Understanding Crankshaft Parts and Their Functions

The functionality of an engine relies heavily on its intricate design and the various elements that work together seamlessly. This section delves into the essential mechanisms that contribute to the performance and efficiency of these vital systems. A closer look at these components reveals the sophisticated engineering that powers modern vehicles.

Within this exploration, we will highlight the critical elements that transform linear motion into rotational force, enabling the smooth operation of the entire assembly. By breaking down the structure into its fundamental segments, we can better appreciate how each plays a unique role in the overall mechanism.

Furthermore, understanding the relationship between these individual elements offers valuable insights into maintenance and optimization. A comprehensive visual representation will aid in grasping the interconnections and functions of these components, providing a clearer perspective on their importance in automotive engineering.

Understanding Crankshaft Functionality

The central component of an internal combustion engine plays a crucial role in transforming linear motion into rotational energy. This transformation is vital for powering the vehicle and facilitating movement. By examining the various functions of this element, we can appreciate its significance in engine performance and efficiency.

Key Functions

- Energy Conversion: The main task is to convert the upward and downward movement of pistons into rotational motion.

- Balance: It ensures the smooth operation of the engine by balancing forces generated during combustion.

- Power Distribution: The rotational energy is transmitted to other components, such as the transmission system, enabling the vehicle to move.

Operational Mechanics

- Rotation Initiation: The process begins when fuel ignites, forcing the piston down.

- Connecting Rod Interaction: The movement of the piston is transferred to the connecting rod, which then pushes against the central component.

- Continuous Motion: As one piston moves down, others are positioned to maintain a consistent rotational force.

Understanding these functionalities highlights the complexity and importance of this engine component in automotive engineering. Its design and efficiency directly influence overall vehicle performance.

