Comprehensive Guide to Bush Hog SQ600 Parts Diagram

Understanding the intricate assembly of your mower is vital for maintaining its performance and longevity. Every component plays a crucial role in ensuring that the machine operates smoothly and efficiently. By familiarizing yourself with the various elements involved, you can enhance your mowing experience and tackle challenges with confidence.

In this section, we will delve into the individual elements that contribute to the overall functionality of your equipment. Each piece is designed with a specific purpose, and recognizing these can empower you to make informed decisions about repairs and upgrades.

Whether you are a seasoned operator or a newcomer, having access to a comprehensive breakdown of these components is the ultimate resource. It allows you to not only troubleshoot issues but also to appreciate the engineering that goes into crafting a reliable mowing machine.

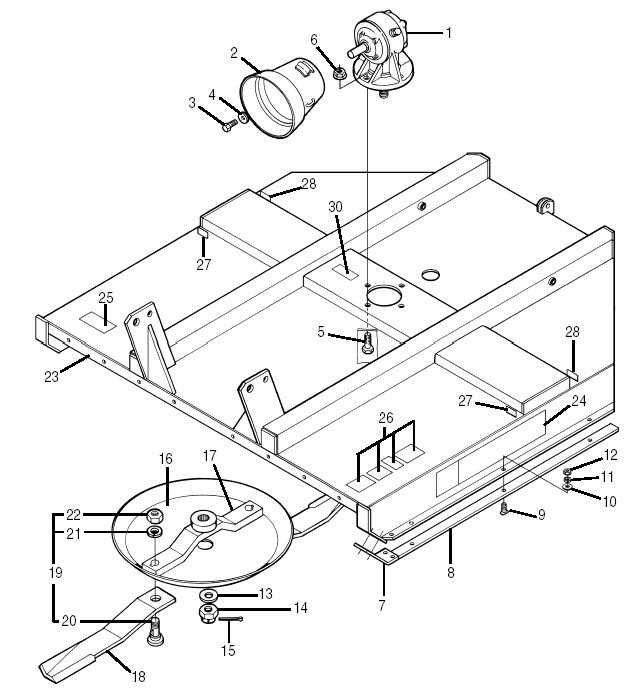

Understanding Bush Hog SQ600 Components

This section explores the essential elements of a specific mowing implement, emphasizing their functions and interactions. Each component plays a critical role in ensuring efficiency and performance in land management tasks.

- Frame: The sturdy structure that supports all other elements.

- Cutter Blades: Sharp tools designed for effective cutting of grass and vegetation.

- Gearbox: Converts engine power into rotational energy for the blades.

- Hitch: Connects the implement to the towing vehicle, ensuring stability.

- Wheels: Provide mobility and support during operation.

Understanding these components allows operators to maintain and troubleshoot the equipment effectively, ensuring optimal performance over time.

Key Features of the SQ600 Model

The SQ600 model stands out for its innovative design and robust functionality, catering to a variety of agricultural and landscaping needs. Its engineering emphasizes durability and efficiency, making it a reliable choice for professionals and enthusiasts alike.

Robust Construction

This model is built with high-quality materials, ensuring long-lasting performance even in challenging conditions. Its sturdy frame provides stability and resilience, essential for heavy-duty tasks.

Versatile Applications

The versatility of this equipment allows it to handle a wide range of tasks, from clearing dense vegetation to maintaining open fields. Its adaptability makes it an ultimate tool for diverse operational requirements.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of these elements serve as essential tools for both professionals and enthusiasts, enhancing their ability to identify and resolve issues efficiently.

Clarity is one of the primary benefits of these visual aids. They provide a straightforward way to view complex assemblies, allowing users to see how individual components interact within the system. This clarity helps in diagnosing problems and planning repairs, minimizing downtime.

Organization also plays a significant role. By breaking down a machine into its respective elements, these illustrations allow for easy reference and retrieval of information. This systematic approach reduces confusion and ensures that every necessary part is accounted for during maintenance procedures.

