Comprehensive Guide to Bobcat 463 Parts Diagram

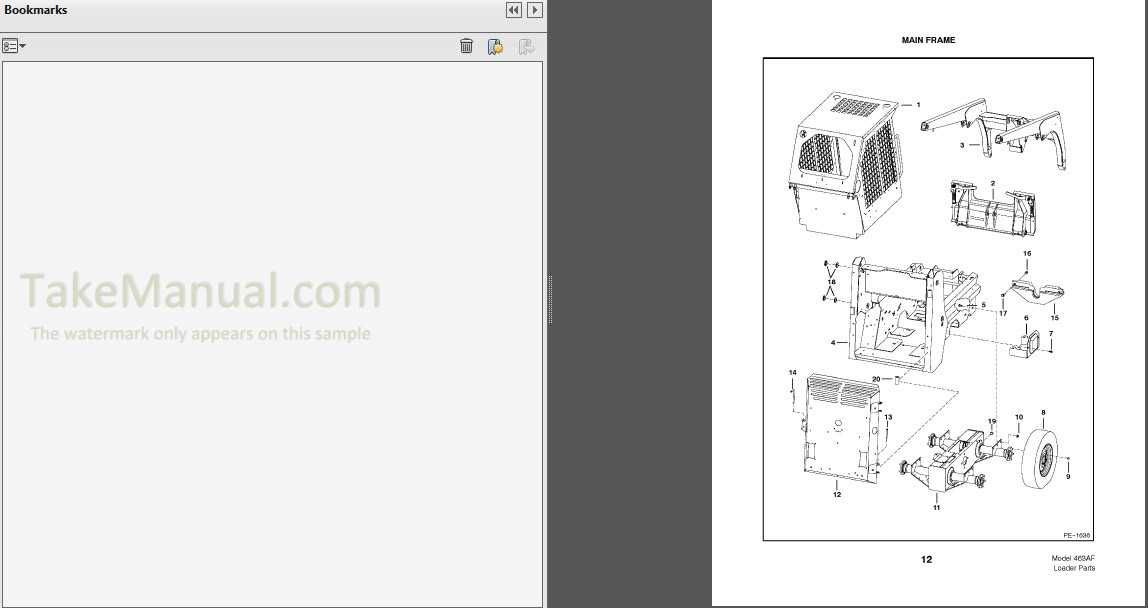

The intricate design of machinery often necessitates a clear visual representation of its components. Such illustrations are invaluable for anyone involved in maintenance or repair, providing a roadmap to navigate through various assemblies and systems. A comprehensive overview enhances the ability to identify parts and understand their functions within the overall mechanism.

In this section, we will delve into a specific model’s schematic, showcasing the arrangement and relationships between different elements. This not only aids technicians in locating specific items but also fosters a deeper comprehension of how these components interact, ensuring optimal performance and longevity.

Whether you’re a seasoned professional or a newcomer to the field, familiarizing yourself with these layouts is crucial. By examining these detailed representations, one can effectively troubleshoot issues and carry out necessary repairs, ultimately leading to improved operational efficiency.

Understanding the Bobcat 463 Parts Diagram

Comprehending the layout of machinery components is crucial for effective maintenance and repairs. A clear representation of the various elements allows operators and technicians to identify, troubleshoot, and replace specific items efficiently.

When analyzing a schematic representation of a compact loader, consider the following key aspects:

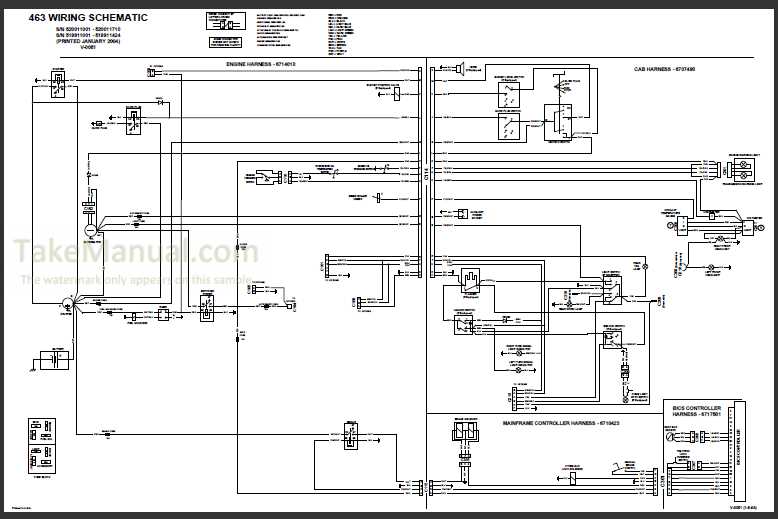

- Component Identification: Familiarize yourself with the different sections, including the engine, hydraulic system, and chassis.

