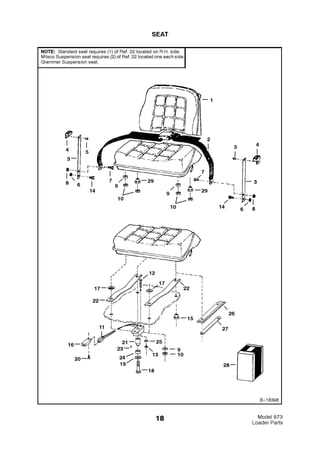

Comprehensive Bobcat 873 Parts Diagram Guide

When working with heavy equipment, a comprehensive understanding of its individual elements is crucial for effective maintenance and repair. This knowledge not only aids in the seamless operation of the machinery but also enhances its longevity. By delving into the specifics of each segment, operators can identify potential issues before they escalate into costly repairs.

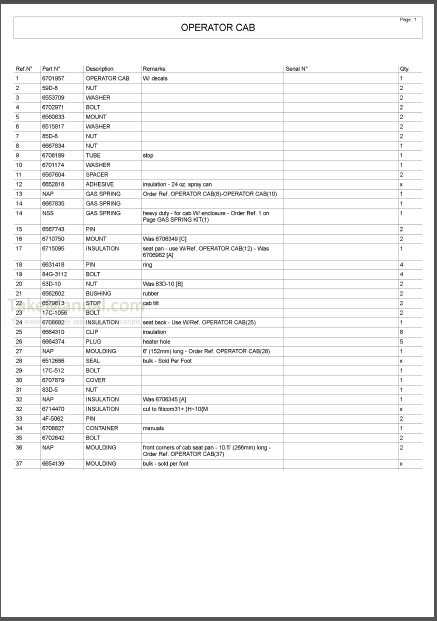

In this section, we will explore the intricacies of a particular model, focusing on the arrangement and functionality of its various components. This examination will serve as a valuable resource for technicians and enthusiasts alike, offering insights into the assembly and operational dynamics of the equipment.

Equipped with a detailed representation of the machinery’s elements, users can easily navigate through complex repairs or upgrades. Understanding how each part interacts with others empowers individuals to tackle challenges confidently, ensuring that the equipment operates at peak efficiency. Whether for routine maintenance or unexpected repairs, a thorough grasp of these components is indispensable.

Understanding Bobcat 873 Parts

This section aims to explore the components of a specific compact machinery model, focusing on their functions and interrelations. A clear comprehension of these elements is essential for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the equipment.

Key Components

Each element plays a crucial role in the overall functionality, contributing to the machine’s efficiency. Understanding these components helps in identifying issues and implementing the necessary solutions promptly.

Common Issues and Solutions

Recognizing frequent problems associated with various elements can significantly enhance operational reliability. Addressing these concerns proactively minimizes downtime and extends the lifespan of the machinery.

| Component | Common Issues | Recommended Solutions |

|---|---|---|

| Hydraulic System | Leakage, Poor performance | Inspect seals, Replace fluids |

| Engine | Overheating, Noise | Check coolant, Regular maintenance |

| Transmission | Slipping, Delayed engagement | Fluid replacement, System checks |

Overview of Bobcat 873 Features

This section explores the distinctive characteristics of a renowned compact machinery model, highlighting its capabilities and advantages. Designed for versatility and efficiency, this equipment has become a favorite in various industries due to its robust performance and user-friendly design.

Key Functionalities

The machine is equipped with powerful hydraulic systems, enabling it to tackle a wide range of tasks, from lifting heavy loads to performing intricate operations. With exceptional maneuverability and stability, it ensures optimum performance even in challenging conditions.

User-Centric Design

Engineered with operator comfort in mind, the unit features an ergonomic cabin that enhances visibility and reduces fatigue during long working hours. The intuitive controls allow for seamless operation, making it accessible for both seasoned professionals and newcomers.

Importance of Accurate Parts Diagrams

Understanding the intricate details of machinery components is essential for effective maintenance and repair. Precise illustrations serve as vital tools for technicians, ensuring that each element is identified and replaced correctly. Without reliable visuals, the risk of errors increases, potentially leading to costly downtime and inefficiencies.

Comprehension of these visual aids allows professionals to delve into the specifics of assembly, fostering a smoother workflow and better results. The ultimate goal is to maintain equipment reliability and longevity, which is only achievable through accurate representations of each component.

