Comprehensive Guide to Bobcat Skid Loader Parts Diagram

In the realm of compact machinery, comprehending the intricate components that drive performance is essential for effective maintenance and operation. Each unit consists of various elements working in harmony, allowing for enhanced productivity and efficiency on the job site.

To achieve optimal functionality, it is crucial to have a clear overview of the layout and relationships among these vital components. By delving into the specifics of each segment, operators can better address potential issues and ensure longevity in their equipment.

Whether you are a seasoned professional or a newcomer, grasping the ultimate configuration of these machines will empower you to make informed decisions, streamline repairs, and maximize your investment. Understanding these details transforms the operation from a mere task into a strategic advantage.

Understanding Bobcat Skid Loader Components

When exploring the intricacies of compact construction machinery, it is essential to familiarize oneself with the various elements that contribute to its functionality. Each component plays a pivotal role, ensuring optimal performance and durability during operations.

Main Elements

- Chassis: The foundation that supports all other components.

- Hydraulic System: Responsible for powering movement and operation of attachments.

- Engine: The heart of the machine, providing necessary power.

- Transmission: Facilitates the transfer of power from the engine to the wheels.

- Electrical System: Powers lights, instruments, and other electronic functions.

Importance of Each Component

- Ensures efficient operation and handling.

- Contributes to safety and stability on various terrains.

- Affects the overall lifespan and maintenance needs of the equipment.

Key Features of Bobcat Loaders

Compact machinery has transformed various industries, offering unparalleled versatility and efficiency. These powerful machines are designed to perform a multitude of tasks, making them indispensable in construction, landscaping, and agriculture. Understanding their standout characteristics can help operators maximize their potential in diverse applications.

One of the most notable aspects is their agility, allowing them to navigate tight spaces with ease. This is particularly beneficial in urban environments or on smaller job sites where larger equipment would be impractical. The intuitive controls enhance operator comfort and reduce fatigue, enabling prolonged usage without sacrificing productivity.

Robust build quality is another significant feature, ensuring durability even in challenging conditions. The hydraulic systems are engineered for optimal performance, providing impressive lifting capabilities and speed. Additionally, a wide array of attachments enhances functionality, allowing these machines to tackle various tasks such as digging, grading, and material handling.

Moreover, advanced safety features are integrated into the design to protect operators and bystanders. Enhanced visibility, stable platforms, and automatic shut-off systems contribute to a safer working environment. Overall, these characteristics not only improve performance but also enhance user experience, making them a top choice among professionals.

