Comprehensive Guide to Bobcat SB200 Parts Diagram

The intricate world of machinery often necessitates a thorough comprehension of its individual elements. Knowing how each component interacts with the others can significantly enhance the efficiency and longevity of your equipment. This section aims to delve into the essential aspects of machinery parts, facilitating a better grasp of their functions and relationships.

For those seeking clarity on how to maintain or repair their machines, visual representations of these components serve as invaluable resources. By examining the layout and connections between various elements, operators can make informed decisions about maintenance and troubleshooting. This guide will explore these resources, shedding light on the intricacies of machinery assembly.

Whether you are an experienced technician or a novice user, familiarizing yourself with the structure and arrangement of each part can empower you in the operational landscape. A well-informed approach can lead to more efficient repairs, reduced downtime, and ultimately, enhanced performance of your machinery.

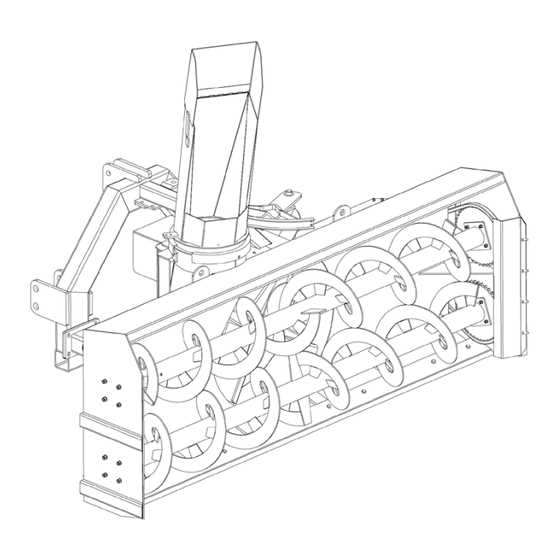

Understanding Bobcat SB200 Overview

This section provides an insightful examination of a compact and versatile machine designed for various tasks in construction and landscaping. Its robust design and efficient performance make it a preferred choice for professionals seeking reliability and functionality in a compact package.

The equipment features a powerful engine that ensures optimal productivity, allowing users to tackle a range of challenges with ease. Its maneuverability is enhanced by a well-thought-out design, making it suitable for tight spaces where larger machines cannot operate effectively.

Users will appreciate the various attachments available, which increase the machine’s versatility, enabling it to perform tasks such as digging, lifting, and grading. The integration of advanced technology ensures ease of operation, contributing to improved efficiency on job sites.

Maintenance and accessibility are also key considerations, with components arranged for easy servicing, minimizing downtime and extending the machine’s lifespan. This makes it an excellent investment for anyone in the construction or landscaping industries.

Key Features of Bobcat SB200

This section highlights the essential attributes of a compact machinery model designed for versatility and efficiency in various applications. Understanding these characteristics can help users maximize productivity while ensuring ease of operation and maintenance.

Compact Design

The equipment boasts a space-saving configuration, making it ideal for navigating tight areas and confined job sites. Its lightweight structure allows for easy transport and maneuverability, enabling operators to tackle diverse tasks without hassle.

Powerful Performance

Equipped with a robust engine, this model delivers impressive power and torque, facilitating effective handling of heavy loads. The advanced hydraulic system ensures smooth operation, while the efficient fuel consumption enhances overall productivity and reduces operational costs.