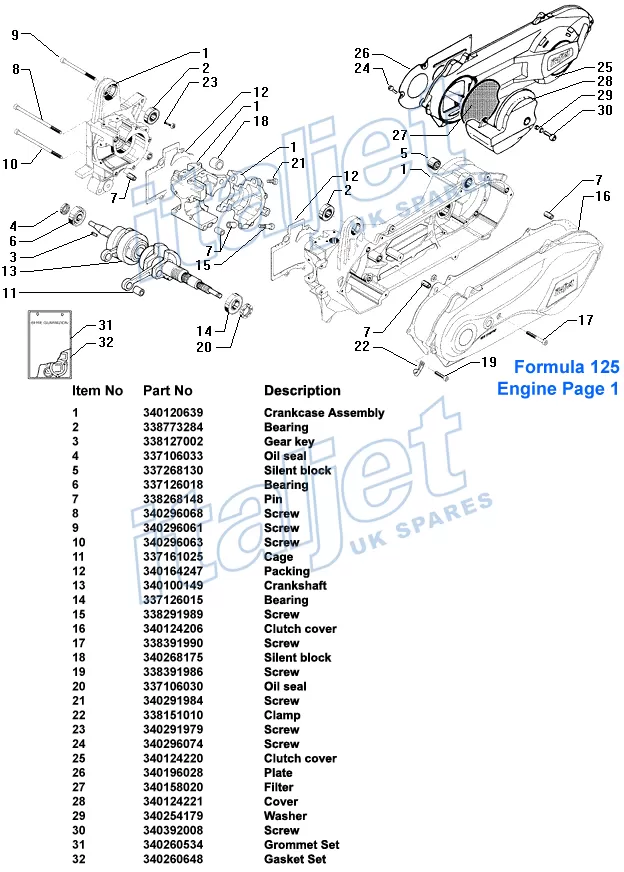

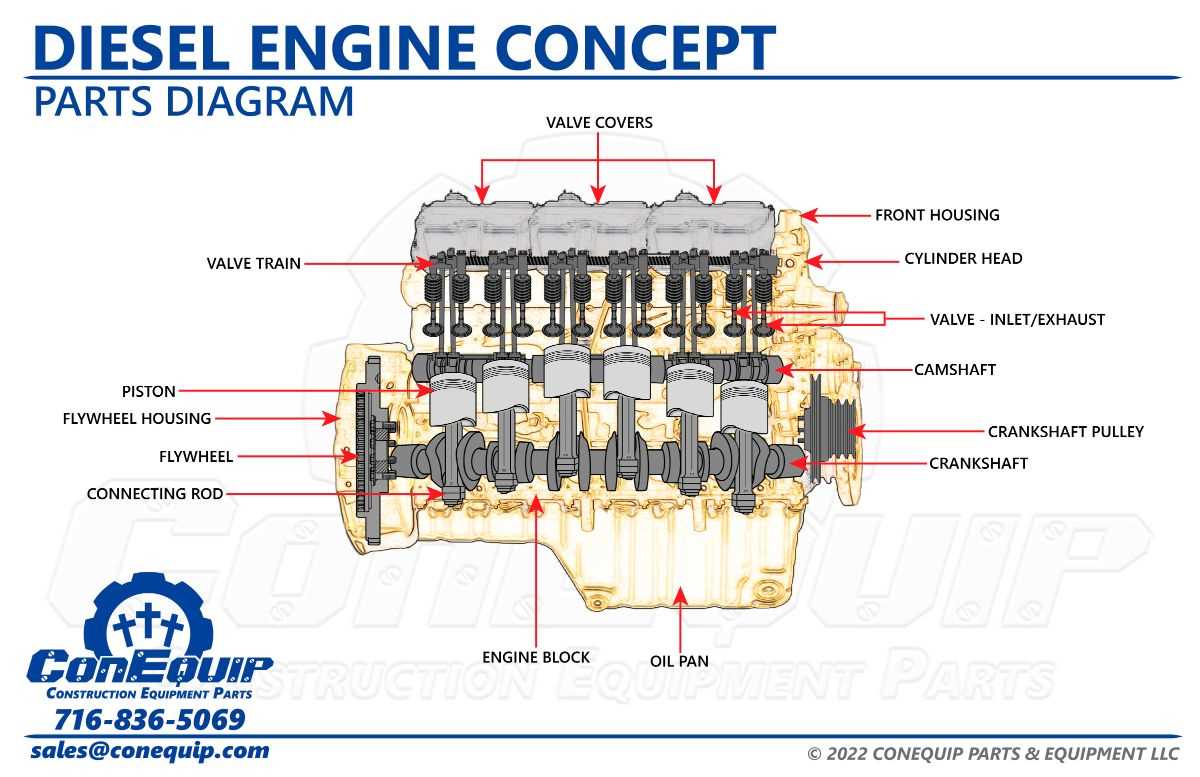

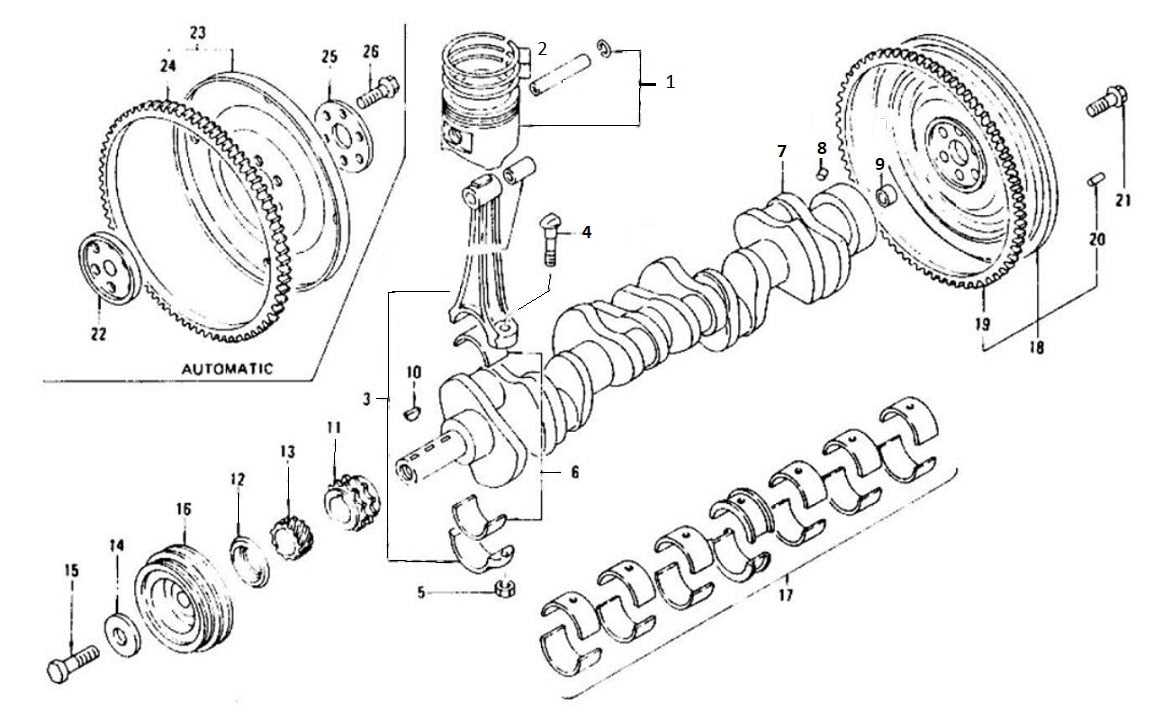

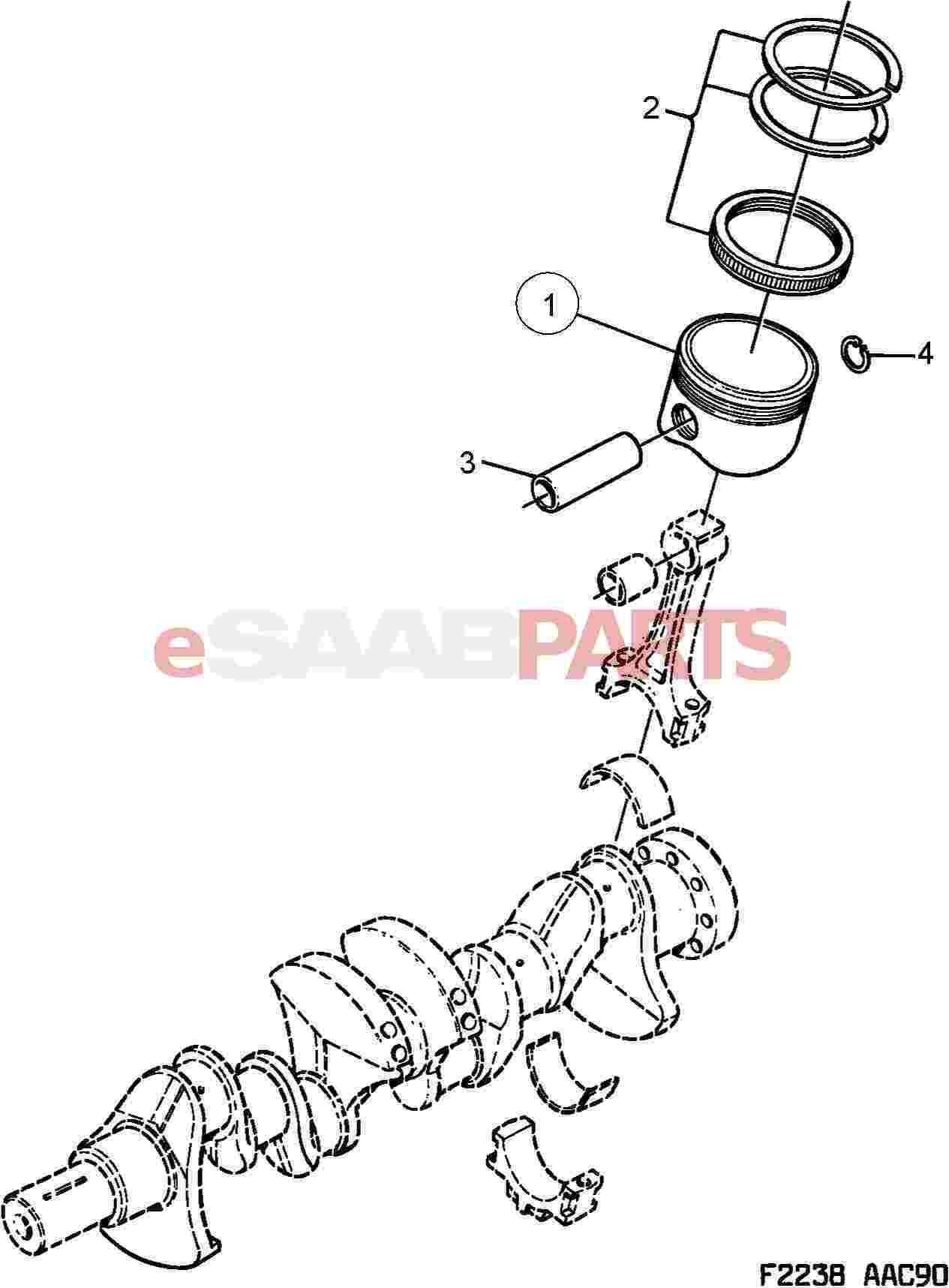

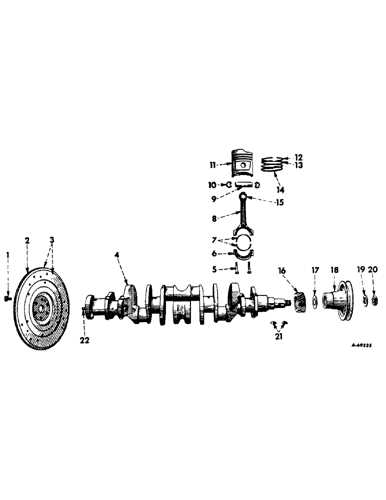

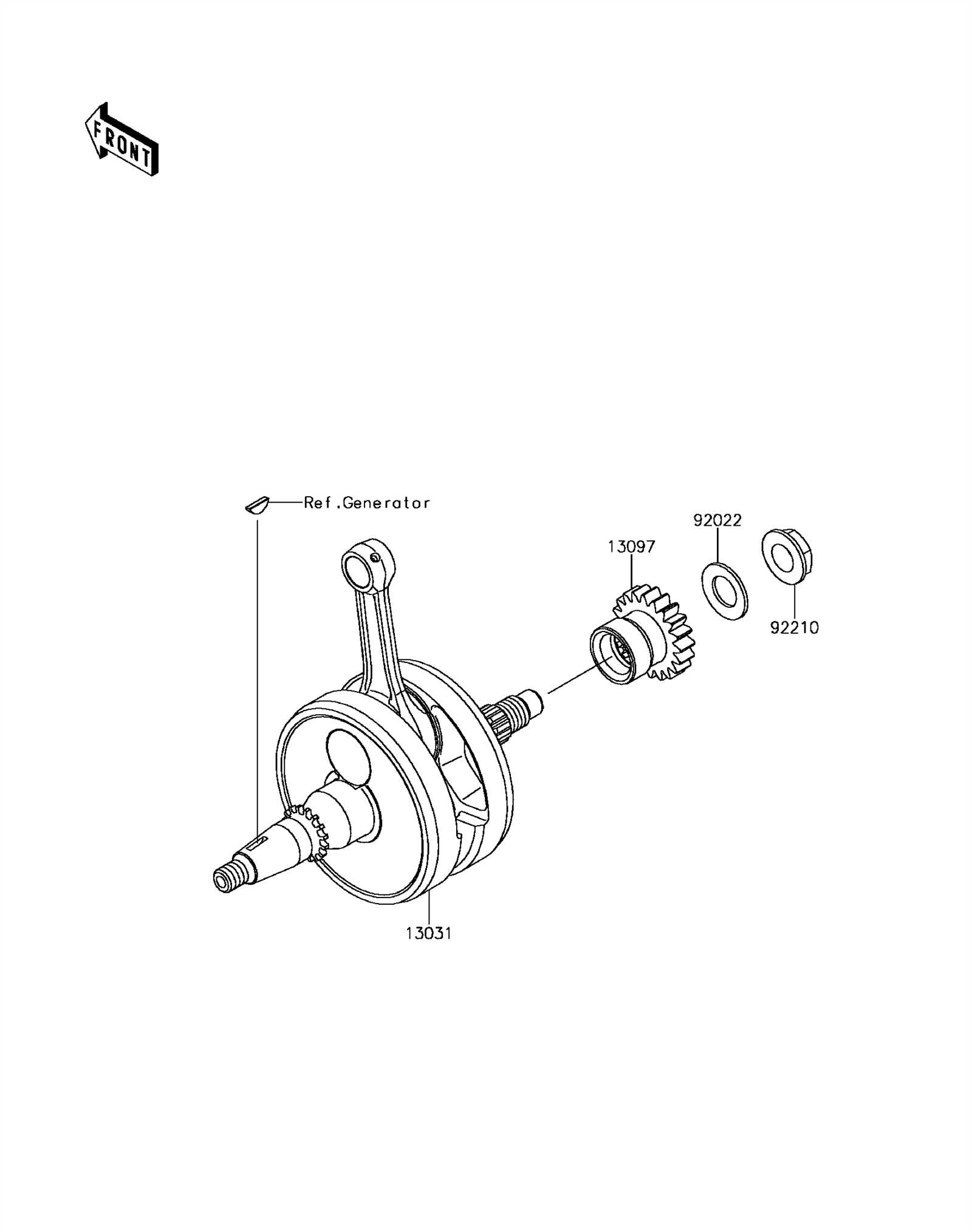

