Understanding the Components of a Condenser Diagram

The intricate workings of refrigeration and air conditioning systems rely on various essential elements that ensure efficient temperature regulation. Each component plays a crucial role in the overall functionality, contributing to the smooth operation of the entire mechanism. A clear comprehension of these individual elements is vital for both maintenance and troubleshooting processes.

Within these systems, specific units facilitate the transformation of gas into liquid and vice versa, highlighting the importance of their design and arrangement. Recognizing how these components interact can greatly enhance one’s ability to diagnose issues and optimize performance. Understanding the layout and function of these vital elements allows for better decision-making during repairs or upgrades.

By delving into the structural organization of these systems, one can uncover the secrets behind their effectiveness. This exploration not only aids technicians and enthusiasts but also fosters a deeper appreciation for the engineering behind modern climate control solutions. As we navigate through the key features and their interconnections, the path to mastering these systems becomes increasingly clear.

Understanding the Condenser Functionality

This section delves into the essential role played by a specific component within thermal management systems. Its primary purpose revolves around the effective transformation of gaseous substances into liquid form, ensuring optimal efficiency and performance. By facilitating heat exchange processes, this element contributes significantly to the overall functionality of various appliances and machinery.

Heat Exchange Mechanism

The mechanism of heat transfer is fundamental to the operation of this component. As vapor enters the unit, it undergoes a cooling process where thermal energy is dissipated. This transition not only enables the conversion to liquid but also maintains the required temperature levels within the system. Understanding this process highlights the importance of proper airflow and surface area to enhance efficiency.

Importance in Systems

In numerous applications, this element is critical for maintaining performance standards. Its effectiveness directly influences energy consumption and operational reliability. When functioning optimally, it ensures that the entire system runs smoothly, reducing the likelihood of malfunctions or energy losses. Regular maintenance and attention to its performance are essential for longevity and efficiency.

