnect can enhance maintenance and repair processes. This exploration delves into the essential segments that constitute heavy-duty equipment, shedding light on their functionalities and interrelationships.

In the realm of mechanized farming, every component plays a critical role in ensuring optimal performance. From the engine to the transmission, each part contributes to the overall efficacy of the machine. By examining these elements closely, operators can identify potential issues before they escalate, thereby maximizing productivity.

Visual representations serve as invaluable tools in grasping the layout and organization of these components. Detailed illustrations provide clarity on the positioning and assembly of parts, facilitating a deeper understanding for users. This knowledge empowers operators to conduct repairs confidently and maintain their equipment in peak condition.

Overview of Belarus 825 Model

This section provides a comprehensive look at a prominent agricultural machine known for its robust performance and versatility. Designed to meet the needs of modern farming, this model excels in various tasks, making it an essential asset for many agricultural operations.

With a powerful engine and a well-engineered chassis, this vehicle is capable of handling demanding fieldwork, including plowing, tilling, and hauling. Its durability ensures long-term reliability, even in challenging conditions. The ergonomic design enhances operator comfort, allowing for extended usage without fatigue.

Furthermore, the adaptability of this machine is notable, as it can be equipped with a range of implements tailored for specific agricultural tasks. This flexibility makes it suitable for different farming practices, from small family farms to large commercial operations. Overall, the combination of strength, efficiency, and adaptability establishes this model as a key player in the agricultural sector.

Key Specifications and Features

This section highlights the essential characteristics and technical details that define this agricultural machine, showcasing its capabilities and advantages in various applications.

- Engine Type: Powerful diesel engine with high torque.

- Horsepower: Robust output for efficient performance.

- Transmission: Advanced gearbox for seamless shifting.

- Weight: Optimized for stability and traction.

- Hydraulic System: Enhanced lifting capacity for implements.

Additional features include:

- Ergonomic operator station for comfort.

- Versatile attachment options for various tasks.

- Durable construction for longevity and reliability.

