Bobcat 7753 Parts Diagram Overview

The efficiency and functionality of a compact loader rely significantly on its various elements. Each component plays a vital role in ensuring optimal performance and longevity of the machine. By gaining insight into these individual pieces, users can better appreciate how they work together to facilitate a wide range of tasks in diverse environments.

Familiarity with the intricate assembly is essential for operators and maintenance personnel alike. Recognizing the significance of each part can lead to more informed decisions regarding repairs and replacements. This knowledge not only enhances operational efficiency but also contributes to minimizing downtime and maximizing productivity.

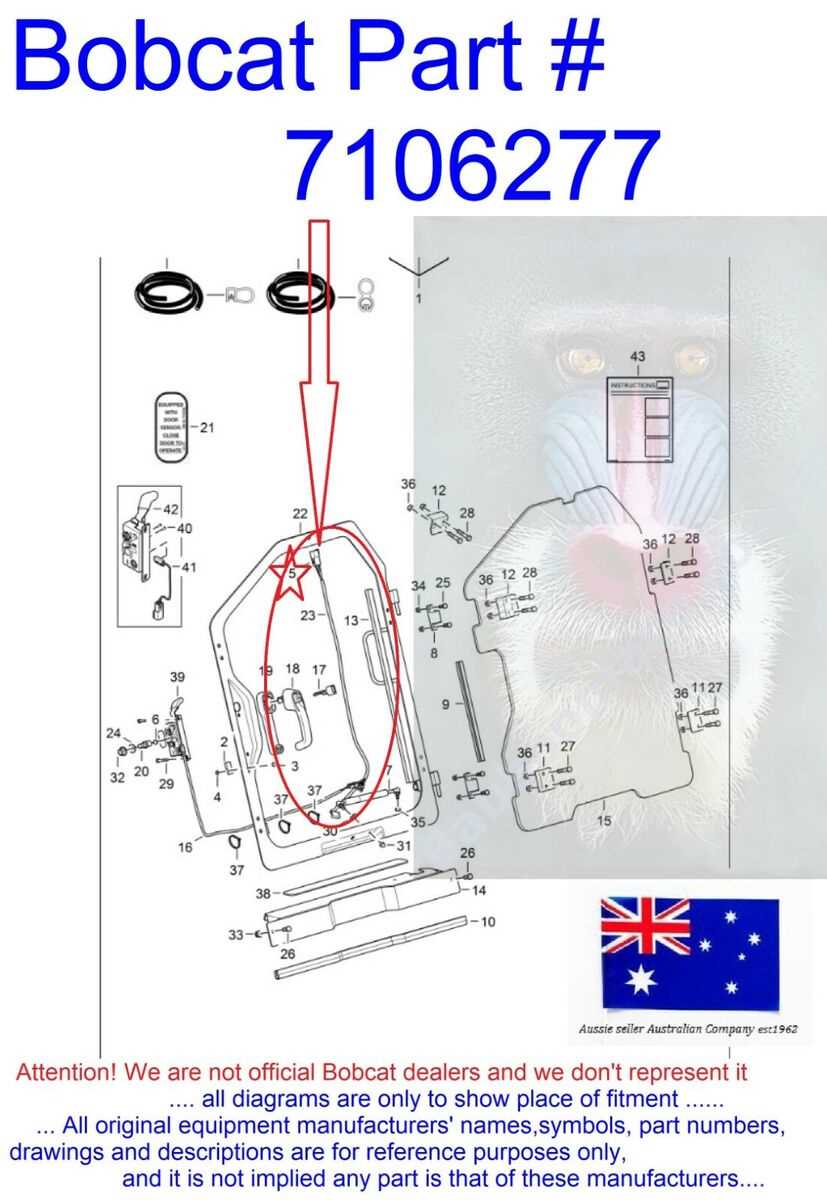

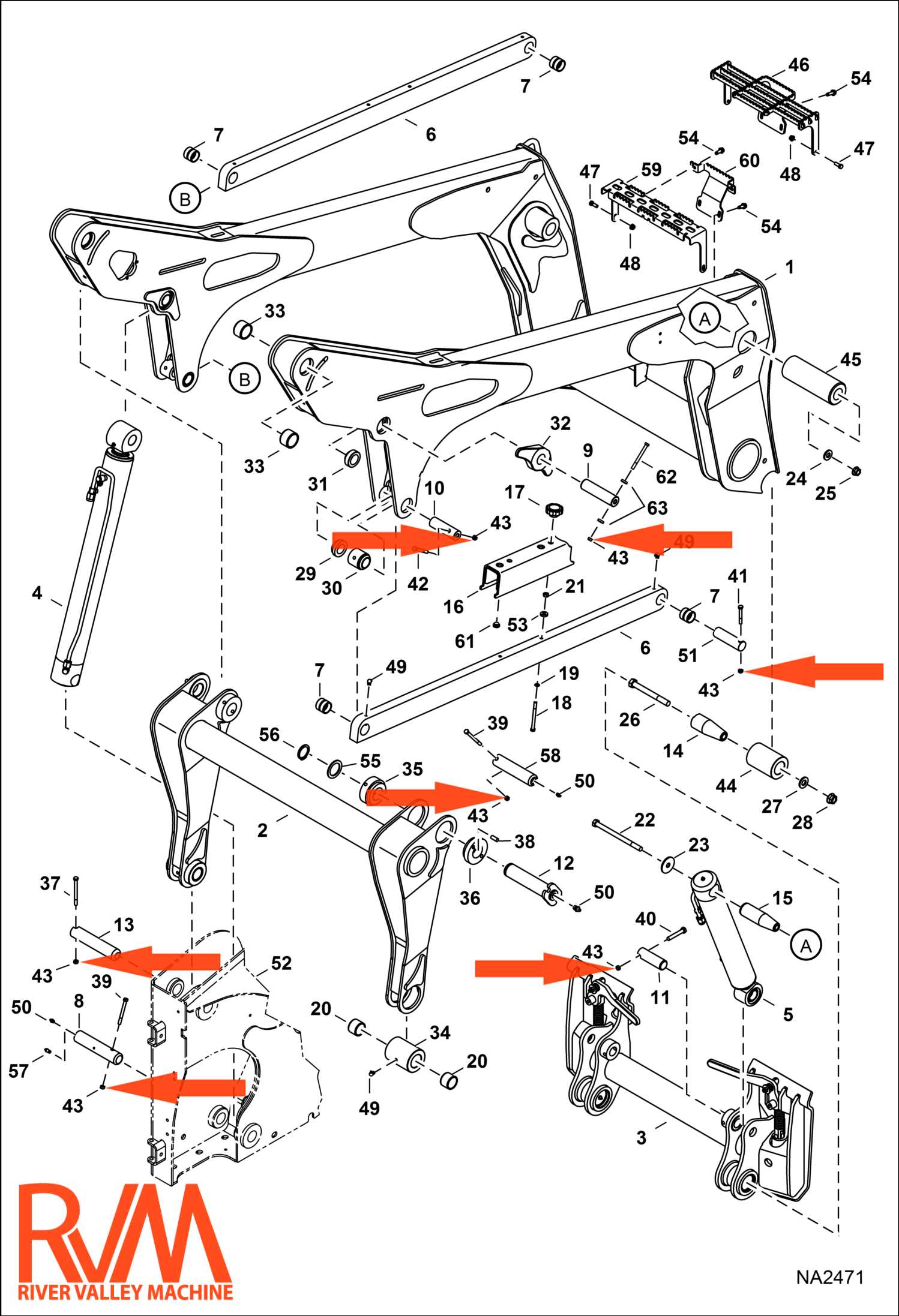

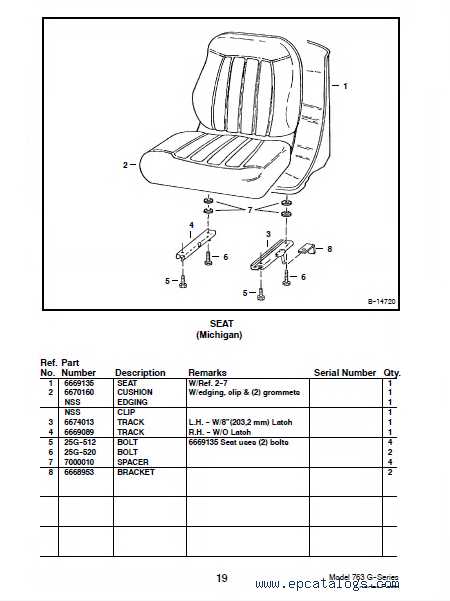

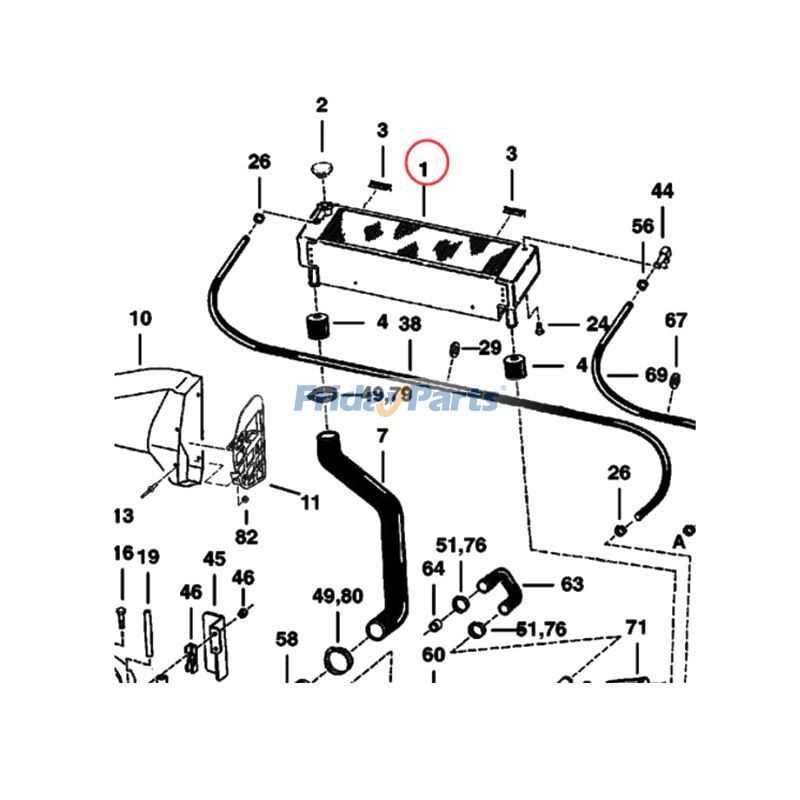

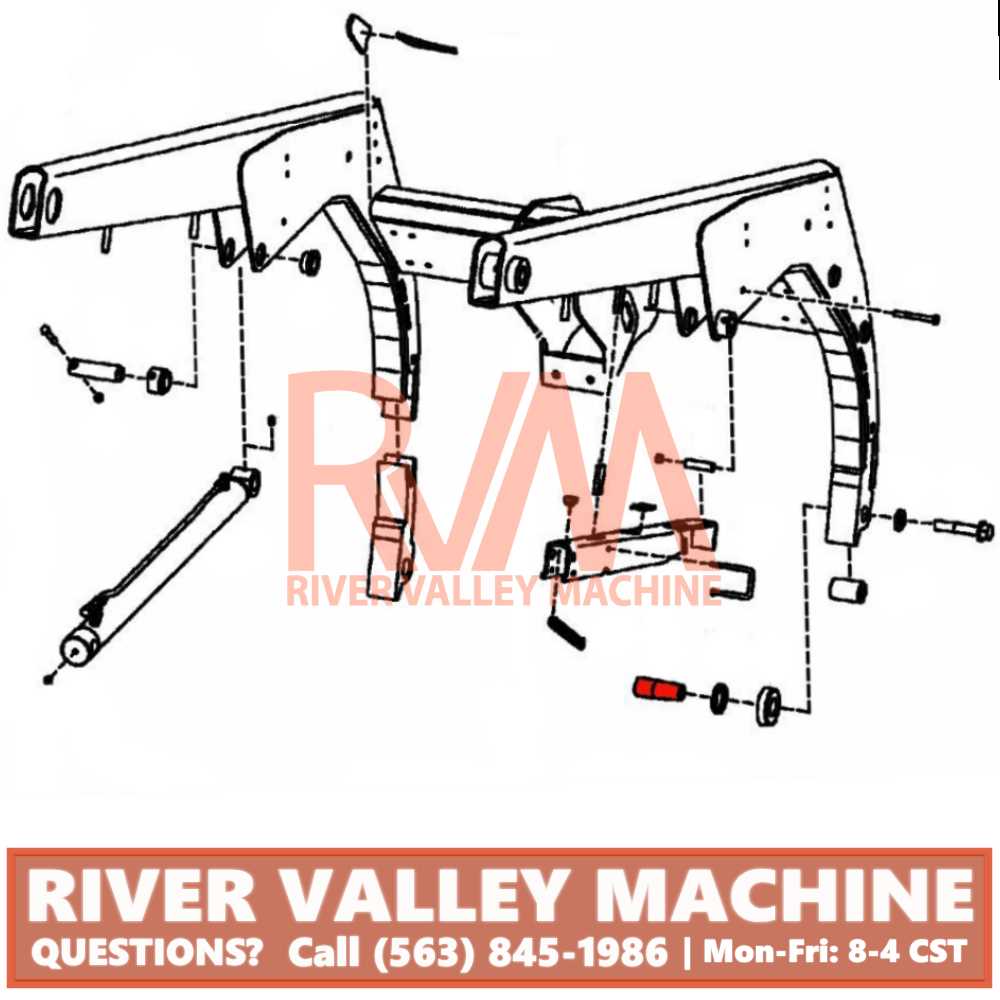

