Understanding the Consew 206rb Parts Diagram for Seamless Repairs

The intricate world of sewing machinery often requires a closer examination of its individual elements to ensure optimal performance. A thorough comprehension of these components not only aids in maintenance but also enhances the sewing experience. By exploring the various sections and functionalities, one can achieve a deeper connection with their equipment.

Every sewing machine consists of numerous parts that work in unison to create seamless stitches and flawless finishes. Recognizing how each segment contributes to the overall functionality is essential for both novice and experienced users alike. This knowledge empowers individuals to troubleshoot effectively and carry out necessary repairs with confidence.

Furthermore, understanding the layout and relationships between these components can lead to the ultimate mastery of machine operation. A detailed exploration of these mechanisms will allow users to delve into the intricacies of their sewing experience, fostering both creativity and efficiency.

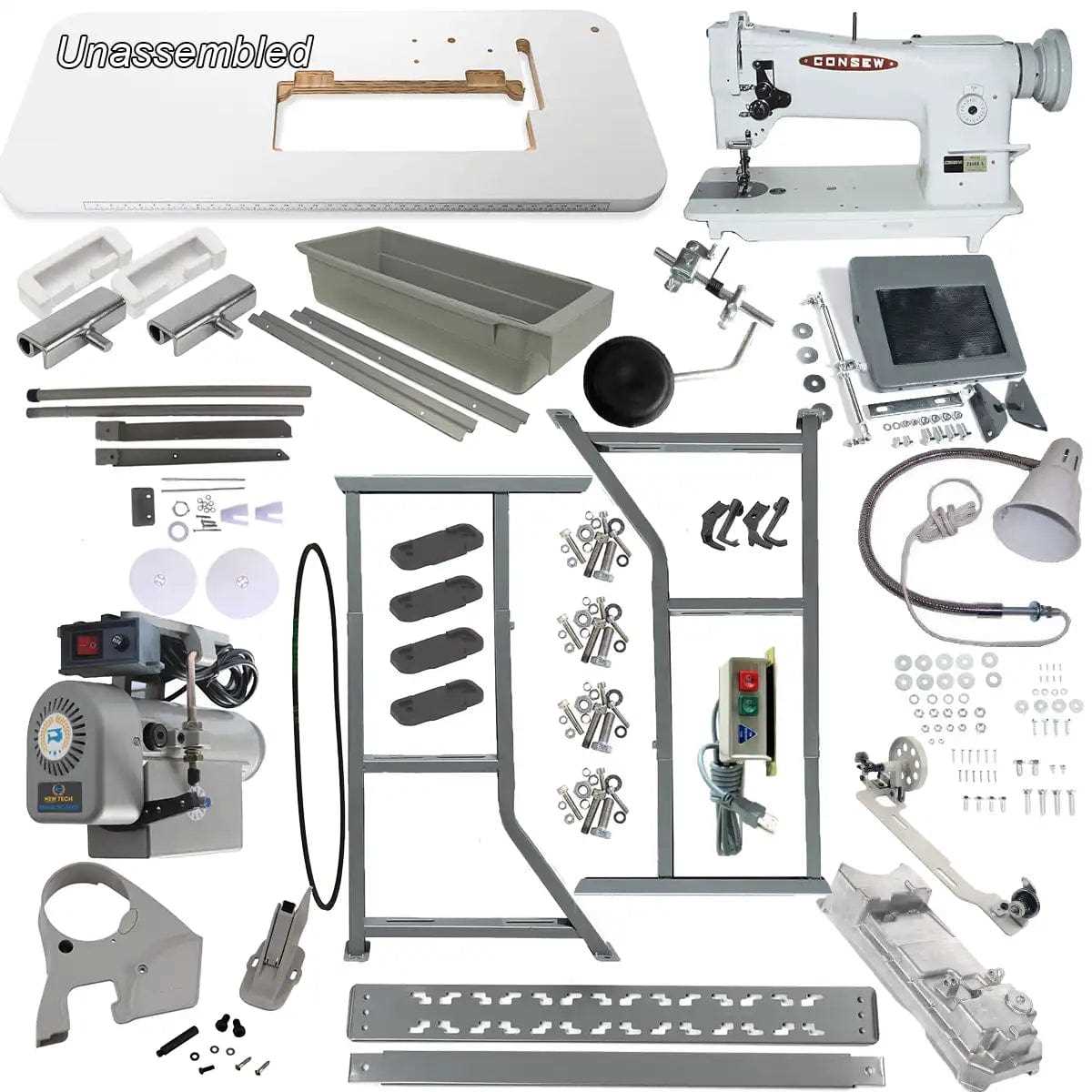

Understanding the Consew 206RB Model

This segment focuses on a specific sewing machine known for its reliability and efficiency. It caters to various sewing needs, offering users a blend of functionality and precision. Understanding its components and how they work together is essential for optimal performance.

Key Features

The machine is equipped with a robust motor, allowing it to handle thicker materials effortlessly. Versatility is one of its standout traits, making it suitable for both light and heavy fabrics. Additionally, the design promotes ease of use, making it accessible for both novices and seasoned professionals.

Maintenance and Care

Proper upkeep is crucial to ensure longevity. Regularly checking the machine’s vital components can prevent breakdowns and enhance performance. Familiarity with its inner workings will empower users to troubleshoot common issues effectively.

Key Features of Consew 206RB

This robust sewing machine is designed to meet the needs of both professionals and enthusiasts. Its innovative construction and advanced capabilities make it a preferred choice for a variety of stitching tasks, ensuring precision and durability in every project.

Versatility is one of its standout characteristics. Capable of handling multiple fabric types, from heavy materials to delicate textiles, it adapts seamlessly to diverse sewing requirements.

The stitch quality is exceptional, with an ability to produce consistent, strong seams. This ensures that finished products not only look professional but also withstand the test of time.

Ease of use is another vital aspect. With an intuitive interface and straightforward setup, even beginners can achieve great results with minimal effort.

Moreover, its durability is noteworthy. Built with high-quality materials, it is engineered to withstand heavy usage, making it a reliable companion for any sewing endeavor.

Lastly, the machine features a compact design, allowing it to fit into various workspaces without sacrificing functionality. This balance of power and convenience makes it an excellent addition to any sewing environment.

