Understanding the Essential Parts of a Diagram Knapsack Sprayer

The functionality and efficiency of portable application equipment hinge on a variety of crucial elements. Each component plays a significant role in ensuring optimal performance and ease of use, enabling effective distribution of liquids in various settings.

In this section, we will explore the intricate assembly of these devices, focusing on their individual roles and how they contribute to the overall operation. By dissecting these essential components, we aim to provide a comprehensive insight that enhances both understanding and application.

From the main housing to the nozzle mechanisms, every section is designed with precision to meet the demands of users. Recognizing the importance of each unit allows for better maintenance and improved outcomes during usage.

Understanding Diagram Knapsack Sprayers

This section explores the essential components of a portable liquid application system, designed for effective and efficient distribution of solutions. Understanding these elements is crucial for maximizing performance and maintenance, ensuring optimal results in various agricultural practices.

Key Components

The main elements of such a system work together to provide a seamless experience for users. Each component plays a vital role in ensuring the device functions properly, allowing for the precise application of liquid substances.

| Component | Description |

|---|---|

| Tank | Holds the solution to be applied, available in various capacities. |

| Pump | Creates pressure to deliver the liquid through the nozzle. |

| Nozzle | Dispenses the liquid in a controlled manner, influencing droplet size and coverage. |

| Hose | Connects the tank and nozzle, allowing fluid transfer. |

Importance of Maintenance

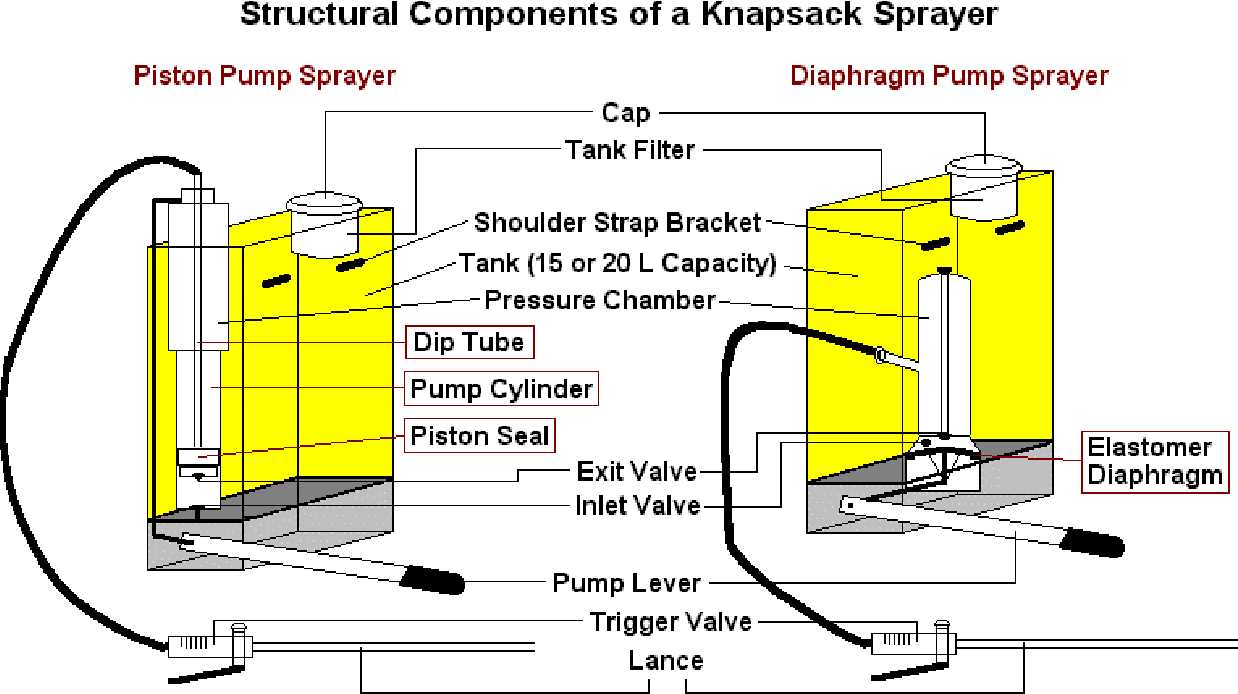

Key Components of Knapsack Sprayers

Understanding the essential elements of this type of equipment is crucial for effective usage and maintenance. Each component plays a significant role in ensuring optimal performance and efficiency during application tasks. Below are the primary features that contribute to the overall functionality of these devices.