Furthermore, a well-structured reference can enhance training processes, enabling new technicians to familiarize themselves quickly with complex systems. Ultimately, investing time in these resources pays dividends in operational efficiency and reduces the likelihood of mistakes.

Common Issues with Bobcat 873

Machinery often encounters various challenges that can hinder performance and efficiency. Understanding these common problems can help in effective maintenance and timely repairs.

- Hydraulic System Failures

- Electrical Malfunctions

- Engine Overheating

- Transmission Issues

- Wear and Tear on Tires

Regular inspections and maintenance practices can significantly reduce the likelihood of these issues arising.

Components of the Hydraulic System

The hydraulic system is crucial for the effective operation of machinery, providing the necessary force and movement through a series of interconnected elements. Understanding these components helps in maintaining and troubleshooting the system, ensuring optimal performance and longevity.

Key Elements

Essential components include hydraulic pumps, which generate fluid flow; valves, responsible for directing the fluid; and cylinders, which convert hydraulic energy into mechanical force. Additionally, hoses and fittings connect these parts, ensuring fluid travels efficiently throughout the system.

Maintenance Considerations

Regular inspection and maintenance of these components are vital to prevent leaks and ensure smooth operation. Replacing worn parts and checking fluid levels can significantly enhance the system’s reliability and efficiency.

Electrical System Breakdown

The electrical framework of machinery plays a crucial role in its overall functionality and efficiency. Understanding the components and their interactions is essential for effective maintenance and troubleshooting. This section delves into the various elements that constitute the electrical system, highlighting their significance and operation.

- Power Source: The primary unit supplying energy to the system, typically a battery or generator, ensuring all components receive adequate voltage.

- Wiring Harness: A network of insulated cables that connects various electrical components, facilitating the flow of electricity throughout the machine.

- Control Module: The brain of the system, responsible for processing inputs from various sensors and making decisions to control other components.

- Sensors: Devices that monitor various parameters such as temperature, pressure, and position, providing critical feedback to the control module.

- Actuators: Components that convert electrical signals into physical movement, playing a key role in executing the commands from the control module.

- Fuses and Relays: Safety devices that protect the system from overloads and ensure proper operation by controlling the flow of electricity.

Each of these elements must function harmoniously to ensure the smooth operation of the machinery. Regular inspection and maintenance of these components are vital for preventing electrical failures and ensuring optimal performance.

Engine Parts and Specifications

This section explores the essential components of the power unit, highlighting their significance in ensuring optimal performance and reliability. Understanding these elements is crucial for maintenance and troubleshooting, enabling operators to enhance machinery functionality effectively.

Key Components

Within the engine assembly, several vital elements work together to generate power and maintain efficiency. Each part plays a unique role, contributing to the overall operation of the system.

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders and essential components. |

| Piston | A moving component that compresses fuel and air mixture. |

| Crankshaft | Transforms linear motion of the pistons into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

| Fuel Injector | Delivers precise amounts of fuel into the combustion chamber. |

Specifications Overview

Specifics regarding the engine’s capacity, output, and other metrics are critical for evaluating its suitability for various tasks. Familiarity with these specifications allows users to match the equipment to their operational needs.

Attachment Options for Bobcat 873

When it comes to enhancing the versatility of your machinery, selecting the right accessories is crucial. Various tools can be added to optimize performance for specific tasks, whether it’s digging, lifting, or grading. The following sections explore different attachments available for this equipment, focusing on their unique benefits and applications.

Popular Accessories

Several accessories are commonly utilized to maximize the efficiency of the machine. Each option serves distinct functions, allowing operators to tackle diverse projects with ease.

| Attachment Type | Primary Use | Benefits |

|---|---|---|

| Bucket | Excavation | High capacity for material handling |

| Forks | Lifting | Ideal for moving pallets and heavy items |

| Grapple | Grasping | Excellent for handling irregular materials |

| Snow Blade | Clearing | Efficient for snow and debris removal |

Choosing the Right Tool

Selecting the most suitable accessory hinges on the specific tasks at hand. Consider the job requirements and the potential for enhanced productivity when making your decision. With the right tools, your machinery can become an ultimate solution for various challenges.

