Understanding the Combine Header Parts Diagram

The integration of various elements plays a crucial role in the overall functionality of any system. By examining how these individual components interact, we can gain insights into the efficiency and coherence of the entire framework. This exploration reveals not only the mechanics behind each segment but also their significance in the broader context.

Through detailed analysis, we can uncover the relationships and dependencies that exist among these segments. Such understanding enables us to optimize designs and enhance performance, ultimately leading to improved outcomes. The careful arrangement of these elements is essential for achieving the desired objectives and maintaining harmony within the system.

In this discussion, we will delve into the intricacies of how these various components unite to create a seamless experience. By focusing on their interactions, we can appreciate the ultimate effectiveness of the structure and the principles that guide its assembly.

Understanding Combine Header Parts Diagram

This section explores the interconnected elements that create a cohesive structure within a system. Each component plays a vital role in the overall functionality, and understanding these relationships is essential for effective design and implementation.

Key Elements

- Component A: Provides foundational support.

- Component B: Enhances connectivity and interaction.

- Component C: Ensures seamless integration with other systems.

Benefits of Understanding These Elements

- Improved clarity in design.

- Enhanced troubleshooting capabilities.

- Greater efficiency in implementation.

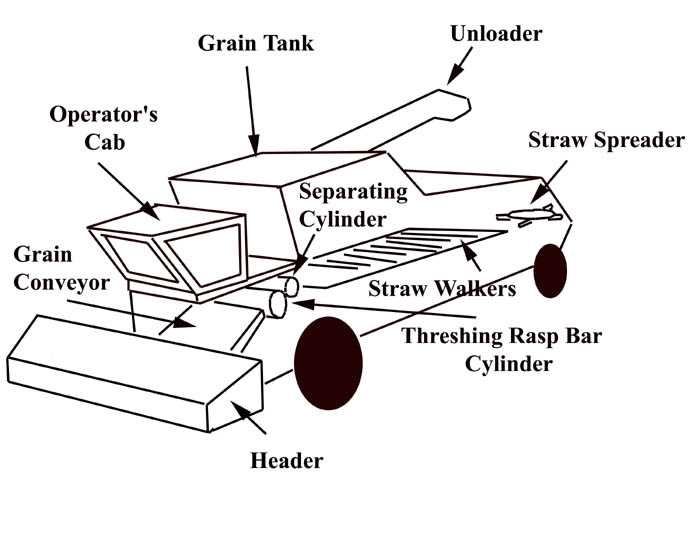

Components of a Combine Header

The functionality of agricultural machinery relies heavily on its various elements, each designed to perform specific tasks that enhance overall efficiency. Understanding these components is essential for optimizing operations in the field, ensuring effective harvesting, and maintaining equipment longevity.

