Understanding the Components of an Alternator Diagram

The efficiency and reliability of a power generation system are fundamentally influenced by its various components. Each element plays a crucial role in the overall functionality, contributing to the generation of electrical energy. Understanding these individual elements allows for better maintenance, troubleshooting, and optimization of the entire system.

In this section, we will explore the key components involved in energy conversion, highlighting their functions and interactions. From the core mechanisms that drive the energy generation process to the auxiliary systems that ensure operational stability, a comprehensive understanding of these elements is essential for anyone involved in energy systems.

By delving into the specifics of each component, we aim to provide valuable insights that can aid in both practical applications and theoretical understanding. This knowledge not only enhances the efficiency of maintenance practices but also fosters a deeper appreciation for the intricate design of modern energy generation solutions.

Understanding Alternator Functionality

The core purpose of this device is to convert mechanical energy into electrical energy, enabling a vehicle to operate various electrical systems. By maintaining the battery’s charge and powering the electrical components, it plays a crucial role in the overall functionality of a vehicle.

This device primarily relies on the principles of electromagnetic induction. When the rotor spins within the stator, it generates a magnetic field that induces an electric current in the windings. This process ensures a steady supply of electricity, which is essential for the vehicle’s ignition, lighting, and other electrical systems.

Moreover, it incorporates a voltage regulator to maintain a consistent output, preventing overcharging and ensuring the longevity of the battery. This regulation is vital for balancing the electrical load and the generated power, allowing for efficient operation and minimizing wear on the electrical components.

Ultimately, understanding how this energy conversion device functions reveals its significance in a vehicle’s performance and reliability, highlighting the importance of regular maintenance and inspections to ensure optimal operation.