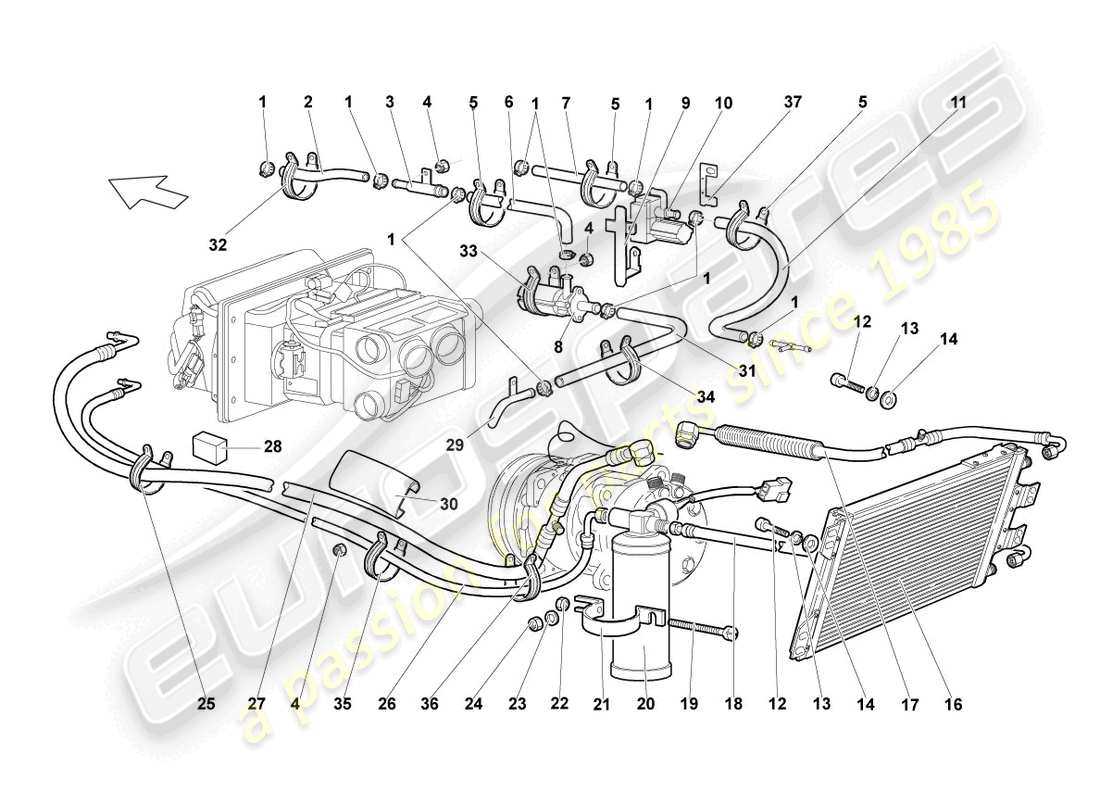

Key Components of a Condenser

The efficient functioning of a heat exchange unit relies on several crucial elements that facilitate the transfer of heat from one medium to another. Understanding these components helps in grasping how such systems operate and their importance in various applications.

| Component | Function |

|---|---|

| Heat Exchanger | Transfers heat between the working fluid and the surrounding environment. |

| Fan or Pump | Circulates air or liquid to enhance heat dissipation. |

| Shell | Provides structural integrity and contains the working fluid. |

| Coils | Increases surface area for efficient heat transfer. |

| Inlet and Outlet Valves | Control the flow of fluids in and out of the unit. |

Each of these elements plays a vital role in ensuring optimal performance, longevity, and energy efficiency of the system.

Common Types of Condensers Explained

Understanding the various types of thermal exchange units is essential for efficient cooling systems. Each design serves a specific purpose and is suited for different applications, ensuring optimal performance in diverse environments.

Air-Cooled Units

Air-cooled systems rely on ambient air to dissipate heat. These models are popular in residential and light commercial settings due to their simplicity and lower installation costs. The air circulates through fins or coils, allowing heat to transfer efficiently, making them ideal for climates with moderate temperatures.

Water-Cooled Units

In contrast, water-cooled systems use water as the cooling medium, providing enhanced efficiency in larger applications. These units often employ cooling towers or chillers to manage heat exchange, making them suitable for industrial settings. Their ability to maintain consistent temperatures under heavy loads is a significant advantage.

Choosing the right type of thermal exchange unit is crucial for maximizing efficiency and ensuring longevity in operation. Understanding the characteristics and applications of each design helps in making informed decisions for specific needs.

