Understanding the Parts of a Can Opener Diagram

Every household relies on specific instruments for daily culinary tasks. Among these tools, there exists one that facilitates the access to preserved food, making meal preparation more convenient. Understanding the inner workings of this essential device can enhance its functionality and longevity.

Within this article, we will explore the various components that come together to make this tool effective. Each element plays a crucial role in the overall operation, contributing to its efficiency and reliability. By examining these individual sections, users can gain insights into maintenance and troubleshooting.

Whether you are a culinary enthusiast or just someone looking to improve your kitchen skills, a deeper comprehension of this instrument can empower you. Let’s delve into the specific functionalities and relationships between each part, shedding light on how they collectively achieve the goal of simplifying access to your favorite foods.

Understanding Can Openers

In the realm of kitchen tools, certain devices are designed to assist in the safe and efficient access to sealed containers. These instruments play a crucial role in food preparation, transforming the way we enjoy a variety of preserved goods. A closer examination of these essential tools reveals their unique functions and components, which contribute to their effectiveness in everyday culinary tasks.

Components and Functionality

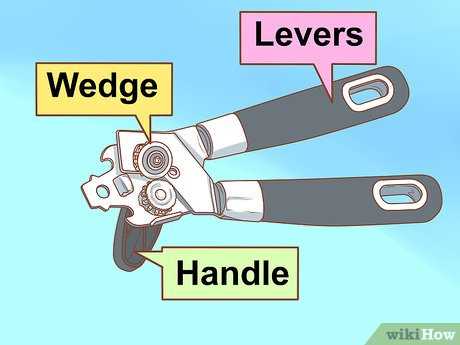

The fundamental structure of these kitchen instruments includes a gripping mechanism, a rotating blade, and a lever system. Each element is meticulously crafted to ensure ease of use and durability. The gripping mechanism securely attaches to the container, while the rotating blade effortlessly punctures and cuts through the metal, allowing for easy removal of the lid. Understanding how these components interact can enhance the user experience and ensure safe operation.

Types and Variations

A variety of designs exist to cater to different preferences and needs. Manual models require physical effort, offering simplicity and reliability, while electric versions provide convenience at the touch of a button. Each type has its own advantages, allowing individuals to choose based on their specific requirements and kitchen environments. Exploring these options can lead to a more efficient and enjoyable cooking experience.

Types of Can Openers

When it comes to opening sealed containers, various mechanisms and designs have been developed to simplify the task. Each type offers unique advantages, catering to different preferences and needs. Understanding these variations can help users choose the most suitable tool for their kitchen or outdoor activities.

Manual Devices

Manual tools are typically operated by hand, requiring physical effort to perform their function. These devices come in different styles, such as the classic wheel design, where a rotating blade punctures the lid, or the lever-type that uses a pressing action to create an opening. Portability and ease of use make them popular among those who value simplicity and traditional methods.