Moreover, such visual tools facilitate communication among team members. When everyone has access to the same reference material, discussions about repairs and upgrades become more productive. This shared understanding can lead to quicker resolutions and a more cohesive work environment.

In addition, familiarity with these representations can enhance training for new technicians. By learning to interpret these visuals, they can gain a deeper understanding of machinery, equipping them with the knowledge needed to perform their roles confidently.

Common Issues with SQ600 Parts

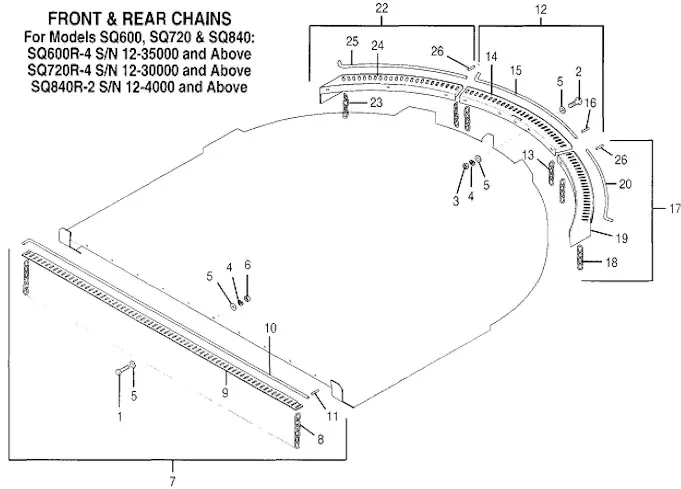

When dealing with agricultural machinery, understanding potential challenges is crucial for maintaining efficiency. Components can often experience wear and tear, leading to performance issues that may affect overall functionality. Identifying these common problems can help in timely repairs and replacements.

One frequent concern is the deterioration of mechanical elements, which can result in reduced effectiveness. Regular inspections can reveal signs of damage, allowing for proactive maintenance. Additionally, improper alignment of the machinery may cause undue stress on specific components, leading to premature failure.

Another issue relates to fluid leaks, which can compromise the system’s integrity and efficiency. Ensuring proper seals and fittings are in place is vital to prevent these leaks. Lastly, electrical malfunctions can hinder operation, highlighting the importance of regular electrical system checks to ensure reliability.

