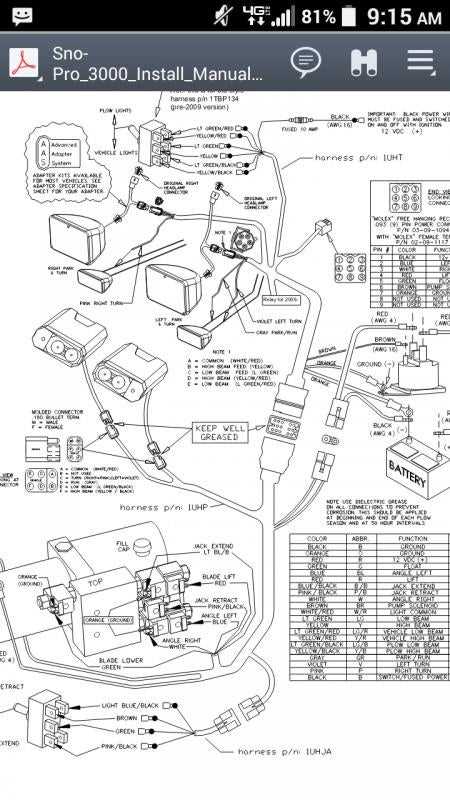

Curtis Sno Pro 3000 Parts Diagram Overview

When navigating the world of snow removal machinery, comprehending the various elements that constitute these powerful machines is essential. Each component plays a pivotal role in ensuring efficiency and performance during harsh winter conditions. Grasping the intricate relationships between these parts allows users to optimize their equipment for the best possible results.

The functionality of snow clearing devices hinges on the precise interaction of numerous mechanisms. A clear visualization of these components not only aids in maintenance but also enhances the user’s ability to troubleshoot potential issues. Recognizing how each piece fits into the larger assembly is crucial for both operators and technicians alike.

By exploring the intricate layout of these systems, one can gain invaluable insights into the operational capabilities of the machinery. This knowledge empowers users to make informed decisions regarding repairs, upgrades, and overall management of their equipment, ultimately leading to improved performance in challenging weather conditions.

Overview

This section provides an insight into a high-performance snow removal system designed for efficiency and reliability. Engineered for optimal functionality, this equipment caters to diverse winter conditions, ensuring a seamless experience for operators. Its robust construction and innovative features make it a preferred choice among enthusiasts and professionals alike.

Key Features

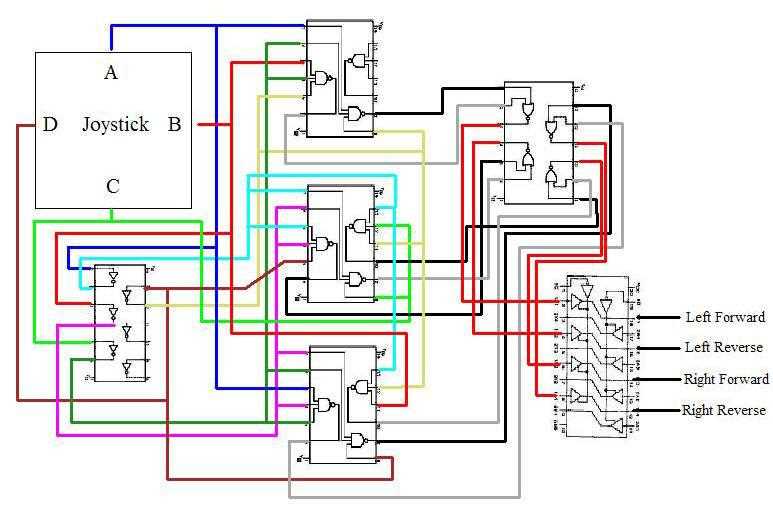

The equipment boasts a powerful engine, advanced maneuverability, and an intuitive control system. These attributes enhance productivity, allowing for swift and effective snow clearing operations. Durability is further ensured through quality materials and meticulous design.