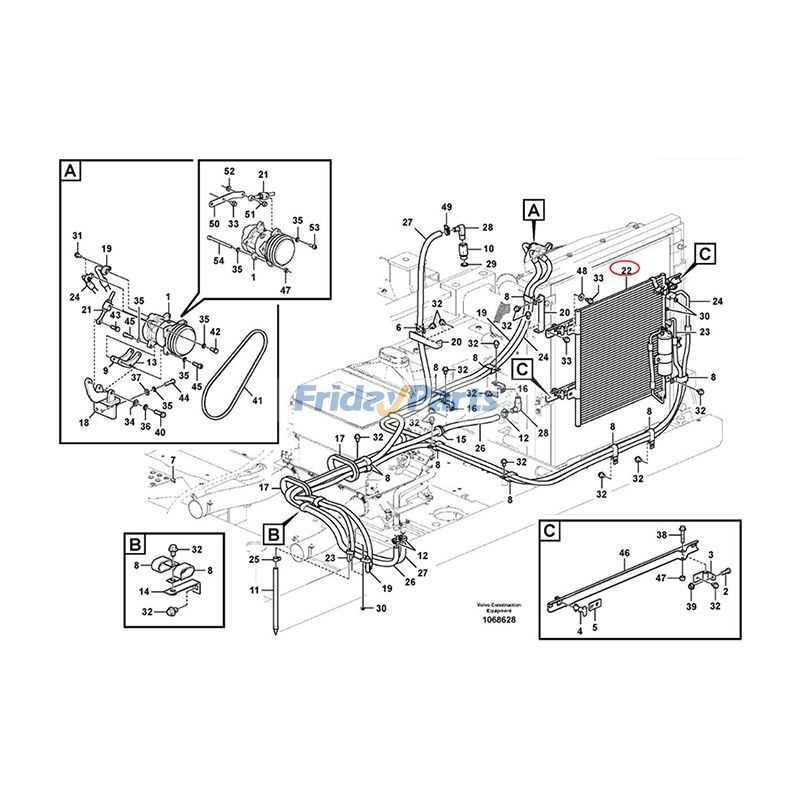

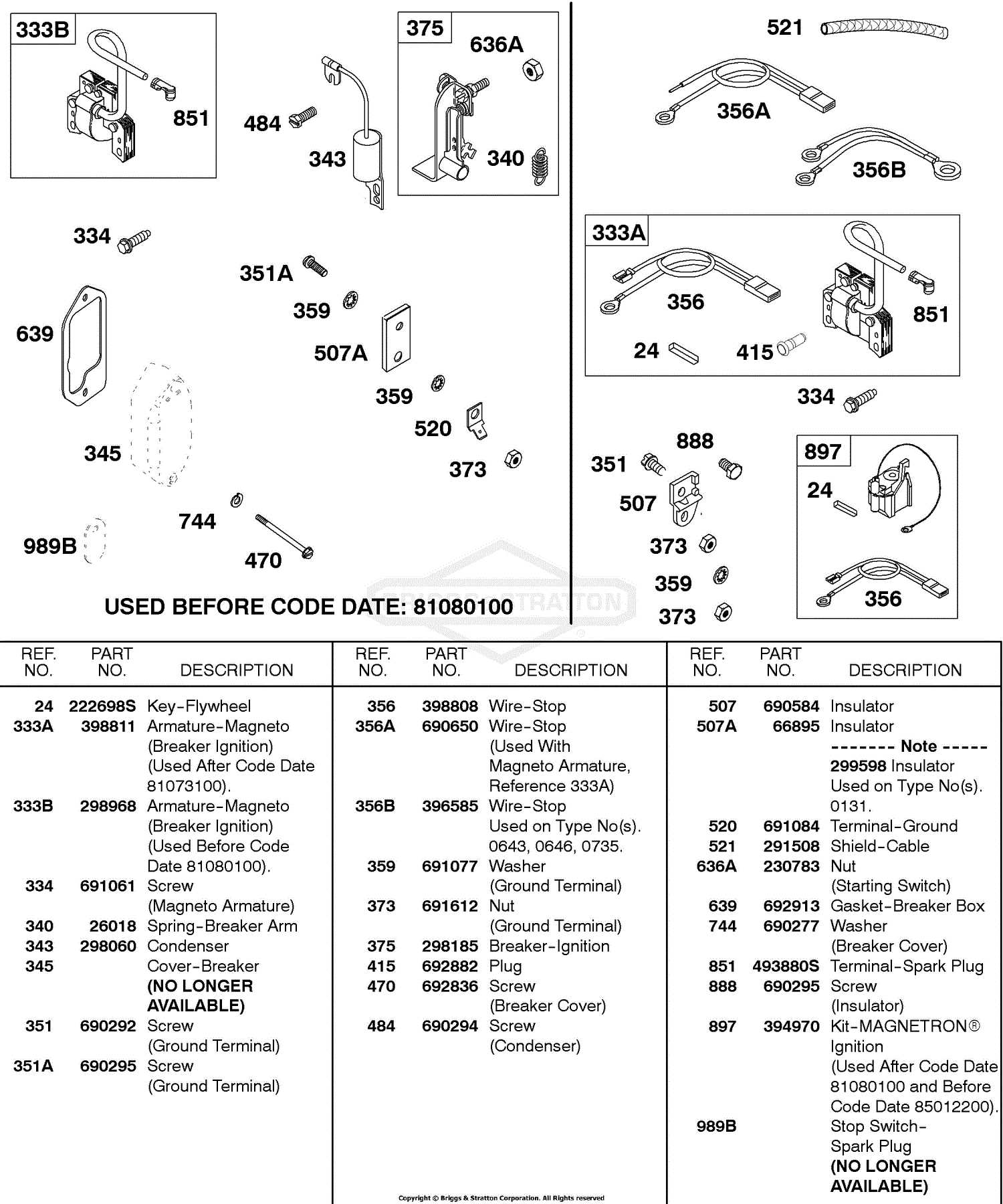

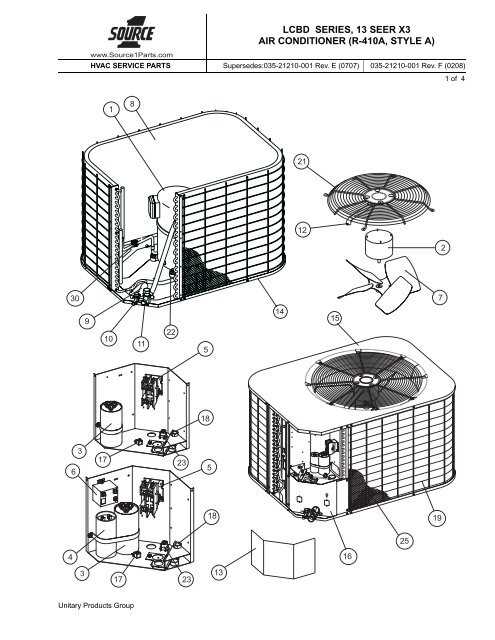

How to Read a Parts Diagram

Understanding technical illustrations can significantly enhance your ability to work with machinery and appliances. These visual representations provide a clear overview of the components involved, allowing you to identify each element’s role and function. Mastering the art of interpreting these graphics is essential for efficient maintenance and repair tasks.

Familiarize Yourself with Symbols

Each illustration employs specific symbols and notations that convey critical information. Start by reviewing the legend, which explains the meaning behind various shapes and lines. Familiarity with these symbols will enable you to quickly discern the relationships between different elements.

Follow the Layout

Typically, these illustrations are organized in a logical sequence, guiding you through the assembly or flow of the components. Pay attention to how parts connect and interact with one another. This understanding will be crucial when troubleshooting or replacing any specific element.

| Symbol | Meaning |

|---|---|

| Circle | Connection point |

| Arrow | Flow direction |

| Square | Component housing |

| Dashed line | Optional or removable part |

Importance of Proper Maintenance

Regular upkeep of essential equipment is crucial for ensuring optimal performance and longevity. Neglecting routine inspections and servicing can lead to decreased efficiency, increased energy consumption, and ultimately costly repairs. Maintaining a well-functioning system not only enhances its reliability but also contributes to a safer operating environment.

Enhanced Efficiency