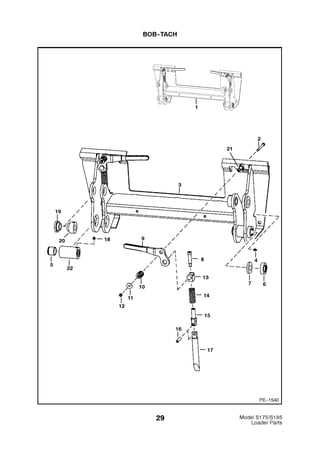

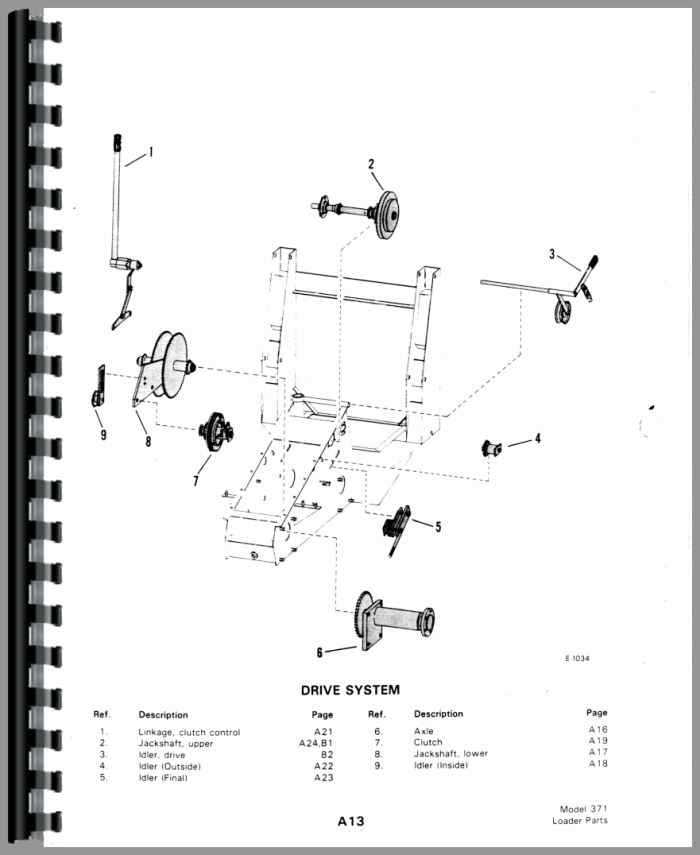

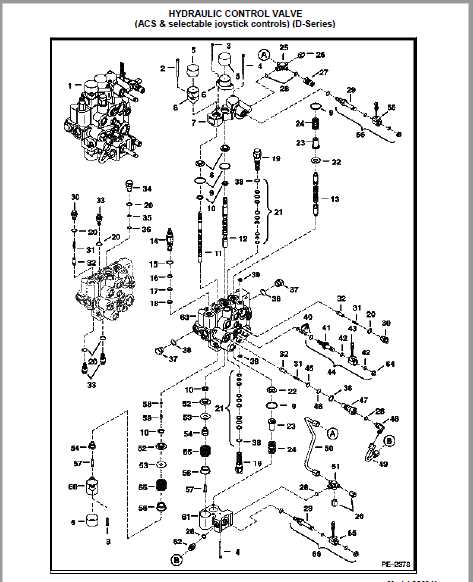

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. They provide clarity and enhance understanding, ensuring that individuals can effectively identify and manage various elements.

- Facilitate efficient troubleshooting

- Improve accuracy during assembly

- Support effective communication among technicians

- Streamline ordering and sourcing of components

By utilizing these illustrations, users can delve deeper into the intricacies of machinery, ultimately leading to better performance and longevity.

Common Issues with Loader Parts

In the world of compact construction equipment, certain mechanical components often face challenges that can affect performance and efficiency. Understanding these frequent issues can help operators maintain their machines in optimal condition, minimizing downtime and repair costs. Regular inspections and timely interventions are essential for addressing these concerns effectively.

Wear and Tear

Components of heavy machinery endure significant stress, leading to gradual deterioration. Common areas affected include hydraulic systems, engine mounts, and drive belts. Identifying signs of wear early can prevent more severe damage and costly repairs.

Fluid Leaks

Leaks are a prevalent problem that can compromise machine performance. Hydraulic fluids, oil, and coolant can escape from seals and hoses, leading to decreased efficiency and potential overheating. Routine checks for leaks are crucial for maintaining optimal functionality.

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Hydraulic failure | Slow or unresponsive operation | Check fluid levels; inspect hoses |

| Engine overheating | Warning lights; unusual noises | Inspect coolant system; replace faulty components |

| Excessive vibrations | Shaking during operation | Examine mounts; balance rotating parts |

