Understanding the Blizzard Plow Parts Diagram for Effective Maintenance

In the world of winter maintenance, having a thorough grasp of the various elements that contribute to the functionality of snow-clearing machinery is essential. This knowledge not only enhances operational efficiency but also ensures that equipment runs smoothly, thereby minimizing downtime during critical weather conditions.

By delving into the intricate details of these crucial mechanisms, one can identify how each segment interacts within the broader system. This insight allows operators to troubleshoot issues effectively and maintain their tools in peak condition, ready to tackle the challenges posed by harsh winter environments.

Furthermore, a comprehensive overview of these components aids in understanding the engineering behind them, paving the way for informed decisions when it comes to upgrades or repairs. Knowledge in this area empowers users to optimize performance and prolong the lifespan of their essential equipment.

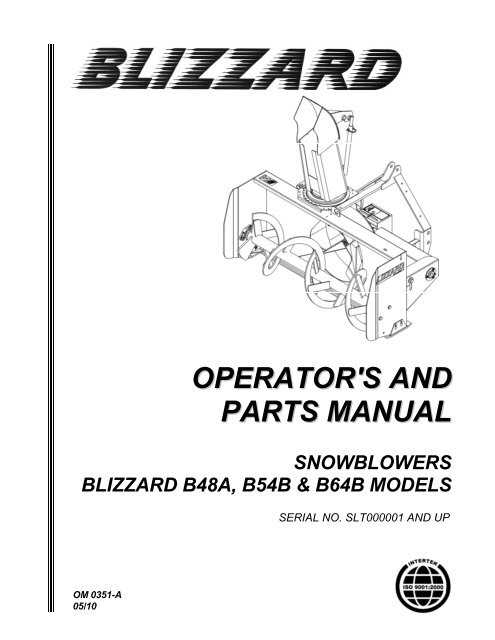

Understanding Blizzard Plow Components

When it comes to efficient snow management, having a thorough knowledge of the essential elements involved is crucial. Each component plays a vital role in ensuring optimal performance and functionality during winter operations. A comprehensive grasp of these elements not only aids in maintenance but also enhances overall operational effectiveness.

Key Elements of Snow Clearing Equipment

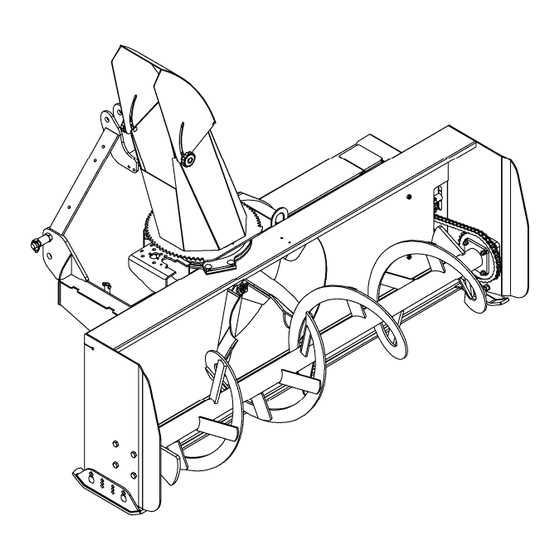

At the heart of any effective snow-clearing machine lies a collection of components that work in harmony. The primary mechanisms include the lifting system, which enables the apparatus to raise and lower, and the cutting edge, designed to effectively scrape surfaces. Understanding how these elements interact can significantly improve both the handling and longevity of the equipment.

Maintenance and Troubleshooting

Regular upkeep of these crucial components ensures that the machinery operates smoothly. Recognizing common issues, such as wear on the cutting edge or hydraulic system failures, is essential for timely repairs. By familiarizing oneself with the layout and function of each element, operators can swiftly diagnose problems and maintain optimal performance.

Overview of Plow Functionality

The operation of a snow-clearing device involves a series of components that work in harmony to ensure efficient movement of accumulated snow. Understanding how these elements interact provides insight into the overall efficiency and effectiveness of the equipment. Each feature plays a crucial role in enhancing performance and adapting to various winter conditions.

The core function revolves around the mechanism’s ability to adjust its angle and height, allowing it to effectively shift snow from driveways, roads, and sidewalks. This adaptability ensures optimal results regardless of the volume or type of snowfall encountered.

| Component | Function |

|---|---|

| Blade | Clears snow by pushing it to the side or away from the surface. |

| Lift System | Adjusts the height of the blade to suit different surfaces and snow depths. |

| Control Mechanism | Allows the operator to modify the blade’s position and angle easily. |

| Skids | Protect the surface underneath while providing stability during operation. |

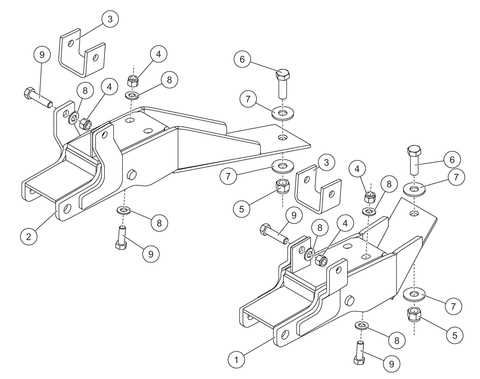

| Mounting Hardware | Secures the unit to the vehicle, ensuring durability and reliability. |

In conclusion, each element of this winter apparatus is designed to facilitate a seamless clearing experience. Understanding these functionalities not only enhances the effectiveness of snow removal but also extends the lifespan of the equipment through proper maintenance and operation.