Tank: The reservoir is where the liquid solution is stored. Its capacity varies, influencing how often users need to refill during operations. A well-designed tank is usually resistant to corrosion and easy to clean.

Pump: This mechanism is responsible for pressurizing the solution, enabling it to be distributed through the nozzle. The type of pump affects the pressure and flow rate, which are critical for achieving uniform coverage.

Nozzle: The nozzle determines the spray pattern and droplet size. Different types are available, allowing users to select the most suitable option for specific applications, whether for precision targeting or broad coverage.

Hoses: Flexible tubes connect various components, allowing the solution to travel from the tank to the nozzle. Durability and resistance to kinks are important characteristics for ensuring consistent flow.

Backpack Frame: This structure supports the entire assembly and is designed for comfort and ease of transport. Adjustable straps and ergonomic design are key features that enhance user experience, especially during extended use.

Filter: Located within the system, the filter prevents debris from clogging the nozzle and pump, ensuring uninterrupted operation. Regular maintenance of this component is essential for optimal performance.

Each of these crucial elements contributes to the effectiveness of the equipment, making understanding their functions vital for anyone involved in agricultural practices.

How Diagrams Aid in Maintenance

Visual representations play a crucial role in understanding complex machinery and their components. They serve as a valuable resource for technicians and users alike, ensuring effective upkeep and troubleshooting. By providing clear illustrations of assembly and functionality, these visuals simplify the maintenance process.

Here are several ways visual aids contribute to efficient maintenance:

- Enhanced Clarity: Illustrations provide a straightforward view of the components, making it easier to identify parts that require attention.

- Step-by-Step Guidance: They often include sequential instructions that guide users through the maintenance process, reducing the likelihood of errors.

- Improved Understanding: By depicting how various elements interact, visuals help users grasp the overall system, leading to better problem diagnosis.

- Quick Reference: Technicians can quickly locate specific components and their functions, saving time during repairs.

- Training Tool: Visual aids are excellent for training new personnel, providing a clear reference that enhances learning.

Incorporating these visual resources into maintenance practices ultimately leads to more effective and efficient operations, ensuring longevity and reliability of equipment.

Common Issues with Sprayer Parts

When utilizing any form of application equipment, various challenges can arise that may hinder optimal performance. Understanding these potential problems is essential for maintaining efficiency and ensuring longevity. From leaks to blockages, several issues can impact the overall functionality of the system.

One frequent concern is the occurrence of leaks, which can lead to a significant loss of liquid and affect precision. Additionally, clogging of nozzles and hoses often disrupts the flow, making it difficult to achieve uniform coverage. Regular maintenance is crucial to prevent wear and tear that can result in diminished output and increased operational costs.

Another notable issue involves the buildup of chemical residues, which can impair the equipment’s efficiency over time. Insufficient cleaning practices can exacerbate this problem, leading to long-term damage. Moreover, mechanical failures, such as pump malfunctions, may require immediate attention to prevent further complications.

By identifying and addressing these common challenges, users can enhance the reliability and effectiveness of their application tools, ensuring they perform at their best when needed most.

Choosing Quality Components for Longevity

Ensuring durability and efficiency in any equipment relies heavily on the selection of superior materials and components. High-quality elements not only enhance performance but also extend the lifespan of the device, leading to greater satisfaction and reduced maintenance costs.

- Material Quality: Opt for corrosion-resistant and durable materials.

- Reliability: Choose components from reputable manufacturers known for their longevity.

- Compatibility: Ensure all elements work seamlessly together to prevent wear and tear.

- Maintenance: Select parts that are easy to maintain and replace when necessary.

By prioritizing these aspects, users can significantly enhance the operational efficiency and overall durability of their equipment, making informed choices essential for long-term satisfaction.