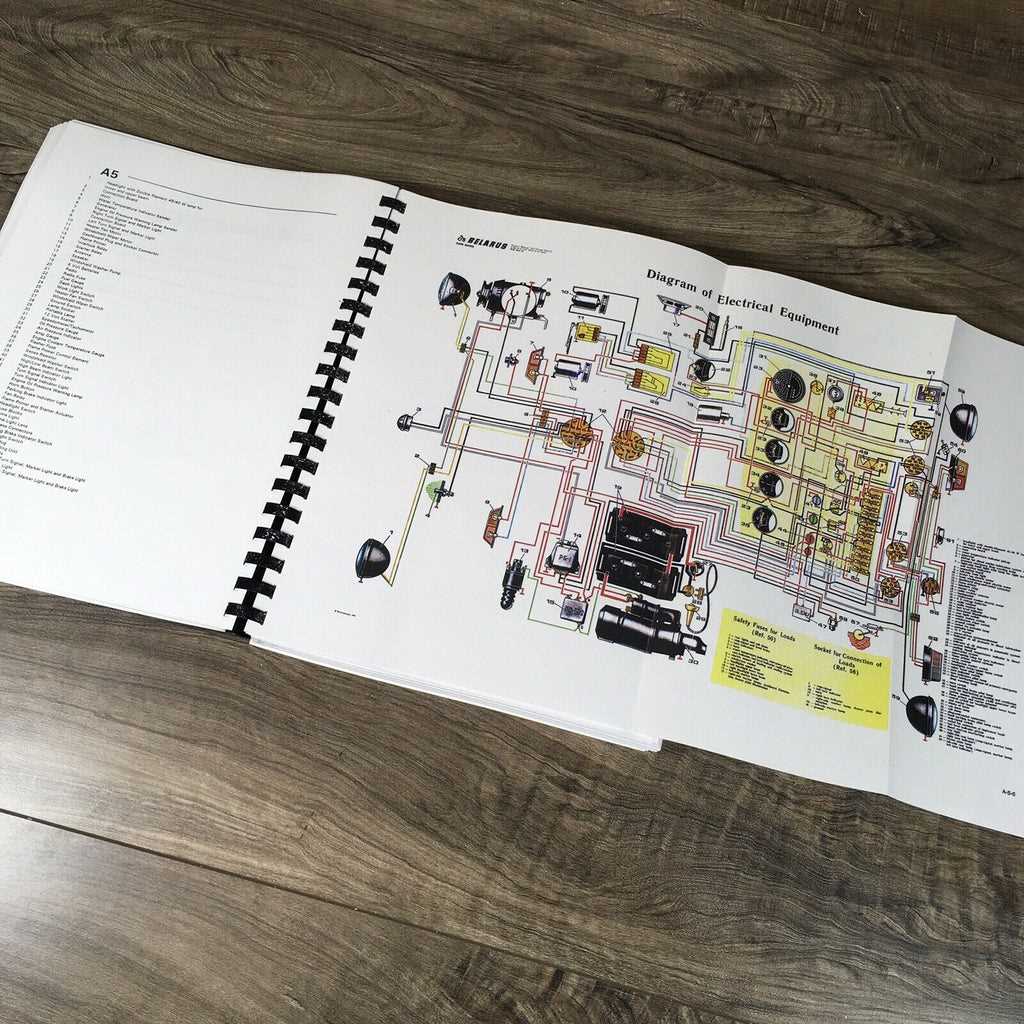

Understanding the Parts Diagram

The visual representation of components serves as a crucial tool for comprehending the intricacies of machinery. By breaking down each element, users can effectively identify and understand the relationships between different sections, facilitating maintenance and repair tasks.

Importance of Component Visualization

Clear illustrations help users navigate complex systems. They highlight the functionality of individual pieces while showcasing how they interact with one another, thus providing a comprehensive overview necessary for efficient troubleshooting.

Key Elements in the Visual Representation

| Element | Description |

|---|---|

| Labeling | Identifies each component for easy reference. |

| Connection Lines | Indicate how components interact and fit together. |

| Color Coding | Helps distinguish between different types of parts or functions. |

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the durability and efficiency of any machinery. A consistent maintenance schedule helps identify potential issues before they escalate, thus prolonging the lifespan of equipment. Neglecting this aspect can lead to significant performance declines and costly repairs.

Key Benefits of Regular Upkeep

Implementing a routine maintenance plan offers several advantages:

| Benefit | Description |

|---|---|

| Enhanced Performance | Regular checks optimize operational efficiency, ensuring smoother functioning. |

| Cost Savings | Addressing minor issues early reduces the likelihood of major breakdowns and expenses. |

| Increased Safety | Proper maintenance minimizes the risk of accidents and enhances user safety. |

Conclusion

Investing time and resources into regular maintenance not only safeguards functionality but also ensures a longer service life for machinery. Prioritizing this practice is essential for optimal performance and economic efficiency.

Common Issues and Solutions

This section aims to highlight frequent challenges encountered with agricultural machinery and provide effective remedies to enhance performance and longevity. Understanding these common problems can lead to more efficient operations and reduced downtime.

Overheating: One prevalent issue is excessive heat generation, often caused by inadequate cooling systems. Regular maintenance and timely replacement of coolant can significantly mitigate this problem.

Fuel Inefficiency: Machines may exhibit poor fuel consumption due to clogged filters or faulty injectors. Cleaning or replacing these components can restore optimal fuel usage.

Electrical Failures: Electrical issues can arise from corroded connections or worn-out wiring. Conducting routine inspections and ensuring proper connections can help prevent these disruptions.

Wear and Tear: Regular wear can lead to decreased performance. Scheduled maintenance and timely replacement of worn parts are essential for maintaining operational efficiency.

How to Identify Genuine Parts

When it comes to machinery maintenance, ensuring the authenticity of components is crucial for optimal performance and longevity. Recognizing original elements can prevent potential issues that counterfeit or substandard alternatives may introduce. Understanding key characteristics of authentic items can save both time and resources in the long run.

