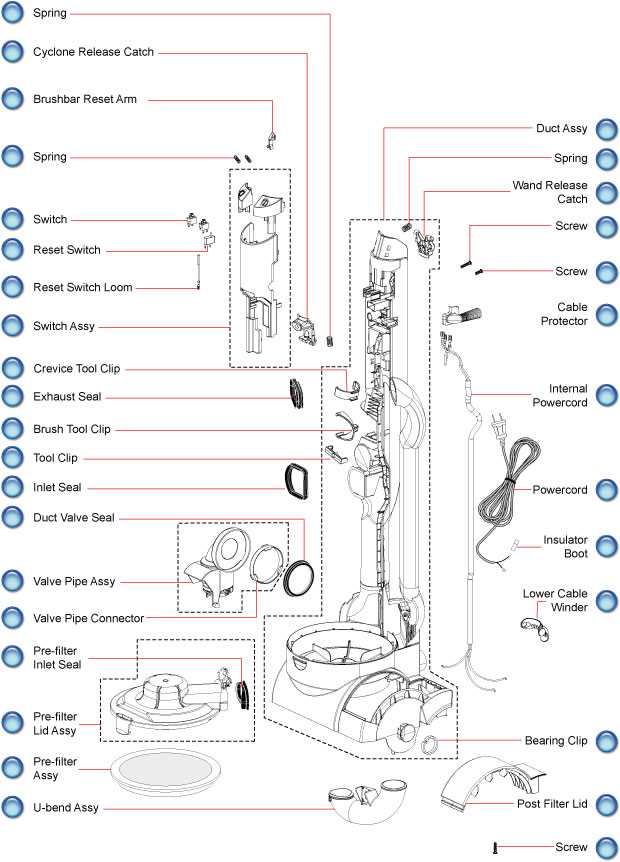

Dyson DC20 Parts Diagram Overview

Understanding the intricate makeup of various cleaning equipment can greatly enhance your ability to maintain and repair it efficiently. Exploring the individual elements that contribute to the overall functionality provides insights into how these machines operate, ensuring a longer lifespan and more effective performance.

In this section, we will delve into the specifics of essential parts that come together to form a seamless system. This knowledge can help in troubleshooting common issues, recognizing wear, and identifying the necessary replacements. With a focus on the internal mechanics, users can better appreciate the precision and engineering involved.

By breaking down each element and exploring its role, you’ll gain a clearer understanding of how to keep your cleaning system running smoothly. Whether you’re performing routine

Dyson DC20 Parts Overview

This section provides a comprehensive look at the individual components that make up this vacuum model. Understanding the various elements is essential for proper maintenance and efficient operation, ensuring longevity and optimal performance.

Core Components

The machine is built with several key elements designed to work in harmony, ensuring effective dirt and dust removal. These include the main suction system, which powers the unit, and additional mechanisms responsible for filtration and airflow management. Each piece plays a crucial role in keeping the device running smoothly.