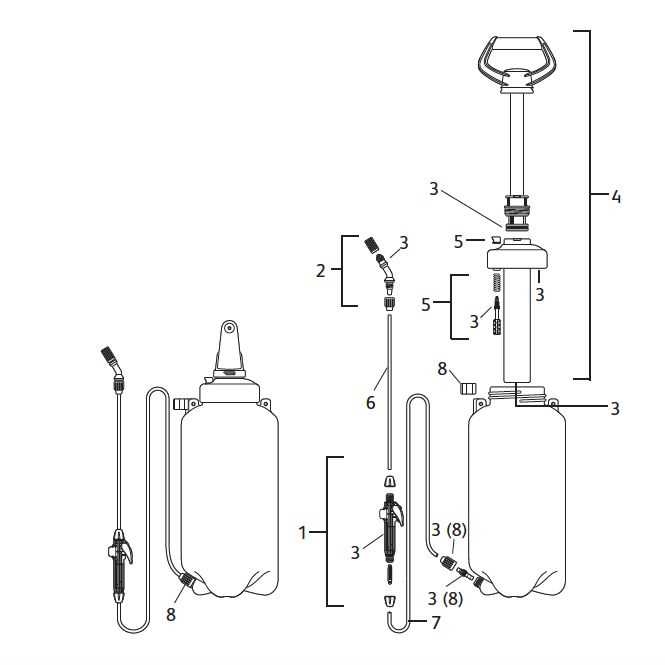

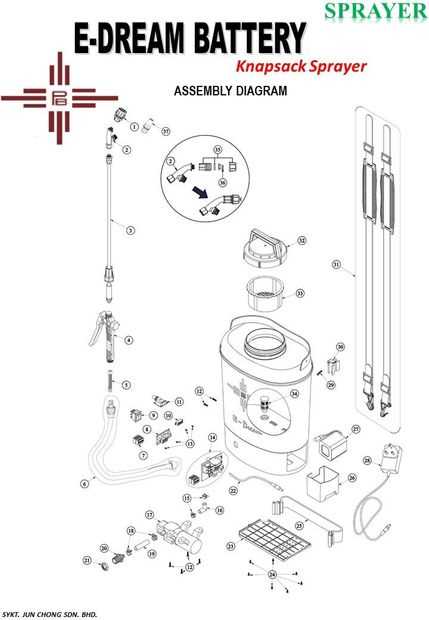

Assembling a Knapsack Sprayer Diagram

Understanding the structure and function of essential components is crucial for effective assembly. This section outlines the key elements and their arrangement to ensure optimal performance of your equipment.

When bringing together various elements, it’s important to follow a systematic approach. Here are the primary components involved:

- Container: Holds the liquid solution.

- Pump: Creates pressure to distribute the liquid.

- Hose: Transports the solution from the container to the nozzle.

- Nozzle: Regulates the spray pattern and flow.

- Frame: Provides support and stability during operation.

To achieve a successful assembly, follow these steps:

- Start by securing the container onto the frame.

- Attach the pump to the container, ensuring a tight seal.

- Connect the hose to the pump and ensure there are no leaks.

- Fix the nozzle at the end of the hose, adjusting it for desired output.

- Conduct a thorough inspection of all connections before use.

By adhering to these guidelines, you will ensure that your equipment functions effectively and efficiently, providing reliable performance for your tasks.

Importance of Proper Calibration

Ensuring accuracy in the application process is crucial for achieving optimal results. Correct adjustments allow for efficient use of resources and minimize the risk of over or under-application. This not only enhances the effectiveness of the substances used but also promotes environmental safety.

Precision in calibration leads to better coverage and adherence, which is essential for the intended outcomes. When equipment is fine-tuned, it guarantees that the right amount of solution reaches the target area, preventing waste and maximizing impact.

Ultimately, regular checks and adjustments are vital to maintaining operational effectiveness. This diligence helps in achieving consistent results and contributes to long-term success in various applications.

Safety Features in Modern Sprayers

Advancements in agricultural technology have led to the incorporation of numerous protective mechanisms designed to enhance user security and environmental safety. These innovations not only improve efficiency but also minimize the risk associated with handling chemical solutions during application processes.

Ergonomic Design and User Comfort

Modern devices are engineered with ergonomic principles in mind. The contours and grips are designed to reduce strain, allowing operators to maintain control with ease. Additionally, padded straps and adjustable harnesses distribute weight evenly, making prolonged use more comfortable and safer for the user.