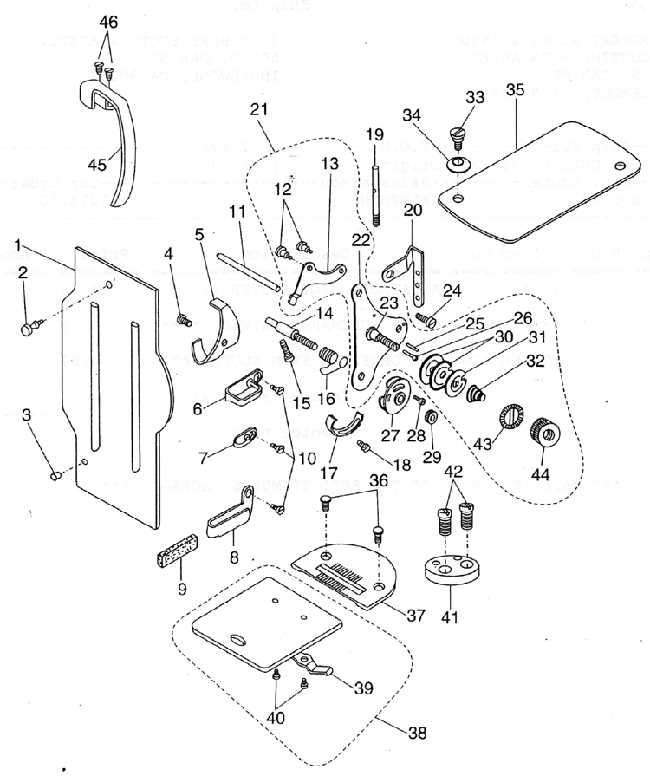

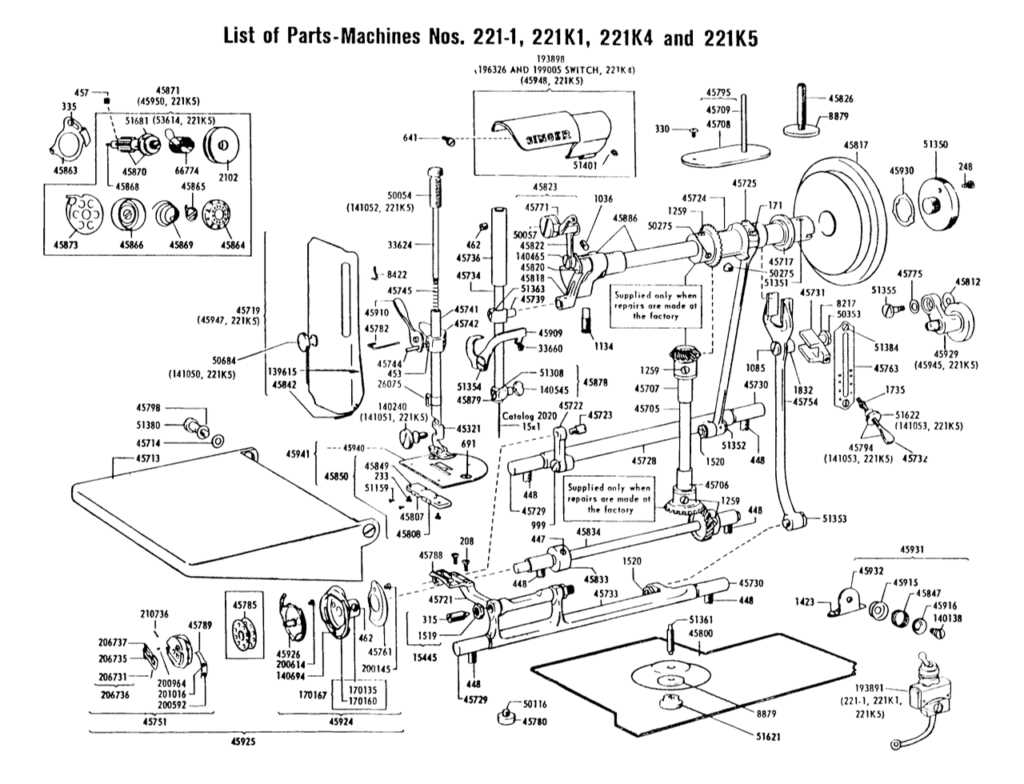

Importance of Parts Diagrams

Understanding the assembly and functionality of a machine is crucial for effective maintenance and repair. Visual representations of components serve as essential tools, helping users navigate through the intricate relationships and structures within their devices. These illustrations not only enhance comprehension but also streamline the troubleshooting process.

Benefits of Visual Guides

- Clarity: Detailed visuals provide an immediate reference, simplifying the identification of each element.

- Efficiency: Quick access to a visual map reduces time spent on locating and replacing specific components.

- Accuracy: Precise illustrations minimize the risk of errors during reassembly or repair, ensuring proper function.

- Training: New users benefit significantly from visual aids, making it easier to learn about complex systems.

Applications in Maintenance

- Facilitating routine checks by highlighting essential parts that require regular inspection.

- Aiding in the preparation for repairs by allowing users to gather necessary tools and replacements in advance.

- Enhancing communication between technicians by providing a common reference point.

