Understanding the Cat C15 Parts Diagram for Optimal Maintenance

In the world of heavy machinery, comprehending the intricacies of engine components is vital for optimal performance and maintenance. Each engine consists of various elements that work in harmony to ensure smooth operation. By gaining insight into these components, operators and technicians can better troubleshoot issues and enhance the lifespan of their machinery.

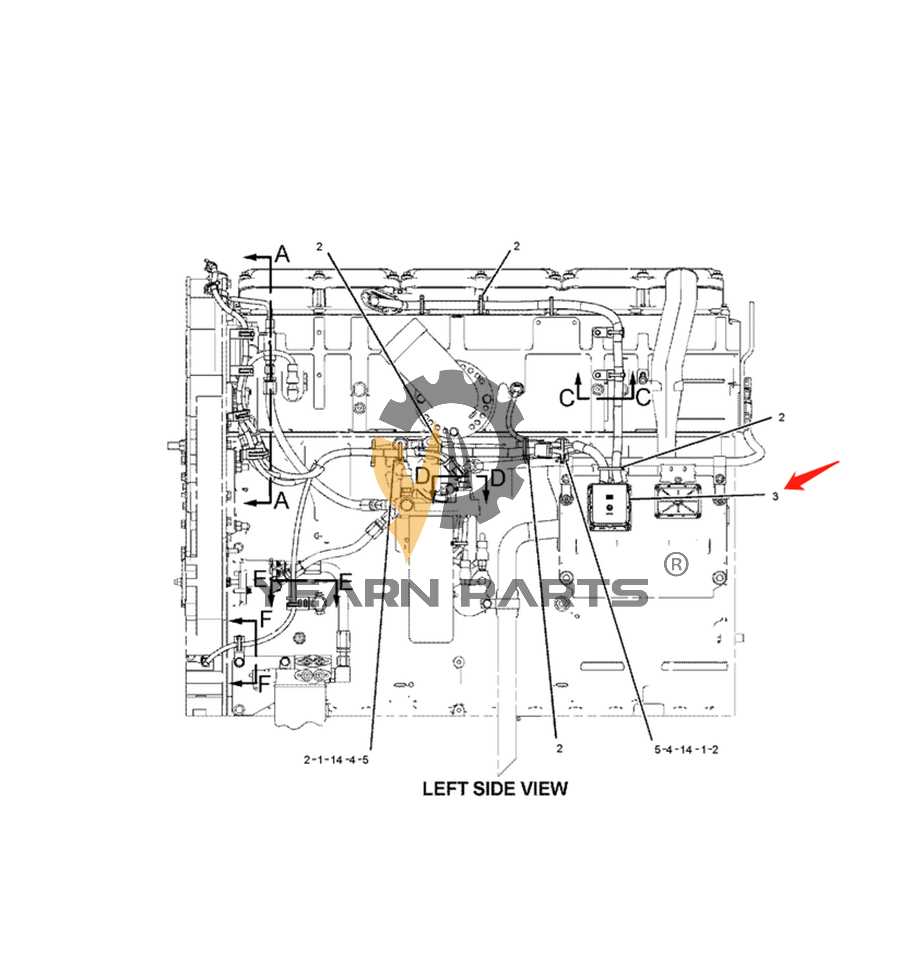

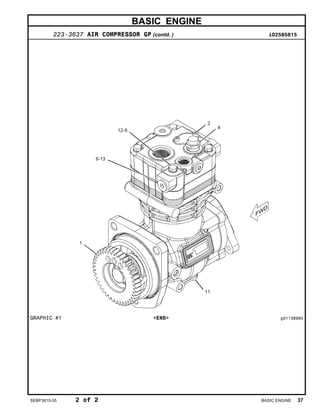

Visual representations play a crucial role in understanding the arrangement and function of engine elements. They serve as a roadmap for identifying parts, facilitating repairs, and executing maintenance tasks effectively. A well-structured illustration provides clarity, enabling users to grasp complex systems at a glance.

For those involved in machinery upkeep, familiarizing oneself with the configuration of engine components is not just beneficial–it’s essential. Engaging with detailed visuals allows for a deeper appreciation of how each piece interacts within the larger system, ultimately leading to improved operational efficiency and reduced downtime.

Understanding the Cat C15 Engine

The engine in question is a powerhouse renowned for its durability and efficiency. It is designed to meet the demanding requirements of heavy-duty applications, providing reliable performance across various environments. This section delves into its essential components, functionalities, and the advantages they offer.

Key characteristics of this engine include:

- Robust Design: Built to withstand harsh conditions, ensuring longevity and reduced maintenance.