Maintenance Tips for Longevity

Ensuring the durability and performance of your machinery requires consistent and thoughtful upkeep. Implementing a regular maintenance routine not only extends the life of your equipment but also enhances its efficiency. This section outlines essential practices that contribute to the long-term reliability of your machinery.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Checks | Weekly | Inspect and top off hydraulic fluids, engine oil, and coolant to prevent overheating and ensure smooth operation. |

| Filter Replacement | Every 250 hours | Change air, oil, and fuel filters to maintain optimal airflow and fuel efficiency. |

| Greasing | Every 50 hours | Apply grease to all pivot points and joints to minimize wear and tear. |

| Tire Inspection | Monthly | Check tire pressure and tread for safety and to improve handling. |

| Battery Maintenance | Every 6 months | Inspect battery terminals for corrosion and ensure proper charge levels to prevent starting issues. |

| Cleaning | As needed | Remove dirt and debris from the machine to prevent damage and improve visibility. |

Adhering to these guidelines will significantly contribute to the operational efficiency and longevity of your machinery. Regular maintenance not only saves costs in the long run but also enhances safety and performance on the job.

Finding Genuine Replacement Parts

When it comes to maintaining the efficiency and longevity of your equipment, sourcing authentic components is crucial. Utilizing genuine items ensures compatibility and enhances performance, ultimately saving time and money in the long run.

Benefits of Authentic Components

- Ensured Compatibility: Genuine items are specifically designed for your machinery, guaranteeing a perfect fit.

- Durability: Authentic components typically offer superior quality, leading to increased lifespan.

- Warranty Protection: Using original parts often helps maintain warranty coverage for your equipment.

- Enhanced Performance: Genuine replacements are engineered to meet the same standards as the original, promoting optimal function.

Where to Find Genuine Components

- Authorized Dealers: Always start with manufacturers or their authorized dealers to ensure you are getting authentic items.

- Reputable Online Retailers: Look for well-known websites that specialize in equipment parts, ensuring they have a good reputation for selling genuine products.

- Local Repair Shops: Many local mechanics or repair shops can source authentic components directly from the manufacturer.

- Trade Shows: Attending industry events can connect you with legitimate suppliers and provide firsthand insights into the latest offerings.

Tools Needed for Repairs

When it comes to conducting repairs on heavy machinery, having the right tools at hand is essential for achieving optimal results. Proper equipment not only ensures efficiency but also enhances safety during the repair process.

Essential Hand Tools

Wrenches, screwdrivers, and pliers are fundamental for disassembly and reassembly tasks. It is advisable to have both metric and standard sizes to accommodate various components. A sturdy hammer may also be necessary for tasks that require forceful adjustments.

Power Tools for Efficiency

Utilizing power drills and impact wrenches can significantly reduce the time spent on repairs. A reliable grinder may also be useful for smoothing out surfaces or cutting through tough materials, making these tools invaluable in the workshop.

Where to Access Parts Diagrams

Finding the right visual references for machinery components can be crucial for effective maintenance and repair. There are several reliable sources where these illustrations can be accessed, catering to both professionals and enthusiasts alike.

Online Resources

The internet offers a plethora of platforms where users can explore detailed schematics. Websites dedicated to equipment support typically house extensive libraries of manuals and diagrams, making it easy to locate the necessary visuals.

Local Dealers and Service Centers

Authorized dealers and service centers are invaluable resources for acquiring accurate illustrations. They often provide printed materials or digital access to comprehensive catalogs, ensuring you have the latest information.

| Source Type | Access Method | Notes |

|---|---|---|

| Online Platforms | Website Browsing | Wide selection, instant access |

| Dealers | In-Person or Phone | Expert assistance available |

| Manufacturer Support | Customer Service | Direct information from the source |

Upgrading Your Bobcat 873

Enhancing your machinery can significantly improve its performance and longevity. By implementing various modifications and incorporating high-quality components, you can optimize efficiency and ensure that your equipment meets your specific operational needs.

| Upgrade Type | Description |

|---|---|

| Hydraulic System | Enhance lifting capacity and speed with upgraded hydraulic components. |

| Engine Tune-Up | Improve fuel efficiency and power output through proper maintenance and tuning. |

| Tracks and Tires | Replace with superior quality options for better traction and durability. |

| Attachment Upgrades | Add specialized tools for increased versatility and productivity. |