Applications

This system is ideal for various settings, including residential areas, commercial spaces, and public facilities. Its versatility ensures that it meets the demands of both small and large-scale snow removal tasks, making it an essential tool during the winter months.

Key Features of Sno Pro 3000

This section explores the standout attributes of a highly regarded winter utility vehicle, highlighting what makes it a favorite among enthusiasts. From performance enhancements to user-friendly designs, these features elevate the overall experience for operators.

Performance and Efficiency

- Powerful engine options for superior acceleration

- Enhanced fuel efficiency, reducing operational costs

- Advanced suspension system for smoother rides on rough terrain

User-Friendly Design

- Intuitive controls for ease of operation

- Spacious storage compartments for gear and equipment

- Ergonomic seating for comfort during long trips

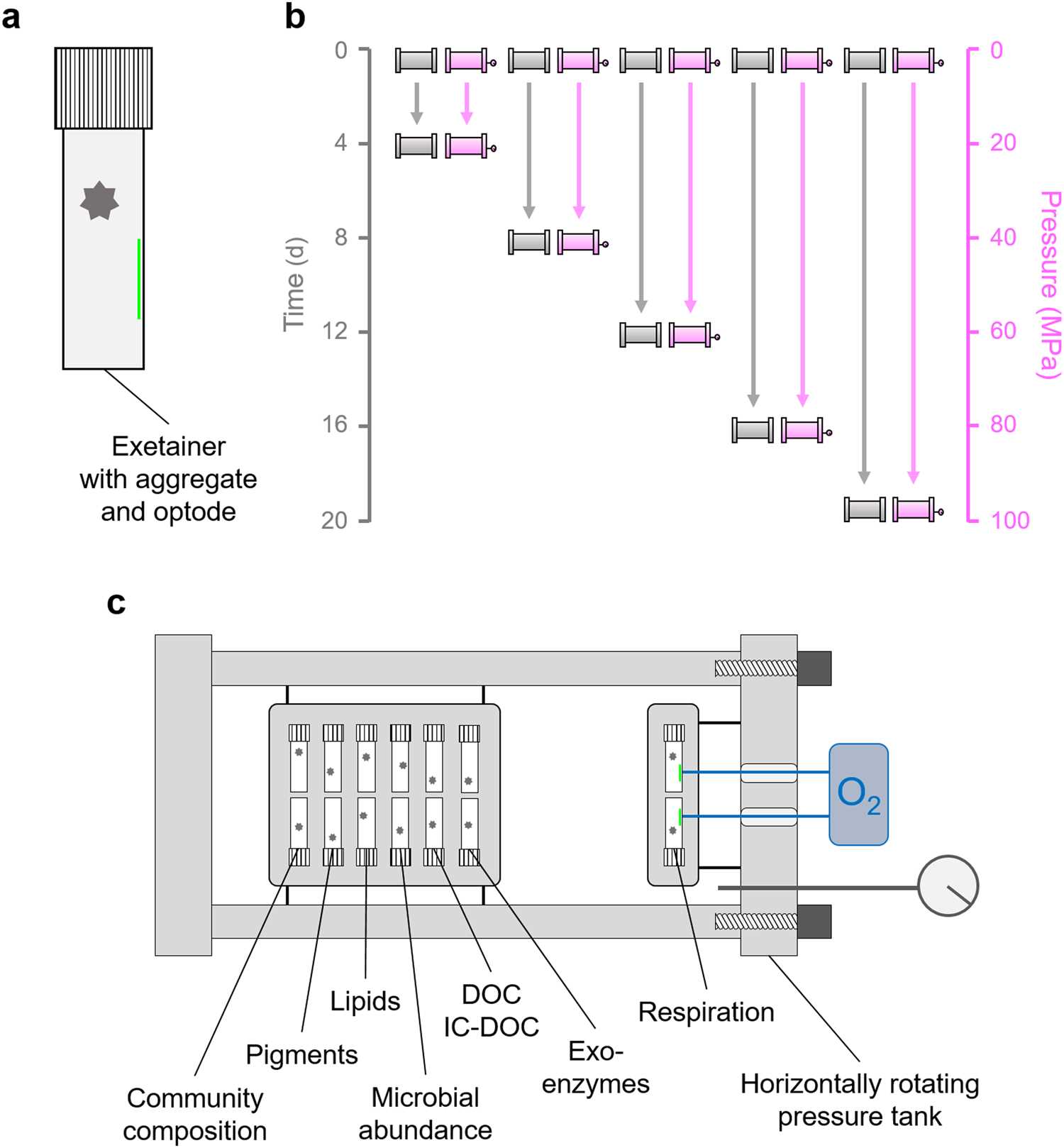

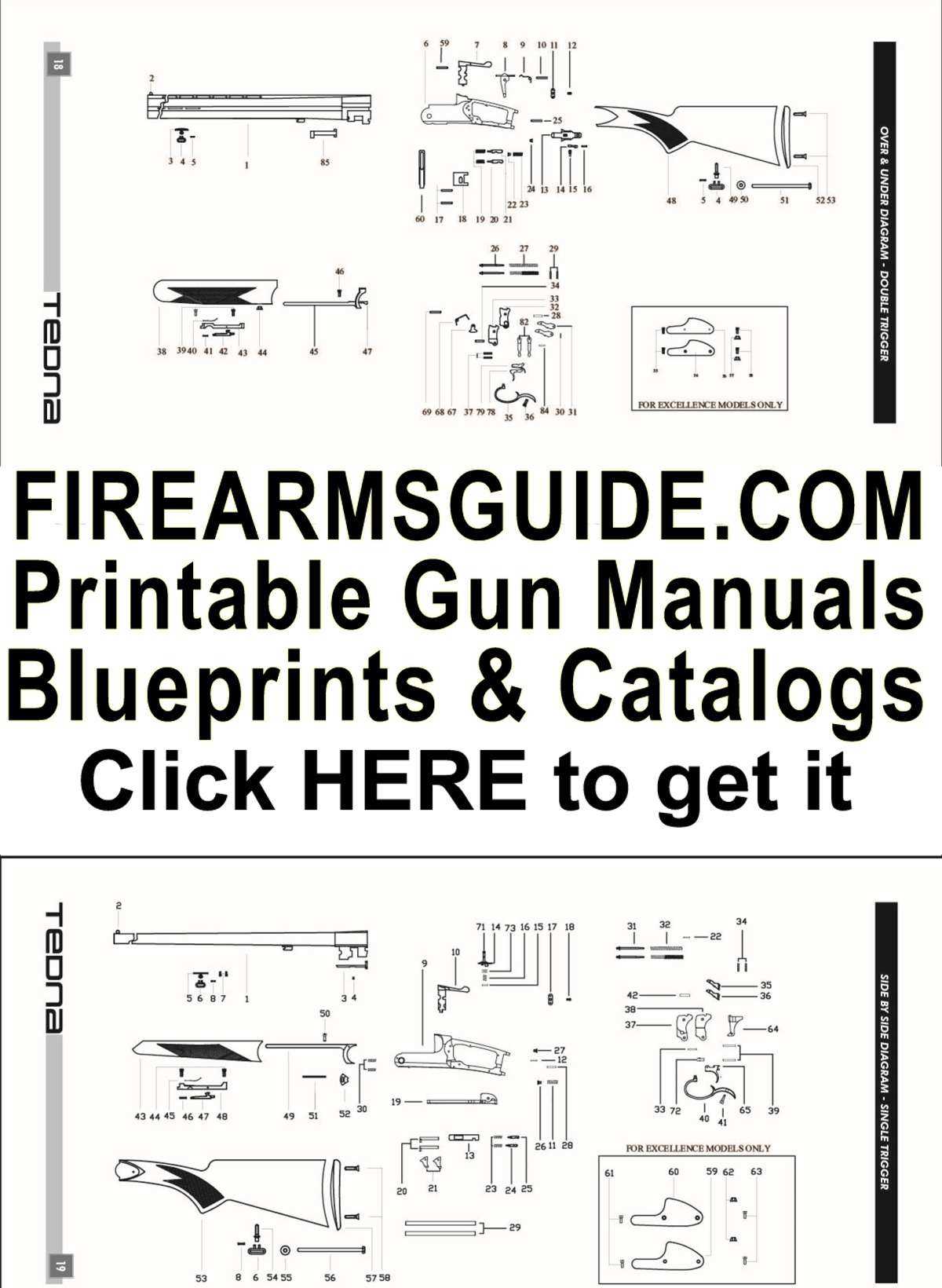

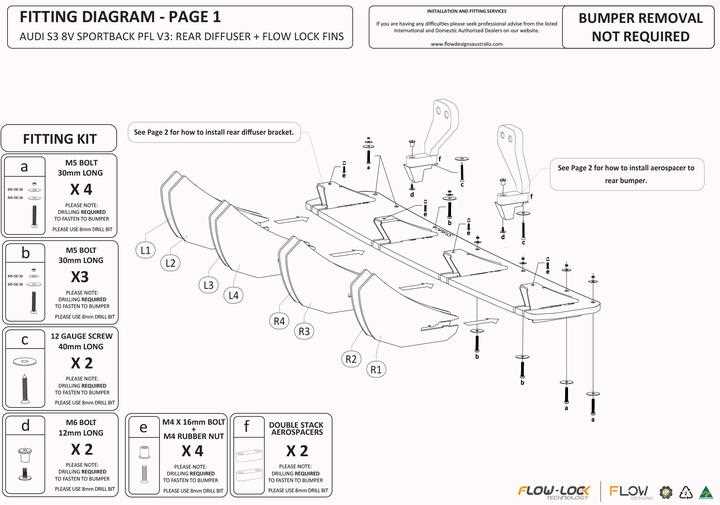

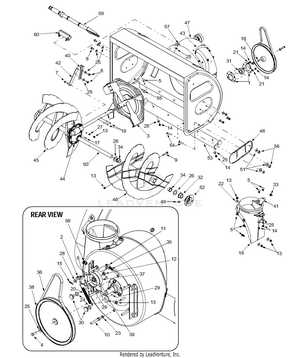

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations offer clarity, enabling users to identify each element and its function within the overall system. This knowledge not only facilitates troubleshooting but also enhances the efficiency of repairs.

Enhancing Repair Efficiency

When users have access to visual aids, they can quickly locate and assess the necessary components. This streamlines the repair process, minimizing downtime and ensuring that equipment remains operational for longer periods.

Supporting Accurate Assembly

Clear illustrations aid in the proper reassembly of machines after maintenance. By following detailed visual guides, individuals can avoid errors, ensuring that all parts are correctly positioned and functioning as intended.

