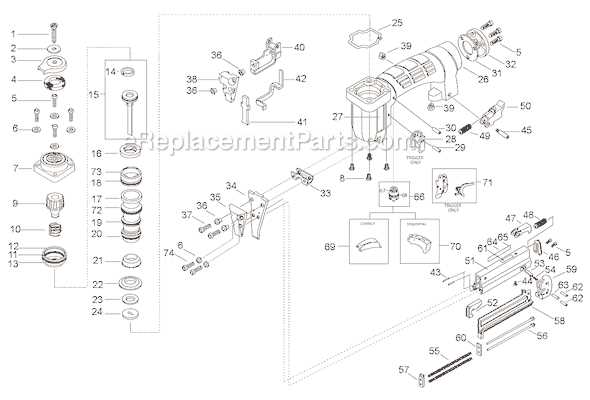

Bostitch T31 Parts Diagram Guide

In the realm of power equipment, a comprehensive grasp of individual components is essential for maintenance and effective usage. Familiarity with the intricate assembly of any device can greatly enhance its longevity and performance. This knowledge not only aids in troubleshooting but also empowers users to carry out repairs with confidence.

Delving into the specifics of a particular model reveals a wealth of information about how each element interacts within the system. By examining these essential elements, one can identify potential issues before they escalate and ensure that the machinery operates at peak efficiency. Such an understanding fosters a more profound appreciation for the engineering behind the equipment.