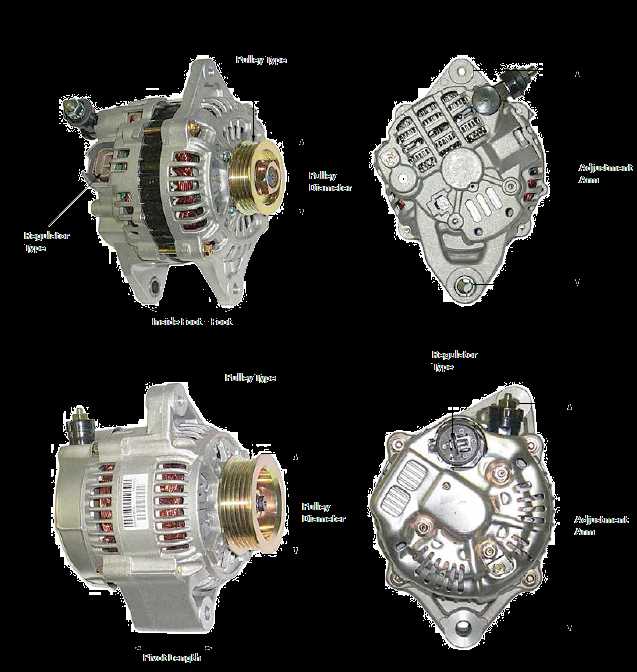

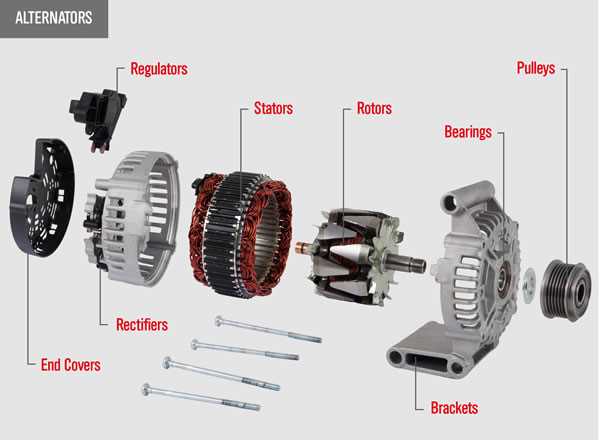

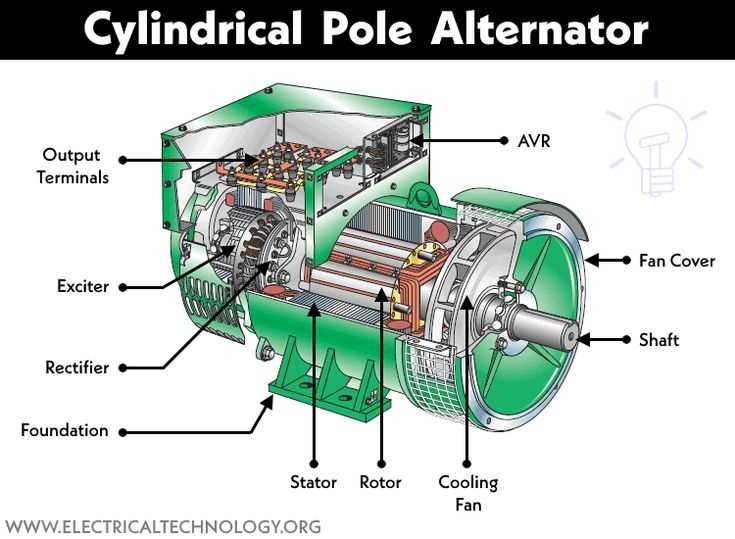

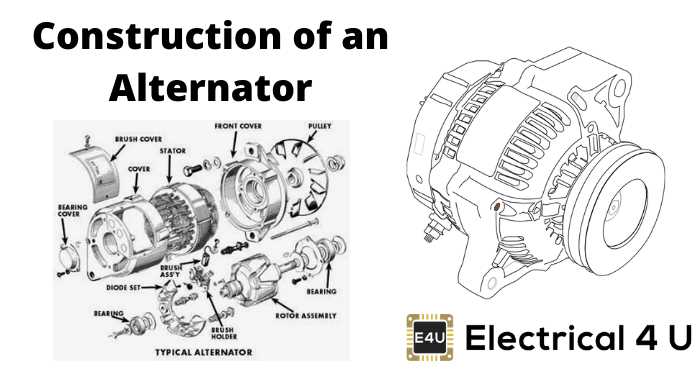

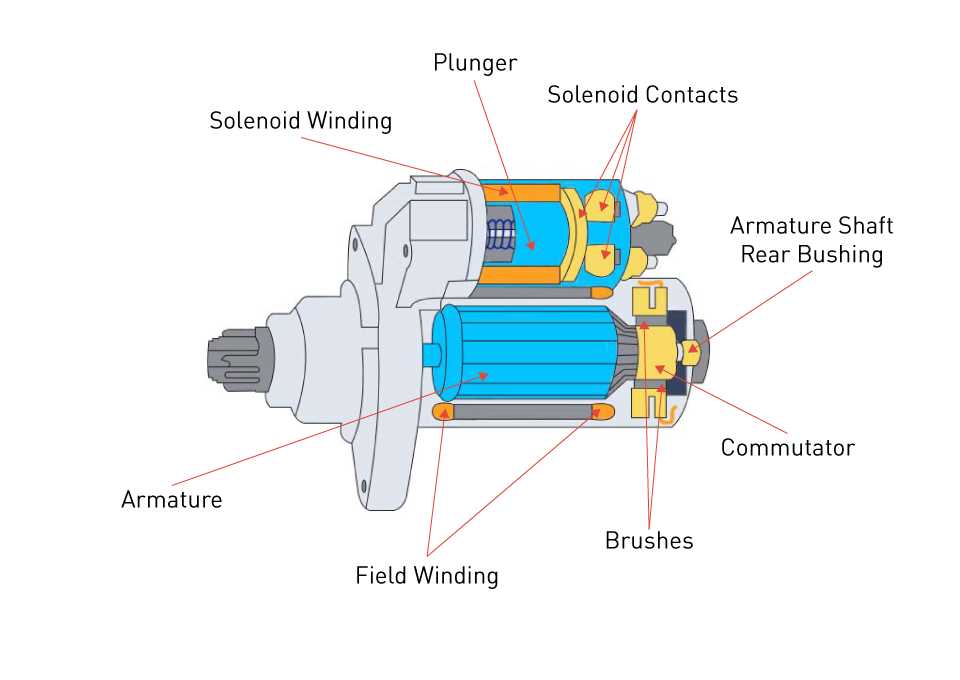

Key Components of an Alternator

Understanding the essential elements that contribute to the operation of an electrical generator is crucial for anyone interested in automotive mechanics. These components work together to convert mechanical energy into electrical energy, ensuring that the electrical system of a vehicle functions smoothly.

Core Elements

The main elements include a rotating assembly, a stationary framework, and a series of electrical windings. Each plays a significant role in generating electricity and maintaining the performance of the vehicle’s electrical system.

Functional Overview

Below is a brief overview of the essential components and their functions:

| Component | Function |

|---|---|

| Rotor | Creates a rotating magnetic field. |

| Stator | Houses the windings that generate electrical current. |

| Diode Rectifier | Converts alternating current to direct current. |

| Voltage Regulator | Maintains consistent voltage output. |

| Cooling Fan | Prevents overheating during operation. |

How Alternators Generate Electricity

The process of producing electrical energy in a rotating mechanism involves converting mechanical energy into electrical energy through electromagnetic induction. This transformation occurs in a carefully designed assembly that harnesses motion to create a flow of electrons, ultimately powering various systems.

At the core of this mechanism lies a magnetic field, which is created by permanent magnets or electromagnets. As a rotor spins within this magnetic field, a phenomenon known as induction takes place, generating alternating current (AC). This current is then transformed into direct current (DC) for practical use in automotive and industrial applications.