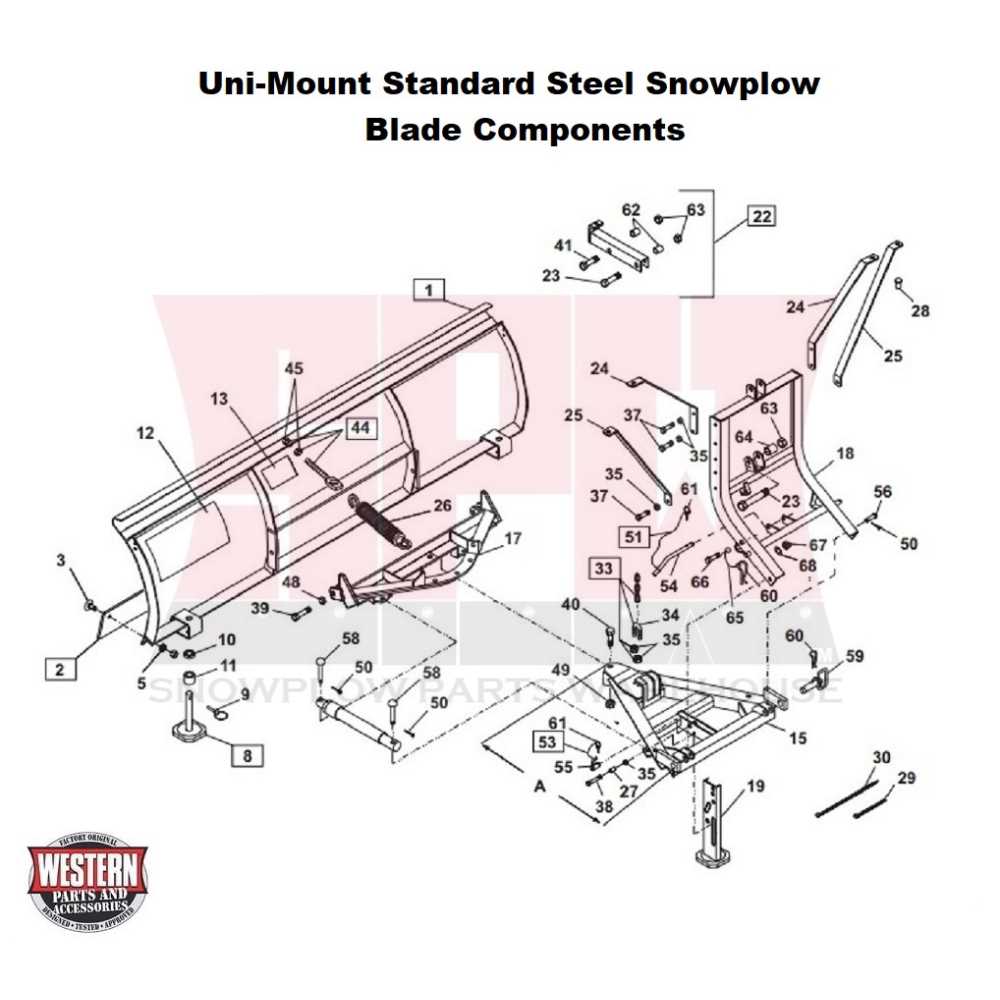

Key Parts of a Blizzard Plow

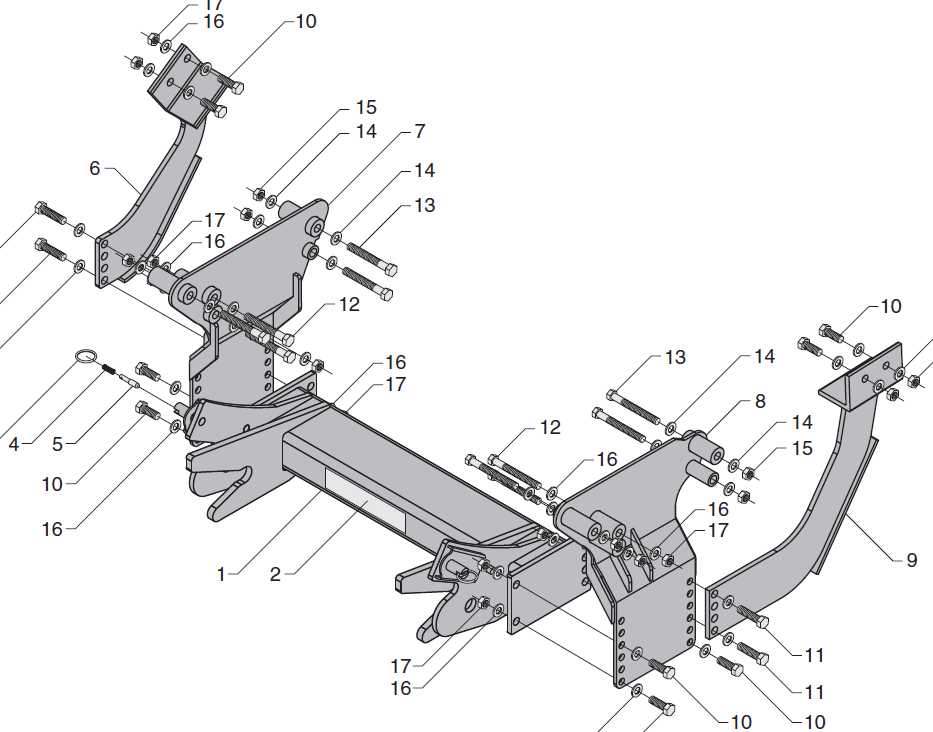

Understanding the essential components of a snow removal system is crucial for effective operation and maintenance. Each element plays a significant role in ensuring efficiency and reliability during winter conditions.

Main Components

- Frame: The sturdy base that supports all other elements, providing stability and strength.

- Blade: The front-facing piece responsible for pushing snow, available in various shapes and sizes for different applications.