- Fuel Efficiency: Optimized for better fuel consumption, helping to lower operational costs.

- Power Output: Capable of delivering significant horsepower, making it suitable for a variety of heavy machinery.

- Advanced Technology: Incorporates modern advancements for improved performance and emissions control.

Understanding the various elements that contribute to its operation can enhance maintenance practices and extend the life of the machinery. Below are some crucial components:

- Cylinder Head: Plays a vital role in the combustion process and overall efficiency.

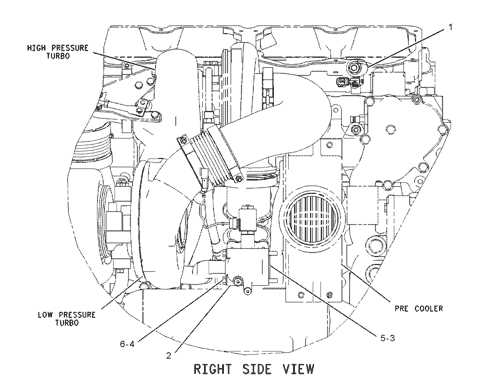

- Turbocharger: Increases air intake, allowing for better combustion and more power.

- Fuel Injectors: Precisely deliver fuel to optimize performance and emissions.

- Cooling System: Essential for maintaining optimal operating temperatures and preventing overheating.

By familiarizing oneself with these aspects, operators can ensure their machinery operates at peak efficiency and reliability.

Key Components of Cat C15

This section explores the essential elements that contribute to the overall functionality and performance of a high-performance engine. Understanding these critical components is vital for anyone looking to optimize efficiency and ensure reliability in demanding applications.

Engine Block and Cylinder Head

The engine block serves as the foundation of the power unit, housing various vital components. The cylinder head is crucial for facilitating airflow and combustion, ensuring that fuel mixes effectively with air for maximum power output.

Fuel and Air Systems

Efficient fuel delivery and air intake systems are paramount for optimal engine performance. The fuel injectors and turbocharger work together to maximize power while maintaining fuel efficiency, which is essential in high-demand environments.

Importance of Engine Diagrams

Engine schematics play a crucial role in understanding the complex machinery that powers vehicles and equipment. They provide a visual representation that enhances comprehension of the various components and their interrelations, making it easier for technicians and engineers to diagnose issues and perform maintenance effectively.

Enhanced Understanding

Utilizing these illustrations allows for a deeper insight into how systems function together. Technicians can quickly identify parts, facilitating faster repairs and minimizing downtime. This visual aid is essential for both training and practical application in the field.

Effective Troubleshooting

When issues arise, having access to a clear representation of engine layout can significantly streamline the troubleshooting process. Understanding the layout enables professionals to pinpoint the source of a problem, ensuring that the ultimate goal of efficient repair is achieved.

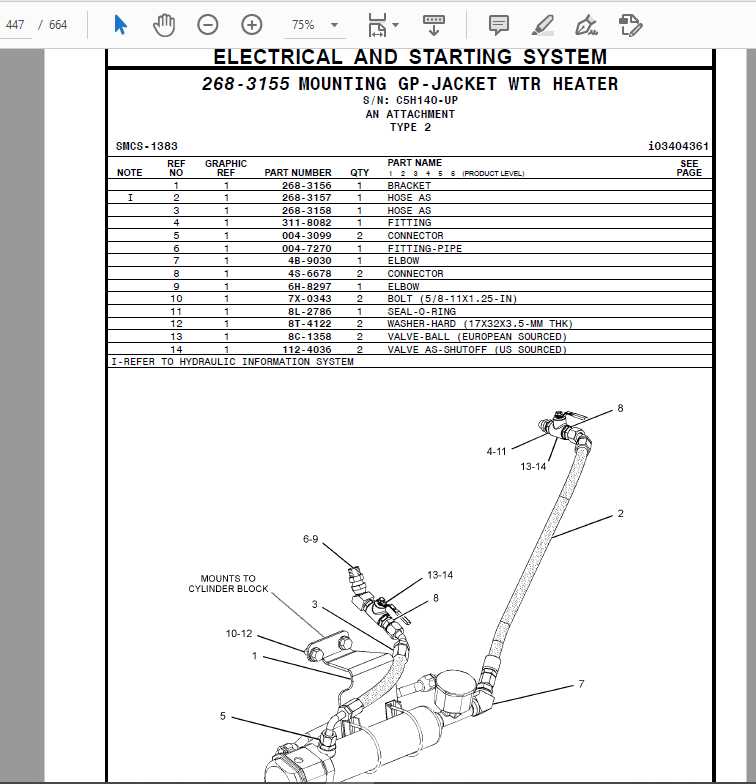

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. Such illustrations provide a visual guide, allowing users to identify individual elements and their relationships within a complex system. By familiarizing yourself with the symbols and layout used, you can streamline the process of troubleshooting and assembly.