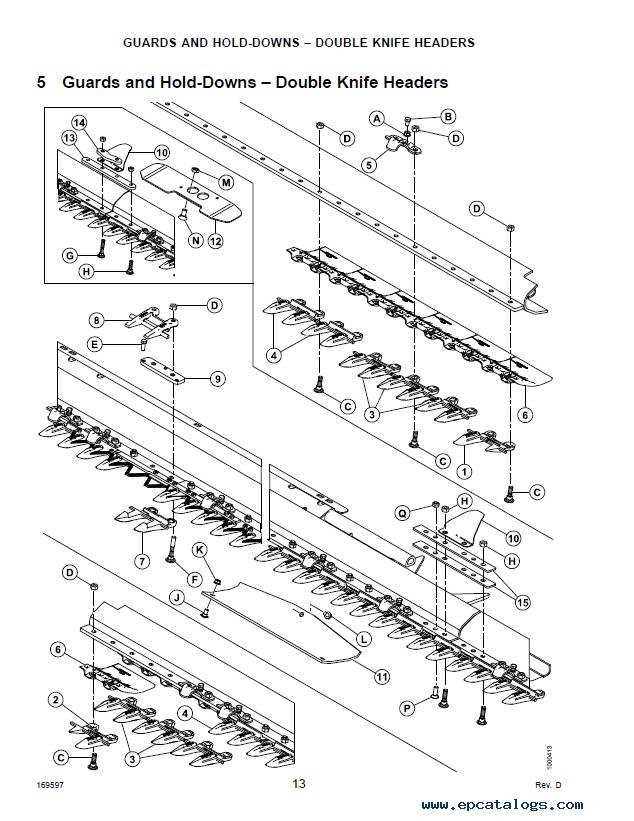

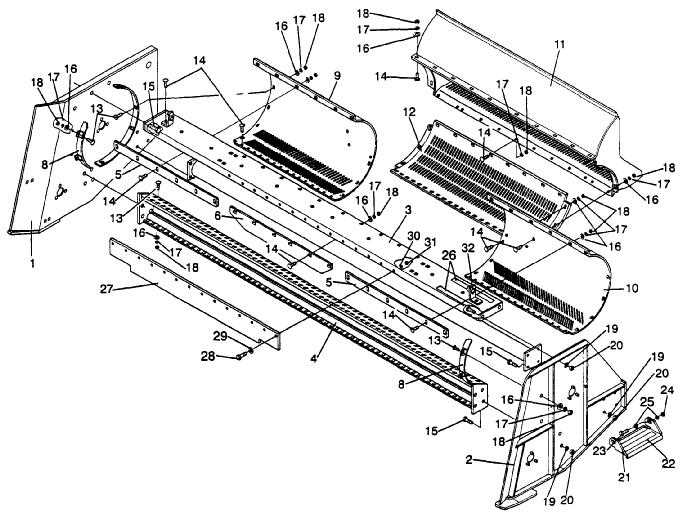

Cutting Bar: This crucial element is responsible for the initial severing of crops. It operates with sharp blades that slice through the stems, allowing for smooth collection and processing.

Auger: Positioned to transport the cut crops from the cutting area to the collection mechanism, the auger plays a pivotal role in maintaining a steady flow of material, minimizing downtime during harvesting.

Feeding System: This assembly facilitates the movement of harvested crops toward the threshing unit. Its design ensures that materials are directed efficiently, preventing blockages and ensuring a consistent supply.

Lift Mechanism: Essential for adjusting the height of the harvesting equipment, this feature allows operators to adapt to varying crop conditions and terrain, promoting effective harvesting across diverse fields.

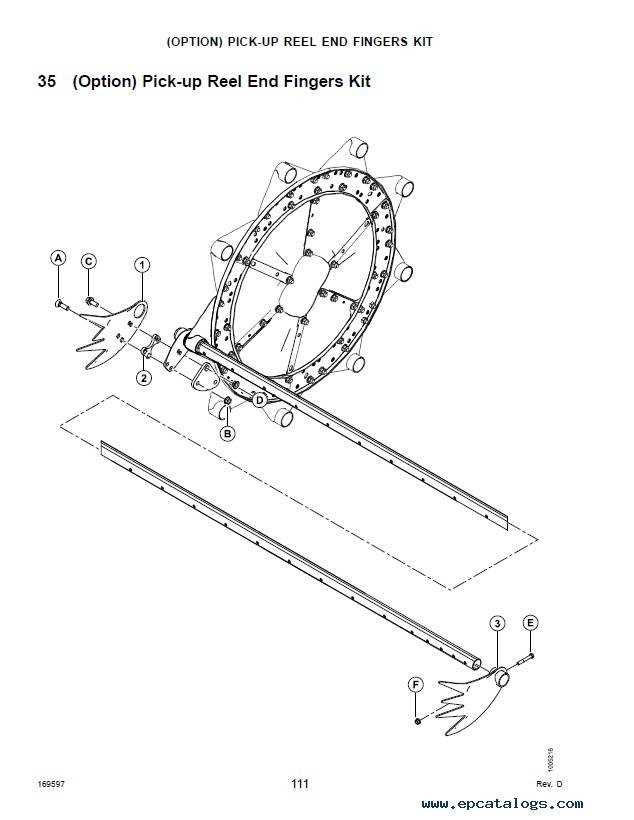

Reel: Serving to gather and guide crops towards the cutting bar, the reel is instrumental in maximizing the amount of material harvested. Its rotating arms help ensure that even lodged crops are effectively collected.