- Lift Mechanism: Enables raising and lowering the blade, crucial for adjusting to different snow depths.

- Mounting System: Connects the snow management unit to the vehicle, ensuring secure attachment and ease of removal.

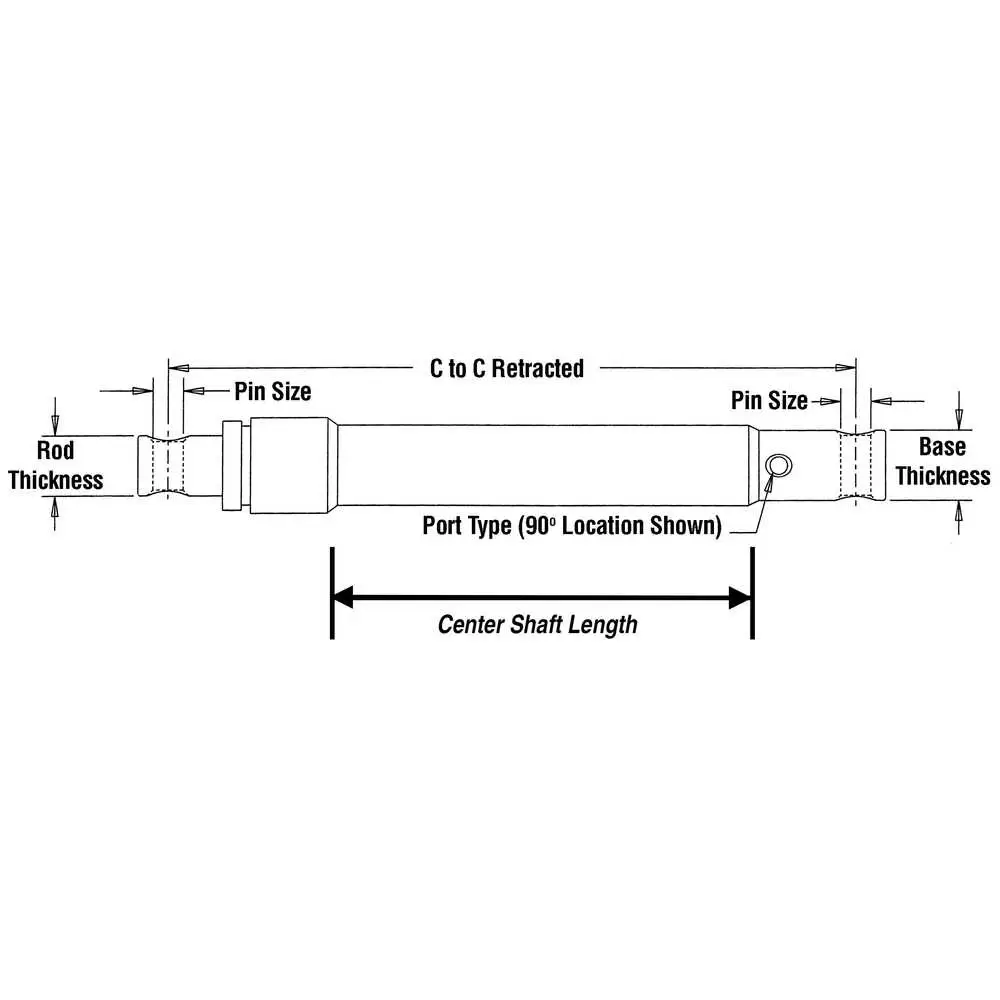

- Hydraulic System: Powers the movement of the blade and other components, allowing for smooth operation.

Additional Features

- Skids: Adjustable runners that control the height of the blade, protecting surfaces from damage.