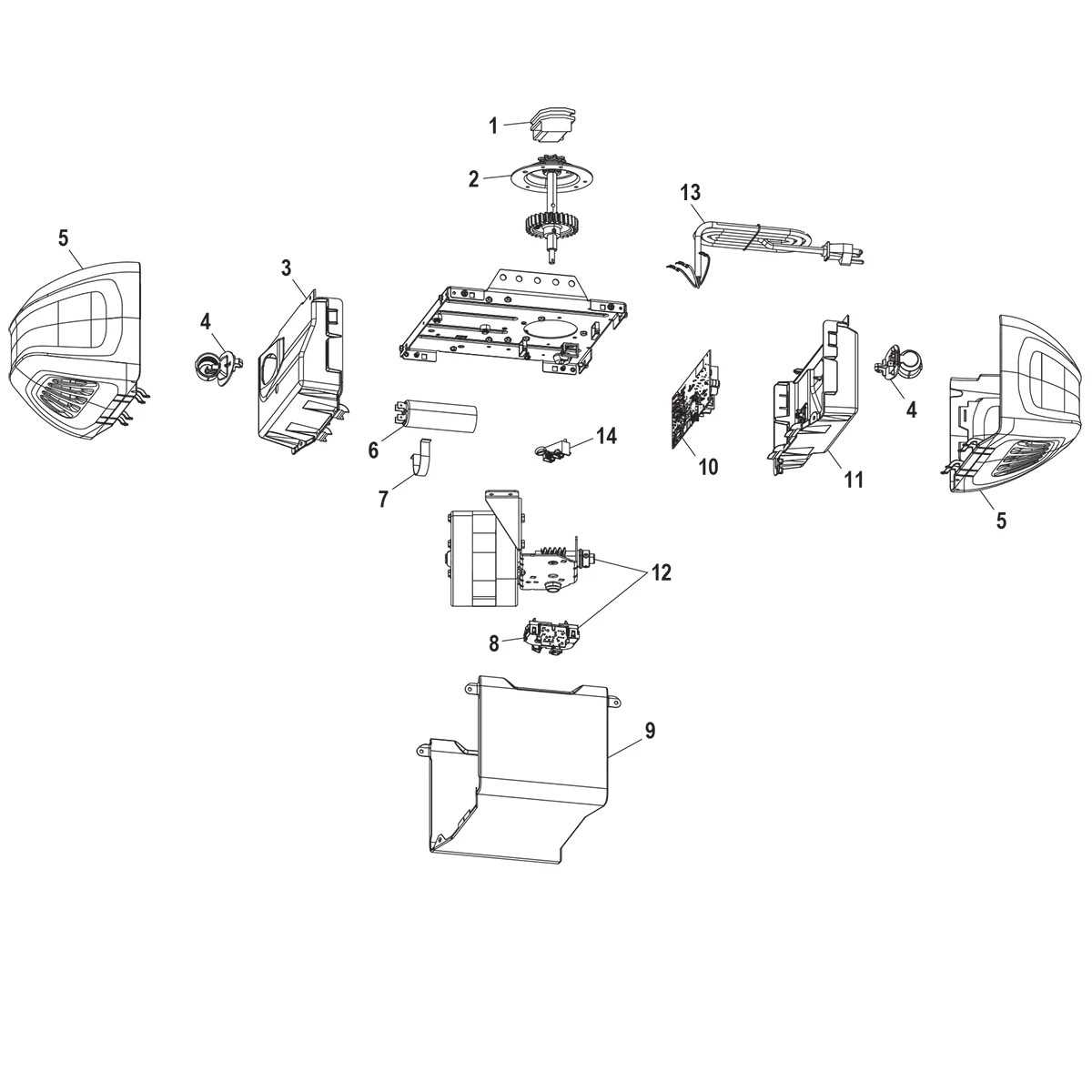

Electric Alternatives

For those seeking convenience, electric models provide an effortless solution. With the push of a button, these gadgets quickly and efficiently create an opening, making them ideal for individuals with limited hand strength or those looking to save time. Many electric variants also feature safety mechanisms to minimize risks during operation. Efficiency and comfort are key benefits that attract users to these modern innovations.