Understanding these individual components provides insight into how they work together to enhance productivity and ensure successful agricultural operations. Proper maintenance and operation of each part contribute to the overall performance of the machinery in the field.

Functionality of Each Part

This section delves into the roles and responsibilities of various components within a structured assembly. Understanding these functions is essential for effective integration and performance optimization. Each element contributes uniquely to the overall system, ensuring seamless operation and synergy.

- Main Structure: Provides the fundamental framework that supports all other components.

- Supporting Elements: Enhance stability and durability, ensuring that the entire assembly can withstand external forces.

- Control Interface: Facilitates interaction, allowing users to operate the system with ease and precision.

- Connection Mechanisms: Enable the secure attachment of components, ensuring that each part functions cohesively.

- Safety Features: Protect against potential hazards, offering security and reliability during operation.

- Indicator Systems: Provide real-time feedback on performance and functionality, assisting in monitoring and maintenance.

Each component not only fulfills its designated role but also interacts with others to create a cohesive unit. Recognizing these functions enhances comprehension of the overall system dynamics.

Importance of Proper Assembly

The significance of meticulous construction cannot be overstated. When components are brought together with precision, the overall functionality and durability of the final structure are greatly enhanced. An effective assembly process ensures that each element contributes to the collective performance, reducing the risk of malfunctions and extending the lifespan of the product.

Moreover, adhering to proper techniques fosters safety and reliability. Flawed integration can lead to serious issues, not only compromising the integrity of the assembly but also posing potential hazards to users. Therefore, investing time in careful assembly practices is crucial for achieving optimal results.

Ultimately, thorough attention to detail during the assembly phase lays the foundation for quality and performance, making it a vital aspect of any engineering endeavor.

Common Issues and Solutions

In any complex system, challenges can arise that hinder optimal performance and efficiency. Identifying these obstacles is crucial for effective troubleshooting and ensuring smooth operations. This section will address typical problems encountered, along with practical solutions to overcome them.

1. Misalignment of Components: One prevalent issue is the misalignment of various elements, which can lead to inefficiencies. To resolve this, regularly check the positioning of all components and use precision tools to adjust them accordingly.

2. Inconsistent Performance: Fluctuations in performance can stem from various factors, including wear and tear or incorrect settings. Implementing a routine maintenance schedule can help identify issues early and keep operations stable.

3. Compatibility Problems: When integrating different units, compatibility may become a concern, resulting in functionality issues. Always verify specifications before combining components and consider using adapters or alternative solutions when necessary.

4. Software Glitches: Software-related issues can disrupt the functionality of the system. Regular updates and thorough testing before implementation can significantly reduce the risk of these glitches.

5. Lack of Documentation: Insufficient or unclear documentation can complicate troubleshooting efforts. Maintaining detailed records and providing clear guidelines can facilitate better understanding and quicker resolutions.

By recognizing these common challenges and applying the suggested solutions, users can enhance efficiency and extend the lifespan of their systems.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of equipment requires consistent care and attention. Implementing effective strategies can significantly extend the lifespan of your assets, reducing the need for frequent repairs and replacements.

Regular Inspections

Conducting routine assessments is essential. This practice allows you to identify potential issues early, preventing minor problems from escalating into major failures.

Proper Storage

Storing equipment correctly protects it from environmental damage. Ensure items are kept in dry, stable conditions to minimize wear and tear, contributing to their overall longevity.

Differences in Header Designs

Various approaches to the upper sections of visual layouts significantly influence user experience and brand perception. Understanding these variations is essential for effective design and communication.

- Structural Elements:

- Logo placement can vary from centered to aligned left or right, affecting visual hierarchy.

- Navigation menus may be horizontal or vertical, influencing usability and accessibility.

- Search bars can be prominently featured or tucked away, impacting user engagement.

- Aesthetic Styles:

- Minimalistic designs focus on simplicity, using fewer elements to create a clean look.

- Rich, graphic-heavy layouts can create an immersive experience but may overwhelm users.

- Color schemes play a crucial role in setting the tone and aligning with brand identity.

- Functional Features:

- Sticky sections remain visible as users scroll, enhancing navigation.

- Dynamic elements, such as animations, can draw attention but may distract if overused.

