Understanding the Coats 5030 Parts Diagram for Efficient Repairs

The intricate world of tire-changing equipment plays a vital role in the automotive service industry. Understanding the various elements that comprise these machines can enhance efficiency and maintenance. Each component is designed to work in harmony, ensuring optimal performance and durability.

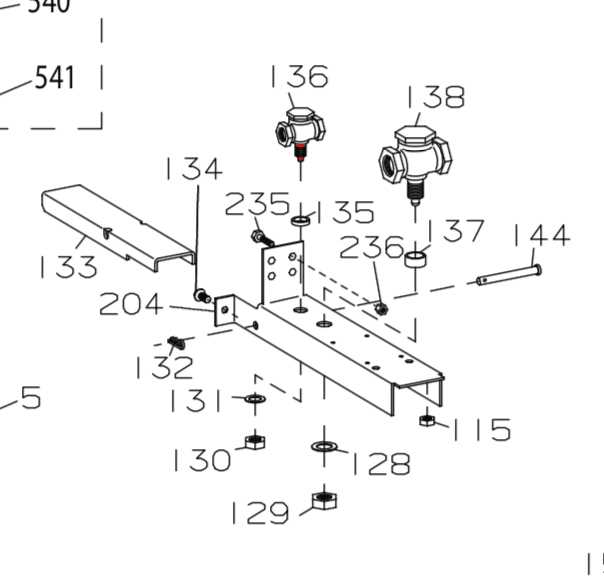

Exploring the layout of these essential tools allows technicians to identify, troubleshoot, and replace specific features when necessary. This knowledge not only aids in repairs but also empowers users to maximize the lifespan of their equipment. A clear visualization of these components can lead to greater insight and informed decision-making.

As you navigate through the specifics of these mechanical systems, it becomes evident that a well-organized representation is crucial. Whether you are a seasoned professional or a newcomer, grasping the organization of these parts will ultimately improve your operational expertise.

Understanding Coats 5030 Parts Diagram

Grasping the intricacies of machinery components is essential for effective maintenance and operation. A visual representation showcasing the arrangement and function of various elements aids in identifying each part’s role within the system. This knowledge not only streamlines repairs but also enhances overall performance.

Familiarity with the layout enables users to pinpoint issues swiftly, ensuring that troubleshooting processes are both efficient and precise. Each segment serves a specific purpose, and recognizing these can significantly impact the longevity and reliability of the equipment.

By exploring the connections and functions of individual pieces, operators can make informed decisions during servicing, ultimately leading to improved workflow and reduced downtime. Mastery of this visual guide empowers users to maintain their equipment with confidence.

Key Components of Coats 5030

This section delves into the essential elements that make up a tire-changing machine, highlighting their roles and functionalities. Understanding these components is crucial for effective maintenance and operation, ensuring optimal performance and longevity of the equipment.

Main Elements

- Mount/Demount Head: This critical part facilitates the tire installation and removal process, providing the necessary leverage and precision.

- Turntable: The rotating platform holds the tire securely, allowing for smooth and efficient handling during the change process.

- Bead Breaker: A powerful tool designed to separate the tire bead from the rim, making it easier to perform tire swaps.

Supportive Features

- Control Panel: The interface that enables the operator to manage functions and settings with ease.

- Safety Guards: Essential for protecting users from potential hazards during operation.

- Air Supply System: Provides the necessary air pressure for various tasks, including inflation and bead seating.

Familiarity with these key components not only enhances operational efficiency but also aids in troubleshooting and repairs, ensuring that the machine remains in peak condition.

Importance of Accurate Diagrams

Clear and precise illustrations are essential for effective communication and understanding in any technical field. They serve as invaluable tools for both professionals and novices, guiding users through complex processes with ease.

Accurate representations enhance efficiency and reduce errors in several ways:

- Clarity: Well-crafted visuals convey information quickly and effectively.

- Guidance: Detailed schematics help users navigate intricate systems and assemblies.

- Problem-Solving: Accurate illustrations assist in identifying issues and facilitating repairs.

- Training: They serve as educational resources for new technicians and operators.

Ultimately, the precision of these resources is critical for successful operations and maintenance, ensuring longevity and reliability in performance.

Common Repairs for Coats 5030

In the realm of tire changers, maintenance and repair are essential to ensure optimal performance and longevity. Various issues can arise during regular use, necessitating timely interventions. Understanding common repair needs can help operators maintain efficiency and reduce downtime.

-

Air Leaks:

Frequent air leaks can occur in the bead seating area or hoses. Regular inspection and replacement of worn components can prevent this issue.

-

Worn Seals:

Over time, seals may degrade, leading to hydraulic fluid leaks. Replacing these seals can restore functionality.

-

Electrical Failures:

Electrical components may malfunction, causing the machine to operate inconsistently. Checking wiring connections and replacing faulty parts can resolve these issues.

-

Clamping Problems:

If the clamping mechanism becomes misaligned, it may not secure tires properly. Adjustments and lubrication are often needed to rectify this.

By addressing these common issues promptly, users can maintain high performance and extend the lifespan of their equipment.

Where to Find Replacement Parts

When it comes to sourcing components for your equipment, various avenues can be explored to ensure you obtain the necessary items efficiently. Whether you’re looking for specific elements or more general supplies, understanding where to look can save time and resources.

Online Retailers: The internet offers a plethora of options, including specialized websites dedicated to machinery components. These platforms often provide detailed catalogs and easy navigation to find what you need.