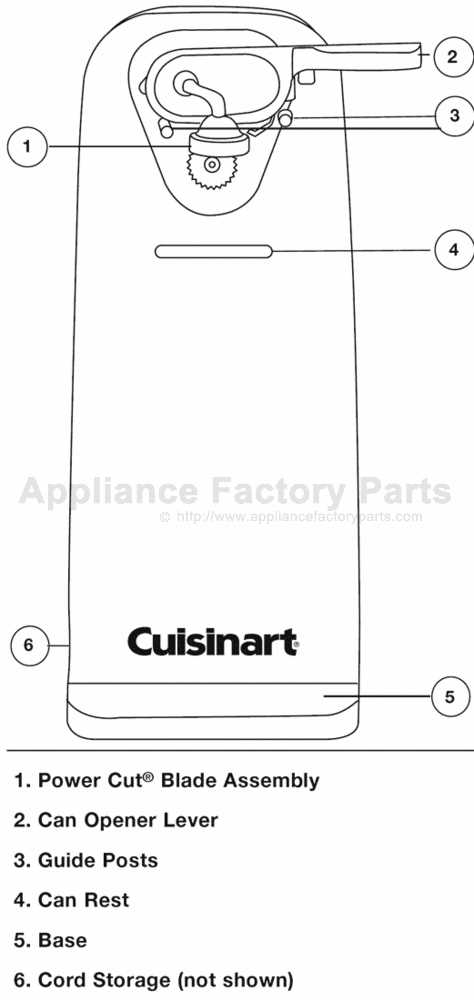

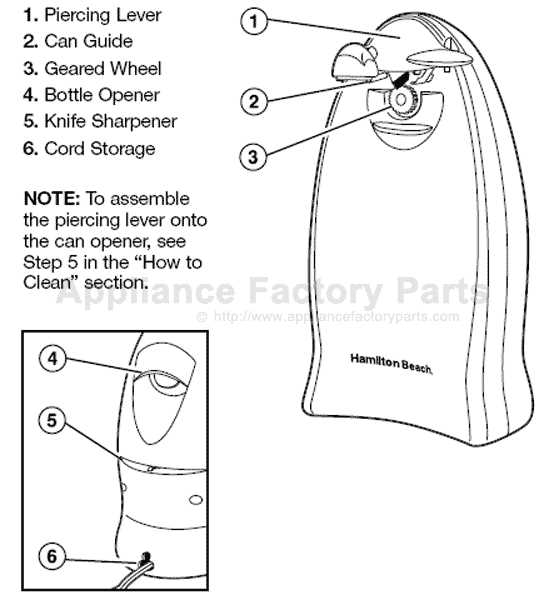

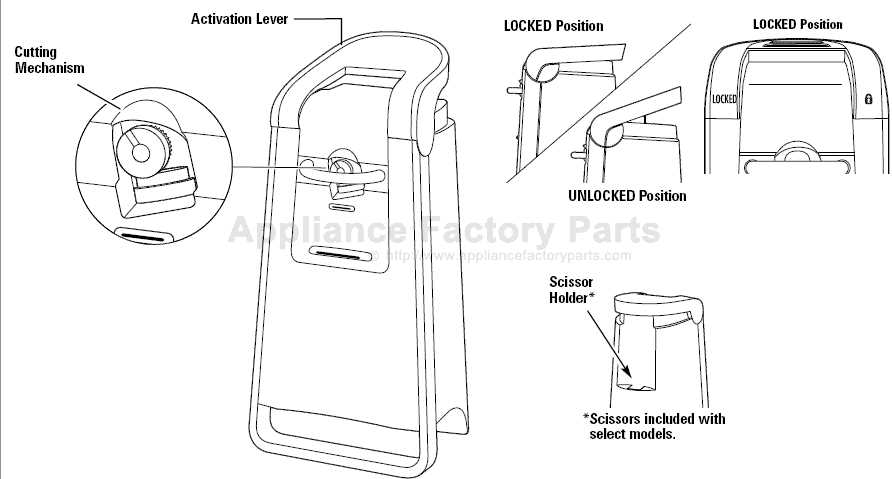

Essential Components of Can Openers

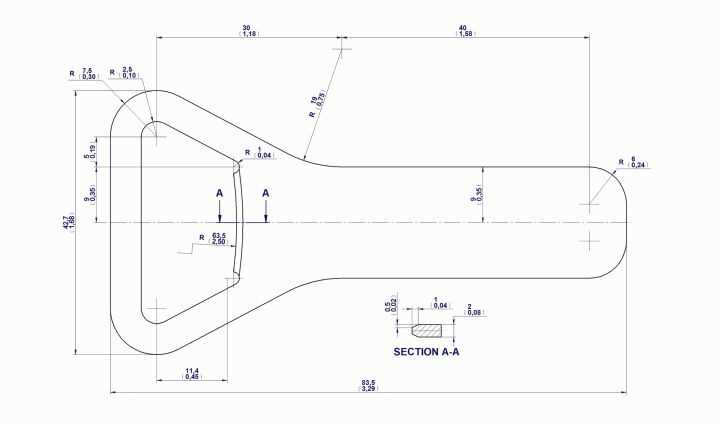

Understanding the key elements that make up this kitchen tool is crucial for effective usage and maintenance. Each component plays a vital role in ensuring that the device functions smoothly and safely. Familiarity with these features can enhance user experience and prolong the lifespan of the tool.