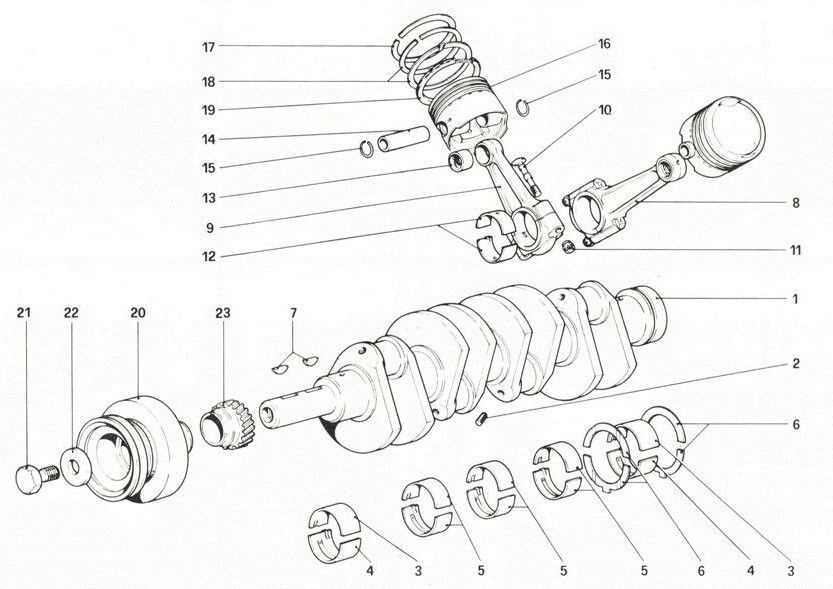

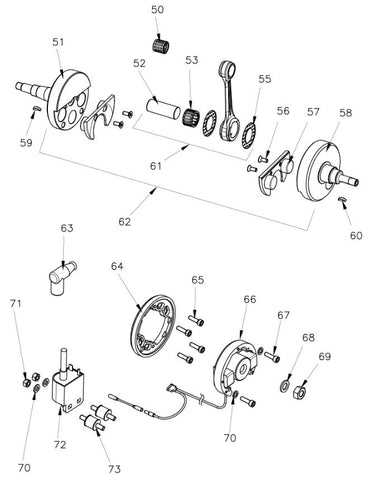

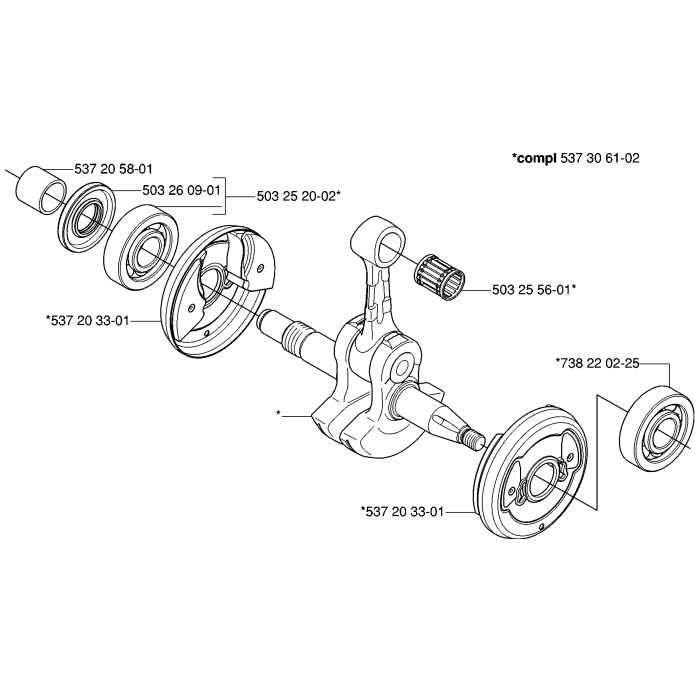

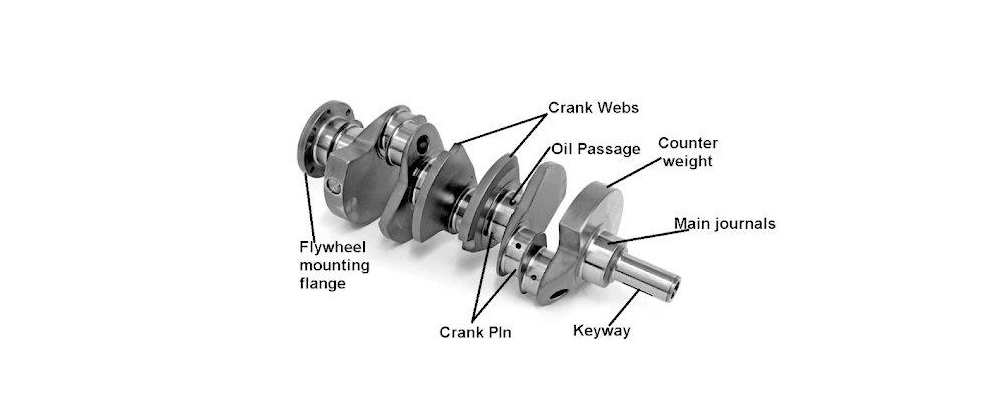

Components of a Crankshaft Assembly

The assembly in question is essential for transforming linear motion into rotational energy, playing a critical role in the overall functionality of an engine. Various elements work in unison to ensure optimal performance and durability, each contributing to the seamless operation of the mechanism.

Pins are crucial components that connect the different sections, allowing for the effective transfer of forces. They enable smooth rotation and are designed to withstand significant stress during operation.