- Connection Points: Note how various parts are interconnected, which is essential for understanding the operational flow.

- Maintenance Guidelines: Look for recommendations on service intervals and potential wear points highlighted in the layout.

Utilizing a visual representation can greatly enhance your understanding of machinery functionality. It serves as a valuable reference for both new users and seasoned professionals aiming to ensure optimal performance.

For effective troubleshooting, follow these steps:

- Identify the specific area of concern.

- Consult the relevant section of the layout for part locations.

- Cross-reference with the manual for specifications and replacement procedures.

By becoming adept at interpreting these illustrations, you empower yourself to maintain and repair equipment with confidence and efficiency.

Overview of Bobcat 463 Features

This section provides a comprehensive look at the various characteristics and functionalities of the compact utility vehicle, highlighting its capabilities and advantages for various applications. Understanding these features can aid operators in maximizing efficiency and productivity on the job site.

Key Features

- Compact Size: Ideal for navigating tight spaces while maintaining robust performance.

- Powerful Engine: Equipped with a reliable motor that delivers strong torque and acceleration.

- Versatile Attachments: Compatible with a range of tools, enhancing functionality for different tasks.

- Durable Construction: Built with high-quality materials to withstand rigorous working conditions.

Operational Benefits

- Improved Maneuverability: The design allows for easy movement in confined areas.

- Enhanced Stability: Features that provide a solid base for various operations.

- User-Friendly Controls: Intuitive interface that simplifies operation for both experienced and novice users.

- Efficient Hydraulics: Advanced hydraulic systems that optimize performance and responsiveness.

Importance of Accurate Parts Identification

Correct identification of components is crucial for the efficient operation and maintenance of machinery. Understanding the specific characteristics and functionalities of each element ensures that repairs and replacements are carried out effectively, minimizing downtime and extending the lifespan of equipment.

Benefits of Precise Component Recognition

- Improved Efficiency: Knowing the right elements allows for quicker repairs, reducing the time machines are out of service.

- Cost Savings: Accurate identification prevents unnecessary purchases, ensuring that only the needed items are procured.

- Enhanced Performance: Properly functioning components lead to better overall machine efficiency, optimizing productivity.

Challenges of Misidentification

- Incorrect installations can lead to operational failures.

- Using incompatible parts may void warranties and complicate future repairs.

- Time spent troubleshooting issues arising from misidentified components can be significant, impacting project timelines.

In summary, meticulous recognition of machinery elements is essential for maintaining optimal performance and ensuring the longevity of equipment. Investing time in proper identification pays off in the long run, facilitating smooth operations and enhancing overall productivity.

Common Issues with Bobcat 463 Parts

When working with compact machinery, operators often encounter various challenges that can hinder performance and efficiency. Understanding these common complications is essential for maintaining optimal functionality. Frequently, components may wear out or malfunction, leading to operational disruptions that can affect productivity.