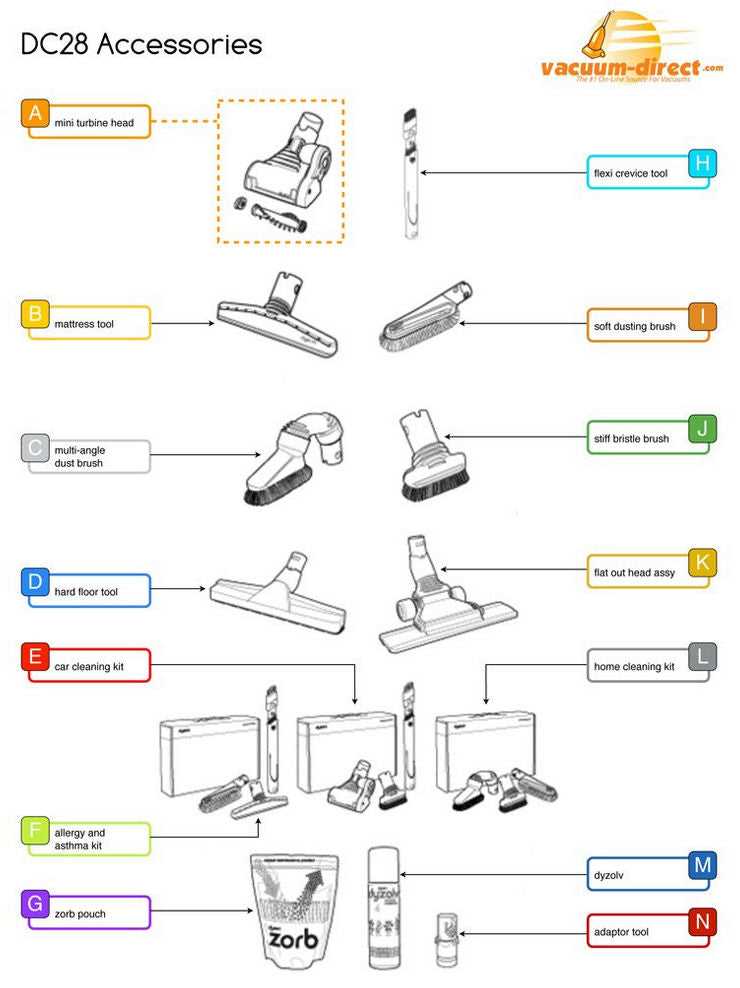

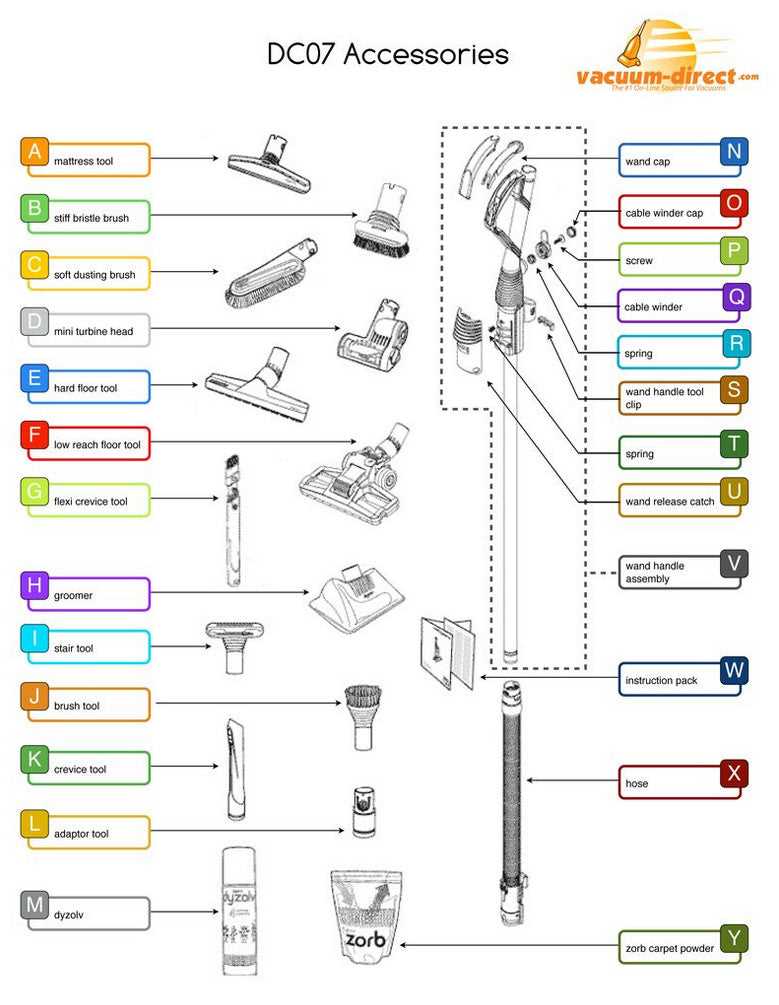

Specialized Attachments

Alongside its primary build, the vacuum includes multiple accessories tailored for different cleaning tasks. These extensions allow users to target specific areas, from upholstery to hard-to-reach corners, enhancing versatility. Each attachment is designed for a specific surface type or cleaning requirement, making it a highly adaptable tool for a variety of cleaning jobs.