- Wear Bars: Replaceable components that shield the blade’s edge from wear and prolong its lifespan.

- Trip Mechanism: A safety feature that prevents damage by allowing the blade to pivot over obstacles.

- Lights: Enhance visibility during nighttime operations, ensuring safety for the operator.

Familiarity with these vital components not only aids in troubleshooting but also enhances the overall performance of the snow removal apparatus, making winter tasks more manageable.

Importance of Maintenance and Care

Regular upkeep and attention are crucial for ensuring optimal performance and longevity of equipment used in demanding environments. Neglecting maintenance can lead to reduced efficiency, increased wear and tear, and ultimately higher costs associated with repairs and replacements. A proactive approach not only enhances functionality but also safeguards against unforeseen breakdowns.

Enhancing Performance

Timely servicing and inspections can significantly improve the effectiveness of machinery. By addressing minor issues before they escalate, operators can maintain consistent operation and achieve better results in their tasks. Proper care translates to smoother functionality, allowing for increased productivity and reduced downtime.

Cost-Effectiveness

Investing in routine maintenance can yield substantial savings in the long run. Regular checks can help identify potential problems early, preventing costly emergency repairs. Additionally, well-maintained equipment typically has a longer lifespan, making it a wise financial choice for any operator or business owner.

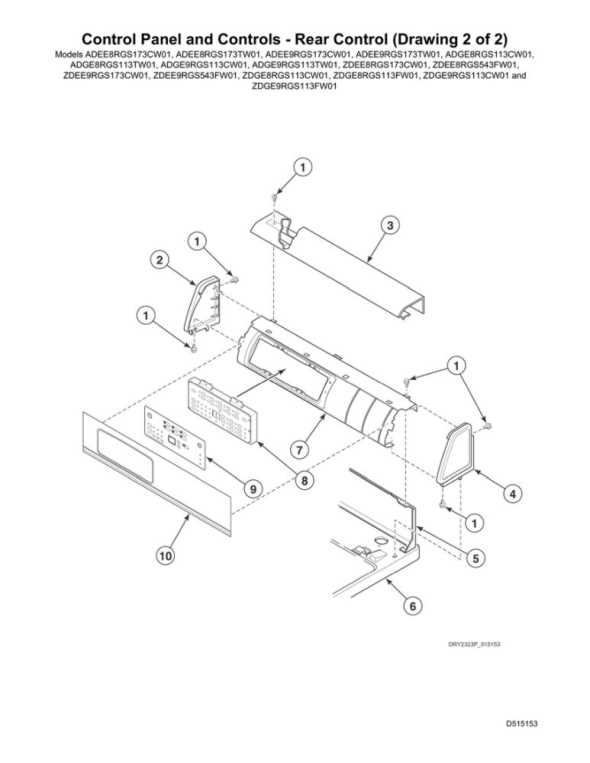

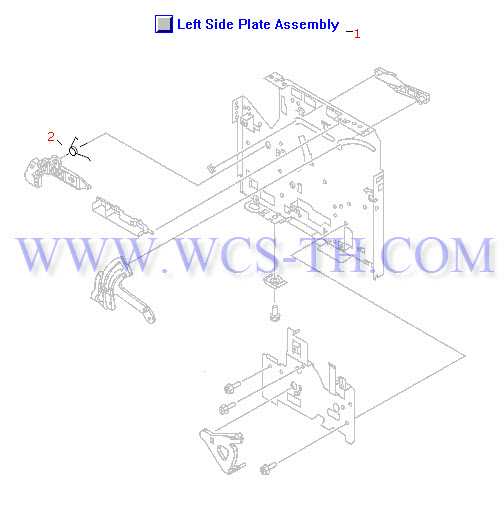

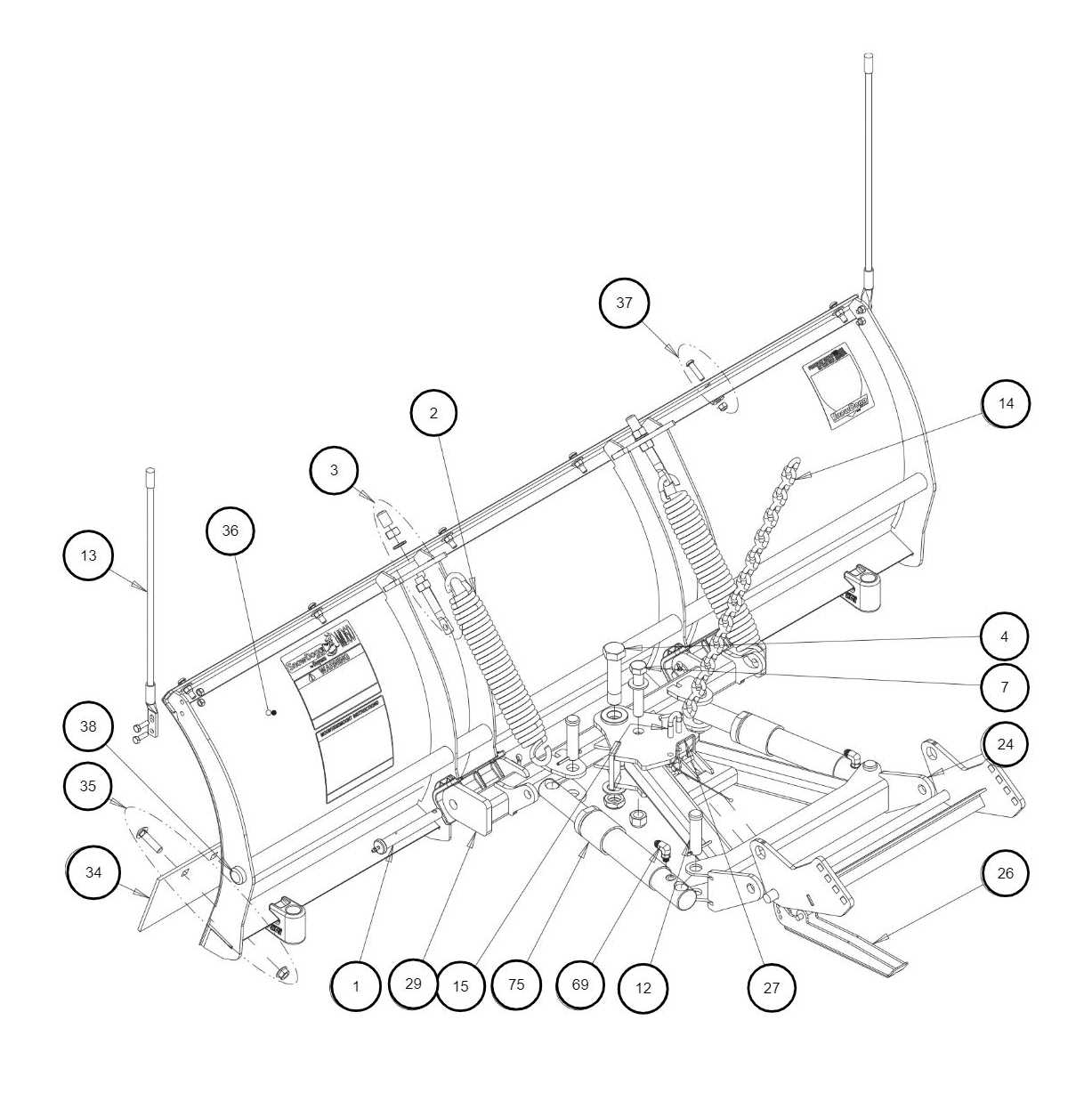

