Understanding the Campbell Hausfeld Paint Sprayer Parts Diagram

When working with specialized machinery, grasping the configuration and individual elements is crucial for effective operation and maintenance. A comprehensive overview of these components not only aids in troubleshooting but also enhances overall performance. This section delves into the intricacies of how various parts interact, ensuring a seamless experience for users.

Each mechanism comprises distinct elements, each with its specific function and contribution to the overall system. Recognizing the role of each part can empower users to make informed decisions during repairs or upgrades. This understanding transforms the approach to handling equipment, allowing for greater efficiency and longevity.

By exploring the relationships and layouts of these components, individuals can better appreciate the design and functionality of their tools. This insight paves the way for more proficient usage and an enhanced grasp of maintenance practices, ultimately leading to improved results in various applications.

Understanding Campbell Hausfeld Paint Sprayers

This section explores the intricacies of high-quality equipment designed for applying coatings. These tools enhance efficiency and precision, making them invaluable for both amateur and professional users. A solid understanding of their components and operation is essential for achieving optimal results in various projects.

Key Features and Benefits

These devices offer a range of features that cater to different applications. Users can select models based on factors such as power, type of finish desired, and ease of use. The versatility of these tools allows for seamless transitions between tasks, whether for home improvement or larger industrial applications. Durability and reliability are paramount, ensuring consistent performance over time.

Maintenance and Troubleshooting

Proper upkeep is crucial to extend the lifespan of the equipment. Regular cleaning and inspection of key components can prevent common issues and ensure that the device operates at peak performance. Understanding how to troubleshoot minor problems will enhance user experience and reduce downtime, allowing for uninterrupted workflow.

Common Components of Paint Sprayers

Understanding the essential elements of spraying equipment is crucial for effective use and maintenance. Each component plays a significant role in the overall functionality, ensuring that the application process is efficient and results in a smooth finish. Familiarity with these elements helps users troubleshoot issues and enhance their spraying experience.

Key Elements

One of the primary components is the motor, which powers the device and influences its performance. Another vital part is the nozzle, responsible for controlling the spray pattern and droplet size, impacting the finish quality. Additionally, the pressure regulator ensures optimal fluid delivery, while the hose connects the various parts, allowing for seamless operation.

Maintenance Considerations

Regular inspection of these elements is essential for longevity. Cleaning the nozzle prevents clogs, while checking the hose for leaks ensures consistent operation. Understanding these core components aids in identifying wear and tear, allowing for timely replacements and maintaining high efficiency during use.

How to Identify Sprayer Parts

Understanding the components of your spraying device is crucial for effective maintenance and operation. Recognizing each element will not only enhance your performance but also prolong the lifespan of your equipment. This guide will help you identify key components and their functions.

Key Components Overview

- Housing: The outer shell that encases the internal mechanisms.

- Motor: The driving force that powers the entire apparatus.

- Fluid Nozzle: The outlet where the liquid is expelled, influencing spray pattern and coverage.

- Trigger: The control mechanism that regulates fluid flow.

- Hose: The conduit that transports material from the reservoir to the nozzle.

- Filter: Ensures that only clean fluid reaches the nozzle, preventing clogs.

Steps to Identify Each Component

- Begin by examining the outer shell for any labels or diagrams indicating component locations.

- Check the user manual for detailed descriptions and images of each element.

- Inspect the fluid nozzle and trigger for different settings or attachments that may alter performance.

- Look at the hose for any signs of wear or damage, which may affect fluid delivery.

- Test the motor by observing its operation when activated to ensure it functions properly.

By familiarizing yourself with these components, you will be better equipped to troubleshoot issues and perform maintenance efficiently.

Importance of Regular Maintenance

Neglecting maintenance can lead to various issues, including:

- Decreased efficiency

- Increased wear and tear

- Frequent malfunctions

- Lower quality of output

Implementing a routine maintenance schedule can provide numerous benefits, such as:

- Enhanced Performance: Regular checks ensure that all components function smoothly, leading to improved results.

- Cost Savings: Proactive maintenance can reduce the need for expensive repairs and replacements.

