Bostitch SB-1850BN Parts Diagram Explained

In the world of construction and woodworking, having a comprehensive understanding of your tools is essential. Every machine comprises various elements that contribute to its overall functionality, and knowing how these parts interact can greatly enhance your efficiency and effectiveness.

By exploring the intricate layout of these components, users can identify potential issues and undertake necessary maintenance. This knowledge not only ensures longevity but also maximizes performance, allowing for smoother operation in demanding projects.

Moreover, familiarizing oneself with the specific elements of a tool empowers users to make informed decisions regarding repairs and upgrades. The ultimate goal is to achieve optimal performance, ensuring that every task is completed with precision and ease.

Bostitch SB-1850BN Overview

This section provides a comprehensive look at a versatile and powerful tool designed for construction and woodworking. Known for its durability and efficiency, it excels in delivering high performance, making it an essential piece of equipment for both professionals and DIY enthusiasts.

Key Features

Among its standout characteristics are a robust design and an impressive firing mechanism that ensures precision and speed. Users appreciate the ergonomic handle, which enhances comfort during prolonged use, while the adjustable settings allow for adaptability across various projects.

Applications

This tool is ideal for tasks such as framing, flooring, and roofing. Its ability to work with a range of fasteners makes it particularly effective in diverse applications, providing the ultimate solution for tackling challenging jobs efficiently.