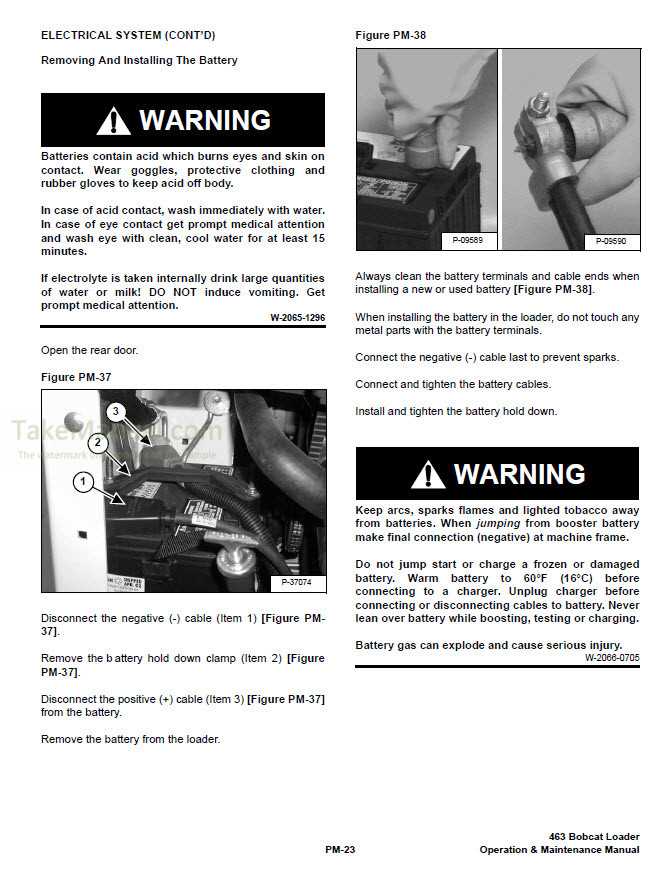

One prevalent issue involves hydraulic components, which can suffer from leaks or loss of pressure, resulting in decreased lifting capability. Regular inspections are necessary to identify signs of wear, as failure to address these issues can lead to more severe damage.

Electrical malfunctions also represent a significant concern. Wiring can become frayed or disconnected over time, impacting the performance of control systems. Ensuring all electrical connections are secure and inspecting for corrosion can help mitigate these problems.

Moreover, the undercarriage often experiences excessive wear due to harsh terrain and heavy loads. Regular maintenance and timely replacement of worn tracks or rollers are vital for maintaining traction and stability.

Lastly, engine performance can decline due to fuel system issues or air filter obstructions. Routine checks and cleanings are essential to keep the engine running smoothly and efficiently. By addressing these common complications promptly, operators can prolong the lifespan of their machinery and ensure reliable operation.

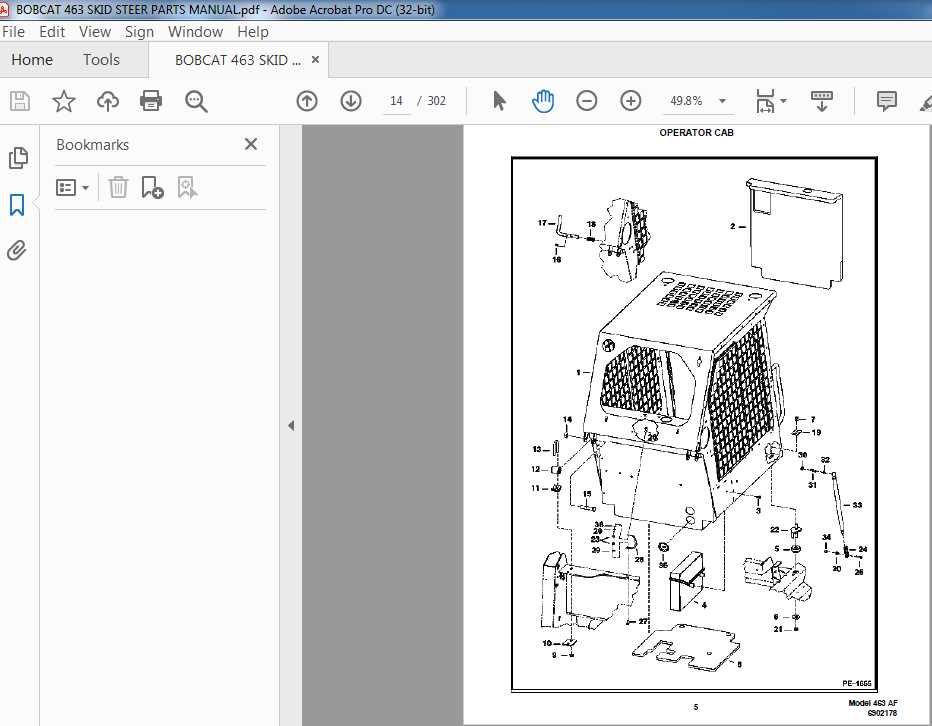

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visuals serve as a roadmap, guiding you through the intricate details of an assembly. By familiarizing yourself with the layout and symbols used, you can streamline your approach to identifying and acquiring the necessary items for your equipment.