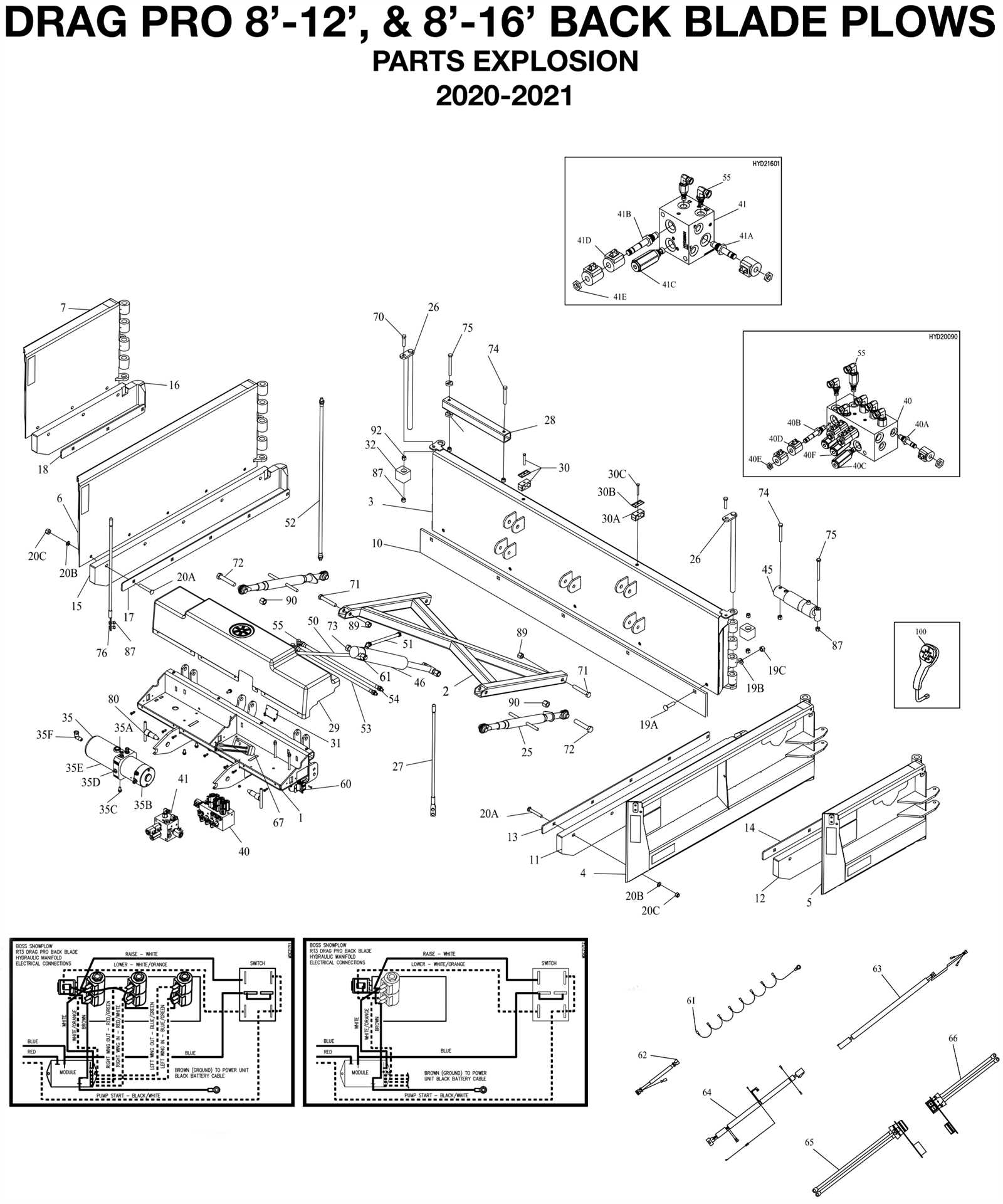

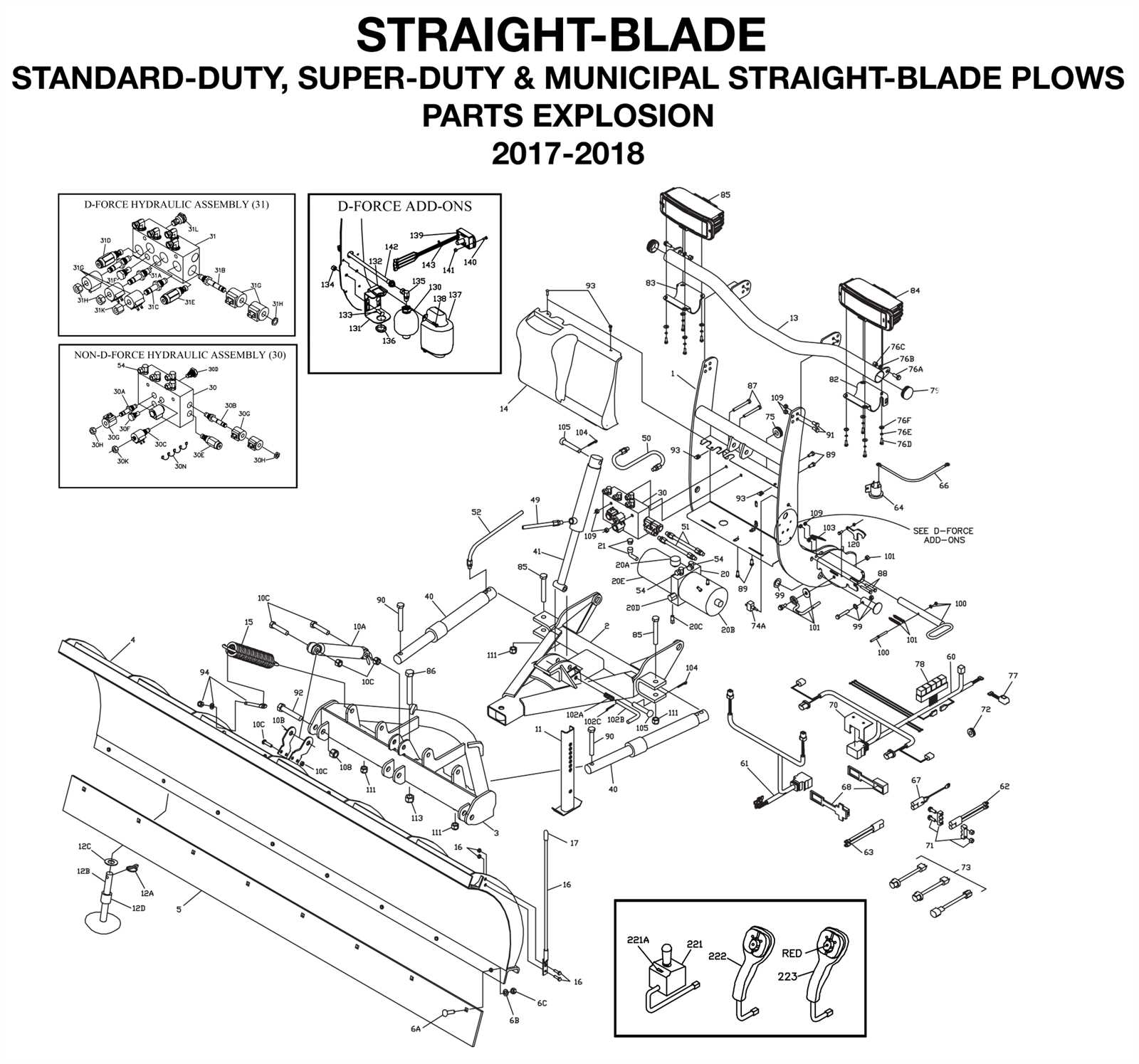

Common Components in the Diagram

This section explores the essential elements commonly found in various technical schematics related to snow removal equipment. Understanding these components is crucial for effective maintenance and operation.

- Engine: The heart of the machinery, providing the necessary power.

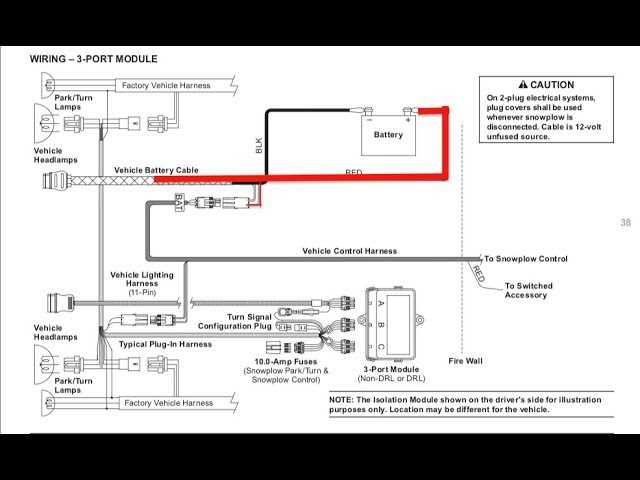

- Drive System: Responsible for transferring power to the tracks or wheels.