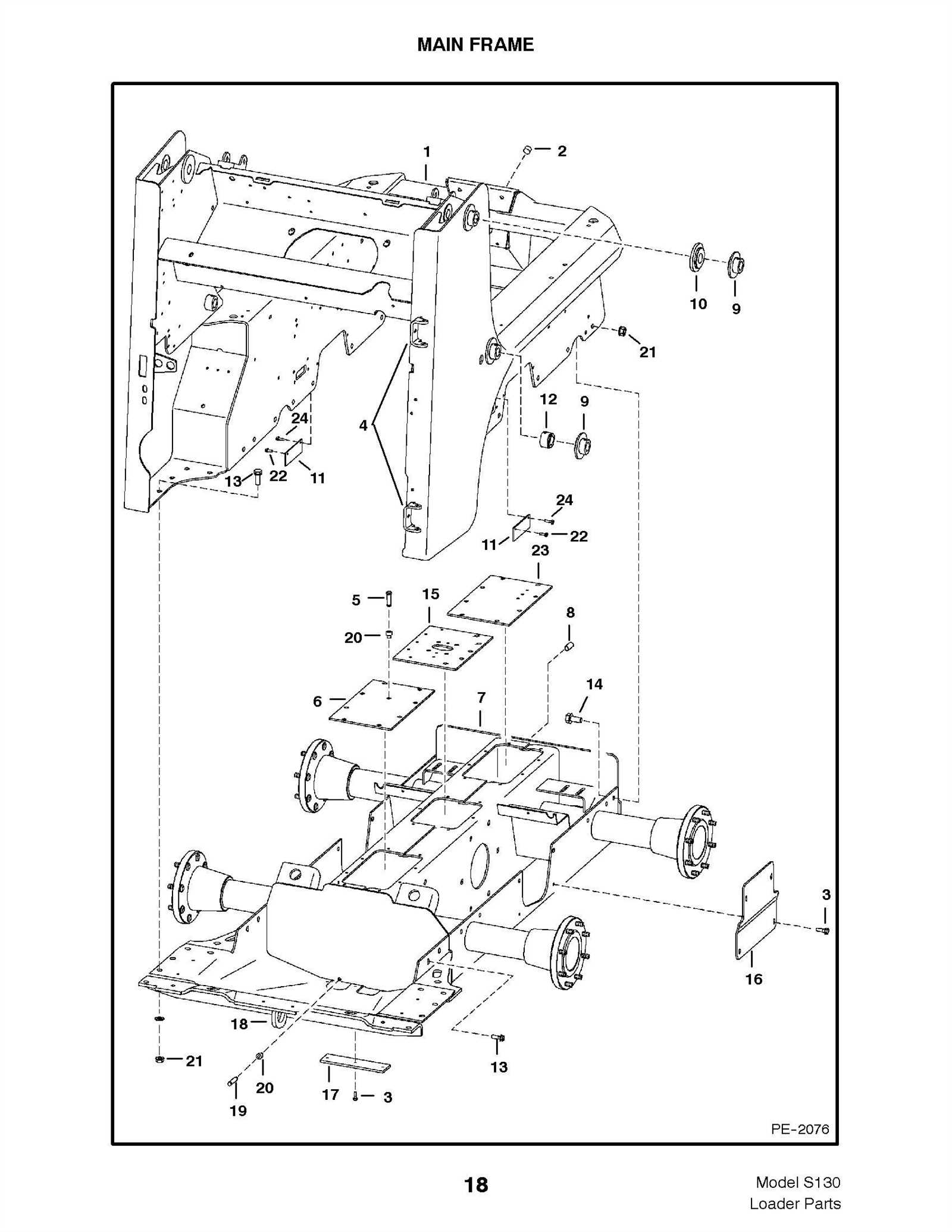

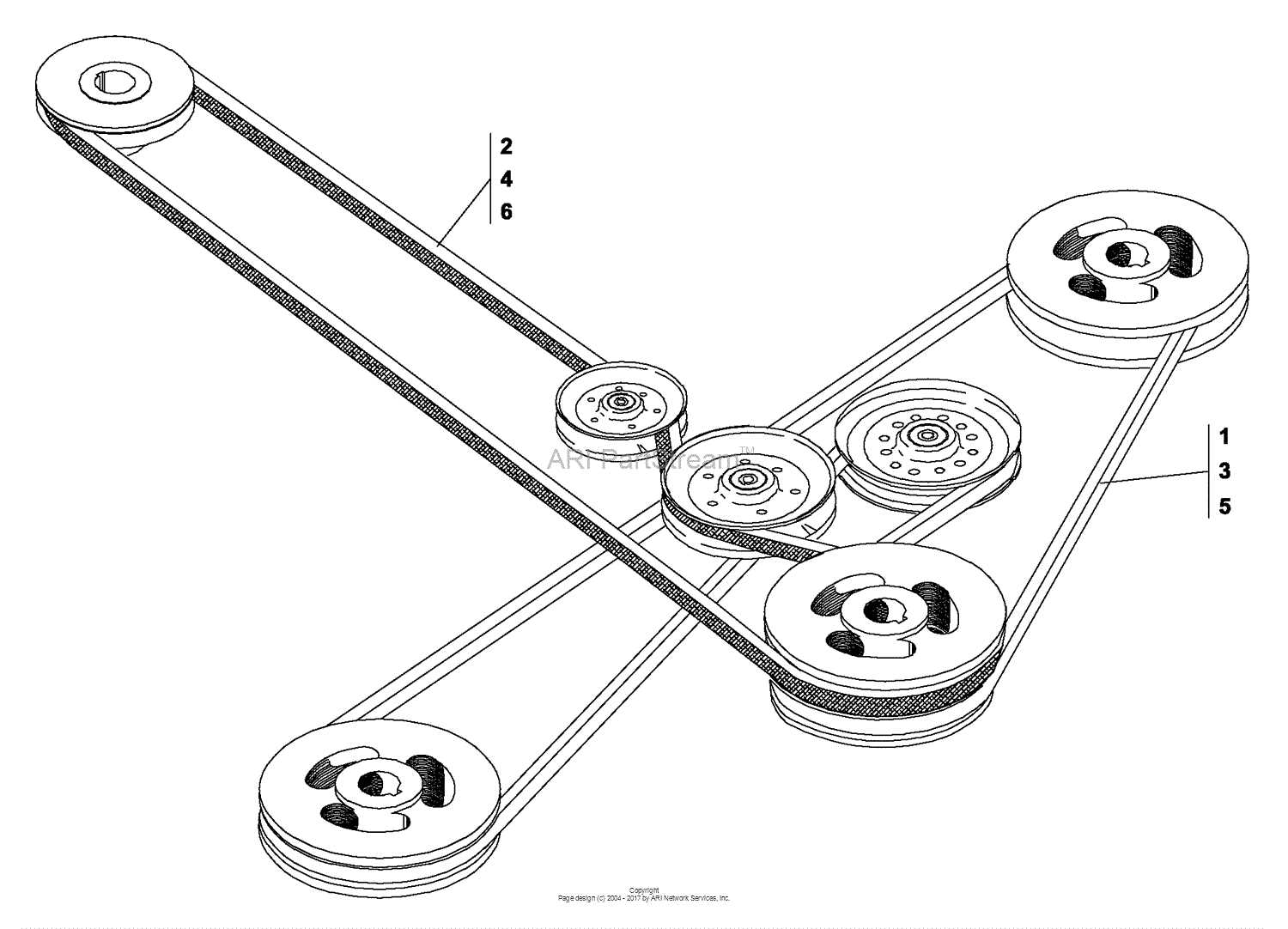

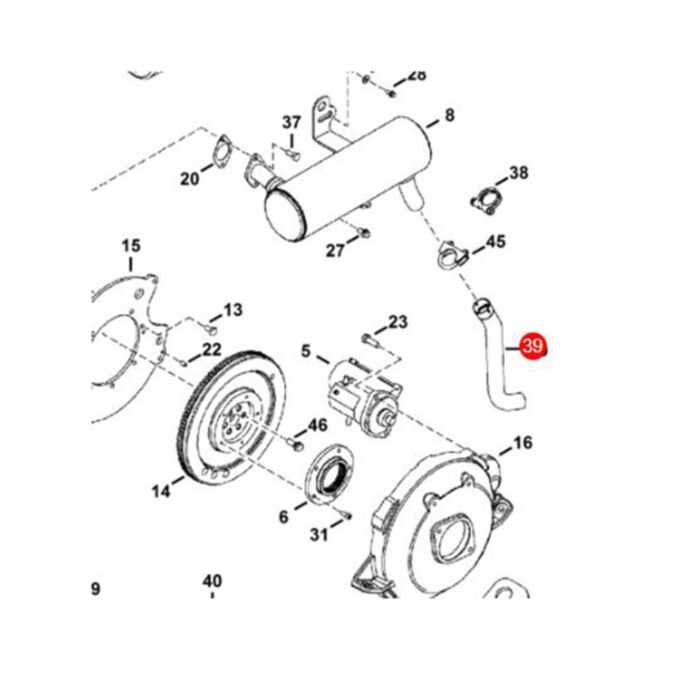

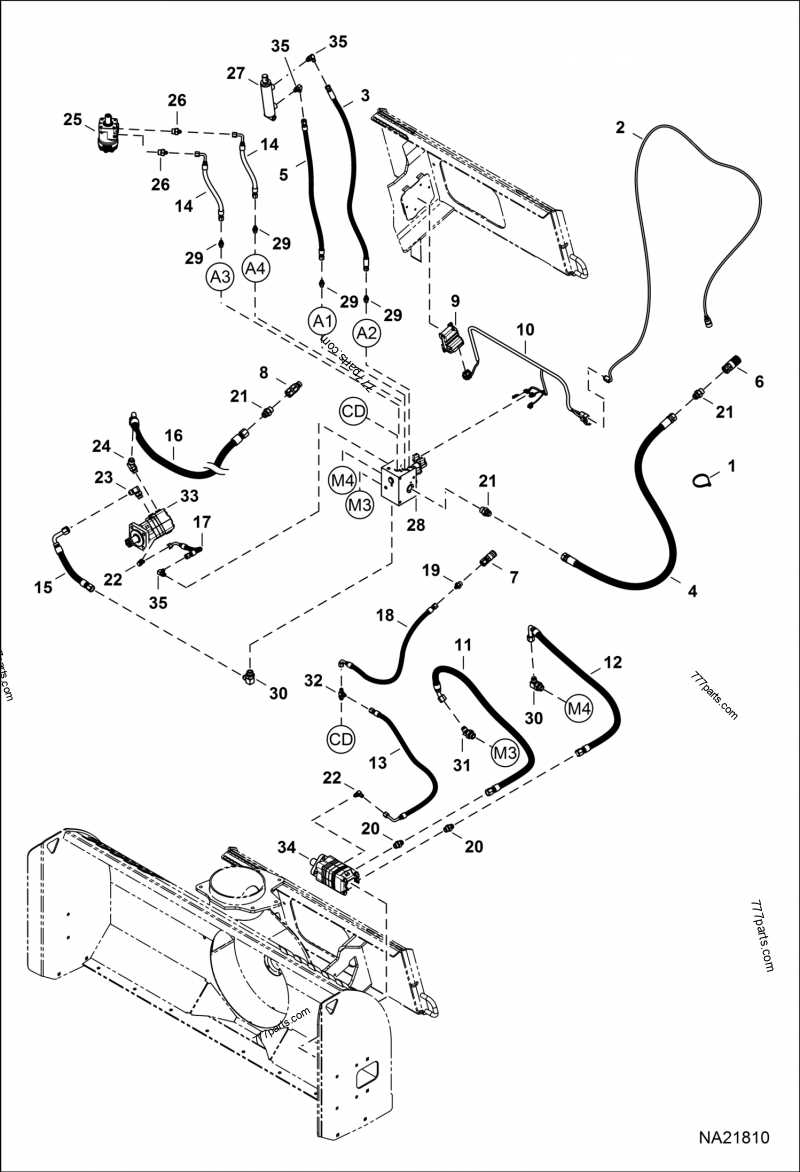

Importance of Parts Diagrams

Visual representations of component assemblies are essential tools for anyone involved in maintenance or repair. These illustrations provide clarity and organization, making it easier to understand how individual elements interact within a larger system.