Here are some key elements to focus on when interpreting such visuals:

- Legend and Symbols: Familiarize yourself with the legend provided. It explains the various symbols and color codes used throughout the illustration.

- Component Labels: Each part is typically labeled with a unique identifier. Take note of these codes as they will aid in cross-referencing with the list of items.

- Connections: Pay attention to how different elements are connected. Understanding these relationships can help you identify the flow of operations within the assembly.

To enhance your comprehension, consider the following steps:

- Start with the Overview: Begin by looking at the entire layout to get a general sense of the structure.

- Identify Main Sections: Break down the schematic into manageable sections. Focus on one area at a time.

- Cross-Reference: Use the identifiers to look up corresponding information in the parts list or catalog.

By applying these techniques, you’ll be better equipped to navigate through any technical visual, ultimately facilitating repairs and ensuring optimal performance of your machinery.

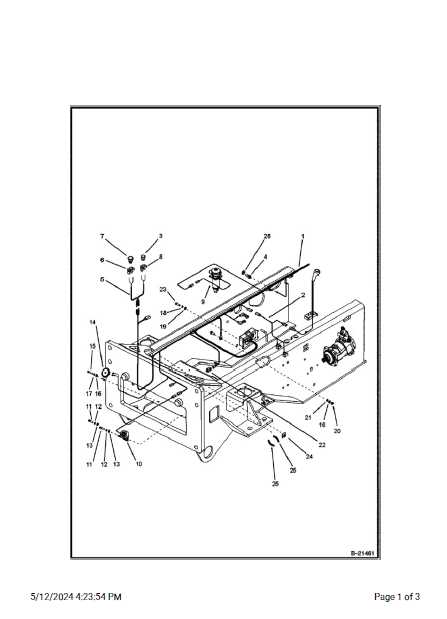

Key Components of Bobcat 463

This section focuses on the essential elements that contribute to the functionality and efficiency of the compact machine. Understanding these crucial components can help operators maintain optimal performance and ensure longevity.

Hydraulic System: The hydraulic system plays a vital role in the movement and operation of attachments. It allows for smooth control and power delivery, essential for various tasks.

Engine: The heart of any machinery, the engine provides the necessary power for operation. Its efficiency directly affects the overall performance and fuel consumption of the unit.

Transmission: The transmission system facilitates speed and torque transfer, enabling the machine to navigate different terrains and handle various loads effectively.

Chassis: The robust frame serves as the foundation, providing stability and durability. A well-designed chassis can withstand harsh working conditions while maintaining balance.

Electrical System: This system controls the machine’s functions, including lights, gauges, and ignition. A reliable electrical setup is crucial for operational safety and efficiency.

Tracks or Tires: The choice between tracks or tires significantly influences traction and maneuverability. Each option offers distinct advantages depending on the working environment.

Finding Replacement Parts Efficiently

Locating components for machinery can often feel overwhelming due to the variety of options available. However, employing systematic approaches can streamline the process and save both time and resources. Understanding where to look and how to assess your needs are crucial steps in ensuring you acquire the right items quickly.

Identify Your Needs

Before diving into the search, it’s essential to clarify what you require. Consider the following:

- Determine the specific component that needs replacement.

- Check the machine’s manual for specifications.

- Assess any related items that may also need attention.

Effective Search Strategies

Once your requirements are clear, you can employ various strategies to find suitable replacements:

- Utilize online marketplaces specializing in equipment components.

- Visit local suppliers who may have the necessary stock.

- Join forums or communities where enthusiasts share resources and recommendations.

- Consult with professionals who might offer insights into alternative options.

By following these guidelines, you can navigate the search for components more effectively and ensure your machinery remains in optimal working condition.

Maintenance Tips for Bobcat 463

Regular upkeep is essential for ensuring optimal performance and longevity of your compact machine. By following a systematic maintenance routine, operators can prevent potential issues and enhance efficiency. This guide offers valuable insights into essential practices that will keep your equipment in top shape.