- Extended Lifespan: Keeping equipment in top shape contributes to its durability, allowing for longer usage periods.

- Safety Assurance: Well-maintained equipment is safer to operate, minimizing risks associated with failures.

To achieve these benefits, consider establishing a maintenance checklist that includes cleaning, lubricating, and inspecting essential components regularly. By prioritizing maintenance, users can ensure that their tools remain reliable and effective over time.

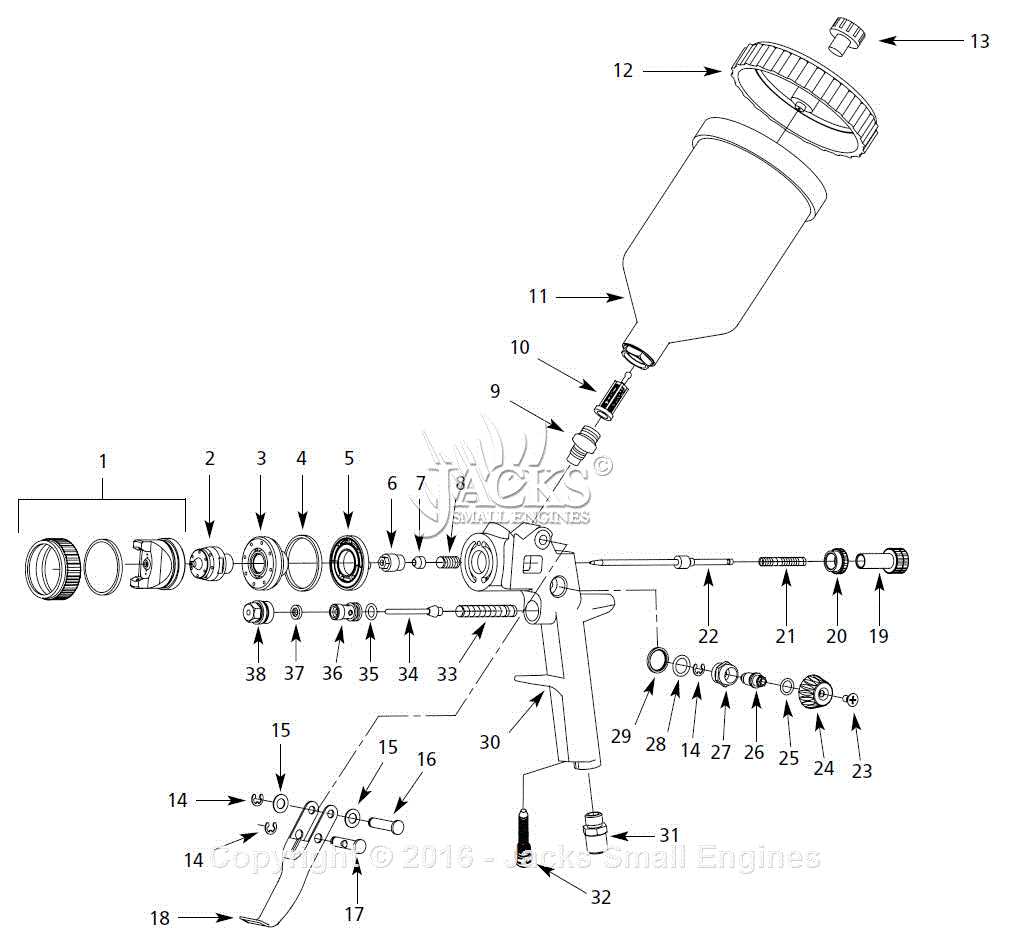

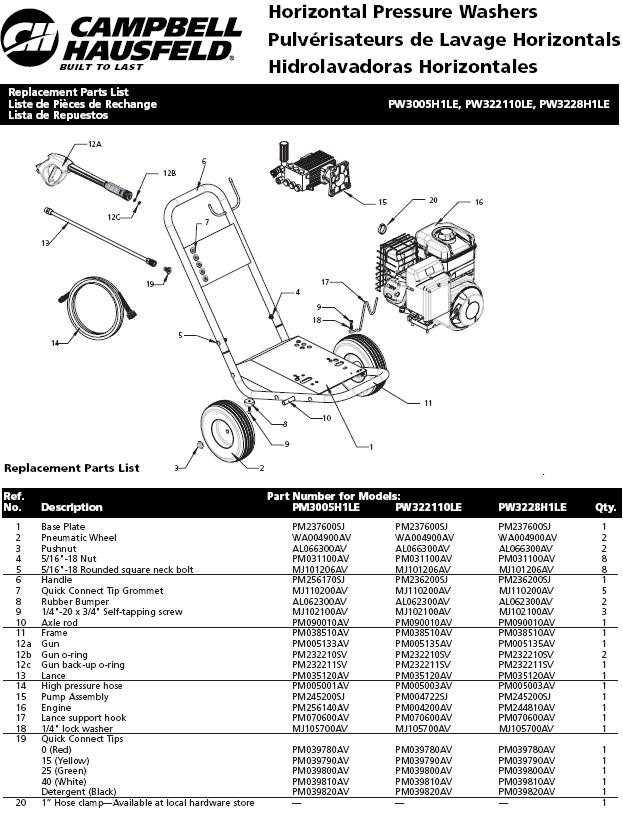

Visual Guide to Parts Diagram

This section provides a comprehensive overview of the components involved in the equipment, illustrating their relationships and functions. Understanding the layout and roles of each element can significantly enhance maintenance and troubleshooting efforts, enabling users to efficiently navigate the assembly.

Understanding the Components

Each section of the illustration highlights specific segments of the apparatus, allowing for easy identification of crucial elements. By familiarizing oneself with these components, users can ensure better performance and longevity of the tool.

Utilizing the Visual Reference

Referencing the visual guide when performing repairs or adjustments streamlines the process, making it easier to locate replacement pieces or assemble the equipment correctly. This resource serves as an invaluable tool for both beginners and seasoned users alike.

Choosing the Right Replacement Parts

Selecting appropriate components for your equipment is essential for maintaining optimal performance and longevity. With various options available, understanding which elements are crucial for your specific model can significantly impact your overall experience. This section will guide you through the considerations necessary for making informed decisions when it comes to replacements.

Understanding Compatibility