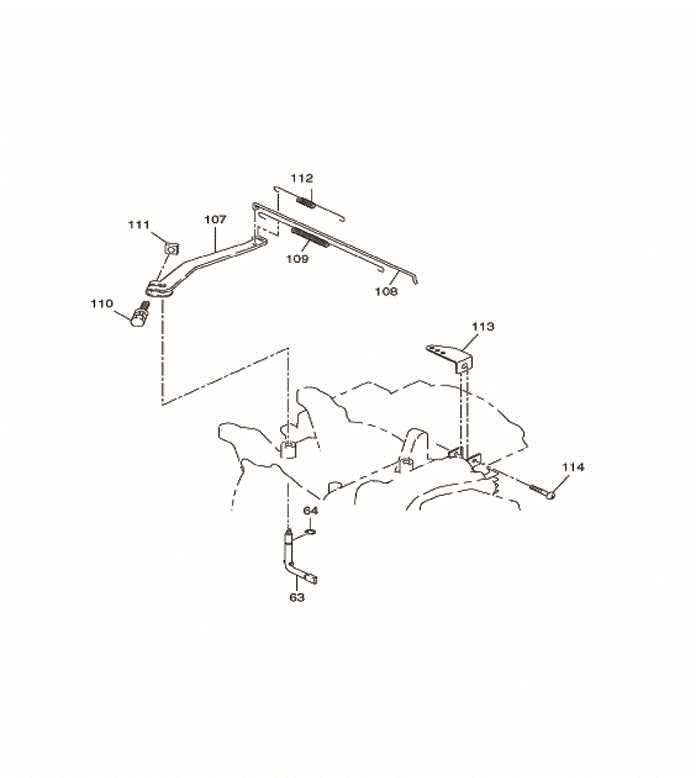

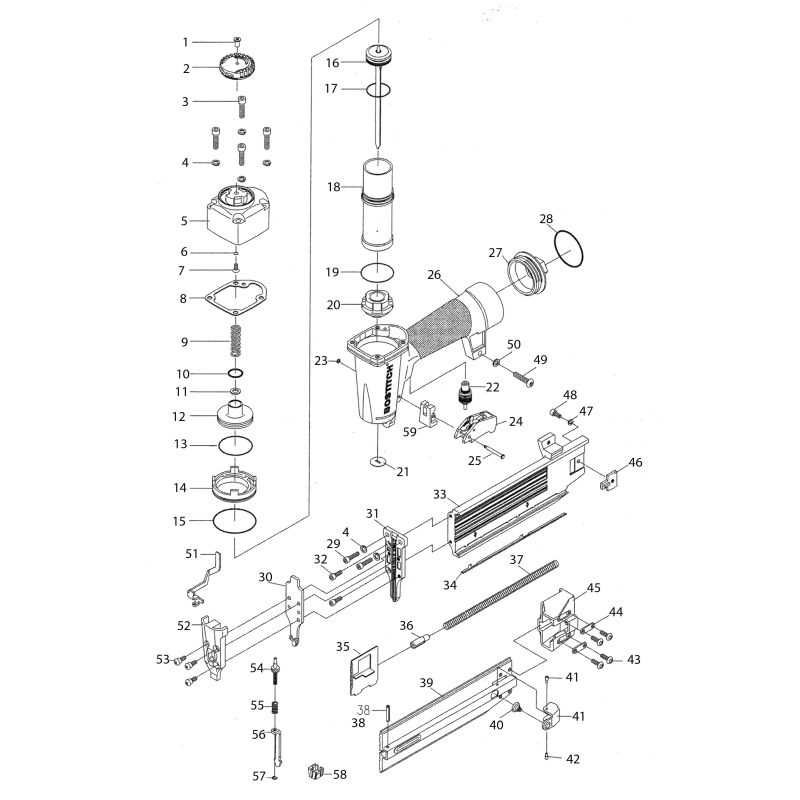

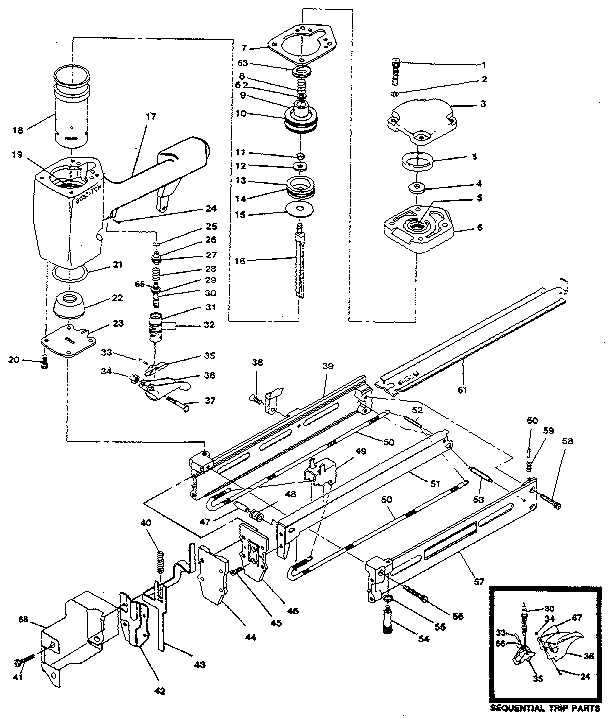

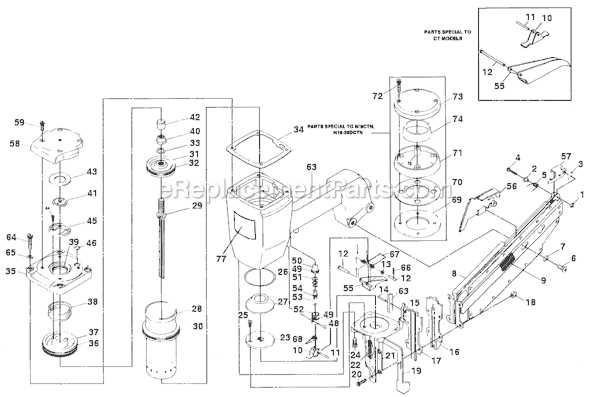

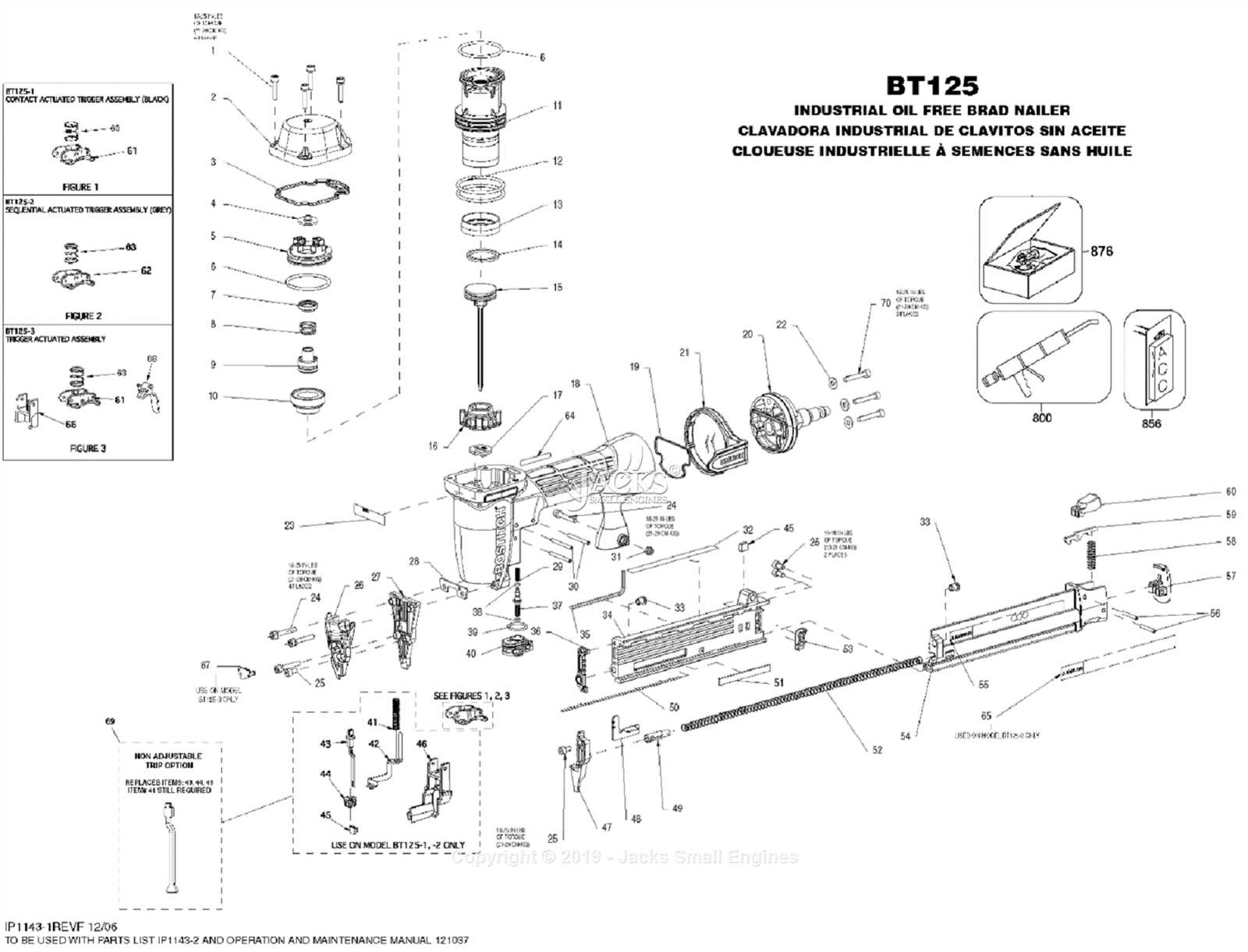

Additionally, having access to a visual representation of the assembly allows for easier identification of parts and their functions. This insight is invaluable for both novice users and seasoned professionals who seek to optimize their workflow and minimize downtime. As we explore the components in detail, a clearer picture will emerge, guiding users towards more effective maintenance practices.

Understanding Bostitch T31 Components

Grasping the various elements of a specific tool is essential for effective operation and maintenance. Each component plays a crucial role in ensuring optimal performance, contributing to the overall functionality. Familiarity with these parts not only aids in troubleshooting but also enhances the user’s ability to maximize the tool’s potential.

Key Elements Overview

The assembly consists of numerous integral pieces, each designed to perform specific tasks. Recognizing these components helps in understanding their interaction and importance within the system. Below is a brief overview of some vital elements.

| Component Name | Function |

|---|---|

| Trigger | Initiates the action of the device when pressed. |

| Pneumatic Cylinder | Generates the necessary force to drive the fasteners. |

| Magazine | Holds and feeds the fasteners into the tool. |

| Exhaust Port | Releases air after the tool has completed its cycle. |

Maintenance Tips

Regular upkeep of these components ensures longevity and reliability. Inspecting and cleaning the parts, as well as replacing worn-out pieces, can significantly enhance performance and safety. Understanding each part’s role makes it easier to identify issues and perform effective maintenance.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair processes. They provide clarity and organization, enabling users to identify each piece and understand its function within the larger assembly. These illustrations simplify complex systems, making it easier for technicians and hobbyists alike to navigate through repairs or upgrades.