Routine Inspections

Conducting frequent inspections is crucial for identifying wear and tear before they escalate into significant problems. Check fluid levels, belts, and hoses regularly. Pay close attention to the condition of the tires and tracks, as these components are vital for stability and traction. Always refer to the manufacturer’s guidelines for specific inspection intervals and procedures.

Fluid Management

Maintaining proper fluid levels is key to ensuring smooth operation. Regularly change the hydraulic fluid and filters to prevent contamination that can lead to costly repairs. Use high-quality fluids recommended for your machine to maintain optimal performance. Additionally, monitor the engine oil and coolant levels, replacing them as needed to avoid overheating and engine damage.

Tools Required for Parts Replacement

When undertaking a maintenance or repair project on machinery, having the right tools is essential for achieving optimal results. Proper equipment not only facilitates efficient work but also ensures safety during the replacement process. Understanding the necessary instruments can greatly simplify the task at hand.

Essential Hand Tools

Among the primary instruments required are wrenches, screwdrivers, and pliers. These hand tools are vital for loosening and tightening various components. Additionally, having a reliable socket set can provide the versatility needed to access hard-to-reach fasteners, making disassembly and reassembly more manageable.

Specialized Equipment

In some instances, specialized tools may be necessary for specific tasks. Torque wrenches ensure that fasteners are tightened to the correct specifications, preventing damage. Furthermore, jacks or hoists can be invaluable when lifting heavy sections of machinery, promoting both efficiency and safety during repairs.

Expert Recommendations for Repairs

When it comes to maintaining and fixing heavy machinery, informed decisions are crucial for ensuring longevity and performance. Engaging with knowledgeable sources can help identify the best practices and essential components needed for effective repairs. This section offers guidance on how to approach the repair process efficiently.

Assessing the Issue

Before diving into repairs, it’s vital to conduct a thorough assessment. Here are some steps to follow:

- Inspect the machinery carefully to identify visible damages or wear.

- Listen for unusual sounds during operation that may indicate underlying problems.

- Review maintenance logs to pinpoint when the last service was performed.

Choosing the Right Components

Selecting appropriate replacement parts can significantly influence repair outcomes. Consider these recommendations:

- Opt for original equipment manufacturer (OEM) components to ensure compatibility and quality.

- Research alternative aftermarket options that have positive reviews from trusted sources.

- Verify that all parts meet industry standards and specifications before making a purchase.

Following these expert recommendations can streamline the repair process and enhance the overall performance of your machinery.

Where to Buy Bobcat 463 Parts

Finding the right components for your machinery can significantly enhance its performance and longevity. Whether you’re seeking replacement items for routine maintenance or specific upgrades, numerous options are available to meet your needs.

Online Retailers offer a vast selection of parts, often with detailed specifications and images to help you make informed decisions. Websites specializing in construction equipment typically provide competitive pricing and customer reviews, ensuring you choose quality items.

Authorized Dealers are another reliable source. They not only carry genuine components but also provide expert advice and support. This can be particularly beneficial if you need guidance on installation or compatibility with your existing equipment.

Local Suppliers can be convenient, allowing you to inspect items before purchase. Establishing a relationship with a nearby vendor may also lead to personalized service and quicker access to urgent needs.

Lastly, consider second-hand markets. Platforms dedicated to used machinery parts can offer significant savings, but ensure that you verify the condition and compatibility of any item before committing to a purchase.

Understanding Warranty and Returns Policy

When purchasing machinery components, it’s crucial to be well-informed about the policies surrounding warranty and returns. These guidelines help ensure that customers are protected against defects and can navigate the process of returning items if necessary. A comprehensive understanding of these policies can enhance your overall purchasing experience and provide peace of mind.

Warranty Coverage

The warranty typically outlines the manufacturer’s commitment to quality and reliability. It generally specifies the duration of coverage and the conditions under which claims can be made. Familiarizing yourself with what is included–such as parts or labor–can prevent potential misunderstandings. Make sure to keep your purchase receipt, as it may be required when filing a claim.

Return Process

Should you need to return an item, the return process is usually defined by specific steps. This often involves contacting customer service to obtain a return authorization. Additionally, understanding the timeframe for returns and any potential restocking fees is essential. Ensure that items are in their original condition to facilitate a smooth return process.