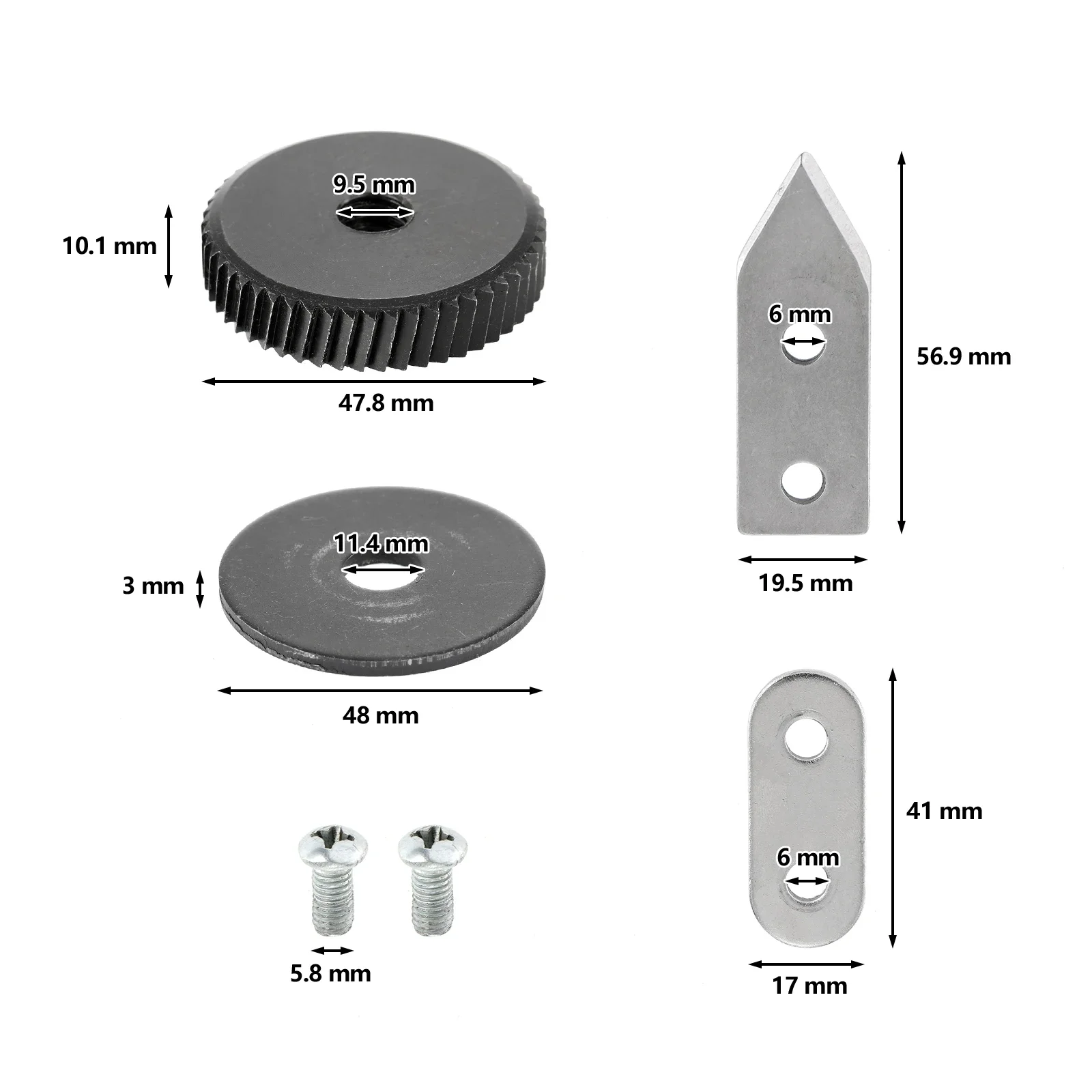

Blade: The cutting edge is perhaps the most critical aspect, designed to pierce through metal surfaces with ease. Its sharpness and durability determine how effortlessly it can tackle various lids.

Wheel: This circular mechanism rotates to facilitate the cutting process. Its design often includes grooves that assist in gripping the lid, allowing for a steady and controlled operation.

Handle: The gripping section provides leverage and comfort during use. A well-designed handle reduces strain and ensures better control, making the task more efficient.

Gear Mechanism: This system helps transfer force from the handle to the blade. Smooth functioning gears ensure that the cutting process is quick and effective, minimizing effort from the user.