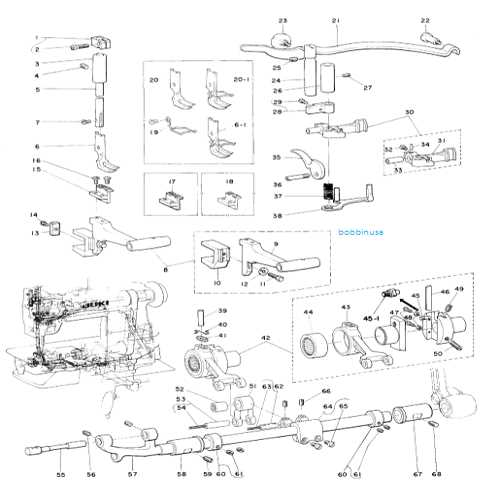

Common Components in the Diagram

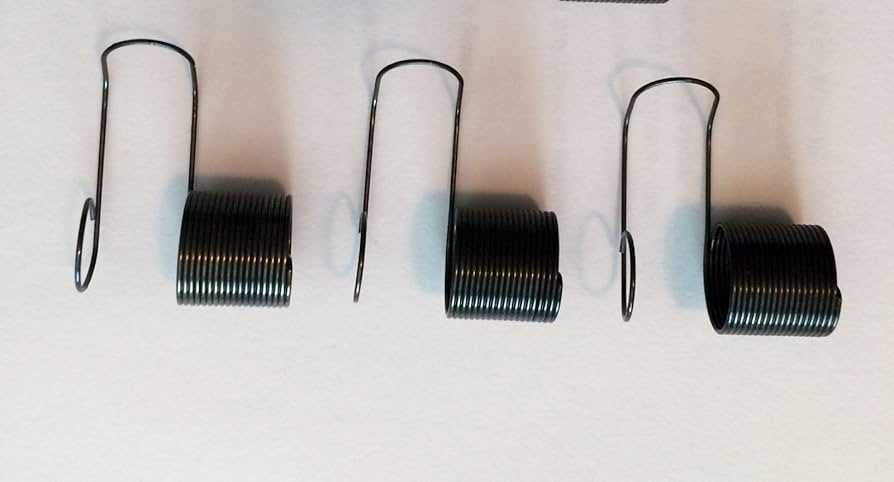

Understanding the essential elements found in mechanical sewing machines is crucial for maintenance and troubleshooting. Each part plays a vital role in the overall functionality, ensuring smooth operation and durability.

- Needle: A critical component that penetrates the fabric, allowing thread to pass through.

- Bobbin: Holds the lower thread and works in conjunction with the needle for stitching.

- Presser Foot: Presses the fabric against the feed dogs, enabling smooth movement during sewing.

- Feed Dogs: These components help in moving the fabric forward as stitches are formed.

- Thread Tension Mechanism: Ensures that the thread is held at the correct tension for balanced stitches.

Each of these components is interconnected, contributing to the ultimate performance of the machine.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear overview of the elements involved in a machine, making it easier to identify and locate specific parts. Mastering the art of interpreting these visuals can significantly enhance your ability to troubleshoot and perform upgrades.

Key Elements to Consider

- Labels: Look for descriptive titles that indicate what each section represents. These often provide vital information about the function and location of each component.

- Numbers and Symbols: Familiarize yourself with any numbering system or symbols used. They typically correlate with a list or legend that offers detailed descriptions.

- Connections: Pay attention to lines and arrows, as they often illustrate how components connect or interact with each other.

Steps to Effectively Use Illustrations

- Start by reviewing the legend or key to understand the symbols and numbers.

- Identify the main components highlighted in the visual guide.

- Cross-reference with the accompanying list for further details about each item.

- Use the visual as a roadmap when disassembling or reassembling parts.

By following these guidelines, you can navigate through complex visuals with confidence, ensuring a smoother maintenance process.

Where to Find Replacement Parts

Finding the necessary components for your sewing machine can greatly enhance its functionality and extend its lifespan. Whether you’re looking to replace worn-out elements or upgrade to better alternatives, knowing where to search is crucial for successful repairs.

Online Retailers

Numerous online platforms specialize in sewing equipment. Websites such as Amazon and eBay often have a wide variety of options available. Additionally, manufacturers’ official sites can provide the ultimate source for authentic items, ensuring compatibility and quality.

Local Sewing Supply Stores

Visiting local sewing supply shops can be a beneficial approach. These establishments often carry essential components and knowledgeable staff who can assist you in finding what you need. Building a relationship with local suppliers can also lead to valuable recommendations for specialized items.