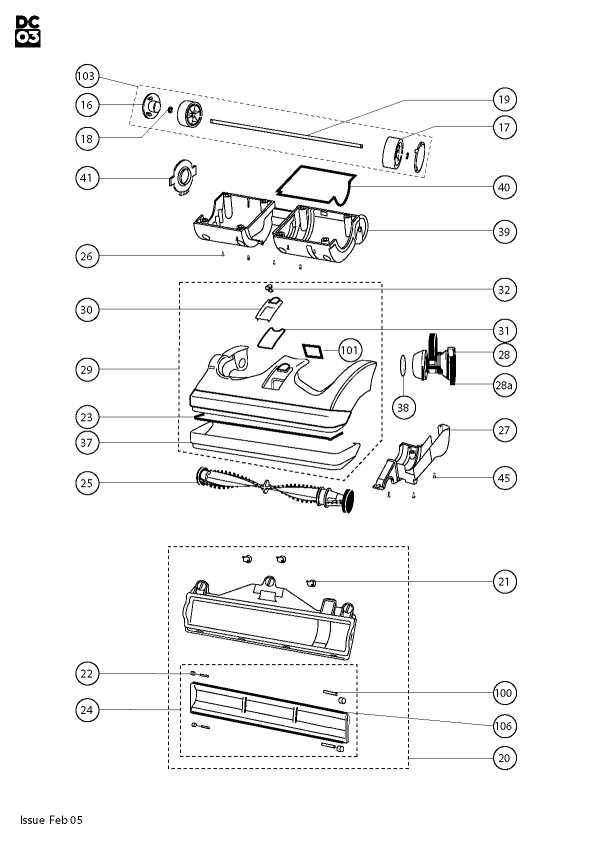

Main Components of the Dyson DC20

The device is comprised of several key elements that work together to deliver efficient cleaning performance. Each element plays a crucial role in ensuring optimal functionality and reliability. The components are designed with precision to maximize durability and effectiveness, ensuring long-lasting use and easy maintenance.

The motor unit serves as the heart of the machine, providing the power necessary for generating strong suction. Its efficient design allows for continuous use without overheating or losing performance.

The filtration system is responsible for trapping dust, allergens, and other particles, ensuring that only clean air is expelled. The multi-layered structure enhances its ability to capture even the finest debris.