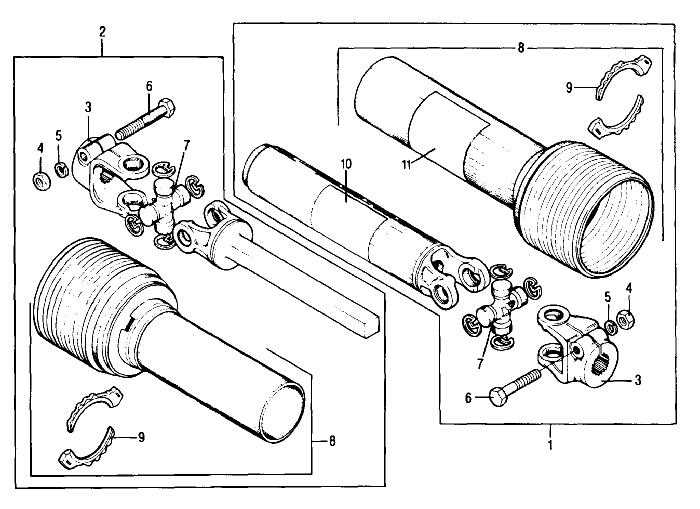

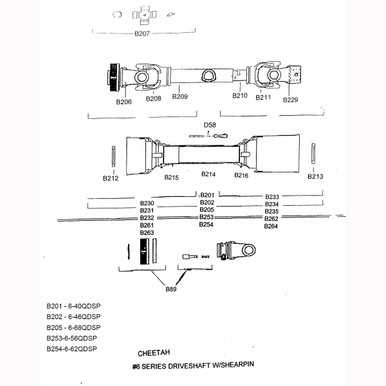

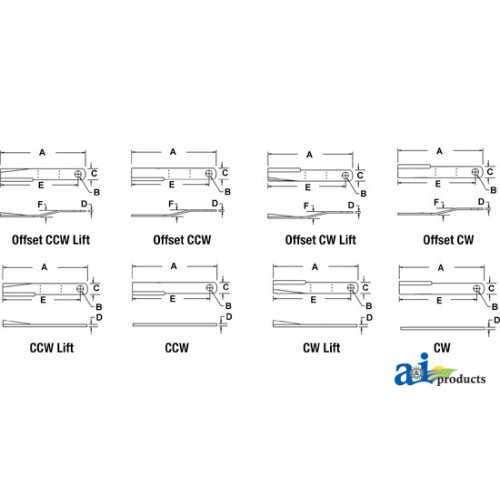

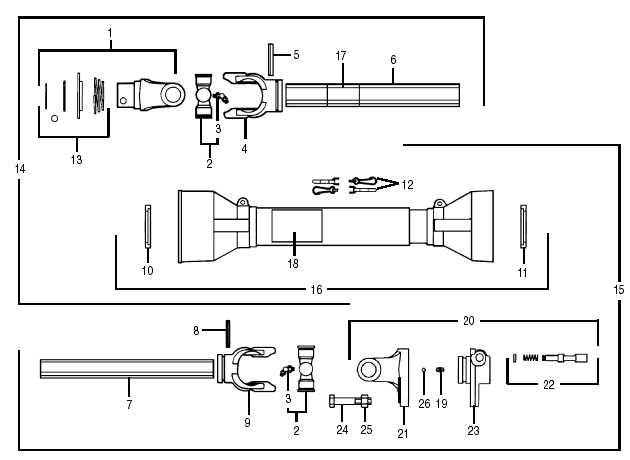

How to Read Parts Diagrams

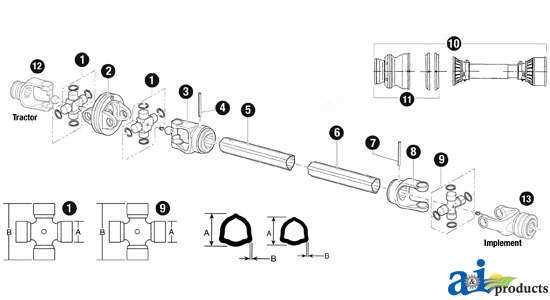

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as guides, helping users identify various elements and their interconnections within a system. Familiarizing yourself with the layout and symbols used in these visuals can significantly enhance your ability to troubleshoot and order necessary replacements.

Start by identifying the key sections, which typically include labels and reference numbers corresponding to each item. This information often includes descriptions that clarify the function of each component. Pay attention to any color coding or grouping, as these can indicate related parts or assemblies.

Next, note the scale of the illustration, which can provide insights into the size and arrangement of the elements. Understanding the orientation is equally important, as it can affect how components fit together in the physical assembly. By meticulously analyzing these aspects, you can build a comprehensive understanding of the system’s architecture.

Finally, always keep a list of frequently needed items based on your observations. This practice will streamline your repair process and ensure you have the necessary tools and materials at hand for future tasks.

Essential Tools for Maintenance

Regular upkeep of machinery is crucial for optimal performance and longevity. Having the right instruments at hand not only simplifies tasks but also ensures efficiency and safety during maintenance procedures.

Basic Toolkit

A well-rounded toolkit is foundational for any maintenance job. It should include various hand tools designed to handle a wide range of tasks. Here are some must-have items:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening bolts and nuts. |

| Screwdrivers | Essential for assembling and disassembling components. |

| Pliers | Useful for gripping, twisting, and cutting. |

| Socket Set | Provides versatility for various fastener sizes. |

Specialized Equipment

In addition to general tools, some specialized equipment can enhance maintenance effectiveness. Investing in these items can save time and reduce wear on machinery.

| Equipment | Function |

|---|---|

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Grease Gun | Facilitates proper lubrication of moving parts. |

| Multimeter | Tests electrical systems for functionality. |

| Oil Filter Wrench | Makes changing filters more efficient. |

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward task if approached correctly. Understanding the right resources and tools available to you can significantly streamline the process. By employing effective strategies, you can ensure that your machinery remains operational without unnecessary delays.