Bearings serve as supporting structures, reducing friction between moving elements. They are vital for maintaining alignment and ensuring the longevity of the assembly, absorbing shock and minimizing wear over time.

Counterweights are strategically placed to balance the assembly, mitigating vibrations that could lead to mechanical failure. Their design is tailored to counteract the inertia generated during movement, ensuring stability.

Flanges connect the assembly to other components, providing a secure interface for attachments. Their design and material choice are critical for maintaining integrity under varying operational conditions.

Seals play a protective role, preventing the ingress of contaminants and retaining lubrication. Effective sealing is essential for the longevity and reliability of the entire assembly.

Understanding these integral components highlights their importance in achieving efficient performance and reliability in any engine configuration. Each element, meticulously engineered, contributes to the overall effectiveness of the assembly.

Common Crankshaft Materials Used

In the manufacturing of engine components, the choice of materials is crucial for performance and durability. Various substances are utilized, each offering distinct advantages that cater to specific requirements. Understanding these materials helps in making informed decisions regarding engine design and longevity.

Steel is one of the most prevalent choices, known for its exceptional strength and resistance to wear. Various alloys are employed, which enhance its mechanical properties and ensure reliability under high-stress conditions.

Cast Iron is another widely used material, prized for its excellent vibration damping qualities and cost-effectiveness. Its inherent properties make it suitable for mass production, while still providing adequate performance in many applications.

Aluminum is favored in lightweight constructions. This metal contributes to improved fuel efficiency and performance by reducing overall weight. Though not as robust as steel, advancements in alloying techniques have made aluminum increasingly viable for certain engine designs.

Composite materials are gaining traction as technology progresses. These materials can be engineered to provide a favorable strength-to-weight ratio, making them attractive for high-performance applications where every gram counts.

Ultimately, the selection of materials hinges on the specific demands of the application, balancing factors such as weight, strength, and cost to achieve optimal performance.

Types of Crankshafts Explained

Understanding the various configurations of engine rotating mechanisms is crucial for grasping how different designs influence performance and efficiency. Each variation serves specific applications, highlighting the diversity in engineering approaches to meet varied demands.

Inline Configuration: This design features a series of cylinders arranged in a straight line. It is commonly found in smaller engines, offering a compact solution with fewer moving components, which contributes to its reliability and ease of maintenance.

V-Type Configuration: Characterized by cylinders arranged in a V shape, this type allows for a more powerful and compact engine layout. It is often utilized in high-performance vehicles, providing increased power output and smoother operation at higher RPMs.

Flat Configuration: In this arrangement, the cylinders are positioned horizontally, creating a low center of gravity. This design enhances vehicle stability and is frequently used in sports cars and aircraft, where balance and aerodynamics are critical.

Rotary Configuration: Unlike traditional linear designs, this type employs a rotating mechanism, allowing for a compact engine with fewer moving parts. Commonly seen in specialized applications, it is celebrated for its lightweight and high power-to-weight ratio.

Each configuration offers unique advantages, and the choice of design significantly impacts engine performance, efficiency, and suitability for various applications. Understanding these differences helps in making informed decisions regarding vehicle design and performance tuning.

Importance of Crankshaft Positioning

Proper alignment of the rotating component in an engine is crucial for optimal performance. This positioning affects various aspects of engine functionality, ensuring smooth operation and longevity. Understanding its significance can lead to improved efficiency and reduced wear over time.

- Enhances engine balance, minimizing vibrations.

- Ensures accurate timing for fuel injection and ignition processes.

- Promotes effective power transfer from the engine to the drivetrain.

- Reduces the risk of component failure due to misalignment.

- Improves overall fuel efficiency, leading to cost savings.

In summary, the precise placement of this rotating mechanism is vital for the overall health of the engine, impacting both performance and durability. Investing in quality installation and maintenance can yield significant long-term benefits.