- Auger Assembly: A key element for snow intake, designed to break up and collect snow.

- Chassis: The frame that supports and houses all components.

- Control Panel: Interface for the operator to manage various functions.

Familiarity with these crucial parts enhances troubleshooting and improves overall functionality.

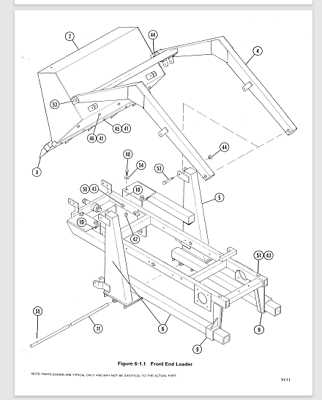

How to Read the Parts Diagram

Understanding an assembly layout is crucial for effective maintenance and repairs. This visual representation provides a detailed view of components, their arrangement, and interconnections, allowing users to identify and locate specific elements quickly. Familiarizing oneself with this illustration can streamline troubleshooting and facilitate the ordering of replacement items.

Key Elements to Note

- Labels and Codes: Each item is usually marked with a unique identifier, making it easier to reference when searching for replacements.

- Sections: The layout is often divided into sections based on functionality or assembly order, helping to simplify navigation.

- Connections: Lines or arrows may indicate how different components interact, providing insight into their function within the system.

Steps for Effective Use

- Familiarize: Take time to understand the overall layout before diving into specifics.

- Identify: Locate the part you are interested in and note its identifier.

- Cross-reference: Use the identifier to find additional information or ordering details in the accompanying documentation.

- Visualize: Consider how the component fits into the larger system to enhance your understanding of its role.

Maintenance Tips for Sno Pro 3000

Regular upkeep is essential for ensuring optimal performance and longevity of your snow equipment. Adhering to a consistent maintenance schedule can prevent breakdowns and enhance efficiency during use. Here are some essential guidelines to keep your machine in top condition.

- Inspect Components Regularly:

- Check belts and cables for wear and tear.

- Examine the electrical system for any loose connections.

- Ensure that all fluids are at the appropriate levels.

- Clean After Use:

- Remove snow and debris from the chassis and engine area.

- Wipe down surfaces to prevent corrosion.

- Lubricate Moving Parts:

- Apply lubricant to joints and bearings as recommended by the manufacturer.

- Use the correct type of oil for optimal performance.

- Check the Track:

- Inspect for cracks or missing segments.

- Ensure proper tension and alignment.

- Store Properly:

- Keep the equipment in a dry, protected environment.

- Use a cover to shield it from dust and moisture.

Following these tips can significantly enhance the reliability and performance of your machinery, ensuring a smooth and enjoyable experience on the snow.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining optimal performance and longevity. There are various resources available that cater to different needs, from online retailers to local suppliers. Understanding where to look will save time and ensure you obtain quality items.

Online Retailers

Many websites specialize in selling components for various machinery. These platforms often provide detailed descriptions, customer reviews, and competitive pricing. Some reputable online stores also offer fast shipping options and a return policy, making them a convenient choice for acquiring necessary items.

Local Distributors

Visiting local distributors can be beneficial for those who prefer hands-on assistance. These suppliers often have knowledgeable staff who can help identify the right components based on your needs. Additionally, buying locally can save shipping costs and reduce wait times.

| Source Type | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, customer reviews, often lower prices | Shipping time, potential for miscommunication |

| Local Distributors | Personal assistance, immediate availability | Limited selection, potentially higher costs |

Understanding Part Numbers and Codes

When navigating the world of mechanical components, the significance of identification systems becomes apparent. These alphanumeric sequences serve as a universal language, enabling users to locate and order the correct items efficiently. Familiarity with these codes is crucial for effective maintenance and repair, ensuring that every element fits seamlessly within its designated system.