Below is a simplified overview of the components involved in this energy generation process:

| Component | Function |

|---|---|

| Rotor | Spins to create a magnetic field |

| Stator | Houses coils of wire that capture induced current |

| Rectifier | Converts AC to DC for usage |

| Voltage Regulator | Maintains consistent output voltage |

This intricate interplay of components ensures the efficient conversion of kinetic energy into electrical energy, facilitating the reliable operation of a wide range of electronic systems.

Types of Alternators Used Today

In the realm of modern automotive and industrial applications, various models of electrical generators play crucial roles in powering systems and supporting vehicle operations. Each type offers unique features and efficiencies suited for specific needs, ensuring optimal performance in diverse environments.

Understanding these generators helps users make informed decisions regarding their application, maintenance, and potential upgrades. Below is a comparison of the most commonly used types today:

| Type | Description | Applications |

|---|---|---|

| Brushless | Utilizes magnetic fields to generate electricity without the need for physical contacts, resulting in less wear and tear. | Heavy machinery, marine applications, and backup power systems. |

| Self-Excited | Generates its own excitation current, simplifying the design and reducing external components. | Small engines and agricultural equipment. |

| Permanent Magnet | Employs permanent magnets for excitation, enhancing efficiency and reducing the size of the unit. | Electric vehicles and compact applications. |

| Single Phase | Generates electricity in a single phase, typically used for low-power applications. | Residential power supplies and small tools. |

| Three Phase | Delivers power in three phases, providing a more stable and efficient energy supply. | Industrial applications, commercial buildings, and large machinery. |

Importance of Voltage Regulators

Voltage regulators play a crucial role in maintaining the stability of electrical systems, ensuring that devices receive a consistent and reliable power supply. These components are designed to manage the output voltage, preventing fluctuations that can lead to damage or inefficient operation of electrical equipment. By regulating the voltage, they protect sensitive components from overvoltage and undervoltage conditions.

In addition to safeguarding equipment, voltage regulators enhance the overall efficiency of power systems. They help in optimizing energy consumption, reducing waste, and improving the lifespan of connected devices. Furthermore, the reliability offered by these regulators is essential for applications in automotive and industrial settings, where consistent performance is critical.

Ultimately, the importance of voltage regulators extends beyond mere functionality; they contribute significantly to the safety and longevity of electrical systems. Their ability to provide stable voltage under varying load conditions makes them indispensable in modern technology, ensuring that devices operate effectively and reliably.

Common Problems in Alternators

Various issues can arise in the components responsible for generating electrical energy in vehicles. Understanding these common faults can help in diagnosing and addressing potential failures effectively.

Insufficient Charging

A frequent challenge faced is inadequate power supply to the battery. This problem can stem from worn-out brushes or poor connections, leading to reduced efficiency in energy transfer. Regular inspections can help identify early signs of this issue.

Strange Noises

Unusual sounds, such as grinding or squeaking, may indicate that the internal mechanisms are malfunctioning. These noises often suggest problems like worn bearings or misalignment, which can lead to further damage if not resolved promptly. It’s essential to address these audible warnings to maintain overall vehicle performance.

Signs of a Failing Alternator

Recognizing the symptoms of a malfunctioning energy generator is crucial for maintaining vehicle reliability. Various indicators can suggest that the electrical component responsible for charging the battery and powering electrical systems is not functioning optimally.

Dim or Flickering Lights: One of the first signs may be a noticeable decrease in the brightness of headlights or dashboard lights. If they appear to flicker or dim while the engine is running, this could indicate an issue with the energy producer’s performance.

Battery Warning Light: A warning light on the dashboard that resembles a battery or the word “ALT” often signals a problem. If this light illuminates while driving, it is essential to have the system checked promptly.

Electrical Failures: Malfunctions in various electrical components, such as power windows, radio, or air conditioning, may arise due to inadequate power supply. If these systems become unreliable, the underlying cause may be a failing energy converter.

Unusual Noises: Strange sounds, such as grinding or whining, can also indicate a problem. These noises may result from worn bearings or other internal issues within the electrical generator.

Difficulty Starting: A struggling engine during startup can be a sign that the electrical unit is unable to provide sufficient power to the battery. If the vehicle requires multiple attempts to start, it is advisable to investigate the energy source.

Alternator Maintenance Best Practices

Ensuring the longevity and efficiency of your energy-generating device is crucial for optimal performance. Regular upkeep not only enhances functionality but also prevents potential failures. Following systematic procedures can significantly extend the life of this essential component.

Routine Inspections

Conducting frequent examinations is vital to identify any wear or damage. Here are key aspects to focus on during inspections:

- Check for loose connections and secure all bolts.

- Inspect belts for signs of fraying or cracking.

- Examine electrical terminals for corrosion and clean them as needed.

- Monitor for unusual noises indicating mechanical issues.

Cleaning and Lubrication

Regular cleaning and proper lubrication can prevent excessive wear and maintain efficiency. Consider the following practices:

- Remove dust and debris from the outer casing using a soft brush or cloth.

- Apply lubricant to moving parts as per the manufacturer’s recommendations.

- Ensure cooling vents are free from obstructions to facilitate heat dissipation.