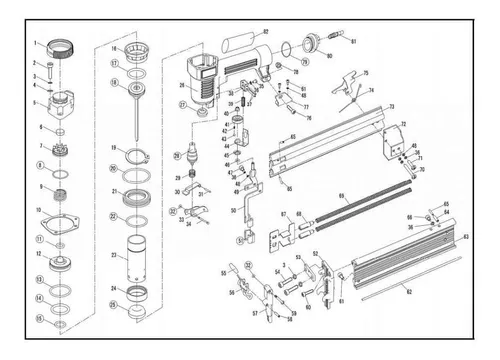

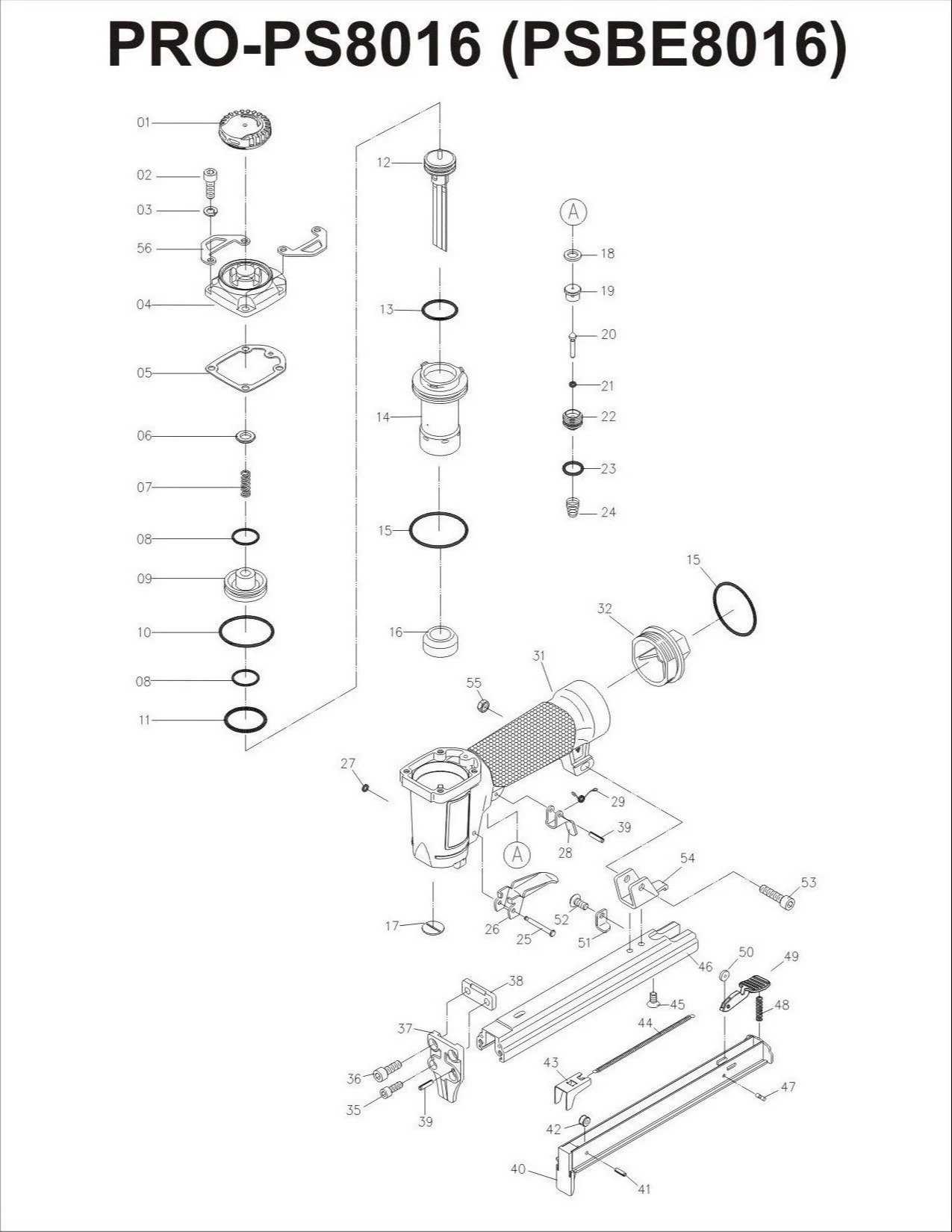

Importance of Parts Diagrams

Understanding the various components of machinery is crucial for effective maintenance and repair. Visual representations that outline each element’s placement and function can significantly enhance one’s ability to troubleshoot and resolve issues. These illustrations serve as essential references, allowing users to quickly identify parts, their connections, and the overall structure of the equipment.

Having access to such visual guides not only streamlines the repair process but also promotes safety. By clearly showing how each component interacts, these resources help prevent improper handling that could lead to accidents or further damage. Moreover, they facilitate more informed decision-making regarding replacements and upgrades, ultimately prolonging the life of the equipment.

Additionally, these visual aids play a vital role in training new technicians. They provide a straightforward way to learn about the equipment’s design and functionality, enabling quicker acclimatization to complex systems. In essence, these graphical representations are invaluable tools for anyone involved in the upkeep or operation of machinery.

Identifying Key Components

Understanding the essential elements of a tool is crucial for effective maintenance and operation. Each part plays a specific role in the overall functionality, contributing to the seamless performance of the device. By familiarizing oneself with these components, users can troubleshoot issues more effectively and ensure longevity.

Main Housing: This is the foundational structure that houses various internal mechanisms. Its durability is vital for protecting the internal parts from damage during use.

Motor Assembly: The powerhouse of the equipment, this unit converts electrical energy into mechanical motion, driving the entire operation. Its efficiency directly impacts the performance and speed.

Trigger Mechanism: Often the user’s point of control, this component allows for precise activation and deactivation, ensuring safety and accuracy during use.

Fastener Guide: This element aids in the correct positioning of materials, enhancing the accuracy of application. Proper alignment is essential for achieving desired results.

Magazine: Serving as the storage for fasteners, this part allows for quick reloading and helps maintain workflow efficiency. Its design can significantly influence the speed of operation.

By recognizing these fundamental elements, users can better appreciate how they work together to achieve optimal functionality and performance.

Common Issues with SB-1850BN

Understanding frequent problems can significantly enhance the longevity and performance of your tool. Various complications may arise during operation, often stemming from wear and tear or improper usage. Here are some of the typical challenges users may encounter:

- Jamming: This often occurs when materials are misaligned or when debris accumulates inside the mechanism.

- Pneumatic issues: Inconsistent pressure can lead to ineffective operation, commonly due to leaks or faulty connections.

- Misfires: This can happen when the device fails to shoot fasteners correctly, often caused by inadequate loading.

- Overheating: Extended use without breaks may lead to overheating, affecting performance and safety.

- Inconsistent depth adjustment: Improper settings can cause fasteners to be driven too deep or not deep enough.

By being aware of these issues, users can take proactive steps to maintain their equipment and ensure optimal functionality.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for ensuring that your equipment remains in optimal condition over time. Regular maintenance not only enhances performance but also extends the lifespan of your tools, allowing them to function effectively for years to come. Following a few key practices can help you achieve this goal.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep your tools free from dust and debris by cleaning them after each use. This prevents buildup that can hinder performance. |

| Lubrication | Apply appropriate lubricants to moving parts regularly. This reduces friction and wear, promoting smoother operation. |

| Inspection | Conduct routine inspections to identify any signs of wear or damage. Addressing issues early can prevent more significant problems later. |

| Proper Storage | Store tools in a dry, clean environment to prevent rust and corrosion. Use protective cases or covers when possible. |

| Follow Manufacturer Guidelines | Adhere to recommended maintenance schedules and procedures outlined by the manufacturer for best results. |

Implementing these strategies will help maintain the reliability and efficiency of your equipment, ensuring that it serves you well for an extended period. Regular attention to detail can make a significant difference in performance and longevity.