Automatic Shutoff and Leak Prevention

To further ensure safety, many contemporary units are equipped with automatic shutoff mechanisms. These systems halt the flow of liquid when not in use, preventing accidental spills and exposure. Coupled with advanced sealing technologies, these features greatly reduce the chances of leaks, safeguarding both the user and the environment from harmful substances.

Overall, these innovative safety features reflect a commitment to protecting individuals and ecosystems while maintaining high performance standards in the field.

Comparative Analysis of Sprayer Models

This section explores various models of agricultural application devices, emphasizing their strengths and weaknesses. By evaluating performance metrics, user feedback, and design innovations, we aim to provide insights into which options might best suit specific needs.

Model A is recognized for its efficiency, boasting a high capacity that allows for extended use without interruption. However, it may lack some advanced features found in newer models.

Model B offers enhanced ergonomics and user-friendly controls, making it ideal for prolonged tasks. While it excels in comfort, it has a lower output rate compared to its counterparts.

Model C incorporates cutting-edge technology, including automated adjustments for different terrains. Though it represents the ultimate choice for tech-savvy users, the initial investment is significantly higher.

In summary, choosing the right device involves weighing factors such as efficiency, comfort, and technological features to match individual operational requirements.

Innovations in Sprayer Technology

The landscape of agricultural application tools is undergoing a remarkable transformation. With advancements in engineering and technology, these implements are becoming more efficient, user-friendly, and environmentally sustainable. The integration of smart features and precision mechanics is setting new standards in the field.

One significant advancement is the incorporation of automated systems. These innovations allow for real-time monitoring and adjustments, ensuring optimal performance while minimizing waste. By utilizing data analytics and sensors, users can achieve precise coverage and reduce the impact on surrounding ecosystems.

Additionally, the development of ergonomic designs enhances user comfort and reduces fatigue during operation. Innovations such as adjustable harnesses and lightweight materials not only improve usability but also promote safety and efficiency in various applications.

Moreover, the introduction of eco-friendly technologies reflects a growing commitment to sustainability. Biodegradable solutions and low-emission engines are just a couple of examples of how the industry is adapting to meet environmental challenges while maintaining effectiveness in application.

As we look to the future, the continuous evolution of these tools promises to further enhance agricultural productivity, driving the sector toward a more sustainable and efficient future.

Best Practices for Sprayer Usage

Efficient application of liquid treatments relies on several key strategies that ensure optimal performance and minimize waste. Understanding these techniques can enhance effectiveness while safeguarding both the environment and the operator.

1. Calibration: Regularly calibrate your equipment to ensure the correct dosage is applied. This prevents overuse and reduces the risk of damage to plants.

2. Protective Gear: Always wear appropriate protective equipment. This not only protects the user but also promotes safe handling of substances.

3. Weather Conditions: Monitor weather forecasts and avoid application during windy or rainy conditions. Ideal weather enhances distribution and absorption of the solution.

4. Maintenance: Keep equipment in top condition through regular cleaning and servicing. This prevents clogs and ensures a uniform spray pattern.

5. Training: Invest in proper training for operators. Knowledge of equipment and best practices is crucial for effective application.

Implementing these strategies can lead to the ultimate success in application tasks, ensuring both efficiency and safety.

Resources for Further Learning

Expanding your knowledge on the components and functionality of portable agricultural devices is essential for effective usage and maintenance. This section provides valuable materials and references to enhance your understanding of various elements and their applications in real-world scenarios.

Consider exploring online courses that focus on agricultural technologies, which often include interactive modules and expert insights. Additionally, industry publications and journals frequently offer in-depth articles that cover the latest advancements and best practices.

Forums and community groups dedicated to agricultural equipment can also be invaluable. Engaging with fellow enthusiasts and professionals allows for the exchange of tips, troubleshooting advice, and experiences that enrich your learning process.

Lastly, instructional videos available on platforms like YouTube can provide visual guidance, demonstrating assembly techniques, maintenance tips, and practical usage scenarios. These resources collectively form a comprehensive toolkit for anyone seeking to deepen their expertise in this field.