Before purchasing any component, ensure that it is compatible with your particular device. Check the specifications and model numbers carefully. Using incompatible elements can lead to subpar performance or even damage, resulting in costly repairs. Always refer to the manufacturer’s guidelines to verify compatibility.

Quality Over Price

While it may be tempting to opt for the most affordable options, prioritizing quality is vital. High-quality components not only enhance performance but also increase the lifespan of your machinery. Look for reputable brands and read reviews to ensure you are investing in durable and reliable parts. Remember, a small investment in quality now can save you significant expenses in the future.

Troubleshooting Common Sprayer Issues

When working with a spraying device, encountering problems can be frustrating. Understanding typical challenges and their solutions can enhance your experience and ensure a smooth operation. This section outlines common issues and practical steps to resolve them, promoting efficient usage and maintenance.

Common Problems and Solutions

- Inconsistent Flow: If the liquid is not flowing smoothly, consider the following:

- Check for clogs in the nozzle or hose.

- Ensure that the material is adequately mixed and not too thick.

- Verify that the pump is functioning correctly.

- Uneven Coating: An uneven application can lead to unsatisfactory results. Address this by:

- Adjusting the spray pattern settings.

- Maintaining a consistent distance from the surface being coated.

- Inspecting the condition of the nozzle.

- Leaking Components: Leaks can hinder performance. To tackle leaks:

- Examine all connections and fittings for tightness.

- Look for wear or damage in seals and gaskets.

- Replace any faulty parts as needed.

lessCopy code

Preventive Measures

To avoid issues in the future, consider these preventive tips:

- Regularly clean the equipment after use.

- Inspect components periodically for wear and tear.

- Follow manufacturer recommendations for maintenance schedules.

By addressing common issues and implementing preventive strategies, users can enhance the performance and longevity of their spraying devices.