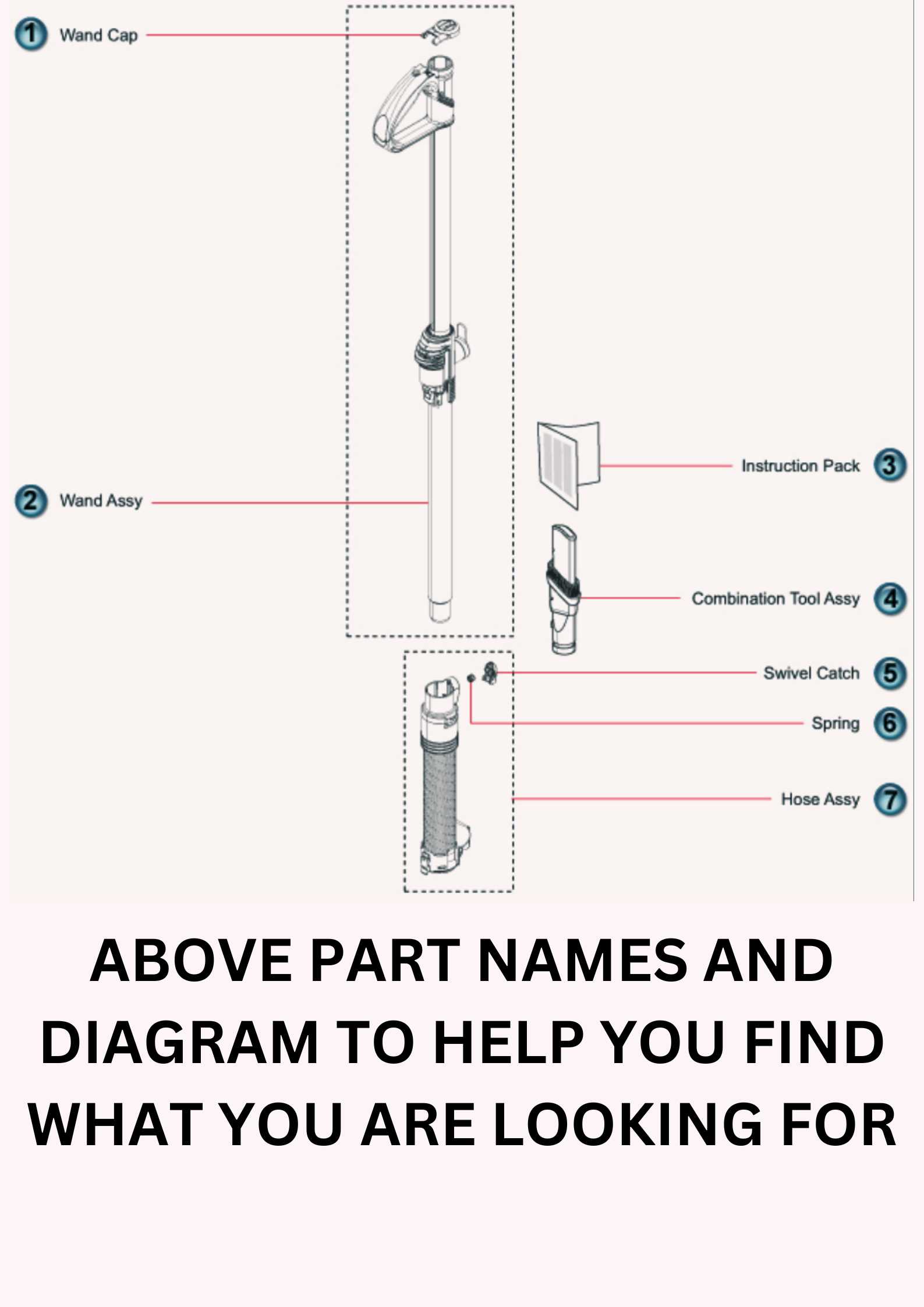

The hose and wand are essential for maneuverability, allowing the user to easily access hard-to-reach areas. Their flexible design ensures smooth handling and comfortable operation.

The dust container is designed for easy removal and emptying. Its transparent structure allows users to monitor when it needs to be emptied, ensuring consistent performance without interruption.

Hose Assembly and Attachments Guide

The hose and its various extensions provide flexibility and ease of use when cleaning different surfaces. The system allows for seamless transitions between different cleaning tasks, ensuring both reach and precision. By using the correct attachment, users can effectively clean areas that are hard to access or require specific care.

Connecting the Hose

To set up the hose, it needs to be securely attached to the main body. Ensure a firm connection, as this guarantees optimal airflow and efficiency. The design typically features a locking mechanism to prevent accidental disconnections during use. Double-check the connection before starting any cleaning tasks.

Available Attachments

A variety of tools can be connected to the hose to target specific areas. A crevice tool is perfect for reaching tight spaces, while a brush attachment can handle delicate surfaces like upholstery. For larger debris, a

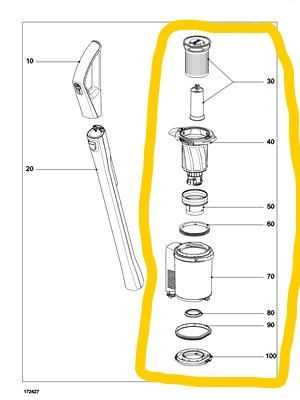

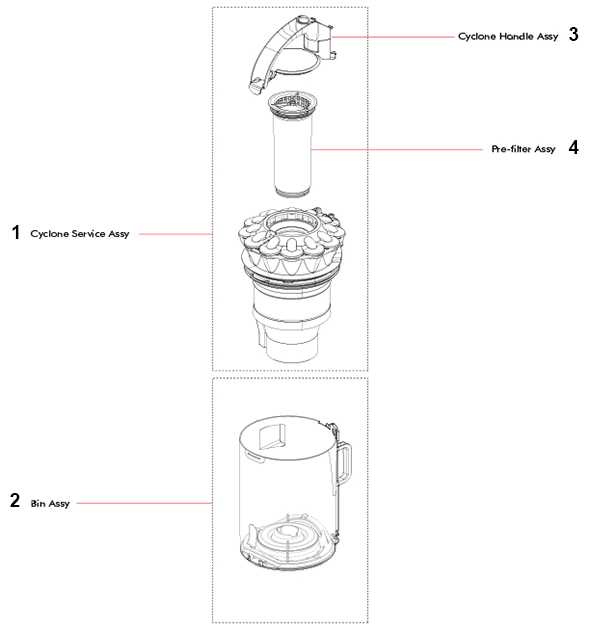

Understanding the Cyclone Technology

The cyclone technology revolutionized modern cleaning systems by leveraging airflow to separate debris from the air. This innovation provides a more efficient method of filtering dust and particles without relying on traditional filters, which can easily clog and reduce suction power.