Here are several key reasons why these visual guides are crucial:

- Enhanced Understanding: They break down complex systems into manageable sections, helping users grasp the functionality of each piece.

- Efficient Repairs: Clear visuals allow for quicker identification of necessary replacements, reducing downtime during maintenance.

- Improved Communication: They serve as a universal language among technicians, facilitating collaboration and troubleshooting efforts.

- Accurate Ordering: When ordering new components, these visuals ensure that the correct items are selected, minimizing errors.

- Training Resource: They can be valuable educational tools for training new staff, providing a visual reference that aids learning.

In conclusion, utilizing these representations significantly contributes to effective maintenance practices and enhances overall operational efficiency.

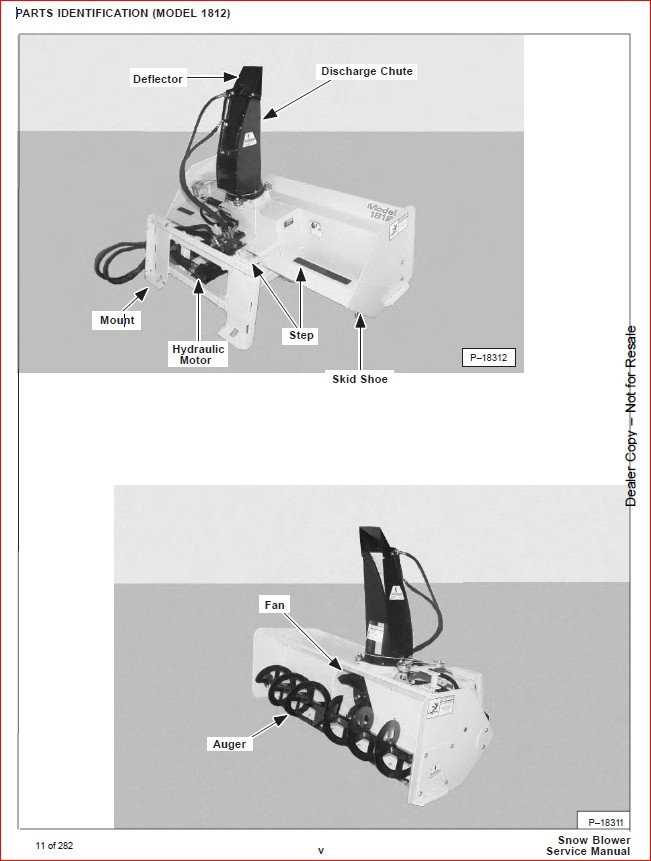

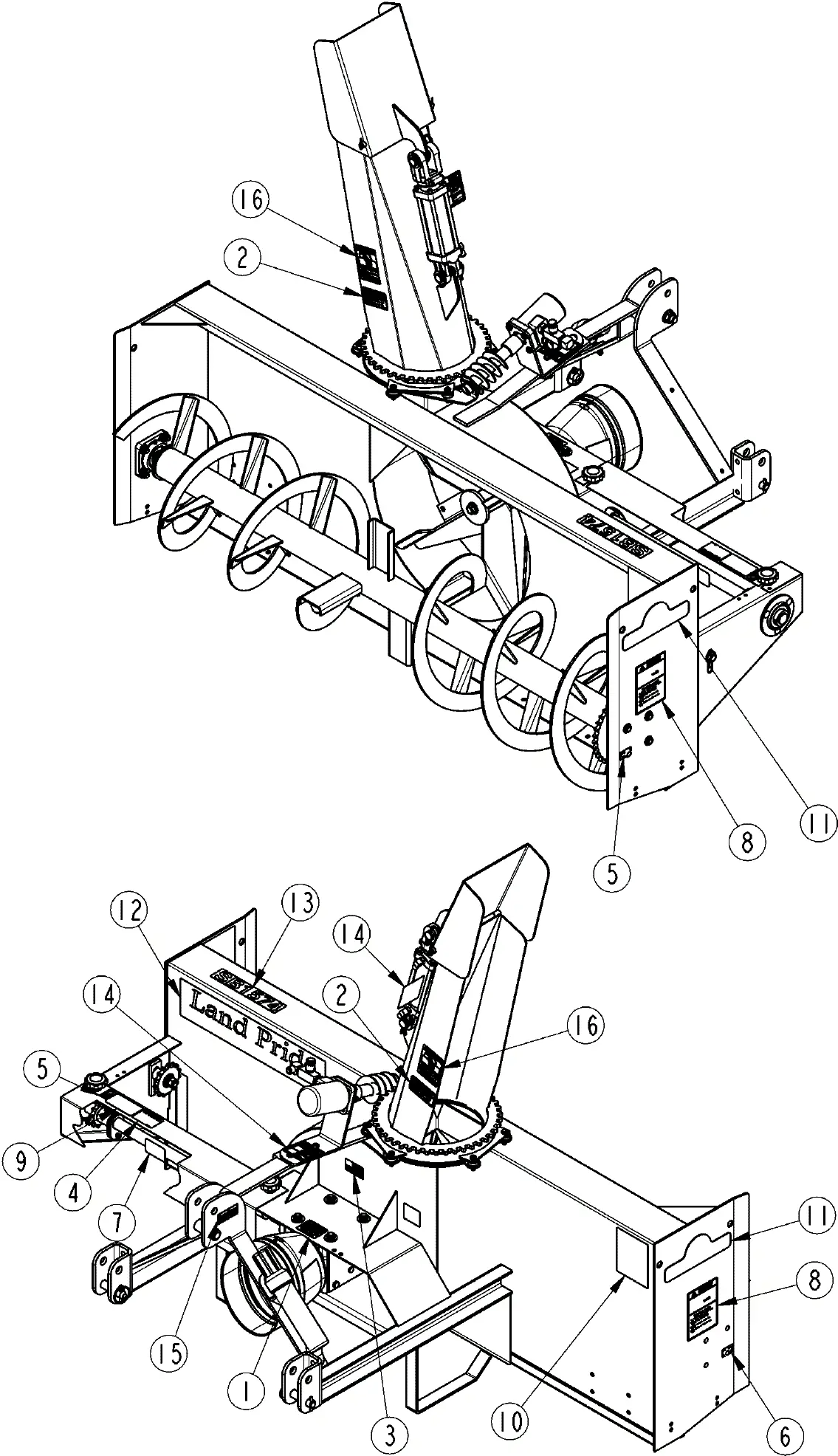

Common Parts in SB200 Machines

Understanding the essential components of these machines is crucial for optimal performance and maintenance. Each unit consists of various elements that work together to ensure efficiency and durability. Familiarity with these components can help operators troubleshoot issues and streamline repairs.

Key elements include the hydraulic system, which plays a vital role in powering various functions, and the engine, essential for driving the machine. The undercarriage, which includes tracks and rollers, supports mobility across different terrains. Additionally, attachments like buckets and blades enhance versatility, allowing the machine to tackle diverse tasks.

Regular inspection and maintenance of these components not only prolong the lifespan of the equipment but also ensure safety and reliability in operation. Operators should prioritize understanding the function and maintenance requirements of these crucial elements.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repair. Such illustrations serve as a roadmap, guiding users through the intricate relationships and arrangements of various elements within a system. Familiarity with the layout and symbols used can significantly enhance your ability to troubleshoot issues and perform replacements efficiently.

To make the most of these visual aids, follow these key steps:

| Step | Description |

|---|---|

| 1 | Identify the Sections: Locate major areas that are typically categorized by function or assembly. |

| 2 | Recognize the Symbols: Learn the common symbols that represent different types of components, such as bolts, brackets, and connectors. |

| 3 | Follow the Connections: Observe how parts interact with each other, noting any dependencies or sequences in assembly. |

| 4 | Refer to the Index: Utilize any accompanying lists that provide part numbers or descriptions to simplify the identification process. |

| 5 | Consult Resources: Use manuals or online databases for additional details on specific components and their functions. |

By following these guidelines, you can enhance your comprehension and effectively navigate through complex mechanical layouts, ensuring that your repair or maintenance tasks are carried out with confidence and precision.