Benefits of Using Paint Sprayers

Utilizing modern application tools can significantly enhance the efficiency and quality of coating surfaces. These devices are designed to deliver a fine mist of material, providing an even finish that traditional methods may struggle to achieve. The advantages extend beyond just aesthetics, impacting speed, precision, and overall satisfaction in projects.

Efficiency and Time Savings

One of the primary benefits of these innovative tools is their ability to cover large areas quickly. Unlike manual techniques, which can be labor-intensive and time-consuming, these machines allow for swift application. This efficiency is especially beneficial for extensive projects, whether in residential or commercial settings.

Uniformity and Coverage

Another significant advantage is the ability to achieve a consistent and uniform layer of material. The fine mist produced ensures that even the most intricate details are adequately covered, minimizing the risk of streaks or unevenness. This level of precision is crucial for achieving a professional finish.

| Benefit | Description |

|---|---|

| Speed | Quickly applies coatings, reducing overall project time. |

| Consistency | Provides an even application, enhancing the quality of the finish. |

| Versatility | Suitable for various materials, including stains and sealants. |

| Reduced Waste | Minimizes overspray, leading to less product waste. |

Comparing Different Sprayer Models

When selecting a model for your coating needs, it’s essential to understand the various types available. Each version comes with distinct features and functionalities, catering to different projects and user preferences.

Here are some key factors to consider when comparing models:

- Power Source: Different models may operate on electricity, gas, or manual mechanisms. Consider the convenience and availability of power sources in your area.

- Spraying Mechanism: Look into whether the device uses a gravity feed, siphon feed, or pressure feed system. Each mechanism impacts the flow and quality of the application.

- Tank Capacity: The size of the tank influences how much material can be applied before needing a refill. Choose based on the scale of your projects.

- Weight and Portability: Heavier models may provide stability but could be cumbersome for larger tasks. Evaluate the balance between weight and ease of transport.

- Price Range: Determine your budget as prices can vary significantly based on brand, features, and capabilities. Look for options that offer the best value for your needs.

Additionally, understanding user feedback can help in making an informed decision. Reviews and ratings provide insights into reliability and performance across various environments.

Ultimately, the right choice will align with your specific requirements, ensuring efficiency and satisfaction in your application tasks.

Tips for First-Time Users

Getting started with a new tool can be both exciting and overwhelming. This section aims to provide essential advice for those embarking on their first experience with a spraying device. Proper preparation and understanding of the equipment will enhance your efficiency and ensure a satisfactory outcome.

Preparation Before Use

- Read the Manual: Familiarize yourself with the user guide to understand the specific features and functions.

- Gather Necessary Supplies: Ensure you have all required materials on hand, including appropriate liquids, safety gear, and cleaning tools.

- Choose the Right Environment: Work in a well-ventilated area to avoid inhaling fumes and to ensure optimal results.

Techniques for Effective Application

- Start with a Test Surface: Practice on a scrap piece or an inconspicuous area to refine your technique.

- Maintain a Consistent Distance: Keep a steady distance from the surface for even application.

- Use Smooth, Even Strokes: Move the tool in steady motions to prevent drips and uneven coverage.

Following these tips will help you achieve a successful start and build confidence in using your new equipment.

Where to Buy Replacement Parts

Finding high-quality components for your equipment is essential to ensure optimal performance and longevity. Whether you need specific items for maintenance or repairs, knowing where to look can save you time and money. Below are several reliable sources to consider when searching for these essential components.

- Manufacturer’s Website: The official site often offers a comprehensive selection of components tailored for your equipment model.

- Authorized Retailers: Visit stores that are recognized as official distributors. They typically carry genuine components and can provide expert advice.

- Online Marketplaces: Websites like Amazon, eBay, and others host various sellers offering both new and refurbished components. Always check seller ratings and reviews.

- Local Hardware Stores: Many local stores carry a range of components and can often order specific items for you if they are not in stock.

- Specialty Supply Shops: Look for businesses that focus specifically on tools and equipment, as they may have a more extensive selection.

- Repair Services: Some repair shops not only fix equipment but also sell components. They can also provide guidance on what you need.

By exploring these options, you can ensure you find the right components for your needs, helping to maintain the efficiency and functionality of your equipment.