Here are some key benefits of utilizing such visual guides:

- Enhanced Understanding: Detailed visuals allow users to grasp the relationships between different elements, ensuring a comprehensive view of the system.

- Efficient Troubleshooting: Identifying faulty components becomes straightforward, reducing downtime and improving repair speed.

- Streamlined Reassembly: Clear visuals assist in reassembling systems accurately, minimizing the risk of errors.

- Parts Identification: Users can easily find specific components when seeking replacements, preventing confusion.

- Educational Value: Beginners benefit from visual aids that teach them about the structure and functionality of devices.

In summary, visual aids are indispensable tools in any repair or maintenance endeavor, promoting efficiency, accuracy, and understanding throughout the process.

Common Issues with Bostitch T31

This section explores typical challenges encountered with a specific model of pneumatic fastening tool. Users often report various operational difficulties that can affect performance and efficiency.

Frequent Problems

Several common issues can arise, impacting the overall functionality. Understanding these can help in troubleshooting and maintenance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Jamming | Incorrect nail size, debris in the feed | Clean the feed mechanism, check nail compatibility |

| Pneumatic leaks | Worn seals, loose connections | Inspect seals and tighten fittings |

| Inconsistent firing | Low air pressure, clogged nozzle | Check air pressure, clean the nozzle |

Maintenance Tips

Regular maintenance can prevent many issues from occurring. Periodic inspections and timely replacements of worn components are crucial for keeping the tool in optimal condition.

How to Identify Parts Quickly

Recognizing components efficiently is crucial for maintaining and repairing equipment. By familiarizing yourself with the various elements and their functions, you can streamline the process of identifying what you need. A clear understanding of the assembly will save time and enhance productivity.

1. Use Reference Guides: Keep handy manuals or online resources that provide clear illustrations and descriptions. These tools can help you match what you see with the necessary item.

2. Organize by Function: Group components based on their roles within the system. Categorizing items such as fasteners, drivers, and housing elements allows for quicker identification during repairs.

3. Label Storage: When storing components, use labels to indicate their names and functions. A well-organized workspace minimizes confusion and speeds up the identification process.

4. Familiarity through Practice: Regularly working with the equipment will increase your familiarity with the individual components. Over time, you will instinctively know where to look for specific items.

5. Utilize Online Communities: Engaging with forums and user groups can provide insights and tips from experienced individuals. Sharing knowledge helps in quickly pinpointing what you need.

By implementing these strategies, you can enhance your ability to identify various components swiftly and efficiently, leading to more effective maintenance and repairs.

Maintenance Tips for Bostitch Tools

Proper upkeep of your tools is essential for ensuring their longevity and optimal performance. Regular maintenance can prevent breakdowns, enhance efficiency, and save on repair costs. This guide provides essential practices that will help keep your equipment in peak condition.

| Task | Frequency | Details |

|---|---|---|

| Clean Tool Exteriors | After Each Use | Wipe down surfaces to remove dust and debris that can cause wear. |

| Lubricate Moving Parts | Monthly | Apply appropriate lubricants to hinges, springs, and other moving components. |

| Inspect for Wear | Every Few Uses | Check for signs of damage or excessive wear on parts like blades and belts. |

| Change Filters | Quarterly | Replace or clean air and dust filters to maintain airflow and efficiency. |

| Store Properly | Always | Keep tools in a dry, safe place to prevent rust and accidental damage. |

By following these maintenance tips, you can extend the life of your equipment and ensure it operates smoothly. Regular care not only enhances performance but also enhances safety during use.

Where to Find Replacement Parts

When equipment requires maintenance or a component needs to be exchanged, locating the right resources can make all the difference. Understanding where to search for these essential elements ensures that you can restore functionality quickly and efficiently. Numerous avenues exist for obtaining the necessary items, ranging from authorized vendors to online marketplaces.