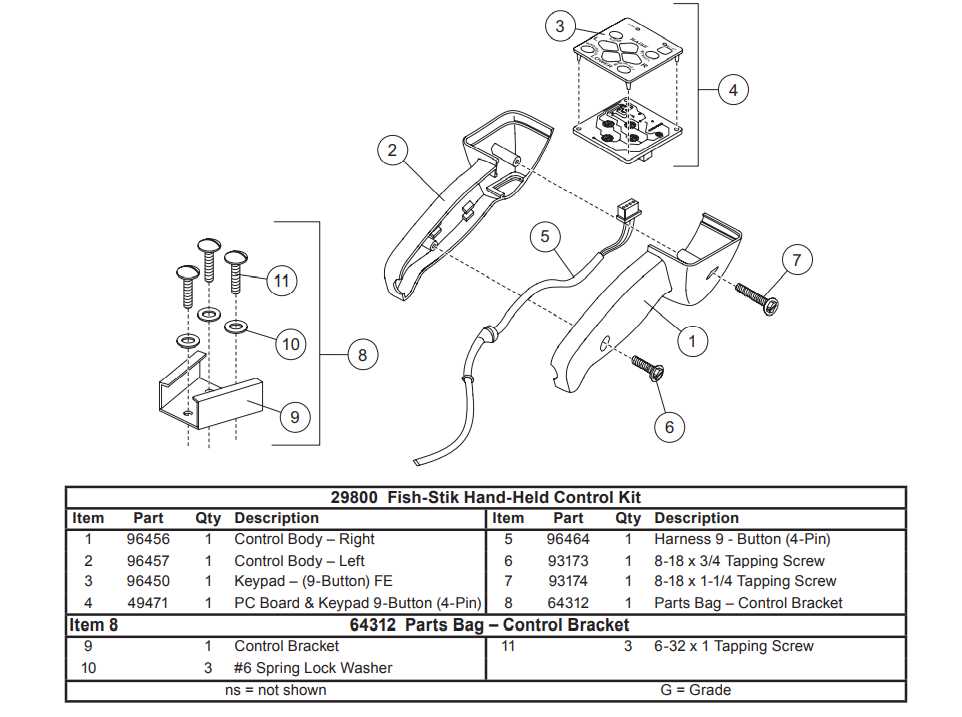

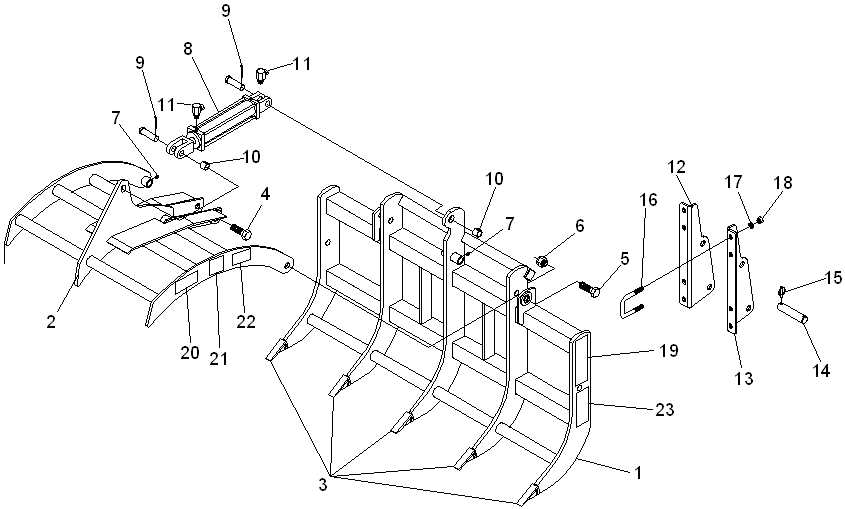

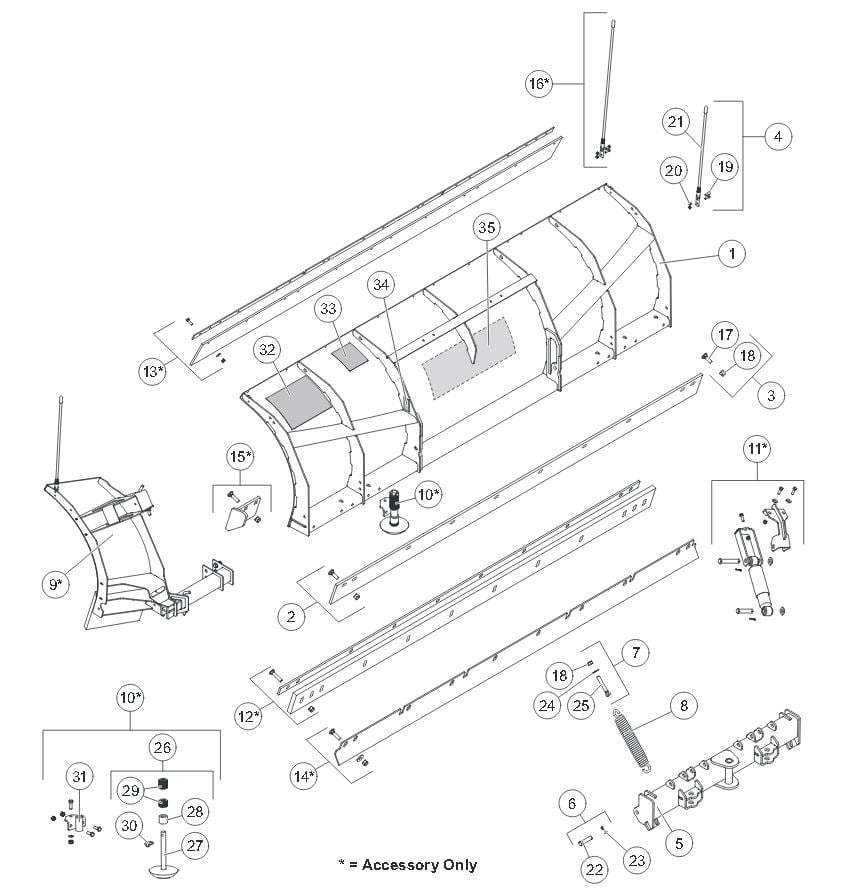

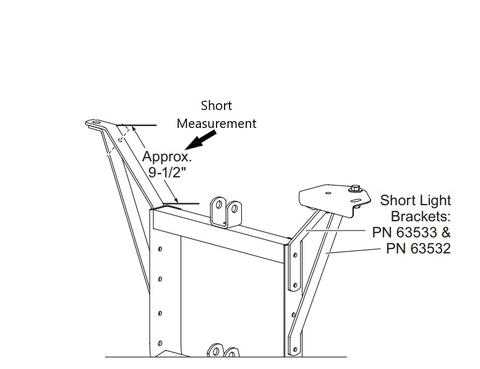

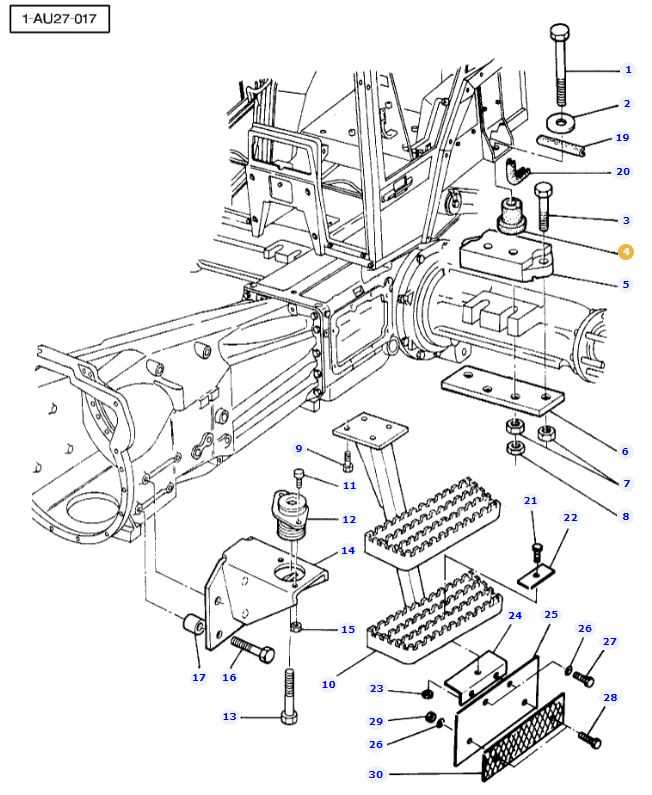

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of various elements, allowing users to identify each piece and its function within the whole system. Familiarity with these representations can significantly streamline the repair process and ensure that all necessary components are accounted for.

To begin interpreting such an illustration, first, familiarize yourself with the overall layout. Look for labels or numbering that indicate specific components. This will help you correlate the visual with the accompanying list or manual that describes each item in detail.

Next, pay attention to connections and relationships between elements. Understanding how parts interact with each other is crucial for troubleshooting. Note any lines or arrows that indicate movement or attachment points, as these details often highlight critical interactions.

Finally, refer to the accompanying documentation for further context. This information can provide insights into installation, maintenance tips, and any specific requirements for each component. By combining visual understanding with detailed descriptions, you can effectively navigate and utilize the representation for your repair needs.

Common Issues with Blizzard Plows

When it comes to snow management equipment, users often encounter a variety of challenges that can affect performance and efficiency. Understanding these common issues is essential for maintaining optimal functionality and ensuring a smooth operation during winter conditions.