At the core of this technology lies the principle of centrifugal force. As air is drawn into the device, it is rapidly spun through a series of conical chambers, which effectively separates fine particles from the air. The heavier particles are pushed to the outer edges and deposited, while cleaner air continues through the system.

This approach ensures a consistent level of performance, maintaining powerful airflow even as the device collects more dirt. By minimizing reliance on conventional filters, this technology also reduces the need for frequent maintenance, offering users a more convenient and efficient cleaning experience.

Dust Bin and Filter Location

The container and filtration system are key components in maintaining the efficiency of your cleaning device. Knowing their exact placement ensures optimal performance and simplifies regular maintenance.

The container is typically located in a central position, easily accessible for emptying when full. It is designed to be removed with minimal effort, allowing quick disposal of collected debris. The filter, crucial for air purification, is usually situated near the bin to maximize the capture of particles before they are expelled back into the air.

| Component | Location | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dust Container | Near the base

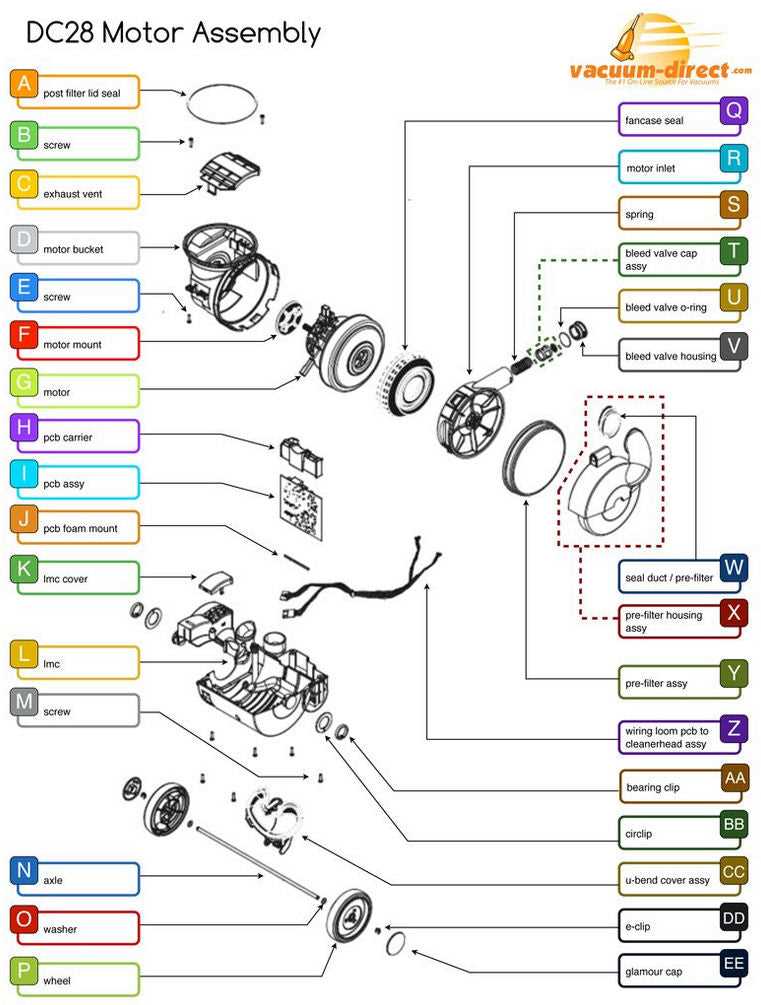

Motor Unit and Its Importance

The motor assembly serves as the heart of any vacuum cleaner, providing the necessary power to drive suction and facilitate efficient cleaning. This essential component converts electrical energy into mechanical energy, enabling the appliance to perform its functions effectively. Understanding its role can help users appreciate the complexity and efficiency of their cleaning devices. Functionality and Performance

A robust motor unit is crucial for maintaining optimal performance. It ensures consistent suction power, which directly influences the effectiveness of the cleaning process. Additionally, a well-designed motor can enhance the lifespan of the appliance by minimizing wear and tear during operation. Maintenance and Care