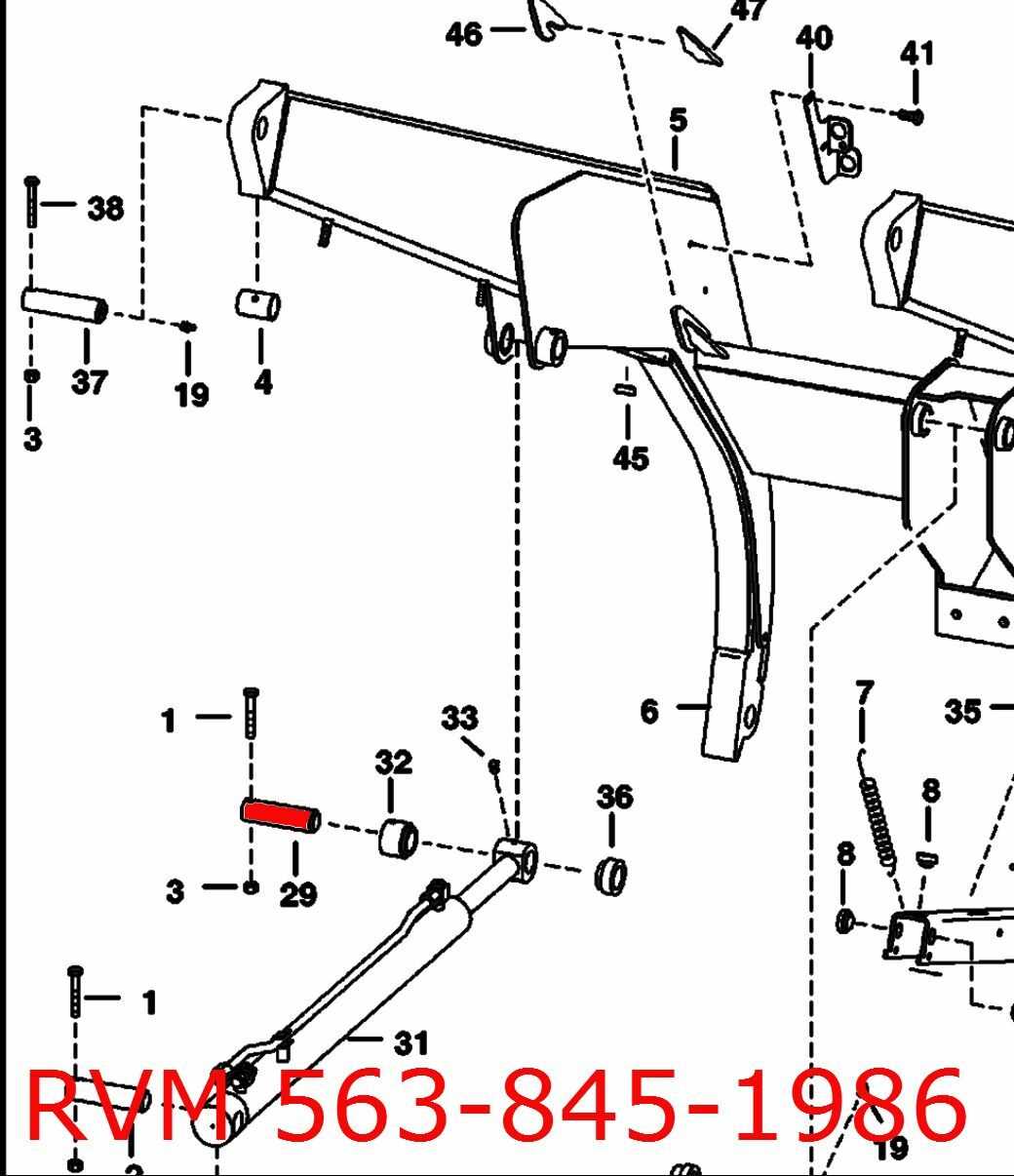

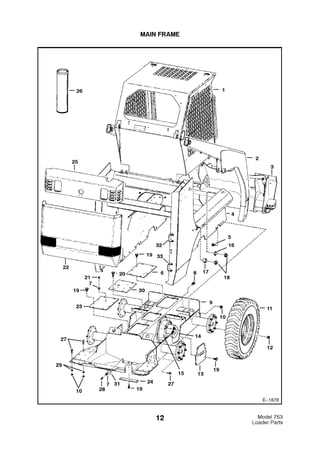

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for efficient maintenance and repair tasks. These visuals provide a comprehensive representation of components, helping users identify each piece’s location and function. Here’s how to effectively interpret such illustrations.

- Familiarize Yourself with the Legend:

- Check for symbols and annotations that explain the components.

- Note color codes that might indicate different categories of parts.

- Identify Key Components:

- Locate the main assemblies or sections within the visual.

- Recognize the connections and how components fit together.

- Follow the Numbering System:

- Each part typically has a unique identifier; use it to cross-reference with a list.

- Ensure you understand the sequence of assembly to avoid confusion.

- Pay Attention to Details:

- Look for notes or additional information that might indicate specific requirements.

- Be aware of any warnings related to handling or installation.

By following these steps, you can navigate an assembly illustration effectively, ensuring that you understand the intricate relationships between the components involved.

Identifying Replacement Parts Easily

Finding the correct components for your machinery can often seem daunting, but with the right approach, it becomes a straightforward task. Understanding the layout and functionality of each element is essential for effective replacement. By familiarizing yourself with the overall system, you can simplify the process and minimize downtime.

Start by consulting the user manual specific to your equipment. This document typically contains crucial information about the various elements and their respective functions. It will guide you in recognizing which components need attention and how they fit into the larger assembly.

Another valuable resource is online databases that provide detailed schematics. These visual aids allow you to see how each part interacts with others, making it easier to pinpoint what needs replacing. Ensure you have the model number at hand, as this will help you find accurate information tailored to your machinery.

Consider joining online forums or communities where fellow operators share insights and experiences. Engaging with others can provide practical advice and tips that may not be found in manuals or databases. Leveraging collective knowledge can often lead to quicker identification of necessary components.

Finally, keeping a record of previous replacements and repairs can serve as a valuable reference. This log will help you track patterns and anticipate future needs, making the identification process even smoother.