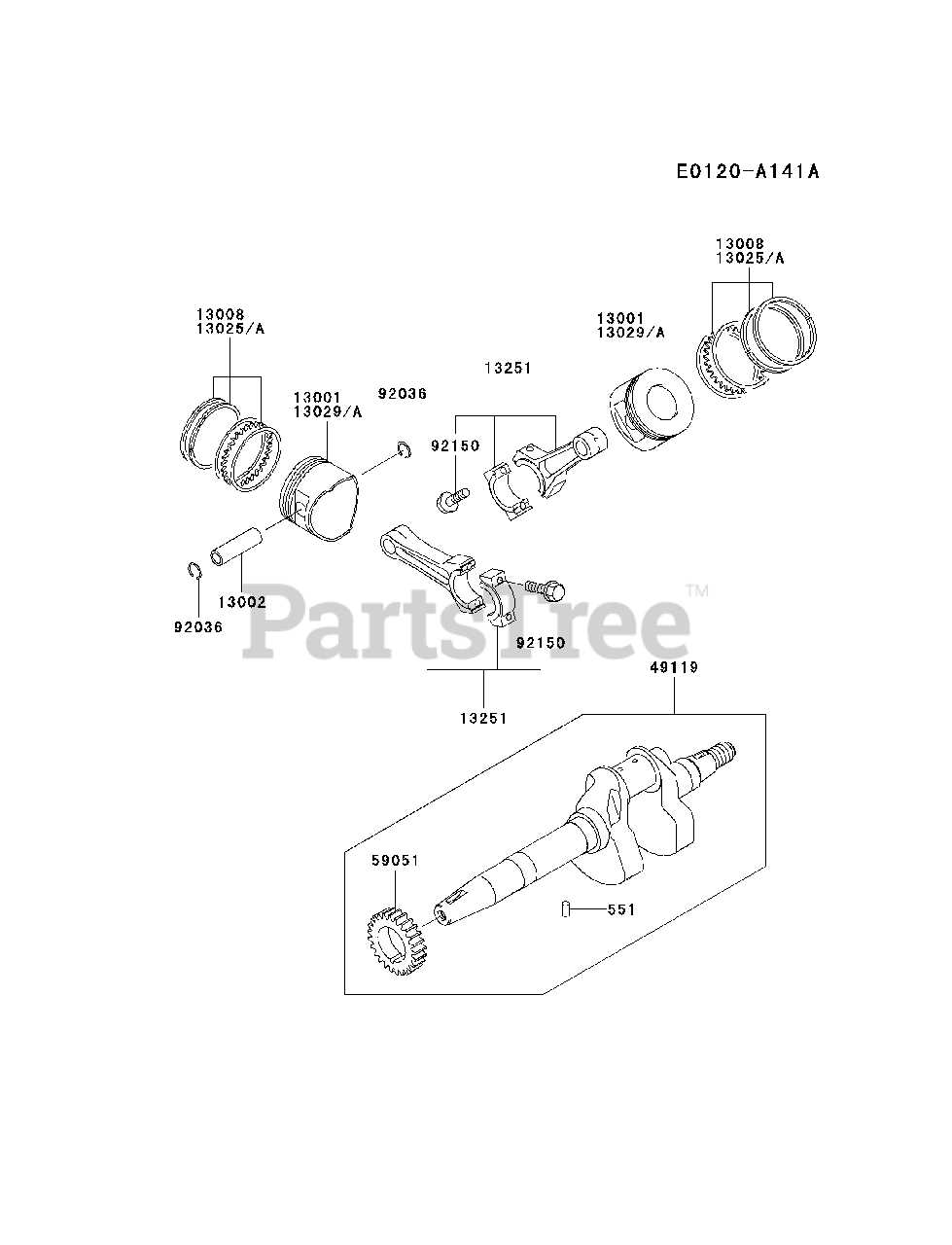

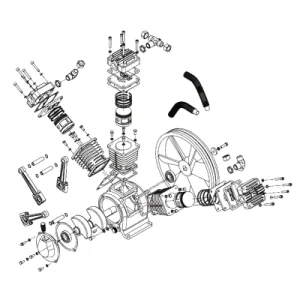

Visualizing the Crankshaft Diagram

Understanding the intricacies of engine components is essential for both enthusiasts and professionals in the automotive field. A visual representation of these elements can significantly enhance comprehension, allowing for a clearer grasp of their functions and relationships within the system.

Utilizing illustrations aids in identifying key features and interactions among various elements. Here are some crucial aspects to consider when examining these visuals:

- Components Overview: A clear depiction can highlight each element’s role and placement, making it easier to recognize their contributions to the overall mechanism.

- Functionality Insights: Visuals often illustrate how different pieces work together, emphasizing the dynamic nature of their operation.

- Maintenance Guidance: Diagrams can serve as valuable references for identifying wear or damage, helping in maintenance and repair decisions.

Incorporating detailed images with labels and annotations further enriches understanding. This method not only makes the information more accessible but also engages viewers by providing a visual learning experience.

Ultimately, mastering the visual representation of these mechanical elements can lead to improved diagnostics, enhanced performance tuning, and a deeper appreciation for the engineering behind modern vehicles.

How Crankshaft Balancing Works

Balancing rotating components is essential for ensuring smooth operation and longevity of an engine. When these elements are not properly weighted, vibrations can lead to excessive wear and potential failure. This process involves meticulous adjustments to achieve harmony in motion, ultimately enhancing performance and reducing stress on surrounding structures.

Principles of Balance

The fundamental goal of this balancing act is to equalize the mass distribution around the rotational axis. This can be achieved through various techniques:

- Static Balancing: Involves placing the component on a pivot point to determine whether it remains level or tilts, indicating uneven weight.