Finding Replacement Parts for SB200

Locating suitable components for your equipment can significantly enhance its performance and longevity. Understanding where to seek out these essential items will ensure your machinery operates smoothly and efficiently. This section provides guidance on sourcing the necessary replacements effectively.

When searching for the right components, consider the following options:

- Authorized Dealers: Reach out to certified suppliers who specialize in machinery. They often have a comprehensive inventory and can provide expert advice.

- Online Retailers: Numerous e-commerce platforms offer a vast selection of components. Ensure that you verify the credibility of the seller before making a purchase.

- Local Repair Shops: Often, these establishments can assist with sourcing specific items or may even have them in stock.

- Forums and Community Groups: Engaging with fellow equipment owners can lead to valuable recommendations on where to find rare or discontinued items.

In addition to these resources, consider the following tips to streamline your search:

- Identify the exact specifications and model numbers needed for the components.

- Keep a record of previous purchases to track what has worked best in the past.

- Check for warranty options or return policies to ensure peace of mind with your purchases.

By utilizing these strategies, you can enhance your chances of successfully finding the necessary components to keep your equipment in optimal condition.

Maintenance Tips for Bobcat SB200

Proper upkeep of machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Following a systematic approach to care can significantly improve the functionality of your equipment.

Regular Inspections

Routine checks play a crucial role in identifying wear and tear before they escalate into serious issues. Examine key components like hydraulic systems, belts, and filters for signs of damage or degradation.

Lubrication and Fluid Levels

Keeping all moving parts adequately lubricated is vital for smooth operation. Regularly check and top off fluids, including hydraulic oil, engine oil, and coolant, to prevent overheating and other operational issues.

| Maintenance Task | Frequency |

|---|---|

| Inspect hydraulic hoses | Monthly |

| Change engine oil | Every 50 hours |

| Check air filter | Every 100 hours |

| Grease fittings | Every 10 hours |

| Inspect tires | Weekly |

Identifying Components in Diagrams

Understanding the various elements in technical illustrations is crucial for effective maintenance and repair. These visual representations serve as guides, allowing users to locate and comprehend each part’s function and interrelation within a complex system. By familiarizing oneself with these components, one can enhance both efficiency and accuracy during troubleshooting or assembly tasks.

Key Features to Recognize

When examining these visual aids, several key features stand out. Labels often denote specific elements, providing immediate identification. Shapes and colors may also convey important information about the function or material of each component. Understanding these features enables a more intuitive grasp of the overall assembly.

Utilizing Reference Guides

In addition to direct observation, reference materials play a significant role in comprehension. Utilizing manuals or online resources can offer detailed explanations and supplementary visuals that clarify any ambiguities. Cross-referencing these materials with the illustrations can foster a deeper understanding of how each part interacts within the entire setup.

Benefits of Accurate Parts Identification

Precise identification of components is essential for maintaining operational efficiency and reducing downtime in any machinery. When individuals are able to accurately recognize and select the correct elements, it leads to smoother maintenance processes and ultimately enhances overall productivity.

Improved Operational Efficiency

When the right components are chosen, machinery can function at its peak performance. This minimizes the risk of malfunctions and unnecessary wear, ensuring that the equipment operates smoothly over an extended period. As a result, the need for frequent repairs is significantly reduced, allowing for uninterrupted workflow.

Cost-Effectiveness

Identifying components accurately can also lead to substantial cost savings. By avoiding incorrect purchases or installations, businesses can prevent financial losses associated with downtime and repairs. Moreover, using the right parts can enhance the longevity of the equipment, further contributing to budgetary efficiency.

In conclusion, a thorough understanding and correct identification of components play a vital role in the successful operation and maintenance of machinery. The benefits extend beyond immediate operational gains, impacting financial and logistical aspects significantly.