- Responsive designs adapt to various devices, ensuring consistent functionality across platforms.

These distinctions not only affect visual appeal but also influence how users interact with content, emphasizing the importance of thoughtful design choices.

Innovations in Combine Technology

The agricultural machinery industry is witnessing a remarkable transformation driven by technological advancements. These innovations enhance efficiency, improve crop yields, and promote sustainable farming practices. Modern machines are now equipped with sophisticated features that streamline operations and reduce the environmental impact.

Automation and Precision Agriculture

One of the most significant trends is the integration of automation and precision farming techniques. Autonomous vehicles equipped with advanced sensors and GPS technology allow for more accurate field mapping and resource management. This leads to optimized planting, harvesting, and monitoring, ensuring that farmers can maximize productivity while minimizing waste.

Smart Technology Integration

The incorporation of smart technologies has revolutionized machinery operations. Data analytics and IoT (Internet of Things) applications enable real-time monitoring and diagnostics. By utilizing data collected from various sensors, farmers can make informed decisions, predict maintenance needs, and enhance overall machine performance. This results in reduced downtime and greater operational efficiency.

Impact on Harvesting Efficiency

The efficiency of agricultural operations significantly relies on the design and functionality of machinery components. Properly optimized elements can lead to improved productivity and reduced resource wastage, ultimately enhancing overall yield. Analyzing how these elements interact allows for better performance during the harvesting process.

Key Factors Influencing Performance

Several factors play a crucial role in determining how effectively crops are gathered. These include the arrangement of components, their compatibility, and the technology integrated into the machinery. Each of these aspects contributes to a seamless operation that minimizes downtime and maximizes output.

Benefits of Optimization

Enhancing the interplay between machinery components can lead to significant gains in harvesting effectiveness. When all elements work in harmony, farmers experience smoother operations, reduced labor costs, and an ultimate increase in profit margins.

Safety Considerations During Operation

Ensuring safety during the execution of any operational tasks is paramount. This involves understanding potential hazards, implementing appropriate precautions, and fostering a culture of awareness among all personnel involved. By prioritizing safety, organizations can significantly reduce the risk of accidents and enhance overall efficiency.

One key aspect of maintaining a secure environment is thorough training. Workers must be well-versed in the equipment they handle and the specific risks associated with their tasks. Regular drills and refreshers can help keep safety protocols top of mind and prepare teams to respond effectively in emergencies.

Additionally, proper maintenance of tools and machinery is crucial. Regular inspections and timely repairs prevent malfunctions that could lead to dangerous situations. It is essential to establish a routine maintenance schedule to ensure that all equipment operates smoothly and safely.

Furthermore, implementing clear communication channels among team members can greatly enhance safety. Establishing protocols for reporting hazards and encouraging open dialogue about potential risks fosters an environment where everyone feels responsible for their own safety and that of their colleagues.

Finally, a comprehensive risk assessment should be conducted before commencing any operation. Identifying potential hazards and evaluating their severity allows for the development of targeted safety measures, ensuring that all necessary precautions are taken to protect personnel and equipment alike.

Future Trends in Header Design

As digital interfaces continue to evolve, the elements that define the upper sections of websites are also transforming. Emerging patterns are focused on enhancing user experience, prioritizing accessibility, and adapting to various devices. The aim is to create a seamless interaction that resonates with the audience while providing essential information at a glance.

Minimalism and Clarity

The trend towards minimalism is gaining momentum, where simplicity reigns supreme. Designers are opting for cleaner layouts that eliminate unnecessary clutter, allowing for better navigation and quicker information retrieval. Whitespace plays a crucial role, giving each element room to breathe, which enhances overall usability. Clear typography and straightforward icons are becoming essential, ensuring that users can easily interpret the content presented.

Personalization and Dynamic Content

Another significant trend is the integration of personalized elements that cater to individual user preferences. Utilizing data analytics, designers can tailor the upper sections to display relevant content based on user behavior. This dynamic approach not only improves engagement but also fosters a sense of connection between the user and the interface. Furthermore, interactive features such as search bars and quick access links are becoming more common, enhancing functionality and user satisfaction.