Where to Find Replacement Parts

When your tool requires new components for optimal performance, locating high-quality replacements is essential. Numerous resources can help you secure the necessary items to ensure your equipment runs smoothly again.

Online Retailers

Many online platforms specialize in selling tool accessories. Websites dedicated to hardware often offer a wide range of options. Be sure to check user reviews and product ratings for the best choices.

Local Hardware Stores

Your nearby hardware store can be a valuable resource for finding the right items. Knowledgeable staff can assist you in identifying what you need, and you may even find compatible options readily available.

Understanding Tool Specifications

Comprehending the characteristics of tools is essential for ensuring optimal performance and longevity. Specifications provide valuable insights into a tool’s capabilities and help users make informed decisions.

Key factors to consider include:

- Power Source: Determines the tool’s operational method, whether electric, pneumatic, or battery-powered.

- Weight: Influences portability and ease of use, especially for prolonged tasks.

- Capacity: Refers to the maximum load or material thickness the tool can handle effectively.

- Speed Settings: Offers versatility for different tasks, enabling users to adjust according to their needs.

- Safety Features: Essential for preventing accidents and ensuring user protection during operation.

By delving into these specifications, users can achieve the ultimate efficiency and effectiveness in their projects.

Assembly and Disassembly Guide

This section provides a comprehensive approach to the process of putting together and taking apart your pneumatic fastening tool. Proper handling ensures optimal performance and longevity, making it essential to follow the steps outlined for each phase.

Disassembly Steps

To begin, ensure the tool is unplugged or disconnected from the air source. Follow these steps to safely disassemble:

| Step | Description |

|---|---|

| 1 | Remove the magazine cover and empty any fasteners. |

| 2 | Detach the front nose by unscrewing the retaining screws. |

| 3 | Carefully extract the driver blade from the cylinder. |

Assembly Steps

After servicing, reassembly is straightforward. Follow these instructions:

| Step | Description |

|---|---|

| 1 | Insert the driver blade back into the cylinder securely. |

| 2 | Reattach the front nose and tighten the screws firmly. |

| 3 | Replace the magazine cover and ensure it locks in place. |

Safety Precautions When Repairing

When undertaking repairs on any mechanical device, prioritizing safety is essential. Ensuring that proper measures are in place can prevent accidents and injuries, making the repair process smoother and more efficient. Familiarity with the tools and equipment involved is crucial, as is understanding the potential hazards associated with them.

Before beginning any repair work, always disconnect the power source to eliminate the risk of accidental activation. Use personal protective equipment, such as gloves and safety goggles, to safeguard against injuries from sharp components or debris. Additionally, working in a well-ventilated area is important to avoid inhaling harmful fumes or dust particles.

Keep the workspace organized to reduce the chances of tripping or losing small parts. Be aware of the specific characteristics of the device you are handling, as different models may have unique safety concerns. Following the manufacturer’s instructions and using the appropriate tools will help ensure a safe and successful repair.

Upgrades and Modifications Available

Enhancing performance and functionality can significantly improve the efficiency of your tool. Various upgrades and modifications are available to elevate your experience, catering to both casual users and professionals seeking optimal results.

Performance Enhancements

Several enhancements can be applied to boost speed and precision. Options include upgraded motors, improved feeding mechanisms, and advanced safety features that ensure a more reliable operation.

Custom Accessories

Customizable accessories can also be added, providing versatility for different tasks. These may include specialized attachments, ergonomic grips, and storage solutions that facilitate easy transport and organization.

| Upgrade/Modification | Description | Benefits |

|---|---|---|

| Enhanced Motor | Higher torque and speed ratings | Improved efficiency and faster work completion |

| Safety Features | Advanced guards and automatic shut-off | Increased user safety during operation |

| Custom Attachments | Specialized tools for specific tasks | Greater versatility and functionality |

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and functionality of specific tools. Here, you’ll find answers to typical concerns that users may encounter, helping to enhance your understanding and usage experience.

What should I do if my tool is not operating correctly?

If you encounter issues with performance, first check for any visible obstructions or damage. Ensure all components are properly assembled and consult the user manual for troubleshooting tips.

How can I find replacement components for my device?

Replacement items can typically be sourced from authorized dealers or online marketplaces. Make sure to verify compatibility with your specific model before purchasing.

What maintenance steps should I take to prolong the life of my equipment?

Regular cleaning, lubrication, and inspection of all moving parts are essential. Following the manufacturer’s maintenance guidelines will significantly extend the lifespan of your device.

Is there a warranty for my tool?

Most manufacturers offer a warranty covering defects and certain malfunctions. Review the warranty information provided at the time of purchase to understand the terms and conditions.

Where can I find detailed information on the assembly of my tool?

User manuals are usually the best resource for assembly instructions. You can often download these from the manufacturer’s website for the most accurate guidance.