One frequent concern involves hydraulic system failures, which can lead to insufficient movement or response times. This often results from leaks or air bubbles within the system, requiring careful inspection and potential repairs to restore proper functionality.

Another prevalent issue is related to the electrical components. Faulty wiring or corroded connections can disrupt the power supply, leading to malfunctioning controls. Regular checks and maintenance can help mitigate these risks.

Wear and tear on cutting edges and other surfaces can also pose a significant problem. Over time, the materials can become dull or damaged, impacting efficiency and necessitating timely replacements to maintain effective snow removal.

Lastly, improper alignment or mounting can result in uneven performance. Ensuring that the equipment is correctly positioned and secured is crucial for optimal operation and to prevent further complications.

Tools for Plow Repairs

Maintaining and restoring snow removal equipment requires the right instruments to ensure efficiency and durability. Proper tools not only facilitate repairs but also enhance the performance of the machinery, extending its lifespan and effectiveness during harsh weather conditions. This section will outline essential tools that every technician should have on hand when tackling maintenance tasks.

Essential Tools

Having a well-equipped toolkit is crucial for any repair job. Below is a table listing some of the key instruments, their purposes, and recommended types:

| Tool | Purpose | Recommended Type |

|---|---|---|

| Wrench Set | For tightening and loosening bolts | Metric and Standard |

| Screwdriver Set | For adjusting screws and fittings | Flathead and Phillips |