- Dynamic Balancing: Assesses the component’s behavior while in motion, allowing for adjustments that account for rotational forces.

- Weight Redistribution: Adding or removing material in specific areas to ensure uniformity around the axis.

Benefits of Proper Balancing

Implementing effective balancing techniques provides several advantages:

- Minimized vibrations, leading to smoother operation.

- Increased component lifespan due to reduced stress.

- Enhanced performance through improved efficiency and power delivery.

- Lower risk of mechanical failure, ensuring reliability.

Overall, a well-executed balancing process is vital for optimal functioning and durability of rotating mechanisms in any engine system.

Symptoms of Crankshaft Failure

Understanding the signs of potential failure in engine components is crucial for maintaining vehicle performance. When these vital elements begin to deteriorate, several symptoms may manifest, signaling that immediate attention is needed to prevent further damage.

Unusual Noises

One of the most common indicators is the emergence of abnormal sounds from the engine. A knocking or tapping noise, particularly during acceleration or under load, can suggest that the internal components are not functioning smoothly, often due to misalignment or wear.

Decreased Performance

A noticeable decline in engine performance is another critical symptom. If the vehicle struggles to accelerate or experiences a drop in power, it may be a sign that the rotational element is failing, affecting the overall efficiency and operation of the engine.

Addressing these issues promptly can help avoid costly repairs and ensure the longevity of the engine.

Maintenance Tips for Crankshafts

Ensuring the longevity and optimal performance of engine components requires regular attention and care. A few simple maintenance practices can significantly extend the life of critical rotating elements, preventing costly repairs and downtime.

Regular Inspections: Conduct routine checks for signs of wear, including any unusual noises or vibrations. Early detection of issues can prevent further damage.

Proper Lubrication: Always maintain adequate oil levels and quality. Using the right lubricant reduces friction and minimizes the risk of overheating, ensuring smooth operation.

Monitor Torque Specifications: When installing or reassembling, follow the manufacturer’s torque recommendations precisely. Incorrect torque can lead to component failure.

Keep Components Clean: Regularly clean surrounding areas to prevent debris from entering and causing damage. Use appropriate cleaning agents to avoid corrosion.

Check Alignment: Ensure proper alignment with other engine components. Misalignment can cause uneven wear and reduce efficiency.

Address Issues Promptly: If you notice any irregularities, such as leaks or performance drops, address them immediately. Ignoring minor problems can lead to significant failures.

Crankshaft Repair vs. Replacement

When faced with issues in the internal mechanism of an engine, the decision to either fix or substitute a damaged component can significantly impact performance and cost. Understanding the nuances of both approaches is crucial for making an informed choice that aligns with the vehicle’s needs and the owner’s budget.

Advantages of Repair

Repairing a malfunctioning element can often be more economical than outright replacement. This option may preserve the original structure, ensuring compatibility with other components. Additionally, skilled technicians can restore functionality and enhance durability through various techniques, reducing the likelihood of future failures.

When to Consider Replacement

In certain scenarios, particularly when extensive damage is present, replacement may be the more practical option. A new component often comes with warranties, offering peace of mind regarding longevity and performance. Furthermore, advancements in technology may provide upgraded versions that can improve efficiency and power.

| Aspect | Repair | Replacement |

|---|---|---|

| Cost | Generally lower | Potentially higher |

| Time | Can be quicker | May take longer |

| Warranty | Varies | Often included |

| Longevity | Depends on the extent of damage | Typically longer lifespan |

| Performance | Restored to original condition | May offer improvements |

Impact of Crankshaft on Engine Performance

The rotational component plays a crucial role in the efficiency and effectiveness of an internal combustion engine. It translates linear motion into rotational energy, significantly influencing the overall functionality and power output of the system. A well-designed element enhances performance, while deficiencies can lead to issues such as vibrations, wear, and energy loss.

Key Factors Influencing Performance

- Balance: Proper weight distribution minimizes vibrations, leading to smoother operation and improved longevity.

- Material Quality: High-strength materials enhance durability, allowing the engine to withstand higher stresses and temperatures.

- Design Geometry: The shape and configuration affect torque delivery and engine responsiveness, impacting acceleration and fuel efficiency.

Effects on Overall Engine Efficiency

Optimizing this crucial element contributes to better fuel economy and reduced emissions. Key advantages include:

- Enhanced power output due to efficient energy transfer.

- Improved thermal management, reducing overheating risks.

- Lower operational noise, creating a more pleasant driving experience.

In conclusion, the significance of this rotational component cannot be understated. Its design and functionality directly correlate with the engine’s performance, affecting everything from power delivery to environmental impact.