Familiarizing with Symbols

Every illustration employs specific symbols to denote various components. Learning these symbols is crucial, as they convey essential information about the function and connection of each part. Refer to the accompanying legend or key, which usually explains what each symbol represents, enabling you to navigate the illustration more efficiently.

Interpreting Connections and Layout

In addition to recognizing symbols, it is important to understand how the elements are interconnected. Lines often represent pathways, indicating how components interact with one another. Pay attention to the layout, as it often reflects the actual arrangement within the system, aiding in visualizing how everything fits together in practice.

Common Issues with Cat C15 Parts

Understanding the typical problems associated with these powerful engines can enhance performance and longevity. Various components may face challenges due to wear, environmental factors, or operational stress.

- Overheating due to coolant leaks or thermostat failures.

- Fuel system malfunctions resulting from clogged filters or injectors.

- Electrical issues often stemming from corroded connections or battery failures.

- Excessive oil consumption linked to worn piston rings or valve seals.

- Turbocharger failures caused by inadequate lubrication or debris ingestion.

Addressing these concerns promptly can lead to improved efficiency and reduced downtime.

Maintenance Tips for Longevity

Ensuring the prolonged performance of machinery relies heavily on consistent upkeep and attention to detail. By following effective maintenance practices, operators can significantly enhance reliability and efficiency while minimizing downtime and costly repairs.

Regular Inspections

Conduct frequent assessments to identify wear and tear. Early detection of potential issues can prevent more severe problems in the future.

Fluid Management

Maintain optimal fluid levels and quality. Regularly check and replace lubricants and coolants to ensure smooth operation and prevent overheating.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Daily | Check for leaks and unusual noises. |

| Fluid Check | Weekly | Ensure all fluids are at recommended levels. |

| Filter Replacement | Monthly | Change air and fuel filters as needed. |

| Comprehensive Service | Quarterly | In-depth examination by a qualified technician. |

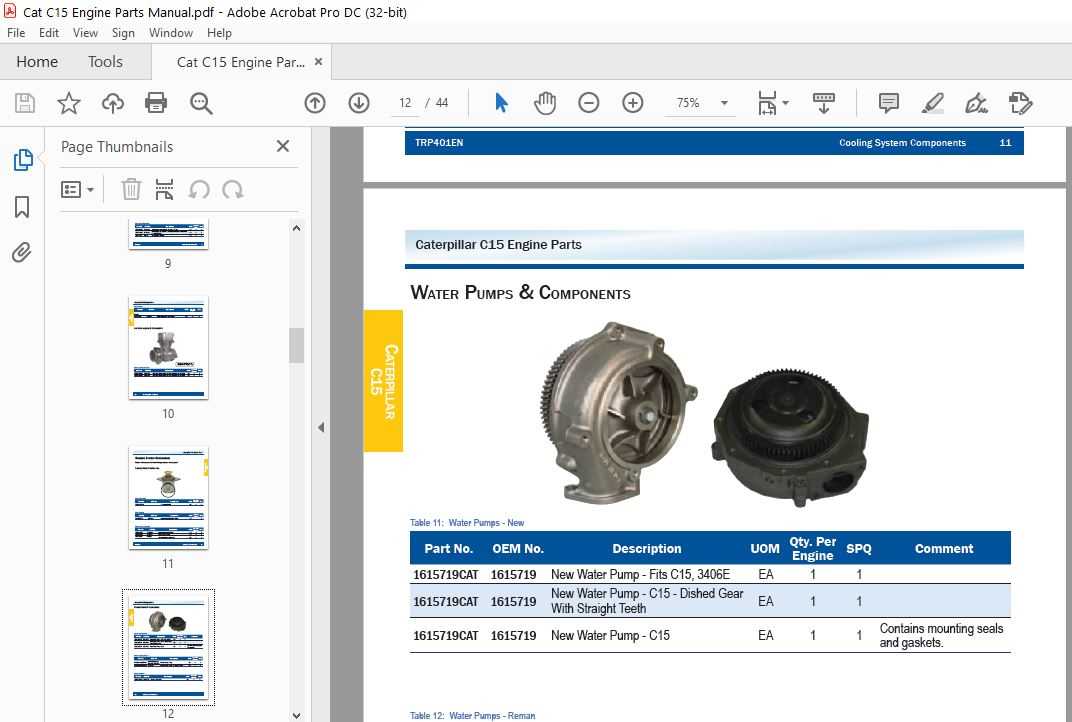

Replacement Parts Availability

Access to high-quality components is essential for maintaining the efficiency and longevity of heavy machinery. When equipment requires servicing, finding reliable substitutes can significantly impact operational downtime and overall performance. This section explores the options available for sourcing essential elements for your machinery needs.