| Torque Wrench | Ensures bolts are tightened to the correct specifications | Click-type or Beam-type |

| Pry Bar | Helps in separating parts during disassembly | Standard and Heavy-duty |

| Jack | For lifting equipment safely | Hydraulic or Mechanical |

Safety Gear

In addition to the necessary tools, proper safety equipment is vital to protect the technician while working. Common safety gear includes gloves, goggles, and steel-toed boots, which provide essential protection against injuries. Investing in quality safety items ensures a secure working environment, allowing for efficient and confident repairs.

Seasonal Maintenance Checklist

Proper upkeep is essential for ensuring that your equipment functions efficiently throughout the year. A thorough seasonal inspection can help identify potential issues and prolong the lifespan of your machinery. Below is a comprehensive checklist to guide you through the maintenance process.

Inspection Steps

- Check fluid levels: Ensure all necessary fluids are topped up, including hydraulic fluid, oil, and coolant.

- Inspect belts and hoses: Look for any signs of wear or damage, and replace them as needed.

- Test electrical systems: Verify that all lights, switches, and connectors are functioning correctly.

- Examine tires: Ensure proper inflation and inspect for any damage or excessive wear.

Cleaning and Lubrication

- Clean all surfaces: Remove dirt and debris from the machinery to prevent buildup.

- Lubricate moving parts: Apply grease to joints and pivot points to minimize friction.

- Check for rust: Address any rust spots to prevent further corrosion.

- Replace filters: Change air, oil, and fuel filters as part of the routine maintenance.