Diagnosing Alternator Issues

Identifying problems within the charging system is crucial for maintaining vehicle performance. Understanding the symptoms and methods of troubleshooting can help pinpoint the root cause of electrical malfunctions. This section explores the common indicators of failure and the steps to effectively assess the situation.

Common Symptoms of Failure

- Warning Lights: Dashboard indicators may illuminate, signaling a potential issue.

- Battery Problems: Frequent battery drain or failure may suggest a malfunction.

- Electrical Failures: Dimming headlights or erratic behavior of electrical components can occur.

- Unusual Noises: Grinding or whining sounds may indicate internal damage.

Troubleshooting Steps

- Visual Inspection: Check for loose connections, corrosion, or physical damage.

- Voltage Testing: Use a multimeter to measure output voltage and ensure it meets manufacturer specifications.

- Load Testing: Assess the system under load to identify performance issues.

- Component Testing: Evaluate individual components for functionality, including diodes and brushes.

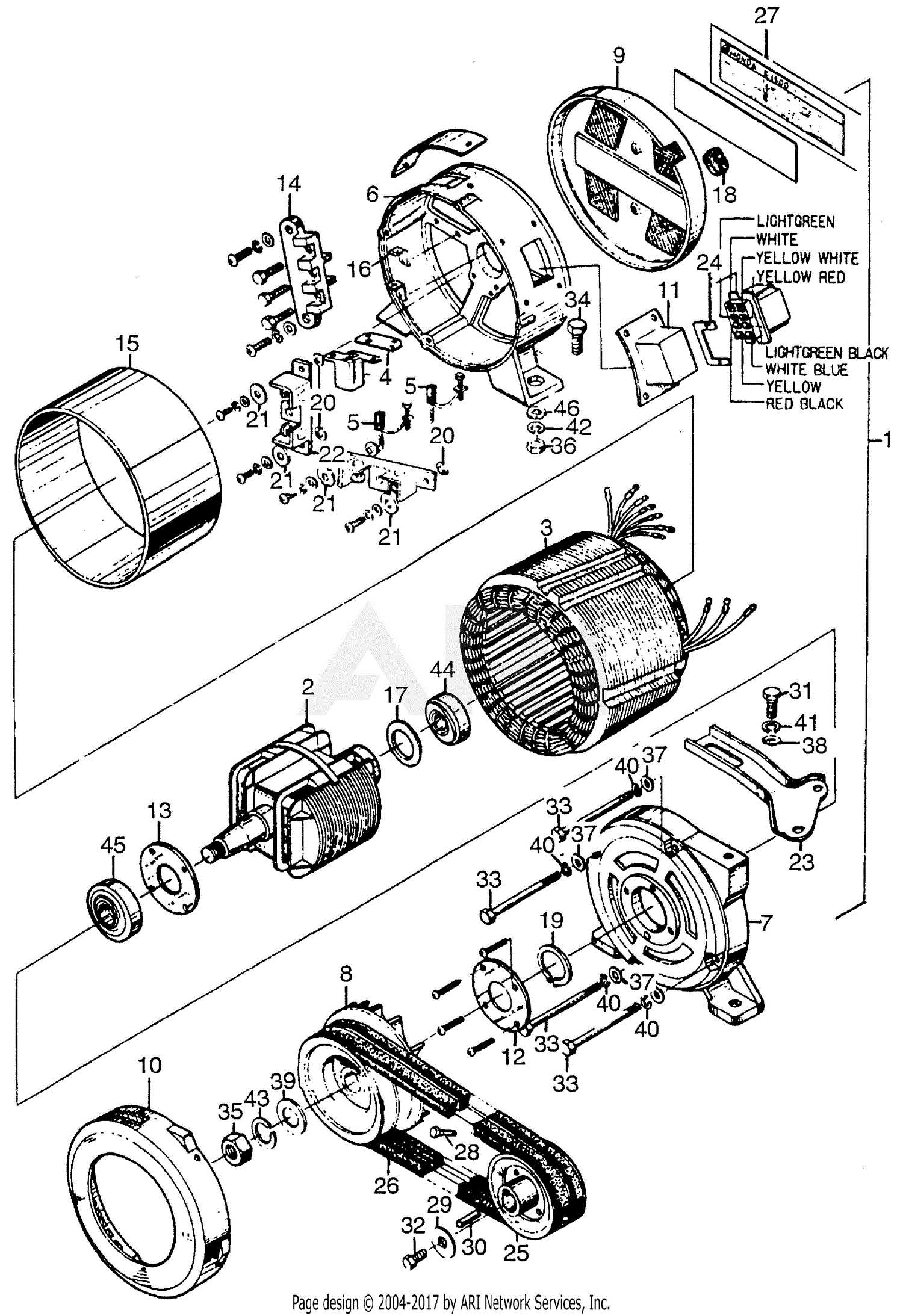

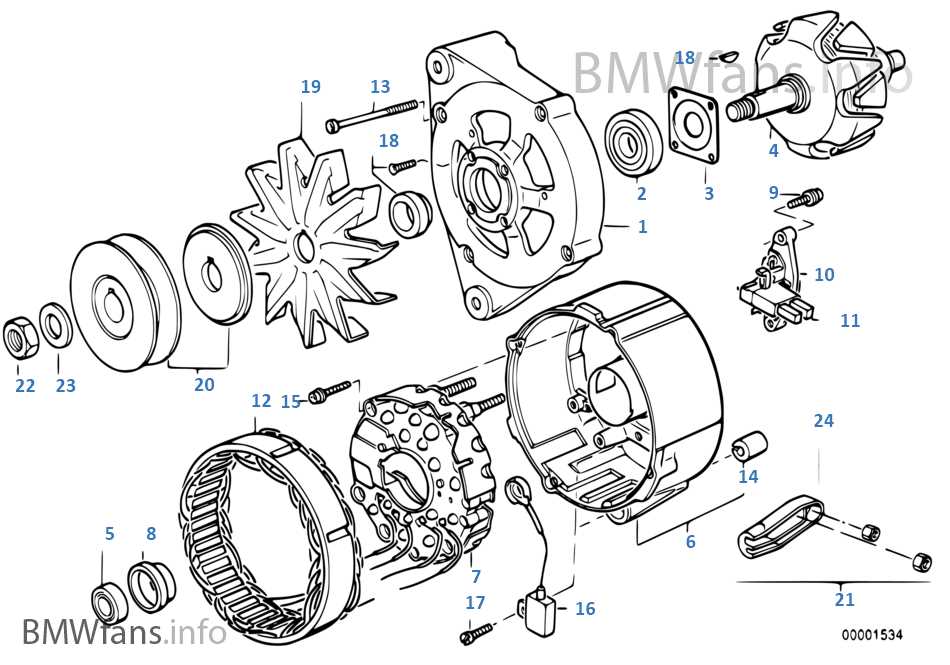

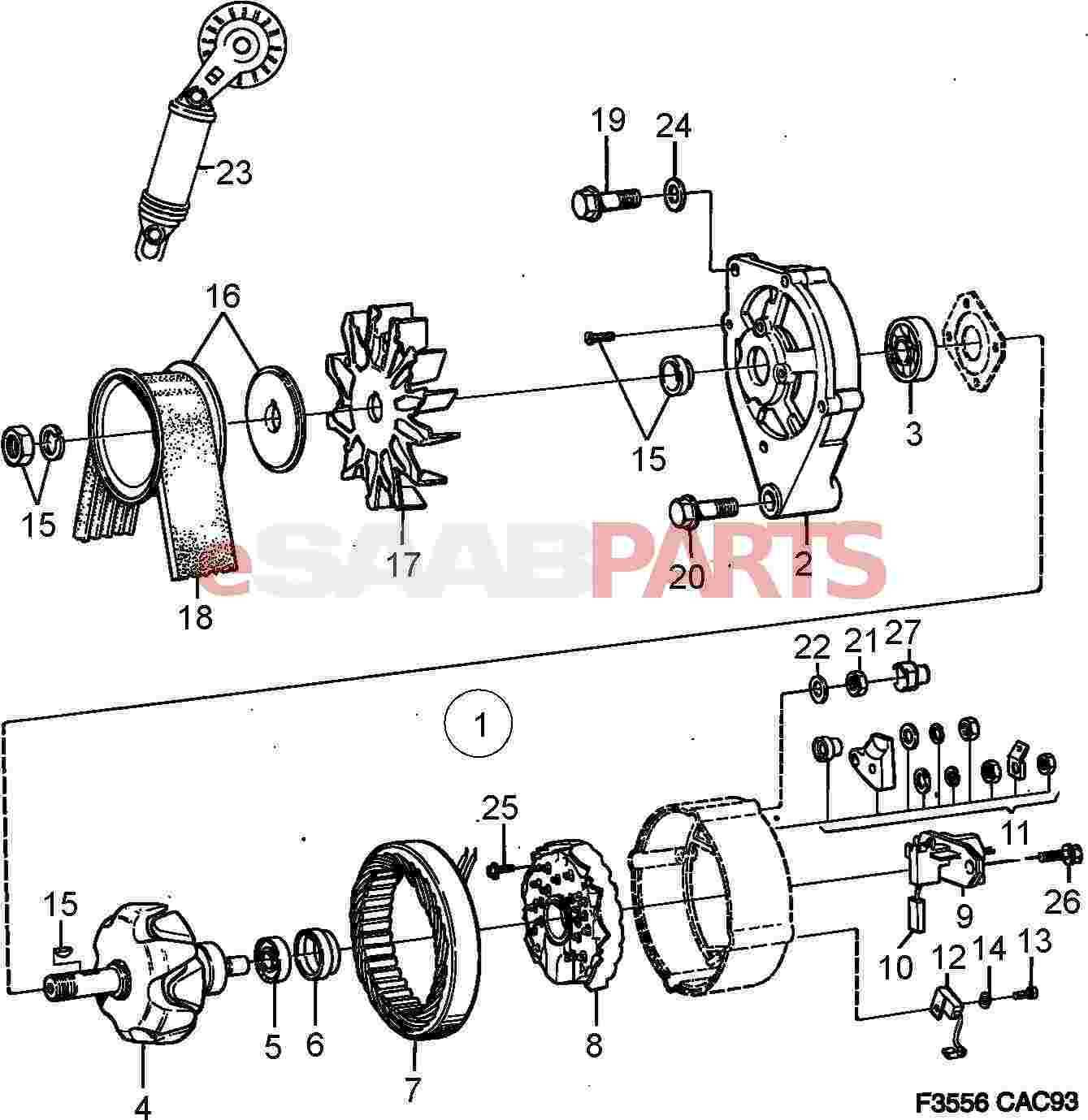

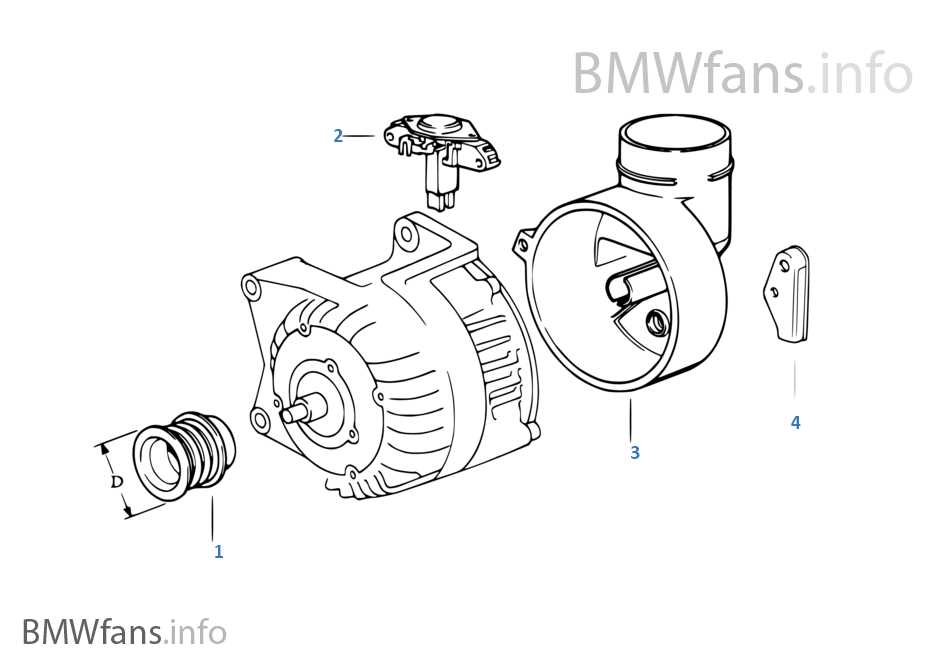

Replacing an Alternator: Step-by-Step

Replacing a crucial component responsible for generating electrical energy in your vehicle is essential for maintaining its performance. This guide outlines a systematic approach to successfully remove the faulty unit and install a new one, ensuring your vehicle operates efficiently.

Tools and Materials Needed

- Socket set

- Wrenches

- Ratchet and extensions

- New unit

- Safety gloves

- Protective eyewear

- Battery terminal wrench

- Torque wrench

Step-by-Step Procedure

- Ensure the vehicle is parked on a flat surface and turn off the engine. Disconnect the negative battery terminal to prevent electrical shorts.

- Remove any covers or components obstructing access to the unit.

- Locate and detach the electrical connections, noting their positions for reassembly.

- Loosen and remove the mounting bolts securing the unit in place. Keep track of these bolts, as you will need them for the new installation.

- Carefully extract the old unit from its housing, ensuring no damage to surrounding components.

- Install the new unit by reversing the removal process. Secure it with the mounting bolts and reconnect the electrical connections as noted earlier.

- Replace any covers or components that were removed earlier.

- Reconnect the negative battery terminal and start the engine to check for proper operation.