Additionally, access to detailed illustrations of these components allows for a clearer understanding of their positioning and interaction within the overall structure. Such resources can serve as invaluable tools during maintenance procedures, guiding users in identifying potential issues and implementing necessary corrective actions effectively.

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations that showcase the arrangement of various elements facilitate quick identification and troubleshooting, ensuring that operators can efficiently manage their equipment.

Enhancing Maintenance Efficiency

Clear illustrations serve as a valuable resource for technicians and operators alike. They provide several benefits:

- Quick reference for identifying components.

- Improved accuracy in ordering replacements.

- Streamlined repair processes, reducing downtime.

Supporting Training and Safety

Educational materials that include visual guides are essential for training new staff. These resources:

- Foster a better understanding of equipment functionality.

- Promote safety by ensuring proper handling and operation.

- Help prevent costly mistakes through clear instructions.

Key Features of Bobcat 7753

This compact machine is designed for versatility and efficiency, making it a popular choice for various construction and landscaping tasks. With its robust capabilities, it allows operators to perform a wide range of jobs, from heavy lifting to precision work.

Some of the standout characteristics include:

| Feature | Description |

|---|---|

| Compact Size | Ideal for maneuvering in tight spaces without sacrificing power. |

| High Lifting Capacity | Enables handling of substantial loads efficiently. |

| Operator Comfort | Ergonomically designed controls and seating for improved user experience. |

| Durability | Built with high-quality materials to withstand tough working conditions. |

| Versatile Attachments | Compatible with a variety of tools for different applications. |

Common Parts and Their Functions

Understanding the various components of machinery is essential for optimal performance and maintenance. Each element plays a significant role in ensuring smooth operation, contributing to the overall efficiency and reliability of the equipment.

- Engine: The heart of the machine, providing the necessary power to operate all functions effectively.

- Hydraulic System: Responsible for transferring energy through fluid, enabling lifting and moving operations with ease.

- Transmission: This component regulates the power from the engine to the wheels, allowing for controlled movement and speed adjustments.

- Chassis: The frame that supports the entire structure, providing stability and durability during operations.

- Control Panel: The interface for the operator, allowing for monitoring and adjustment of machine settings as needed.

- Wheels: Designed to facilitate movement, these components are crucial for maneuverability in various terrains.

Regular inspection and maintenance of these elements are crucial for ensuring longevity and performance. Understanding how each component interacts contributes to better troubleshooting and operational efficiency.