Keeping components in top condition directly impacts their operational efficiency. When systems are regularly checked and serviced, potential issues can be identified early, preventing unnecessary energy loss. Timely maintenance ensures that all elements work in harmony, maximizing productivity and minimizing waste.

Cost Savings

Investing in regular care translates into significant long-term savings. By avoiding major breakdowns and the associated repair costs, organizations can allocate resources more effectively. Furthermore, well-maintained machinery often requires less energy to operate, leading to reduced utility expenses. Prioritizing maintenance is not just a smart choice; it’s an essential strategy for sustainable operations.

Identifying Faulty Parts Easily

Recognizing malfunctioning components in a system is crucial for maintaining efficiency and prolonging lifespan. With the right approach, you can swiftly diagnose issues, ensuring timely repairs and minimizing downtime. This section outlines effective methods to pinpoint defects without the need for extensive technical knowledge.

One effective strategy is to familiarize yourself with the typical characteristics of functioning elements versus those that show signs of wear or failure. Regular visual inspections, along with periodic performance checks, can help in early detection. Below is a simple guide to assist in identifying common issues:

| Observation | Potential Issue | Recommended Action |

|---|---|---|

| Unusual noises | Wear or damage | Inspect and replace if necessary |

| Leaking fluids | Seal failure | Check seals and replace if damaged |

| Inconsistent performance | Clogging or blockages | Clean or replace affected components |

| Overheating | Insufficient cooling | Examine airflow and clean filters |

By keeping these observations in mind and conducting regular maintenance, you can enhance the reliability of your equipment and ensure optimal performance over time.