Decoding Alphanumeric Systems

Alphanumeric designations often contain valuable information about a component’s specifications, such as size, material, and intended application. For instance, the initial letters may indicate the category or type of the item, while the subsequent numbers can represent dimensions or production sequences. Understanding this structure allows for quicker identification and comparison of similar elements.

Importance of Consistency

Consistency in coding is essential for manufacturers and users alike. Standardized identification not only simplifies inventory management but also enhances communication among technicians, suppliers, and customers. By adhering to a common coding framework, the likelihood of errors decreases, leading to improved operational efficiency.

In summary, mastering the intricacies of identification systems not only streamlines the procurement process but also empowers users with the knowledge needed for effective maintenance and operation.

Compatibility with Other Models

This section explores how various components can interchange between different equipment models, enhancing versatility and ease of maintenance. Understanding these relationships can be crucial for users seeking to optimize their machinery performance.

Similar Models

- Identifying models with shared features can lead to cost-effective solutions.

- Commonality in design may allow for the use of parts across different brands.

- Compatibility charts can aid in quick identification of interchangeable components.

Benefits of Compatibility

- Reduces downtime during repairs.

- Offers more options for sourcing replacement components.

- Enhances overall functionality through optimized parts usage.

Common Repairs and Upgrades

Maintaining and enhancing performance is essential for ensuring optimal operation. Regular attention to specific components can significantly improve reliability and efficiency. Below are some common repairs and upgrades to consider.

-

Battery Replacement:

Regularly check battery health. Replacing an old battery can enhance power and extend run time.

-

Track Adjustment:

Ensure that tracks are properly aligned. Regular adjustments can prevent uneven wear and improve traction.

-

Skid Replacement:

Inspect and replace worn skids for better handling and reduced drag.

-

Drive Belt Inspection:

Check for signs of wear on the drive belt. A worn belt can lead to performance issues, so timely replacement is crucial.

-

Engine Tune-Up:

A thorough tune-up can optimize engine performance, increasing efficiency and reducing emissions.

-

Lighting Upgrades:

Upgrading to LED lights enhances visibility and reduces energy consumption.

By addressing these common issues and considering enhancements, operators can ensure a more enjoyable and efficient experience.

Customer Reviews and Feedback

This section provides valuable insights from users who have experience with the equipment in question. Reviews and comments can reveal essential information about performance, reliability, and user satisfaction, helping potential buyers make informed decisions. Feedback from real users often highlights strengths and weaknesses that may not be evident from specifications alone.

User Experiences

Many users appreciate the durability of the machinery, noting that it withstands harsh conditions effectively. One customer mentioned, “I’ve used this model for several seasons, and it still runs like new.” Such testimonials are crucial, as they reflect the long-term reliability that buyers seek.

Areas for Improvement

While most feedback is positive, some users have pointed out areas that could be enhanced. For instance, a few have commented on the complexity of the assembly process. One review stated, “The initial setup took longer than expected, but once it was up and running, it performed exceptionally well.” Constructive criticism like this can guide manufacturers in making future improvements.

Resources for Further Assistance

Accessing detailed information and support is crucial for those seeking to enhance their understanding of specific components and mechanisms. This section provides valuable avenues for obtaining guidance and expertise, ensuring users can effectively navigate their needs.

Online Communities

Engage with enthusiasts and professionals through forums and social media groups. These platforms often feature discussions, troubleshooting tips, and shared experiences that can deepen your knowledge and resolve queries.

Manufacturer Support

Contacting the original manufacturer can be a reliable way to acquire precise information. They typically offer technical documentation, manuals, and customer service that can assist with specific inquiries or concerns.