Base Plate: The supporting structure stabilizes the entire tool during operation. A sturdy base plate contributes to balance and precision, preventing slips or accidental injuries.

By recognizing these essential features, users can appreciate the intricacies of this everyday tool and make informed choices regarding their purchase and upkeep.

How a Can Opener Works

The mechanism designed for piercing and removing metal lids operates through a combination of leverage and cutting action. By applying force in a specific manner, this tool efficiently breaks the seal, allowing access to the contents inside.

At its core, the device utilizes a rotating wheel that features sharp edges. As the user turns the handle, this wheel engages with the lid, gradually cutting through the material. The design ensures that minimal effort is required for maximum effectiveness.

Once the lid is sufficiently penetrated, a lever mechanism typically comes into play, lifting the cut piece away from the container. This dual-action process highlights the ingenuity behind such a simple yet essential kitchen tool, making it an ultimate convenience for everyday use.

Common Can Opener Designs

This section explores various mechanisms used to access sealed containers, highlighting their unique features and functionality. Each design caters to specific user needs and preferences, ensuring ease of use and efficiency in opening.

Manual Models: These devices typically utilize a rotating mechanism operated by hand. Users apply pressure to puncture the lid, allowing for controlled access to the contents.

Electric Variants: Powered options offer convenience and speed, often requiring minimal effort. They are particularly beneficial for individuals with limited hand strength.

Lever-Type Designs: This style employs a lever system to create leverage, making it easier to pierce and lift the lid. It’s favored for its ergonomic design and user-friendly operation.

Safety Models: Designed to minimize sharp edges, these tools cut the lid in a way that prevents injury. This innovative approach enhances safety, especially in households with children.

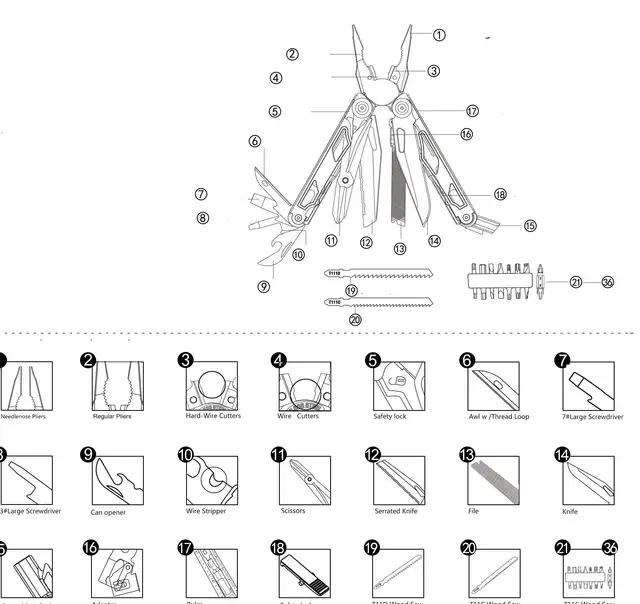

Multifunctional Devices: Combining various tools, these options serve multiple purposes, often including features for opening bottles or other sealed packages, making them versatile for everyday tasks.

Materials Used in Can Openers

The effectiveness and durability of a device designed for lid removal largely depend on the materials utilized in its construction. These materials not only influence performance but also ensure longevity and ease of use.

- Stainless Steel: Commonly used for cutting edges due to its strength and resistance to rust.

- Plastic: Often found in handles and grips, providing comfort and reducing weight.

- Aluminum: Lightweight and corrosion-resistant, it may be used in various structural components.

- Rubber: Employed in grips for enhanced control and comfort during operation.

Understanding these materials helps consumers make informed choices based on durability and functionality.

Safety Features in Can Openers

When it comes to kitchen tools designed for opening sealed containers, ensuring user safety is paramount. Various mechanisms are integrated into these devices to minimize risks and enhance ease of use. Understanding these features can help users select the most suitable tool for their needs while prioritizing safety.

Key Safety Mechanisms

- Blade Protection: Many models include guards or shields that prevent accidental cuts when handling the instrument.

- Ergonomic Handles: Designed for comfort, these grips reduce strain and improve control, minimizing the chance of slipping during operation.