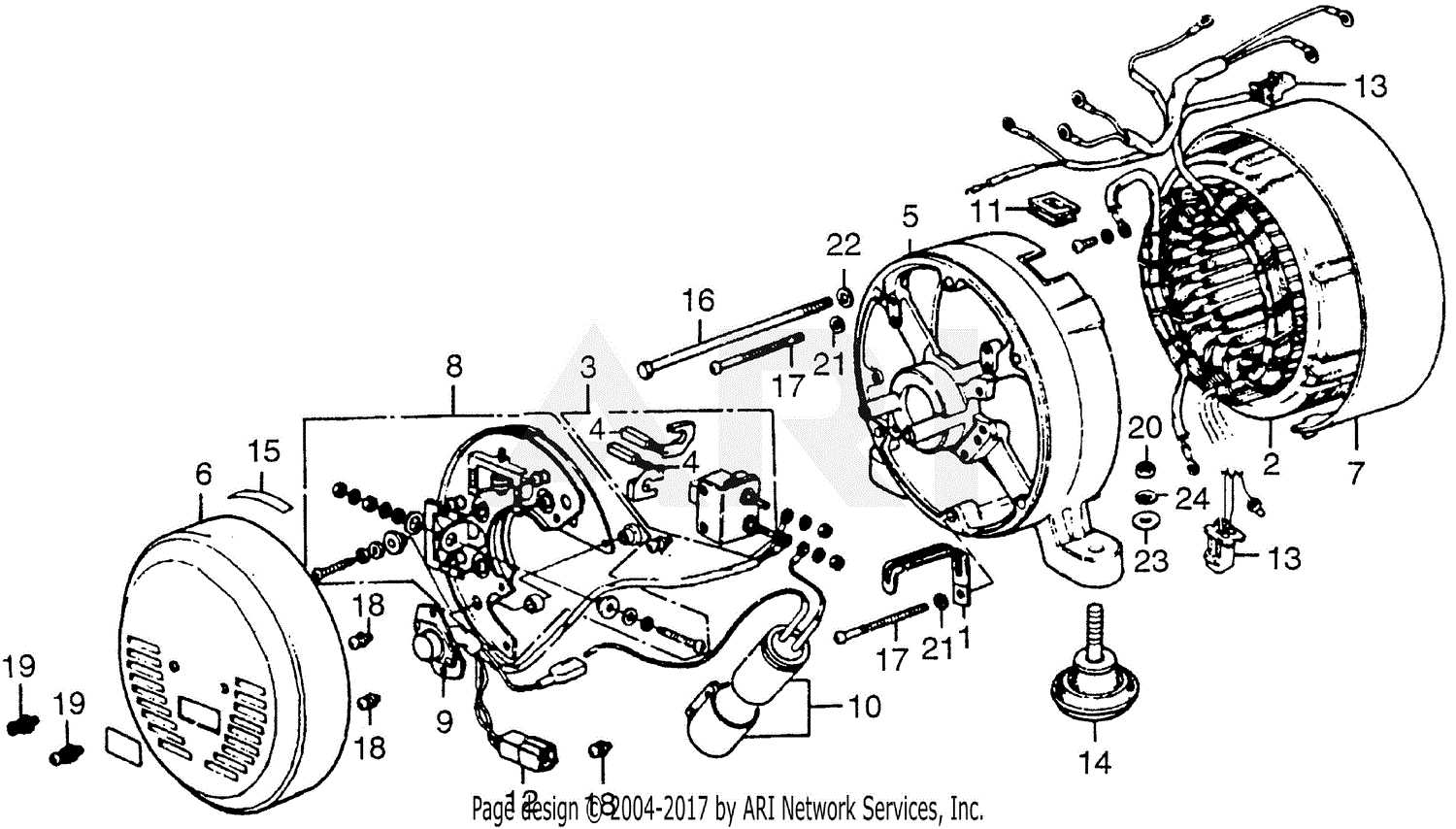

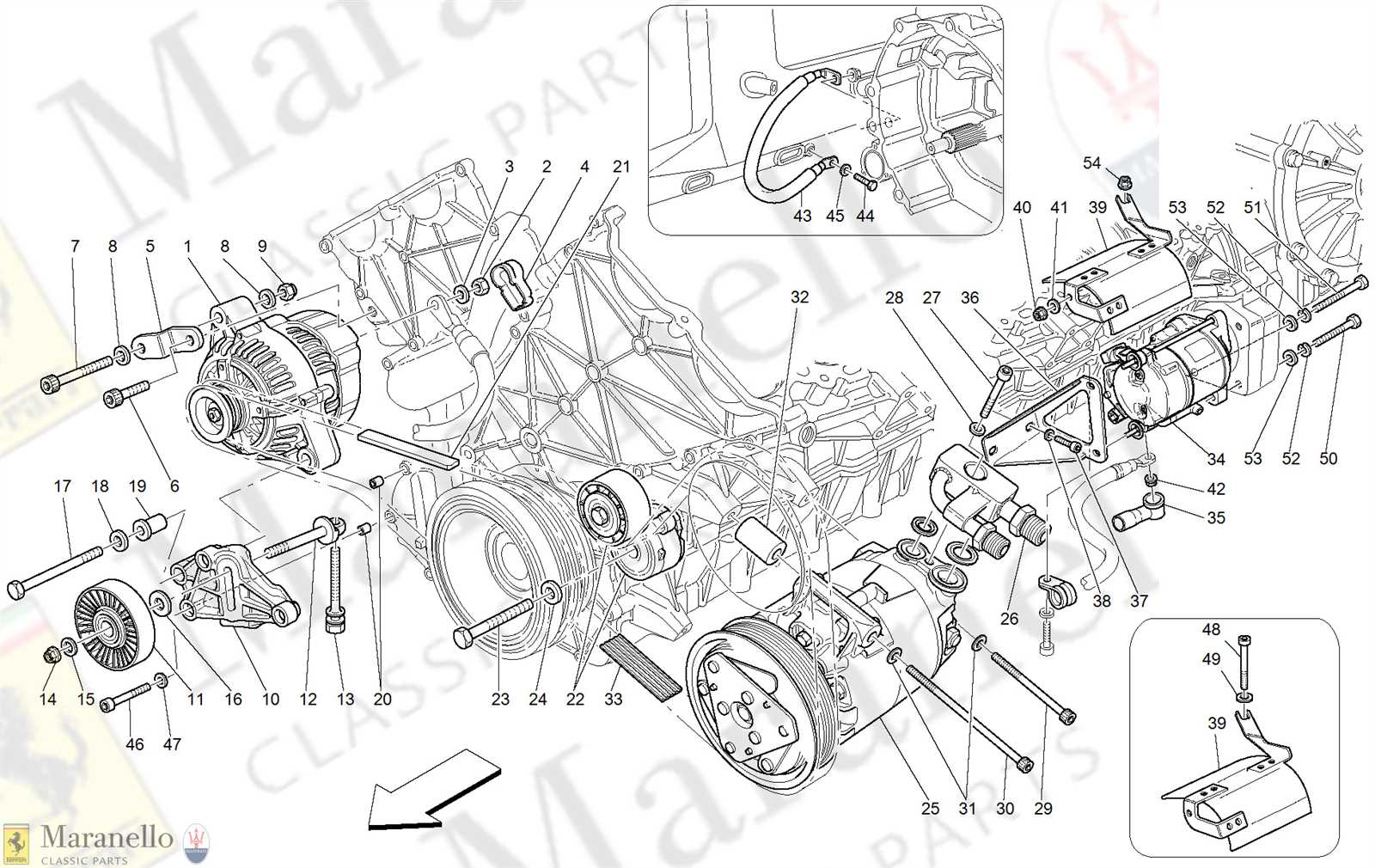

Understanding Alternator Wiring Diagrams

Comprehending the connections and components of a vehicle’s charging system is essential for effective troubleshooting and maintenance. Visual representations of these connections can help users understand how electricity flows and how various elements interact with one another. This knowledge is crucial for diagnosing issues and ensuring optimal performance.

Typically, these illustrations include various symbols and lines that represent the wiring and components involved. Familiarity with the symbols used is essential for accurate interpretation, as each one signifies a specific element within the system.

| Symbol | Description |

|---|---|

| Battery | Indicates the power source for the electrical system. |

| Ground | Represents the return path for electrical current. |

| Regulator | Controls the voltage output to prevent overcharging. |

| Field Coil | Generates the magnetic field necessary for electricity production. |

| Output Terminal | Point where electrical current exits the system. |

By familiarizing oneself with these symbols and their meanings, anyone can gain insight into the functionality of the system and troubleshoot problems more effectively. This foundational knowledge can empower vehicle owners and technicians alike, promoting better maintenance practices and enhancing overall vehicle reliability.

Upgrading Your Alternator Options

Enhancing your vehicle’s energy management system can significantly improve its performance and efficiency. By considering various enhancements, you can ensure your vehicle meets the demands of modern technology and additional accessories. This section will explore the benefits and considerations when looking to upgrade your energy-generating unit.

Benefits of Upgrading

Investing in a more efficient unit offers several advantages:

- Increased Power Output: A more powerful unit can support additional electrical components, such as sound systems and advanced lighting.

- Improved Reliability: Upgraded units often feature advanced technology that enhances durability and reduces the risk of failure.

- Better Fuel Efficiency: Optimized systems can reduce strain on the engine, leading to improved fuel consumption.

Considerations Before Upgrading

Before making a decision, consider the following factors:

- Compatibility: Ensure the new unit is compatible with your vehicle’s existing electrical system.

- Installation Requirements: Assess whether professional installation is necessary, as this can impact the overall cost.

- Brand Reputation: Research and choose reputable brands known for quality and reliability.

By weighing the benefits and considerations, you can make an informed choice about enhancing your vehicle’s energy capabilities.

Impact of Alternators on Vehicle Performance

The efficiency of a vehicle’s electrical system is crucial for its overall functionality and performance. A key component in this system plays a significant role in ensuring that various electrical functions operate smoothly and effectively, directly influencing the vehicle’s performance metrics.

Several factors illustrate the impact of this vital unit on vehicle operation:

- Power Supply: A reliable energy source is essential for the ignition system, fuel management, and other electronic components.

- Battery Health: Proper functioning of the unit ensures that the battery remains charged, which prevents unexpected breakdowns.

- Fuel Efficiency: A well-functioning system optimizes engine performance, contributing to better fuel economy.

- Accessory Performance: Devices such as air conditioning, audio systems, and navigation depend on a stable power supply for optimal operation.

In conclusion, the efficiency and reliability of this electrical component are paramount for enhancing the overall performance of the vehicle, ensuring it operates at its best under various conditions.