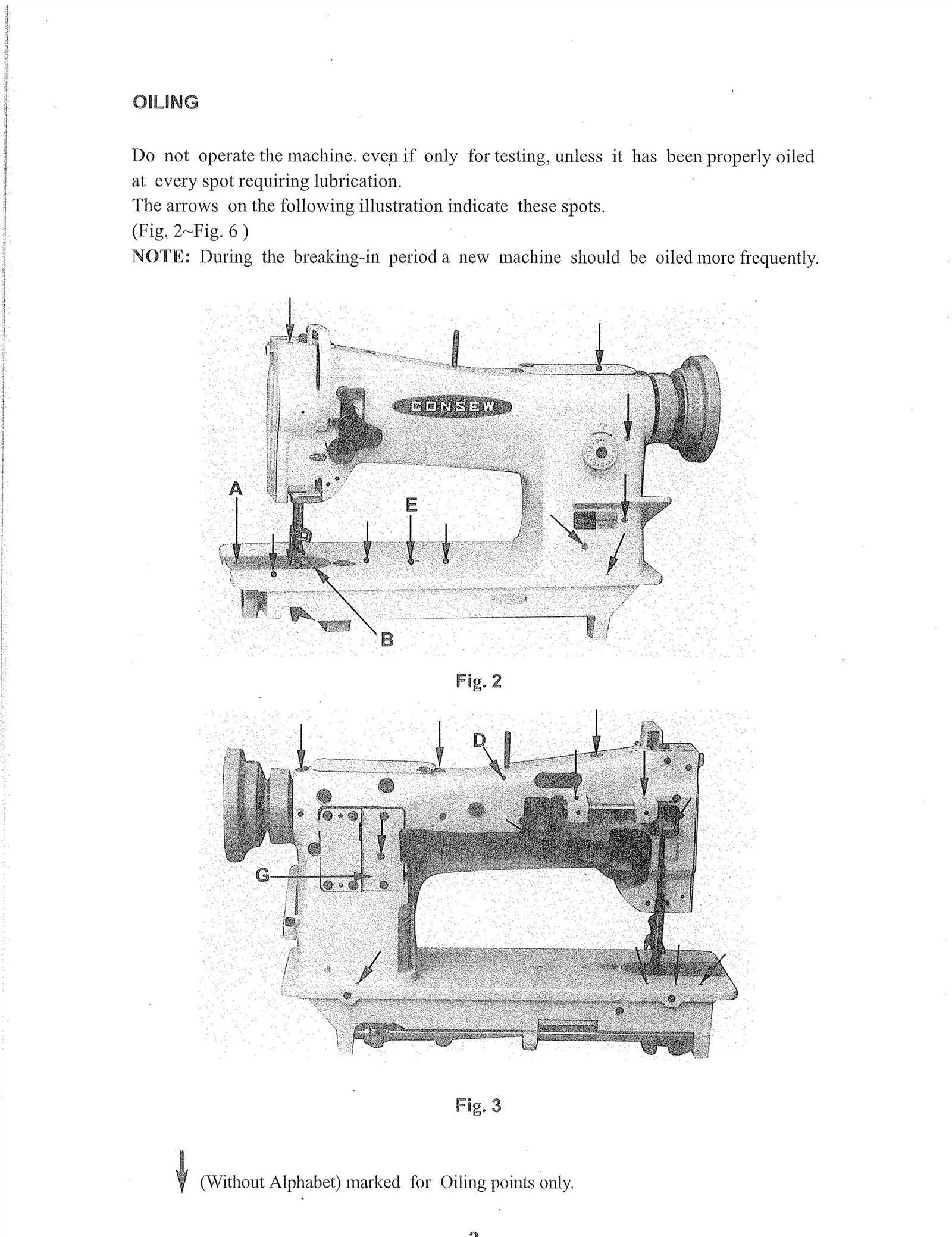

Maintenance Tips for Consew 206RB

Regular upkeep of your sewing machine is essential for ensuring optimal performance and longevity. Following a systematic maintenance routine can prevent common issues and enhance the machine’s efficiency. Here are some key practices to consider for keeping your equipment in top shape.