- Automatic Shut-off: Some devices feature an auto-stop mechanism that halts the function once the task is complete, preventing potential injuries.

Usage Tips for Enhanced Safety

- Always keep fingers away from sharp edges during operation.

- Ensure the device is placed securely on the container before starting.

- Regularly inspect the tool for wear and tear, replacing it if any components are damaged.

By understanding these safety features and adhering to proper usage guidelines, users can enjoy a secure and efficient experience with their kitchen tools.

Maintaining Your Can Opener

Proper upkeep of your kitchen tool is essential for ensuring longevity and optimal performance. Regular attention to maintenance not only enhances functionality but also promotes safety during use. Understanding how to care for this device can make a significant difference in its lifespan and efficiency.

Cleaning Procedures

To maintain hygiene, it is crucial to clean the device after each use. Rinse all components under warm water to remove residue. For stubborn debris, a gentle scrub with a soft brush or sponge is recommended. Avoid abrasive materials that may scratch surfaces. Once cleaned, allow it to air dry completely to prevent rust and deterioration.

Storage Tips

Proper storage plays a vital role in preserving your kitchen tool. Store it in a dry, cool place away from direct sunlight and moisture. Using a protective cover can shield it from dust and potential damage. Ensure that sharp edges are not in contact with other utensils to avoid dulling and accidental injuries.

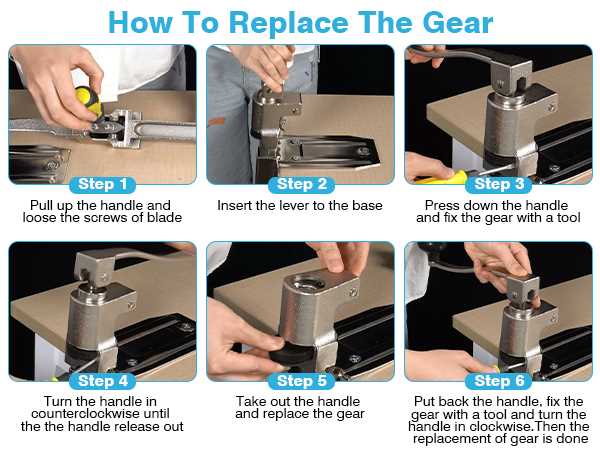

Repairing Common Issues

Addressing frequent problems with this kitchen tool can enhance its functionality and prolong its lifespan. Understanding typical malfunctions allows users to troubleshoot effectively, ensuring seamless operation. From improper engagement to mechanical failures, recognizing symptoms is crucial for timely fixes.

One common challenge is when the device fails to grip securely. This may result from worn-out gripping mechanisms or debris buildup. Cleaning and inspecting these areas often resolves the issue, restoring proper function.

Another frequent concern is resistance during operation. This might indicate misalignment or insufficient lubrication. Regular maintenance, including applying appropriate oils, can help mitigate this problem, ensuring smooth and effortless use.

Lastly, if the lever does not return to its original position, it may require adjustment or replacement of the internal springs. Checking these components and replacing them when necessary can significantly improve performance.

Choosing the Right Can Opener

Selecting the ideal tool for opening metal containers can significantly enhance your kitchen experience. With various models available, understanding their distinct features is essential for making an informed decision. The right choice not only improves efficiency but also ensures safety and ease of use.

Consider your needs: Assess how frequently you’ll use the tool and whether you require a manual or electric version. Manual tools are often more compact and easier to store, while electric variants can save time and effort, especially for individuals with limited hand strength.

Explore the design: Look for features such as ergonomic handles, which provide a comfortable grip, and sturdy materials that promise longevity. A well-designed tool should allow for smooth operation without excessive strain.

Safety features are another crucial aspect. Some models come equipped with mechanisms that minimize the risk of sharp edges, ensuring a safer opening process. Additionally, a tool that offers a smooth cut can prevent food debris from contaminating the contents.

Finally, read reviews and seek recommendations to gauge user satisfaction. Choosing the right tool not only simplifies your culinary tasks but also adds a touch of convenience to your daily routine.

Innovations in Can Opener Technology

Recent advancements in the field of kitchen tools have led to significant improvements in functionality, ease of use, and safety. These innovations reflect a growing emphasis on user experience and ergonomics, making essential tasks more efficient and accessible for everyone.