Common Repairs for Bobcat SB200

When operating heavy machinery, regular maintenance and timely repairs are crucial for optimal performance and longevity. Understanding the common issues that may arise can help operators effectively manage their equipment. Below are some frequent repairs that may be needed to keep your unit running smoothly.

-

Hydraulic System Maintenance:

- Inspect and replace worn hoses.

- Check fluid levels and quality.

- Repair or replace faulty hydraulic pumps.

-

Electrical System Repairs:

- Diagnose and fix wiring issues.

- Replace blown fuses and damaged relays.

- Test and repair battery connections.

-

Engine Tune-Ups:

- Change oil and filters regularly.

- Inspect and replace spark plugs as needed.

- Check cooling systems for leaks or blockages.

-

Track and Tire Maintenance:

- Inspect for wear and tear on tracks.

- Adjust tension as required.

- Replace damaged tires promptly to prevent further issues.

By staying ahead of these common repairs, operators can ensure their machinery remains efficient and reliable, ultimately reducing downtime and increasing productivity.

Online Resources for Parts Diagrams

Accessing visual references for machinery components is essential for maintenance and repair tasks. Fortunately, various online platforms provide detailed schematics that can assist users in identifying specific elements and understanding their relationships within the overall system. These resources are invaluable for both professionals and enthusiasts seeking to keep their equipment in optimal condition.

Key Online Platforms

- Manufacturer Websites: Many manufacturers offer downloadable resources directly on their websites, allowing users to easily find and access comprehensive visuals.

- Repair Forums: Community-driven platforms often feature shared resources and user-generated content, providing unique insights and tips from experienced users.

- Online Retailers: Some e-commerce sites specialize in parts and may include schematic images alongside product listings for easy reference.

- Technical Manuals: Websites that host technical documents may have sections dedicated to equipment diagrams, offering detailed views and breakdowns of various systems.

Benefits of Using Online Resources

- Accessibility: Users can access resources from anywhere, making it convenient to find necessary information at any time.

- Variety: Multiple sources ensure a wide range of schematics, catering to different models and configurations.

- Community Support: Engaging with others online can provide additional help and clarification when dealing with complex systems.

- Cost-Effectiveness: Many resources are available for free, making it budget-friendly for users looking to minimize repair costs.

Choosing Quality Replacement Parts

When it comes to maintaining machinery, selecting high-quality components is crucial for ensuring optimal performance and longevity. The right elements not only enhance efficiency but also prevent premature wear and potential breakdowns. Understanding how to identify reliable substitutes can save time and resources in the long run.

Here are some key considerations for selecting superior alternatives:

- Material Quality: Look for components made from durable materials that can withstand wear and tear.

- Manufacturer Reputation: Research brands known for their reliability and performance in the industry.

- Compatibility: Ensure that the replacement fits seamlessly with your equipment to avoid operational issues.

- Warranty: A good warranty often indicates the manufacturer’s confidence in their product’s quality.

- Reviews and Feedback: Check customer reviews for insights into the performance and durability of the items.

By focusing on these aspects, you can make informed decisions that contribute to the effective operation of your machinery.

Expert Advice on SB200 Maintenance

Proper upkeep of your machinery is essential for longevity and optimal performance. Regular maintenance not only ensures that your equipment runs smoothly but also minimizes the risk of unexpected breakdowns. By following expert recommendations, you can enhance efficiency and extend the lifespan of your unit.

Routine Checks

Conducting routine inspections is crucial. Focus on fluid levels, filters, and belts. Ensure that hydraulic fluid is clean and at the appropriate level, as this directly affects performance. Regularly replace air and fuel filters to maintain efficient operation. Additionally, inspect belts for wear and tension to prevent operational failures.

Cleaning and Lubrication

Keeping your machine clean is equally important. Remove dirt and debris that can accumulate in hard-to-reach areas. Use a soft brush and compressed air to keep components free of contaminants. Furthermore, applying the right lubricant to moving parts reduces friction and wear. Adhering to the manufacturer’s recommendations for lubrication intervals will ensure optimal function.