Regular maintenance of the motor assembly is vital for preserving its functionality. Users should periodically check for dust accumulation and clean the components to prevent overheating and maintain performance. Proper care can significantly extend the lifespan of this essential unit, ensuring reliable operation for years to come. Cleaning the Dyson DC20 Filters

Maintaining optimal performance of your vacuum cleaner requires regular attention to its filtration system. Clean filters not only enhance suction power but also improve air quality in your home. This section provides essential steps for effectively cleaning the filters of your device. To ensure that your filtration components are functioning at their best, follow these guidelines:

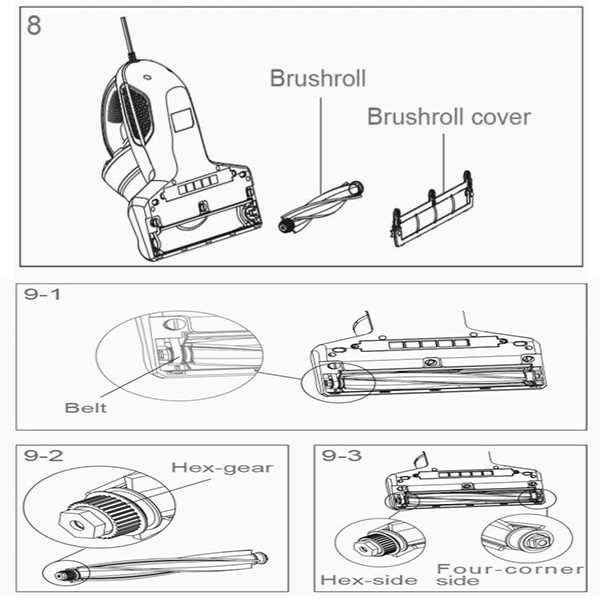

Following these steps regularly will ensure that your vacuum cleaner operates efficiently, providing cleaner air and better performance during use. Brushbar Mechanism and Replacement Tips

The brushbar is a critical component in any vacuum cleaner, playing a vital role in ensuring effective dirt and debris removal from various surfaces. Understanding its mechanism and maintenance needs can significantly enhance the performance of your cleaning device. Understanding the Brushbar MechanismThe brushbar operates by rotating at high speeds, agitating carpet fibers and loosening dirt trapped within. This action not only improves suction efficiency but also allows for better cleaning of hard floors. The mechanism typically involves a motor that drives the brush, and it is essential to keep it free of blockages and tangles to maintain optimal functionality. Replacement Tips

When it comes time to replace the brushbar, ensure you follow a few key steps. First, consult the manufacturer’s guidelines for the specific model to identify the correct replacement part. Before beginning the replacement process, unplug the device to avoid any accidents. After removing the old brushbar, clean the housing area thoroughly to remove any debris. Finally, install the new brushbar securely and check its rotation to ensure it functions properly. Wheels and Maneuverability FeaturesThe design of cleaning devices often emphasizes the importance of mobility and ease of use. A well-engineered set of wheels can significantly enhance the user experience, allowing for effortless navigation across various surfaces. The incorporation of advanced maneuverability features ensures that these machines can easily traverse tight spaces and around furniture, making the cleaning process more efficient. Typically, these models are equipped with multi-directional wheels that provide a smooth and agile movement. The combination of swivel and fixed wheels allows for easy turns and stability, while larger rear wheels can aid in rolling over obstacles without hindrance.

The thoughtful integration of these features contributes to an overall user-friendly experience, allowing individuals to maintain cleanliness in their environments with minimal effort. The effectiveness of the design becomes apparent when navigating through various spaces, where every turn and movement feels natural and fluid. Cord Rewind System ExplainedThe cord rewind mechanism is an innovative feature designed to enhance the user experience by simplifying the storage of electrical appliances. This system allows for effortless retraction of the power cord, eliminating the hassle of manual winding and ensuring neat storage when the device is not in use. Key components of the cord rewind system include:

Benefits of this system encompass:

In summary, the cord rewind feature is a practical innovation that significantly enhances functionality and safety, making electrical appliances more user-friendly and efficient. Maintaining Optimal Suction PowerEnsuring peak performance of your cleaning device is essential for effective dust and debris removal. Over time, various components can impact the airflow and suction capabilities. Regular maintenance is crucial to prevent loss of efficiency and maintain a clean environment. Key Maintenance Practices