Local Distributors: Establishing connections with nearby suppliers can also yield valuable results. They often carry a range of items and can offer personalized assistance in locating the right components.

Manufacturer’s Resources: Don’t overlook the manufacturer’s official channels. Many producers provide lists of authorized dealers or direct sales options for genuine replacements.

Forums and Community Groups: Engaging with online forums or local community groups can lead to recommendations from experienced users who may have encountered similar needs.

Second-Hand Markets: Exploring resale platforms can uncover affordable options. Just ensure that the quality meets your standards before purchasing.

By delving into these sources, you can ultimately enhance the efficiency and longevity of your machinery.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of any mechanical device. This guide outlines a systematic approach to maintaining your equipment, enabling you to enhance its functionality and reduce the risk of unexpected breakdowns.

Preparation and Inspection

Begin by gathering necessary tools and materials. Conduct a thorough inspection to identify any signs of wear or damage. Pay attention to components that require lubrication or replacement, as addressing these issues early can prevent larger problems down the line.

Routine Servicing Steps

Follow these essential steps for effective maintenance:

- Clean the Equipment: Remove dust and debris from surfaces to improve efficiency.

- Lubricate Moving Parts: Apply the appropriate lubricant to ensure smooth operation.

- Check and Replace Filters: Regularly inspect and swap out filters to maintain optimal airflow.

- Test Functionality: Run a series of tests to confirm that all systems are functioning as intended.

By adhering to this guide, you will ultimately enhance the reliability and performance of your machinery.

Troubleshooting Common Issues

When working with tire changing machines, various problems may arise that can hinder their performance. Identifying and addressing these challenges is crucial for maintaining efficiency and ensuring safety during operations. This section aims to explore frequent complications and provide practical solutions to help users optimize their equipment.

One common issue is inconsistent tire mounting, which can result from improper alignment or worn components. Regularly inspecting the machine’s calibration and replacing any damaged parts can mitigate this problem. Additionally, ensuring that the tire and rim are compatible can prevent mounting difficulties.

Another frequent concern involves pneumatic systems losing pressure. This may stem from leaks or faulty seals. Checking hoses and connections for wear can help detect issues early. Proper maintenance and timely replacements are essential to keep the system functioning optimally.

Finally, excessive vibration during operation may indicate imbalances within the machine. Evaluating the components for wear and realigning them as necessary can reduce vibrations and enhance stability. Consistent monitoring and maintenance play a vital role in addressing these and other common challenges.

Comparing Models: Coats 5030 vs Others

When evaluating tire changers, it’s essential to explore how different models stack up against one another. Each device offers unique features that cater to various needs, impacting efficiency, usability, and overall performance. By examining these differences, potential buyers can make informed decisions that align with their requirements.

Performance and Efficiency

Many devices on the market boast impressive performance metrics, yet some stand out due to their innovative designs and user-friendly interfaces. The ultimate goal is to enhance workflow, minimize downtime, and provide reliable results. Understanding these distinctions can guide you toward selecting the right equipment for your shop.

Cost and Value

Price is often a deciding factor in the purchase process. However, evaluating the value proposition of each model reveals that cheaper options may not always deliver the same quality or longevity. It’s crucial to delve into the features and warranties offered to determine which investment is most worthwhile in the long run.

Understanding Hydraulic Systems in Coats

Hydraulic systems play a crucial role in the functionality of various machinery, enabling efficient operation through the power of fluid dynamics. These systems rely on the movement of hydraulic fluid to transmit force, facilitating the operation of different components.

Key Components of Hydraulic Systems

- Pumps: Responsible for generating flow and pressure within the system.

- Valves: Control the direction and flow of hydraulic fluid.

- Cylinders: Convert hydraulic energy into mechanical motion.

- Reservoirs: Store hydraulic fluid and allow for heat dissipation.

Benefits of Hydraulic Systems

- High power-to-weight ratio, allowing for compact design.

- Smooth and precise control of motion.

- Ability to transmit power over long distances without significant loss.

- Versatility in various applications, from lifting to steering.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines not only protects the individual performing the work but also ensures the longevity and proper functioning of the equipment involved. Implementing effective safety measures can significantly reduce the risk of mishaps and enhance the overall repair experience.

Personal Protective Equipment

Utilizing personal protective equipment (PPE) is crucial during any repair activity. This includes items such as gloves, safety goggles, and sturdy footwear. These tools act as barriers against potential hazards, such as sharp objects or hazardous materials. Ensuring that the PPE fits correctly and is in good condition is equally important for optimal protection.

Proper Tools and Workspace

Having the right tools readily available can make a significant difference in safety and efficiency. Always ensure that tools are well-maintained and suitable for the task at hand. Additionally, keeping the workspace organized minimizes the risk of slips or falls. Clear any clutter and ensure proper lighting to facilitate a safer environment for performing repairs.

Benefits of Regular Maintenance Practices

Consistent upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. By engaging in routine care, users can prevent minor issues from escalating into major problems, thus safeguarding investments and enhancing efficiency.

Enhanced Reliability

Regular attention to equipment significantly boosts its reliability. Routine checks identify potential malfunctions early, allowing for timely interventions. This proactive approach minimizes downtime and ensures that operations run smoothly.

Cost Efficiency

Investing time and resources into systematic maintenance can lead to substantial cost savings. Preventive measures reduce the need for extensive repairs, lower energy consumption, and prolong the lifespan of components, ultimately yielding a higher return on investment.