- Cleaning: Regularly remove dust and lint from the machine’s exterior and interior components. Use a soft brush and a vacuum cleaner attachment to reach difficult areas.

- Oiling: Apply lubricant to moving parts as specified in the manual. This reduces friction and wear, allowing for smoother operation.

- Thread Tension: Periodically check and adjust the thread tension for consistent stitch quality. Incorrect tension can lead to various sewing problems.

- Needle Replacement: Change the needle frequently, especially when switching between different fabrics. A dull or damaged needle can cause skipped stitches and fabric damage.

Implementing these simple yet effective strategies will help you maintain the performance and reliability of your sewing machine for years to come.

Troubleshooting Common Issues

When working with sewing machines, various problems can arise that hinder performance. Identifying and resolving these issues quickly can enhance efficiency and prolong the machine’s lifespan. Below are some frequent challenges encountered and steps to remedy them.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Skipped Stitches | Incorrect needle type, dull needle, improper threading | Change to the correct needle, replace if dull, re-thread machine |

| Thread Bunching | Incorrect tension, tangled thread | Adjust tension settings, clear any tangles |

| Machine Not Sewing | Power issues, jammed parts | Check power connection, inspect and clear jams |

| Unusual Noises | Lack of lubrication, foreign objects | Lubricate moving parts, remove any debris |

Benefits of Using Genuine Parts

Opting for authentic components in your equipment ensures optimal performance and longevity. Genuine pieces are crafted to meet specific standards, providing a reliable solution that enhances the overall functionality of your machinery.

Quality Assurance

When you choose original components, you receive a guarantee of quality that aftermarket options often lack. These items undergo rigorous testing and adhere to stringent manufacturing protocols, ensuring they will withstand wear and tear effectively.

Enhanced Performance

Utilizing authentic elements leads to improved efficiency. They are designed to work seamlessly with your system, minimizing the risk of malfunctions and providing the ultimate user experience.

Comparing Aftermarket vs. OEM Parts

The choice between alternative components and original manufacturer components can significantly impact both performance and longevity. Understanding the differences between these options is crucial for making an informed decision.

Quality and Performance

One of the primary factors to consider is the quality and performance of the components. Each option has its own set of advantages:

- Original Manufacturer Components: Typically adhere to strict quality standards, ensuring reliability and compatibility.

- Alternative Components: May offer enhanced features or improved performance, but quality can vary widely among different manufacturers.

Cost Considerations

Cost is often a deciding factor when choosing between these two types of components:

- Original Manufacturer Components: Usually come at a higher price point due to their guaranteed quality and brand reputation.

- Alternative Components: Often more affordable, providing an appealing option for budget-conscious consumers, though it’s important to evaluate long-term reliability.

Ultimately, the decision should align with individual needs, budget constraints, and the importance of quality in specific applications.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to troubleshooting and fixing common issues related to your sewing machine. Following these steps will help ensure that your equipment operates smoothly and efficiently.

- Identify the Problem

- Check for any unusual sounds.

- Examine stitches for consistency.

- Look for any error messages on the display.

- Gather Necessary Tools

- Screwdrivers (flat and Phillips)

- Cleaning brush

- Replacement parts if needed

- Disconnect Power

- Unplug the machine from the electrical outlet.

- Remove the foot pedal if applicable.

- Open the Access Panels

- Use a screwdriver to remove screws.

- Carefully detach any covers to access internal components.

- Inspect Internal Parts

- Check for loose connections or worn components.

- Clean any dust or lint buildup.

- Make Necessary Repairs

- Tighten any loose screws.

- Replace damaged parts with new ones.

- Reassemble the Machine

- Carefully replace all access panels.

- Secure with screws.

- Test Functionality

- Plug the machine back in.

- Run a test stitch to ensure everything is working properly.

Following this guide will not only help resolve common issues but also enhance your understanding of your equipment’s inner workings.