Several reputable suppliers offer an extensive range of aftermarket and OEM components to cater to various requirements. These providers often stock a wide selection, ensuring that most commonly needed items are readily available. Additionally, many vendors facilitate online ordering, making it convenient to acquire necessary components promptly.

Key factors to consider when seeking replacements include compatibility, warranty, and price. Evaluating the specifications of each item against your equipment’s requirements ensures optimal performance. Moreover, selecting parts with a solid warranty can provide added peace of mind, protecting your investment.

For those who prefer personalized service, local distributors can offer tailored advice based on their understanding of your machinery. Establishing a relationship with a trusted supplier can lead to better support and faster access to critical components, reducing the risk of prolonged equipment downtime.

In conclusion, ensuring the availability of quality replacements is crucial for maintaining operational efficiency. By exploring various sourcing options and considering important factors, you can effectively manage the upkeep of your machinery.

Comparing OEM and Aftermarket Options

When considering components for machinery, the choice between original manufacturer products and third-party alternatives is crucial. Each option presents unique advantages and potential drawbacks that can impact performance, longevity, and overall value.

Quality and Reliability

Original equipment products are often associated with higher quality and reliability due to rigorous testing and manufacturer standards. In contrast, third-party alternatives may vary significantly in quality, with some offering excellent performance at a lower price, while others might compromise on durability.

Cost Considerations

While OEM products typically come at a premium, they often include warranties and support. Aftermarket options can be more budget-friendly, but it’s essential to evaluate the potential trade-offs in quality and warranty coverage.

| Aspect | OEM | Aftermarket |

|---|---|---|

| Quality | High, standardized | Variable, not standardized |

| Cost | Higher | Lower |

| Warranty | Often included | Variable, less consistent |

| Availability | Limited to manufacturer | Widely available |

Diagram Sources and Resources

This section aims to provide valuable references for obtaining schematics and visual aids related to heavy machinery. Having access to accurate illustrations is essential for effective maintenance and repair, ensuring that operators can perform tasks efficiently and safely.

Online Resources

- Manufacturer Websites: Many producers offer downloadable resources and guides.

- Industry Forums: These platforms often share user-generated content, including helpful images and diagrams.

- Technical Blogs: Dedicated blogs provide insights and detailed visuals on machinery.

Printed Materials

- User Manuals: Comprehensive guides typically include useful illustrations.

- Service Books: Published resources containing detailed schematics and maintenance tips.

- Repair Guides: Specialty books that focus on specific machinery systems.

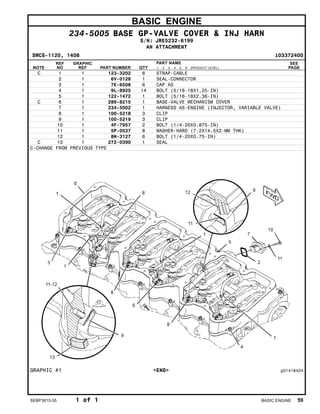

Visualizing Engine Assembly Process

Understanding the intricacies of engine assembly is crucial for ensuring optimal performance and longevity. This process involves multiple stages where various components come together, each serving a specific purpose. A clear visualization of these steps can enhance comprehension and efficiency in assembly practices.

Here’s a breakdown of the essential phases involved in the assembly process:

- Preparation

- Gather all necessary components and tools.

- Ensure a clean and organized workspace.

- Review assembly instructions and schematics.

- Base Assembly

- Install the crankshaft and bearings into the engine block.

- Secure the oil pan to the bottom of the block.

- Cylinder Head Installation

- Place the head gasket onto the engine block.

- Attach the cylinder head and secure it with bolts.

- Accessory Mounting

- Install the intake and exhaust manifolds.

- Add any necessary sensors and electrical connections.

- Final Checks

- Inspect all connections for tightness and leaks.

- Review fluid levels and ensure proper lubrication.

- Conduct a preliminary test to verify functionality.

This organized approach allows for a systematic assembly process, minimizing errors and enhancing performance. By visualizing each stage, technicians can better anticipate challenges and ensure a successful outcome.