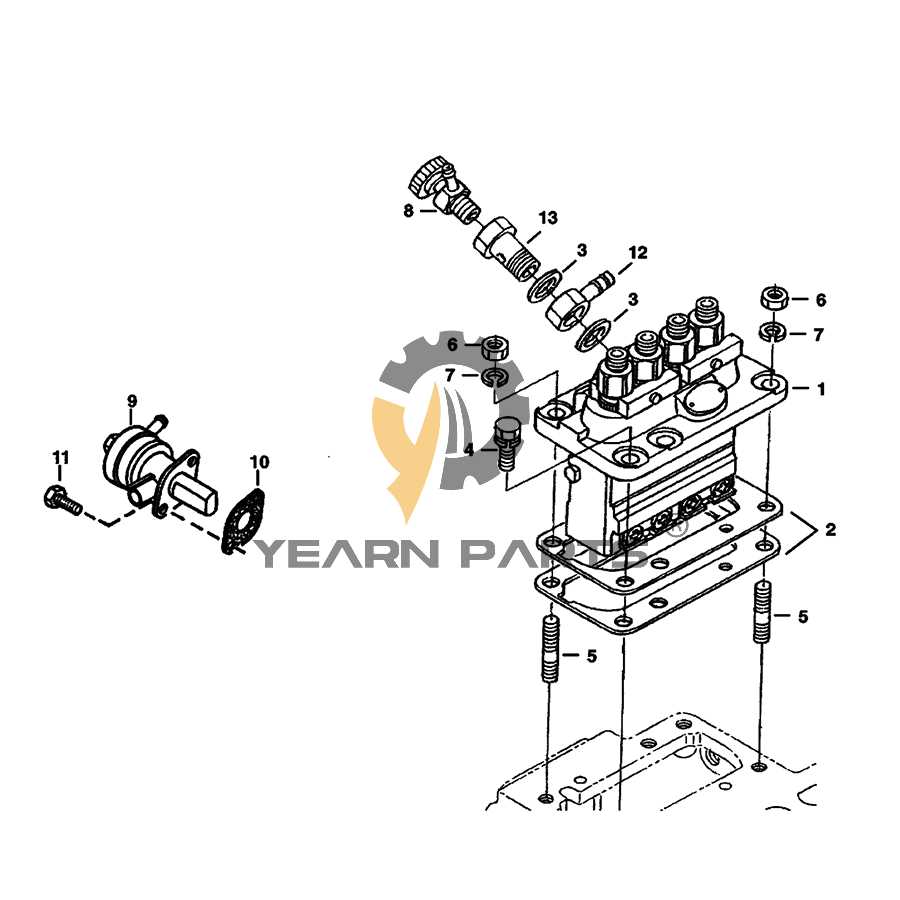

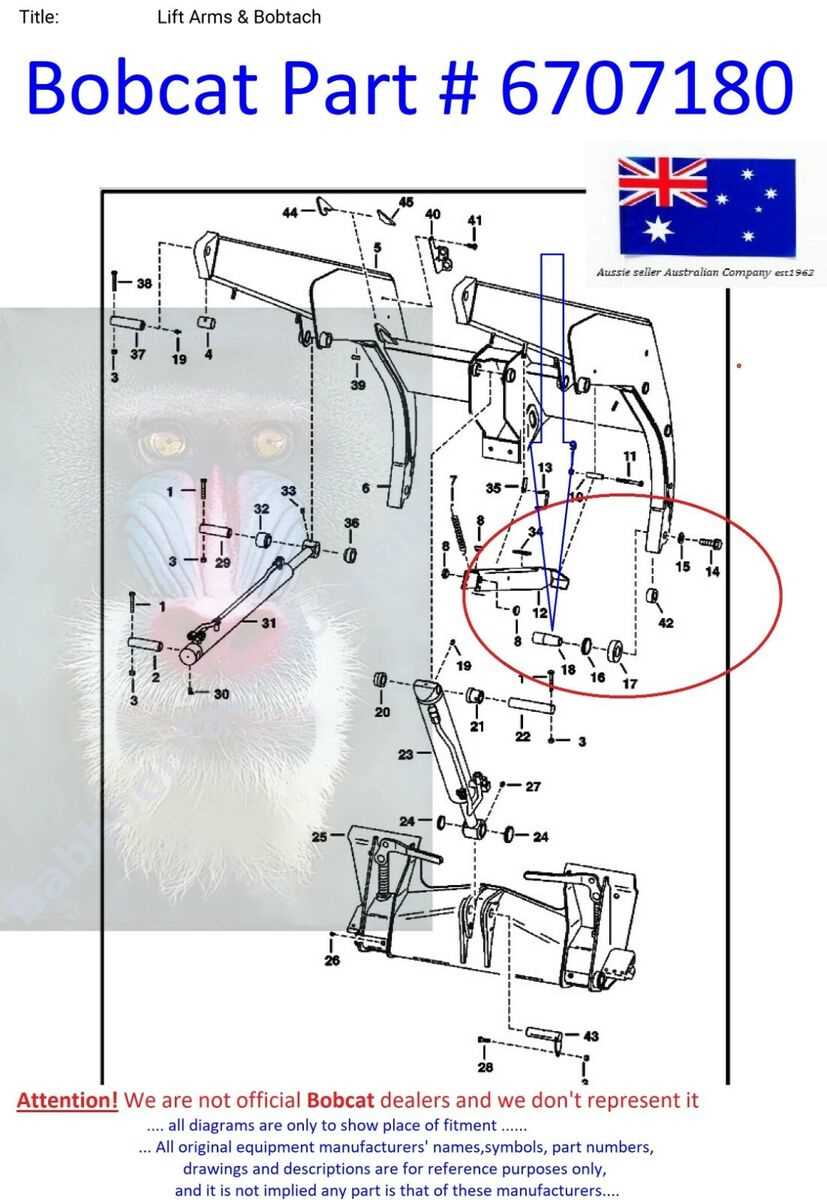

How to Interpret the Diagram

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visuals provide a detailed representation of components and their relationships, allowing users to gain insights into assembly and disassembly processes. By familiarizing yourself with the symbols and layouts used in these illustrations, you can navigate complex machinery more confidently.

Familiarizing with Symbols

Every technical illustration includes a set of symbols that denote specific parts and their functions. It is crucial to consult the accompanying legend or key, which explains what each symbol represents. This foundational knowledge will enable you to identify various components quickly and understand how they interact within the overall system.

Understanding the Layout

The arrangement of elements within the visual is designed to reflect the physical configuration of the machinery. Observing the positioning and connections between components can provide valuable context about their operational flow. Pay close attention to arrows and lines that indicate movement or linkage, as they highlight how different parts work together to achieve functionality.

Maintenance Tips for Bobcat 7753

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. By adhering to a few simple guidelines, operators can enhance performance and reduce the likelihood of unexpected failures.

-

Routine Inspections:

Conduct regular checks on all vital components, including hydraulic systems, filters, and engine oil levels. Early detection of issues can prevent costly repairs.

-

Fluid Changes:

Timely replacement of hydraulic fluid and engine oil is crucial for optimal operation. Follow the manufacturer’s recommendations for intervals.

-

Clean Filters:

Ensure that air and oil filters are clean to maintain efficient performance. Clogged filters can lead to engine strain and reduced functionality.

-

Tire Maintenance:

Regularly check tire pressure and tread wear. Properly inflated tires improve traction and reduce fuel consumption.

-

Battery Care:

Inspect battery terminals for corrosion and ensure secure connections. Clean terminals can enhance the longevity of your power source.

By implementing these practices, operators can ensure their machinery operates smoothly and efficiently, ultimately extending its life and performance.

Replacing Worn-Out Components

Maintaining optimal functionality in machinery is crucial for ensuring efficiency and prolonging service life. Over time, certain elements may experience wear and tear due to regular usage, leading to diminished performance. It is essential to recognize the signs of deterioration and take appropriate measures to replace these components to restore the equipment’s full capabilities.

Identifying Signs of Wear

Before initiating the replacement process, it is important to identify which components require attention. Common indicators of wear include:

- Unusual noises during operation

- Decreased performance or efficiency

- Visible signs of damage or deterioration

- Increased operational vibrations

Steps for Replacement

Once the worn components have been identified, follow these steps for replacement:

- Gather necessary tools and replacement parts.

- Ensure the machinery is turned off and properly secured.

- Carefully remove the damaged components.

- Install the new parts, ensuring proper alignment and fit.

- Test the equipment to confirm functionality.

By systematically addressing worn components, operators can significantly enhance the reliability and performance of their machinery, ultimately leading to more efficient operations.

Finding Genuine Bobcat Parts

When it comes to maintaining your machinery, sourcing authentic components is crucial for optimal performance and longevity. Ensuring the use of original equipment not only enhances reliability but also supports efficient operation. This section will guide you through the process of identifying and acquiring high-quality replacements.