Start by utilizing online resources that specialize in machinery components. Websites often provide comprehensive catalogs and detailed specifications, making it easier to identify what you need. Forums and community groups can also be invaluable, as they offer insights and recommendations from other users who have faced similar challenges.

Consider contacting local dealers or service centers directly. They can provide personalized assistance and may have the items you require in stock. Additionally, establishing a relationship with these professionals can lead to future benefits, such as exclusive deals or timely updates on new inventory.

Lastly, don’t overlook the importance of keeping records of your equipment’s specifications. Having a detailed history can simplify future searches and ensure that you obtain the correct items promptly.

Preventive Maintenance Tips for Longevity

Maintaining equipment in optimal condition is essential for extending its lifespan and ensuring reliable performance. Regular attention to specific components can significantly reduce the risk of unexpected failures and enhance overall efficiency.

1. Regular Inspections: Schedule consistent check-ups to identify wear and tear before it escalates into major issues. Look for signs of damage, corrosion, or loose connections.

2. Cleanliness: Keep all machinery free from dirt and debris. Accumulation can lead to overheating and other operational problems. Regular cleaning can improve performance.

3. Lubrication: Ensure that moving parts are properly lubricated to minimize friction. Use the recommended lubricants and apply them at intervals specified by the manufacturer.

4. Component Replacement: Replace worn or damaged parts promptly. Utilizing quality components will enhance durability and reduce downtime.

5. Operator Training: Ensure that operators are well-trained in the correct use and maintenance of equipment. Proper handling can prevent unnecessary strain and prolong functionality.

Comparing SQ600 with Other Models

This section explores the distinctions between the SQ600 and alternative machinery options within its category. By evaluating key features, performance metrics, and usability, users can make informed choices tailored to their specific needs.

Key Features Comparison

- Engine Power: Assessing horsepower variations can highlight efficiency differences.

- Cutting Width: Different models may offer varying widths, affecting coverage and time efficiency.

- Weight and Stability: Heavier models may provide better stability on uneven terrain.

Performance Metrics

- Fuel Efficiency: Analyzing how each model performs in terms of fuel consumption.

- Maintenance Requirements: Some machines may demand more frequent upkeep, impacting overall cost.

- Versatility: Evaluating how well each model adapts to diverse tasks and environments.

By closely examining these aspects, potential buyers can identify which model aligns best with their operational requirements and preferences.

Upgrades and Customizations Available

Enhancing the performance and versatility of your equipment can significantly improve productivity and user experience. Various options are available that cater to specific needs, whether for increased efficiency, better maneuverability, or durability under challenging conditions.

Performance Enhancements

Investing in advanced components can lead to remarkable performance boosts. Upgrading the cutting blades to high-grade materials or adding reinforced features can ensure longevity and superior results. Custom engine modifications also allow for enhanced power, making the equipment more capable in demanding tasks.

Functional Additions

Incorporating additional features can further tailor the machine to your requirements. Options like adjustable hitches, enhanced wheel systems, or specialized attachments provide greater flexibility. These modifications enable users to adapt quickly to varying job demands and environmental conditions.

Resources for Further Learning

Expanding your knowledge in the field of agricultural machinery can significantly enhance your skills and understanding. A variety of materials, including manuals, online forums, and instructional videos, are available to help you gain deeper insights into the maintenance and operation of equipment. These resources provide valuable information for both novice users and seasoned professionals looking to refine their expertise.

Consider exploring technical manuals that offer detailed guidance on equipment functionality and troubleshooting. Online communities can also serve as excellent platforms for sharing experiences and tips, allowing you to connect with fellow enthusiasts. Additionally, educational videos on popular platforms demonstrate practical techniques, making complex tasks more accessible and understandable.

By utilizing these resources, you can cultivate a well-rounded understanding of machinery, ensuring you are well-prepared to tackle any challenges that may arise in your work.