Examine Packaging: Authentic components often come in high-quality packaging that includes detailed information such as part numbers, manufacturer logos, and certifications. Inspecting the packaging for any signs of wear or tampering can provide initial insights into the item’s legitimacy.

Check for Markings: Genuine components usually feature specific markings, including serial numbers or barcodes. These identifiers are often unique and can be cross-referenced with manufacturer databases to verify authenticity.

Research Supplier Reputation: Purchasing from reputable suppliers or authorized dealers is essential. Conducting thorough research on the seller’s background can help avoid counterfeit products and ensure you are receiving what you expect.

Material Quality: Authentic items are manufactured using high-grade materials that meet industry standards. Analyzing the texture, weight, and overall construction can reveal discrepancies that may indicate a fake component.

Price Comparison: If a deal seems too good to be true, it often is. Comparing prices with established market rates can help identify suspicious offers that may not reflect genuine products.

By paying close attention to these factors, individuals can significantly reduce the risk of acquiring counterfeit items, ensuring their machinery operates smoothly and efficiently.

Assembly Instructions for Belarus 825

This section provides essential guidelines for the assembly process of agricultural machinery, ensuring that each component is properly integrated for optimal performance. Adhering to these instructions will facilitate a smooth assembly experience and enhance the overall efficiency of the equipment.

Preparation Steps

Before beginning the assembly, gather all necessary components and tools. Ensure that the workspace is clean and organized, as this will help prevent any loss of parts. Review the provided documentation to familiarize yourself with the assembly sequence and identify any specific requirements for each component.

Assembly Procedure

Start by connecting the main frame with the chassis, ensuring all bolts are tightened securely. Progress through the individual sections methodically, referring to the guidelines for each part. Pay special attention to alignment and fit to avoid issues during operation. Finally, conduct a thorough inspection to confirm that everything is assembled correctly before proceeding to testing.

Tools Needed for Repairs

Proper maintenance and fixing of machinery require a specific set of instruments to ensure efficiency and accuracy. Having the right tools not only simplifies the process but also enhances safety and extends the life of the equipment.

Essential items include wrenches, screwdrivers, and pliers, which facilitate the disassembly and assembly of various components. Additionally, diagnostic tools such as multimeters and pressure gauges help identify issues accurately, allowing for targeted repairs.

Safety equipment, such as gloves and goggles, is crucial to protect the user from potential hazards during the repair process. Finally, a well-organized toolbox ensures that all necessary tools are readily accessible, streamlining the workflow and minimizing downtime.

Upgrading Components for Performance

Enhancing machinery efficiency involves a strategic approach to improving individual elements. By focusing on specific upgrades, operators can achieve better performance and longevity, ultimately leading to increased productivity.

- Engine Modifications: Upgrading the power unit can significantly boost torque and efficiency.

- Transmission Enhancements: Installing high-performance gear systems improves speed and responsiveness.

- Cooling Systems: Upgrading to advanced cooling solutions prevents overheating and extends operational life.

- Suspension Upgrades: Enhancing the suspension system leads to better stability and handling under load.

Implementing these upgrades allows for a tailored approach, ensuring that the equipment meets the demands of various tasks while optimizing overall performance.

Comparison with Other Tractors

This section explores the distinctions and similarities between various agricultural machines, highlighting their design features, performance capabilities, and user preferences. By analyzing these vehicles, we can better understand their roles in modern farming practices and the unique advantages they offer.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Engine Power | 85 HP | 75 HP | 90 HP |

| Weight | 3,000 kg | 2,800 kg | 3,200 kg |

| Fuel Efficiency | 10 L/h | 9 L/h | 11 L/h |

| Transmission Type | Manual | Automatic | Manual |

| Lift Capacity | 2,500 kg | 2,000 kg | 3,000 kg |

These comparisons reveal key insights into how different models cater to specific agricultural needs, thus allowing farmers to make informed choices based on their operational requirements.