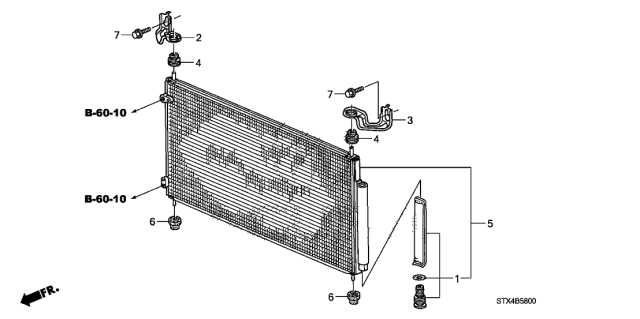

Installation Tips for New Condensers

Proper installation of cooling units is crucial for ensuring optimal performance and longevity. Adhering to best practices during the setup process can significantly enhance efficiency and minimize potential issues. This section provides essential guidance to help you achieve a successful installation.

Preparation and Tools

Before starting the installation, gather all necessary tools and equipment. Ensure that you have items such as screwdrivers, wrenches, and levelers on hand. Additionally, review the manufacturer’s guidelines thoroughly to familiarize yourself with the specifications and requirements for your particular unit. A well-planned approach will help streamline the process and reduce the likelihood of errors.

Placement and Leveling

Choosing the right location is vital for effective operation. Ensure the unit is placed on a stable, level surface to prevent vibrations and maintain functionality. Additionally, consider accessibility for maintenance and airflow around the unit. Avoid areas with excessive debris or direct sunlight to enhance performance and durability.

Upgrading Your Condenser System

Enhancing the efficiency of your cooling system is crucial for optimal performance and energy savings. An upgrade can involve various elements, including modern technology, improved materials, and better configurations. This section will explore key considerations and steps to elevate your system effectively.

Benefits of Upgrading

Investing in an upgrade offers numerous advantages. Enhanced efficiency leads to lower energy consumption and costs. Furthermore, modern systems often incorporate advanced features such as smart technology, which allows for better monitoring and control. Overall, these improvements can significantly extend the lifespan of your setup.

Key Components to Consider

When planning an upgrade, focus on essential components that can impact performance. Below is a table summarizing important elements to assess:

| Component | Benefits of Upgrading |

|---|---|

| Fans | Improved airflow and energy efficiency |

| Heat Exchangers | Better heat transfer and durability |

| Controls | Enhanced automation and user interface |

| Insulation | Reduced energy loss and improved efficiency |

Assessing these components will help you identify areas for improvement and guide your upgrade process effectively. With careful planning and execution, you can achieve a significant boost in your cooling system’s performance.

Safety Precautions When Working

Ensuring a safe working environment is crucial when dealing with complex machinery. Proper precautions can significantly reduce the risk of accidents and injuries. Awareness of potential hazards and adherence to safety protocols should be a top priority for anyone involved in maintenance or assembly tasks.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes safety goggles, gloves, and sturdy footwear. These items provide essential protection against flying debris, sharp edges, and electrical hazards.

Before starting any work, thoroughly inspect the area and tools. Ensure that all equipment is in good condition and that the workspace is clean and organized. A clutter-free environment minimizes the risk of slips, trips, and falls.

Moreover, be sure to follow all manufacturer guidelines and safety protocols. Familiarize yourself with the equipment’s operating procedures to avoid improper handling. If you are unsure about any aspect, do not hesitate to seek assistance or consult a supervisor.

Finally, remember to keep emergency contact numbers readily available. In case of an accident, prompt access to medical assistance can make a significant difference. Always prioritize safety to ensure a secure working atmosphere for everyone involved.

Future Trends in Condenser Technology

The advancement of thermal management systems is crucial in various industries, particularly in enhancing efficiency and sustainability. As the demand for innovative cooling solutions grows, new technologies and materials are being explored to improve performance and reduce environmental impact. These trends not only aim to optimize energy consumption but also to adapt to changing regulatory standards and market needs.

Innovative Materials and Designs

One of the most significant trends involves the use of advanced materials that enhance thermal conductivity and durability. Researchers are investigating nanomaterials and composites that offer superior performance while being lightweight and cost-effective. Additionally, innovative designs, such as microchannel configurations, are gaining popularity due to their ability to increase heat exchange efficiency and minimize fluid consumption.

Integration with Smart Technologies

The integration of smart technologies into thermal management systems is becoming increasingly prominent. IoT-enabled devices allow for real-time monitoring and optimization of performance, leading to greater efficiency and proactive maintenance. This shift towards automation not only enhances operational efficiency but also contributes to predictive analytics, ultimately extending the lifespan of the systems involved.