Following this checklist will help ensure that your equipment is ready for the demands of the upcoming season, minimizing downtime and maximizing performance.

Where to Buy Replacement Parts

Finding quality components for your equipment is essential for maintaining its performance and longevity. Fortunately, there are several reliable sources where you can obtain these necessary items. Whether you prefer shopping online or visiting local retailers, options are abundant to meet your needs.

Online Retailers are often the most convenient choice. Websites specializing in outdoor machinery offer a vast selection of items, often at competitive prices. When purchasing online, be sure to check customer reviews and product specifications to ensure compatibility with your equipment.

Local Dealers provide another excellent option. Many authorized distributors stock genuine components, ensuring you receive high-quality products tailored to your machinery. Visiting a dealer allows you to speak directly with knowledgeable staff who can assist you in finding the right solutions.

Salvage Yards can also be a treasure trove for those seeking affordable alternatives. These establishments often have used components that are still in great condition, offering significant savings. Just be sure to inspect items thoroughly before purchasing.

Additionally, Manufacturer Websites typically have dedicated sections for ordering components directly. This route guarantees that you are getting authentic items designed specifically for your machinery, providing peace of mind.

Ultimately, choosing the right source depends on your specific requirements, budget, and urgency. By exploring these options, you can efficiently locate the necessary items to keep your equipment in optimal working condition.

DIY Repair Tips for Plow Owners

Maintaining your snow-moving equipment can save time and money, allowing you to keep it in optimal working condition throughout the winter months. By taking a hands-on approach, you can address common issues and extend the life of your machinery. Here are some practical tips to help you with repairs and maintenance.

Regular Inspections

Conducting frequent assessments is crucial for identifying wear and tear before it leads to more significant problems. Check all components for signs of damage, such as cracks or corrosion. Pay special attention to the hydraulic system, as leaks can significantly impact performance.

Simple Fixes and Upgrades

Many minor issues can be resolved with basic tools and a little know-how. For example, replacing worn-out seals or tightening loose bolts can enhance functionality. Additionally, consider upgrading your equipment with aftermarket accessories designed to improve efficiency. Always consult your manual for specific guidelines and recommendations.

Safety Considerations When Operating Plows

Ensuring safety during the operation of snow removal equipment is paramount to prevent accidents and injuries. Operators should be well-informed about the potential hazards associated with their machinery and adopt appropriate precautions. A proactive approach to safety can enhance both the efficiency of the task and the well-being of the personnel involved.

Pre-Operational Checks

Before commencing any snow-clearing activity, a thorough inspection of the equipment is essential. This step helps identify any issues that could lead to malfunction or accidents. Key aspects to check include fluid levels, electrical systems, and physical integrity of the machinery.

| Inspection Item | Recommended Action |

|---|---|

| Fluid Levels | Ensure all fluids are topped up |

| Electrical System | Test lights and signals |

| Physical Condition | Check for visible wear or damage |

| Safety Equipment | Verify that all safety gear is in place |

Operational Guidelines

During operation, it is crucial to maintain a safe distance from obstacles and other vehicles. Operators should remain alert and avoid distractions to respond quickly to any changes in their surroundings. Additionally, proper training and adherence to manufacturer guidelines can significantly reduce the risk of accidents.

Upgrading Your Plow System

Enhancing your snow removal setup can significantly improve efficiency and performance. By incorporating advanced components and technologies, you can streamline operations, reduce downtime, and tackle winter conditions with greater ease. This section explores key considerations and options for upgrading your equipment.

Evaluating Current Equipment

Before making any enhancements, assess your existing machinery. Identify any limitations or areas for improvement. Consider factors such as power output, durability, and ease of use. By understanding the strengths and weaknesses of your current setup, you can make informed decisions on which upgrades will yield the best results.

Choosing the Right Additions

When selecting new elements for your snow clearing system, focus on those that enhance functionality and efficiency. Look for features such as improved hydraulics, enhanced blade designs, and advanced control systems. Investing in high-quality accessories can make a significant difference in performance. Additionally, consulting with professionals or experienced operators can provide valuable insights into the most effective upgrades for your specific needs.

Resources for Further Learning

Expanding your knowledge about equipment maintenance and functionality can greatly enhance your skills and understanding. Numerous resources are available to guide enthusiasts and professionals alike in mastering their craft. Below are some valuable materials and platforms to consider for a deeper insight.

Online Courses and Tutorials

- Platforms like Coursera and Udemy offer specialized courses focusing on machinery and maintenance techniques.

- YouTube has a plethora of instructional videos from experienced mechanics and enthusiasts, covering a wide range of topics.

- Industry-specific webinars can provide up-to-date information and best practices from experts.

Books and Manuals

- Technical manuals often provide detailed guidance on equipment repair and upkeep.

- Books on machinery maintenance offer comprehensive theories and practical advice for all skill levels.

- Reference guides can serve as quick checklists for troubleshooting and routine inspections.

Utilizing these resources can enhance your proficiency and ensure you stay informed about the latest techniques and innovations in the field.