To keep your device operating at its best, consider the following practices:

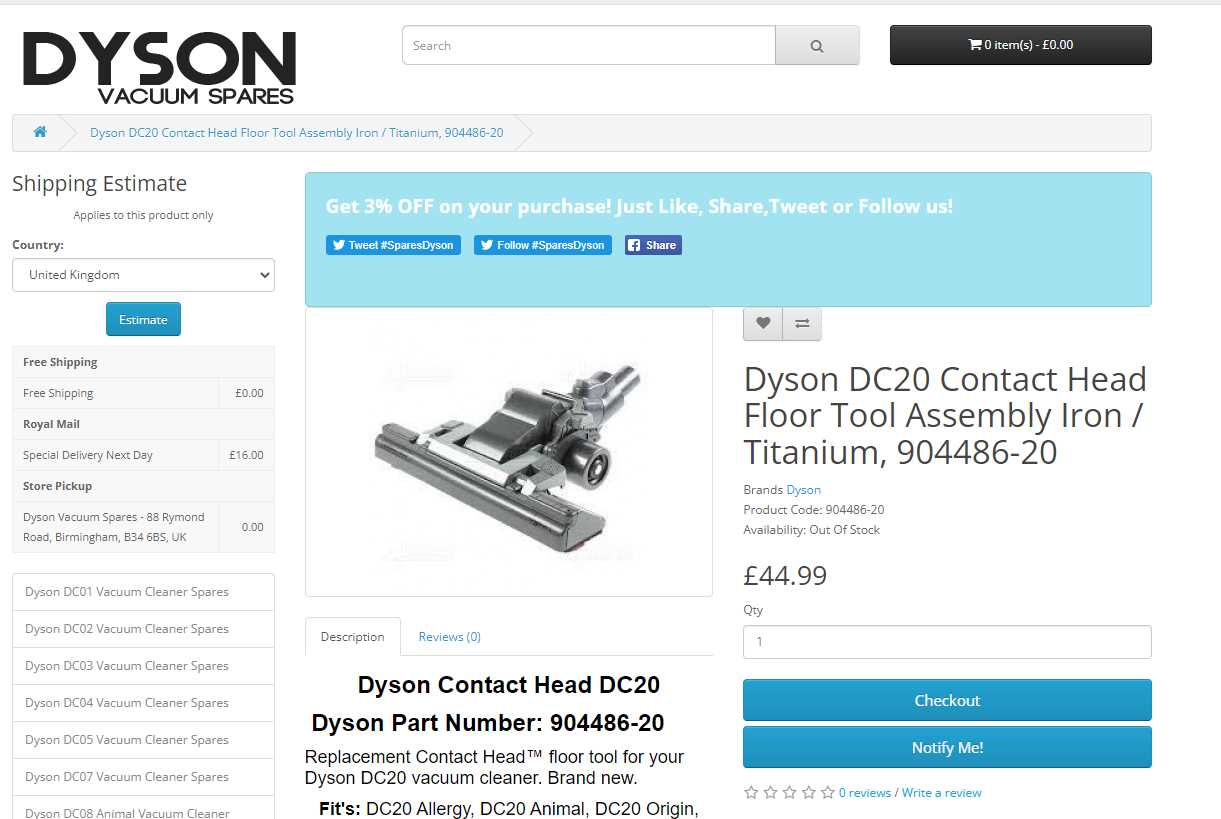

Signs of Reduced PerformanceBe aware of indicators that suggest your appliance may need attention. If you notice decreased suction, unusual noises, or an increase in cleaning time, these may be signs that maintenance is required. Addressing these issues promptly will ensure longevity and optimal functionality. Common Spare Parts for Repairs

When it comes to maintaining and fixing your cleaning device, several components are frequently replaced. These essential elements play a vital role in ensuring the optimal performance of your machine. Understanding which items are commonly needed can help you keep your device running smoothly for longer periods. Key Components

Among the various components, some are more prone to wear and tear. Replacing these parts can significantly enhance the functionality and efficiency of your equipment. Below is a list of typical replacements you might consider:

Maintaining Performance

Regularly inspecting and replacing these crucial elements can help maintain your cleaning tool’s performance |