Maintenance Tips for Bobcat Loaders

Regular upkeep is essential for the longevity and efficiency of your machinery. Proper care not only enhances performance but also prevents costly breakdowns. Understanding key maintenance practices will ensure that your equipment remains in peak condition throughout its operational life.

Daily Inspections

Performing daily checks can significantly extend the life of your machinery. Inspect fluid levels, filters, and belts to catch potential issues early. Cleaning the exterior helps prevent rust and wear, while ensuring that all connections are secure promotes operational safety.

Scheduled Servicing

Establish a routine maintenance schedule based on usage. Regularly change oil and filters, as well as inspect hydraulic systems for leaks. Timely servicing not only optimizes performance but also safeguards against unexpected failures, ensuring your equipment operates at its ultimate potential.

Where to Find Parts Diagrams

Accessing detailed visual guides for machinery components can significantly enhance repair and maintenance efforts. Various resources are available for enthusiasts and professionals alike, ensuring that everyone can find the necessary information to keep equipment in top shape.

- Manufacturer Websites: Often, the official websites provide comprehensive resources, including manuals and visual references.

- Online Retailers: Many online shops specialize in machinery supplies and offer helpful visuals for ordering the correct items.

- Forums and Community Groups: Engaging with fellow equipment users can yield valuable insights and shared resources.

- Repair Manuals: Purchasing or downloading repair guides can offer in-depth visual assistance.

- YouTube Tutorials: Video demonstrations frequently include visual aids that can serve as a helpful reference.

Popular Bobcat Loader Models

In the realm of compact machinery, several models stand out due to their versatility and efficiency. These models are designed to tackle various tasks, making them essential for construction, landscaping, and agricultural projects.

Here are some of the most notable models that have gained popularity among users:

- S-Series: Known for their exceptional performance and ease of use, these machines are perfect for a wide range of applications.

- E-Series: These compact units are celebrated for their agility and ability to work in tight spaces, ideal for urban environments.

- T-Series: Equipped with advanced technology, these models offer enhanced productivity and operator comfort.

- 1900 Series: With a robust design, these machines are suited for heavy-duty tasks, providing impressive lifting capacity.

- 300 Series: These units are highly regarded for their fuel efficiency and reliable performance, making them a favorite among contractors.

Each of these models showcases unique features that cater to different operational needs, ensuring that users can find the right fit for their specific requirements.

Cost-Effective Repair Solutions

Finding affordable methods for maintenance and repairs can significantly reduce operational expenses while prolonging equipment lifespan. Implementing smart strategies not only ensures efficient performance but also minimizes downtime, making it essential for any machinery owner.

Utilizing Aftermarket Components

Exploring alternative suppliers for components can lead to substantial savings. Aftermarket options often provide similar quality at a fraction of the cost, allowing for budget-friendly repairs without compromising reliability.

Regular Maintenance Practices

Adopting consistent upkeep routines can prevent major failures and costly repairs. Simple tasks like routine inspections and timely fluid changes can enhance functionality and extend the life of machinery, proving to be a wise investment.

Choosing Quality Replacement Parts

When it comes to maintaining equipment, selecting high-grade components is crucial for optimal performance and longevity. Quality replacements not only ensure reliability but also enhance the efficiency of machinery, ultimately leading to reduced downtime and lower operational costs.

Here are key factors to consider when choosing components:

| Factor | Description |

|---|---|

| Material | Look for durable materials that withstand wear and tear. |

| Compatibility | Ensure the components fit seamlessly with your existing machinery. |

| Manufacturer Reputation | Choose suppliers known for their quality and reliability. |

| Warranty | Opt for products that come with a solid warranty for peace of mind. |

Investing in superior replacements can significantly impact performance and reduce the likelihood of future issues. Prioritize these aspects for the ultimate reliability in your equipment.

Frequently Asked Questions on Parts

This section aims to address common inquiries related to components and their functionality in machinery. Understanding these elements is crucial for efficient operation and maintenance.

Common Inquiries

Below are frequently asked questions regarding the various elements that contribute to the performance of your equipment.

| Question | Answer |

|---|---|

| What is the lifespan of these components? | The lifespan varies based on usage and maintenance, typically ranging from several months to years. |

| How do I identify a faulty component? | Look for signs of wear, unusual noises, or performance issues as indicators of a problem. |

| Where can I find replacement elements? | Authorized dealers, online retailers, and specialized shops often carry the necessary replacements. |

Maintenance Tips

Regular inspections and timely replacements are essential to ensure the longevity and efficiency of your machinery.