Authorized Retailers

Official dealers are often the best place to start when seeking out specific components. They provide authentic items and reliable service. Here’s a brief overview of what to expect:

| Vendor Type | Benefits |

|---|---|

| Official Dealers | Genuine components, warranty support |

| Local Hardware Stores | Immediate availability, local support |

Online Resources

The internet opens up a vast array of options for sourcing necessary items. Websites dedicated to tools and accessories often have extensive catalogs. Consider these platforms:

| Website Type | Advantages |

|---|---|

| E-commerce Platforms | Wide selection, competitive pricing |

| Specialized Forums | Community recommendations, used items |

Diagram Interpretation for Beginners

Understanding visual representations of machinery can be a challenging yet rewarding task for newcomers. These illustrations serve as valuable tools that communicate the layout and functionality of various components. Mastering the ability to read these images can enhance your mechanical skills and improve your troubleshooting capabilities.

To effectively navigate these illustrations, consider the following key aspects:

- Familiarization with Symbols: Different shapes and lines represent specific elements and their relationships. Take time to learn what each symbol signifies.

- Identifying Sections: Most representations are divided into sections, each detailing a specific area or function. Focus on one section at a time for easier understanding.

- Reading Annotations: Pay attention to notes and labels that accompany the visual. These often provide essential information about dimensions and material types.

For beginners, it’s beneficial to start with simple images and progressively work towards more complex ones. Here’s a suggested approach:

- Begin with basic illustrations to grasp fundamental concepts.

- Gradually introduce yourself to more detailed representations.

- Practice interpreting different styles to build confidence.

By honing your skills in understanding these visual guides, you’ll find yourself better equipped to engage with machinery and perform maintenance tasks efficiently.

Using Diagrams for Troubleshooting

Visual representations can significantly enhance the troubleshooting process, providing a clear overview of complex systems. By utilizing these illustrations, users can identify components and their interrelationships more effectively, leading to quicker diagnosis and resolution of issues. This method serves as an essential tool for both novice and experienced technicians, ensuring that each part’s role is understood within the broader context of the mechanism.

When encountering difficulties with a device, referring to an illustration can guide you through a systematic approach to identifying faults. Here’s how these visual aids can streamline troubleshooting:

| Benefit | Description |

|---|---|

| Clarity | Provides a visual layout of components, making it easier to spot problems. |

| Efficiency | Reduces the time spent figuring out which part needs attention. |

| Accessibility | Makes complex systems more approachable for users of all skill levels. |

| Guidance | Offers step-by-step support, facilitating methodical inspections. |

Incorporating these visuals into the diagnostic process not only simplifies understanding but also promotes effective repairs, ultimately enhancing the longevity of equipment and ensuring optimal performance.

Comparing T31 to Other Models

When evaluating various tools in the same category, it’s essential to understand their unique features and specifications. Each model brings something different to the table, catering to diverse needs and preferences of users. This comparison aims to highlight the distinctions and similarities among different options available, allowing potential buyers to make informed decisions.

Key Features Overview

| Model | Weight | Power Source | Capacity |

|---|---|---|---|

| Model A | 5 lbs | Electric | 50 nails |

| Model B | 6 lbs | Pneumatic | 75 nails |

| Model C | 4.5 lbs | Battery | 30 nails |

| Model D | 5.5 lbs | Electric | 60 nails |

Performance and Usability

Different models exhibit varying performance levels, influenced by their design and intended use. While some tools prioritize lightweight construction for easy handling, others may focus on power and capacity for more demanding tasks. Users often need to balance these factors based on the specific applications they require. Understanding these nuances helps in selecting the right tool for any project.

Upgrading Parts for Better Performance

Enhancing the components of your equipment can lead to significant improvements in functionality and efficiency. By selecting high-quality alternatives or advanced versions of existing elements, you can optimize performance, extend longevity, and increase overall satisfaction during use. This approach not only improves output but also ensures that the machinery operates smoothly under various conditions.

When considering upgrades, it’s essential to analyze the specific components that have the most impact on performance. Below is a table that outlines common upgrades and their benefits:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Motor | High-efficiency motor | Increased torque and reduced energy consumption |

| Fasteners | Premium quality fasteners | Enhanced durability and resistance to wear |

| Cylinders | Heavy-duty cylinders | Improved pressure handling and reduced maintenance needs |

| Hoses | Reinforced hoses | Greater flexibility and resistance to cracking |

Investing in quality enhancements will lead to a more reliable and efficient setup, ultimately contributing to better outcomes in your projects. Always ensure that the selected upgrades are compatible with your existing system to maximize their effectiveness.