One notable development includes the integration of electric mechanisms that simplify the process, reducing physical effort and allowing for one-handed operation. This technology is particularly beneficial for individuals with limited hand strength, ensuring that anyone can easily access their food without struggle.

Another exciting trend is the use of smart technology, which connects these devices to mobile applications. Users can receive alerts for maintenance, track usage, and even explore recipes tailored to the ingredients they have on hand. This not only enhances convenience but also promotes creativity in meal preparation.

Additionally, innovations in materials have led to more durable and corrosion-resistant designs. This focus on longevity ensures that tools withstand the rigors of daily use while maintaining their aesthetic appeal. Furthermore, environmentally friendly options are becoming more prevalent, catering to the growing demand for sustainable kitchen solutions.

Overall, the evolution of these essential kitchen instruments continues to reflect broader trends in technology and design, enhancing the culinary experience for users worldwide.

DIY Can Opener Solutions

Creating your own tools for opening sealed containers can be both a fun and practical endeavor. Whether you’re looking to repair a broken device or invent a new one, there are numerous ways to approach this challenge using everyday materials. This section will explore various innovative solutions that can enhance your kitchen experience.

Creative Alternatives

- Using a sturdy spoon: A metal spoon can be an effective tool. Position the edge under the lid and gently pry it upwards.

- Employing a knife: A small, sharp knife can be used to cut through the seal. Exercise caution to avoid injuries.

- Leveraging a rubber grip: A thick rubber band can provide the extra grip needed to twist off stubborn lids.

- Incorporating pliers: Needle-nose pliers can grasp and twist the lid for easy removal.

Repairing Broken Tools

- Check for loose components: Tighten screws or bolts that may have come undone.

- Replace worn-out grips: Adding new rubber or foam can enhance your existing device’s functionality.

- Utilize duct tape: This versatile tape can temporarily fix any loose parts or cracks.

- Modify for better leverage: Alter the handle or body to improve grip and force application.

By exploring these alternatives and repair methods, you can not only solve your immediate needs but also enjoy the satisfaction of crafting your own solutions.

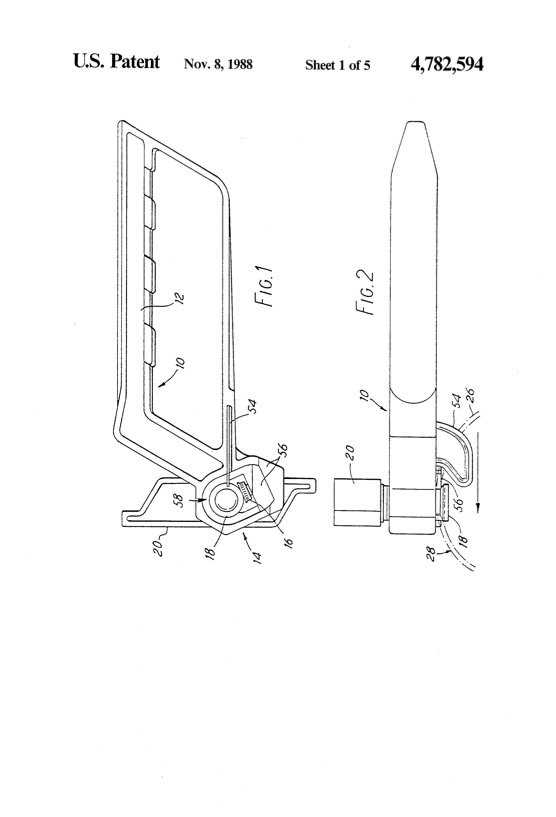

History of Can Openers

The evolution of devices designed to access sealed food containers reflects innovation driven by necessity. Over time, the quest for convenience and efficiency led to the creation of various tools, each enhancing user experience and safety. Understanding this progression reveals not only technological advancements but also cultural shifts in how food preservation and consumption have been approached.

The earliest known methods for accessing sealed metal containers date back to the 19th century, coinciding with the advent of canned food. Initially, soldiers and sailors used knives and chisels to break through metal, illustrating the urgent need for practical solutions in challenging environments. As demand grew, inventors began experimenting with different designs to simplify this laborious process.