Benefits of Authentic Components

- Guaranteed compatibility with your equipment

- Improved performance and durability

- Manufacturer support and warranty

Where to Look for Authentic Components

- Authorized dealers who specialize in your machinery brand

- Official manufacturer websites that offer direct purchasing options

- Reputable online marketplaces known for selling genuine parts

Utilizing the Diagram for Repairs

When undertaking maintenance on heavy machinery, having a visual reference can significantly enhance the repair process. A detailed illustration serves as an essential guide, allowing operators and technicians to identify components and understand their relationships within the overall system.

Referencing this illustration effectively can streamline troubleshooting. By pinpointing specific areas of concern, users can focus their efforts on diagnosing issues accurately. This approach not only saves time but also minimizes the risk of overlooking critical elements during repairs.

Additionally, utilizing the reference aids in the assembly and disassembly of parts. Knowing where each component fits within the machine helps ensure that everything is reassembled correctly, reducing the likelihood of future malfunctions. Consequently, this method contributes to the longevity and efficiency of the equipment.

Common Issues and Solutions

In the realm of compact machinery, users often encounter various challenges that can hinder performance and efficiency. Understanding these common problems and their corresponding solutions can significantly improve operational longevity and functionality.

Hydraulic System Failures: A prevalent issue involves the hydraulic system, which may experience leaks or insufficient pressure. Regular inspection of hoses and connections is crucial. If leaks are detected, immediate repairs or replacements should be made to maintain optimal performance.

Engine Overheating: Overheating can occur due to blocked cooling systems or low coolant levels. Routine maintenance of the cooling system, including cleaning radiators and ensuring proper fluid levels, can prevent this issue. Additionally, checking for any obstructions in airflow will enhance engine performance.

Electrical Problems: Faulty wiring or poor connections can lead to electrical malfunctions. Inspecting wiring regularly and ensuring all connections are secure can mitigate these risks. Should electrical issues arise, consulting a professional may be necessary to ensure safety and functionality.

Track or Wheel Wear: Over time, tracks or wheels may wear down, affecting mobility and stability. Monitoring wear patterns and replacing tracks or wheels as needed will help maintain effective operation. Regularly lubricating moving parts can also extend their lifespan.

Comparing Parts with Other Models

When evaluating components across different machine variants, it becomes essential to identify similarities and differences that could affect performance and compatibility. Understanding these distinctions can significantly influence maintenance and replacement decisions.

Several key factors should be considered when comparing components:

- Compatibility: Ensure that the parts from one model can effectively function in another. This includes assessing the dimensions and connection points.

- Material Quality: Different machines may use varying materials that impact durability and efficiency. It is crucial to compare the robustness of components.

- Performance Impact: Evaluate how interchangeable parts affect the overall functionality and output of the equipment.

- Cost Efficiency: Analyzing the price points of components can reveal potential savings when choosing alternatives from other models.

In summary, a thorough comparison of elements from various machinery can provide valuable insights for users looking to enhance their operational efficiency and reduce costs.

Resources for Bobcat 7753 Owners

Owning a compact loader can bring numerous challenges, but having access to the right information can make a significant difference. This section provides essential tools and materials that can aid operators in maintaining and optimizing their equipment’s performance.

Online Forums and Communities offer a platform for users to share experiences, troubleshoot issues, and exchange tips. Engaging with fellow enthusiasts can provide valuable insights and practical advice that enhance operational knowledge.

Maintenance Manuals are crucial resources for understanding the operational aspects of the machinery. These documents typically include maintenance schedules, safety procedures, and troubleshooting guides, ensuring users can perform routine checks and repairs effectively.

Video Tutorials on platforms like YouTube serve as visual aids for users seeking hands-on guidance. These videos often demonstrate repair techniques, maintenance procedures, and tips for maximizing efficiency, making complex tasks more accessible.

Parts Suppliers specializing in machinery components play an important role in ensuring equipment longevity. Access to reliable vendors allows users to find quality replacements and upgrades, enhancing the overall functionality of their machines.

Local Workshops provide an option for those who prefer hands-on assistance. Establishing a relationship with skilled technicians can lead to personalized service and expertise in maintaining the equipment in optimal condition.

By leveraging these resources, operators can ensure their compact loaders remain efficient, reliable, and ready for any task at hand.