Earthway Spreader Parts Overview

The proper functioning of any outdoor application device relies on a comprehensive understanding of its individual elements. By exploring the key constituents of these tools, users can ensure optimal performance and longevity. This section provides valuable insights into the assembly and functionality of these essential items, allowing for effective maintenance and troubleshooting.

Whether you are a novice or an experienced user, familiarizing yourself with the various sections of your equipment is crucial. Recognizing how each component interacts within the overall system will empower you to make informed decisions regarding repairs and upgrades. The information presented here aims to enhance your knowledge and improve your experience in managing your outdoor tasks.

With clear illustrations and descriptive labels, this guide serves as a reference for identifying and understanding the various elements involved. By taking the time to study these details, you can significantly enhance your proficiency and confidence in handling these valuable tools.

Understanding the essential components of your equipment is crucial for optimal performance and maintenance. Each element plays a specific role, contributing to the overall functionality. Familiarizing yourself with these critical components can enhance efficiency and prolong the lifespan of your machinery.

| Component Name | Description |

|---|---|

| Hopper | The container that holds the material to be distributed. |

| Wheel Assembly | The set of wheels that facilitate movement across various terrains. |

| Handle | The part used for maneuvering the device, providing control during operation. |

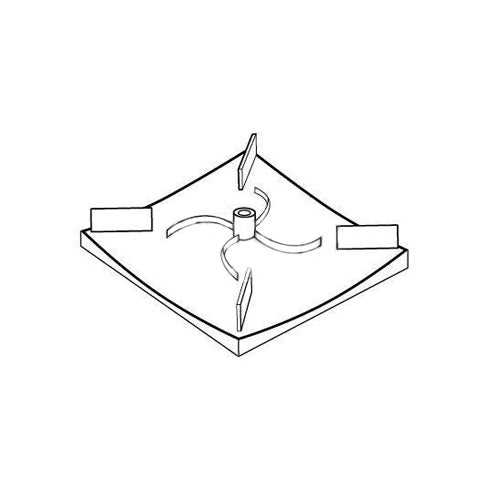

| Distribution Mechanism | The system that regulates the release of materials from the hopper. |

| Frame | The structural support that holds all components together. |

Benefits of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring optimal performance and longevity. Regular attention not only enhances functionality but also reduces the likelihood of unexpected breakdowns. By adopting a proactive approach to care, users can enjoy a range of advantages that contribute to efficient operation.

Some key benefits include:

- Improved Efficiency: Regular servicing helps maintain the efficiency of machinery, ensuring that it operates at peak performance.

- Cost Savings: Preventative measures can significantly reduce repair costs by addressing minor issues before they escalate into major problems.

- Increased Lifespan: Routine maintenance extends the life of equipment, allowing for a better return on investment over time.

- Safety Assurance: Well-maintained machinery minimizes the risk of accidents and ensures safe operation for users.

- Consistent Results: Regular checks help ensure that equipment delivers consistent and reliable performance, meeting user expectations every time.

By recognizing and acting upon the importance of regular upkeep, users can enjoy enhanced performance and greater peace of mind.

Common Replacement Parts

When maintaining a garden tool, it is essential to know which components may need replacement over time. Regular use can lead to wear and tear, affecting performance. Identifying and replacing worn-out elements ensures that your equipment continues to operate efficiently.

Frequently Replaced Components

- Wheels: These are crucial for mobility and may become damaged or worn.

- Tires: Ensure proper traction and may require replacement if punctured or degraded.

- Hoppers: The container can wear down or crack, necessitating a new one for effective use.

- Linkages: Connect various parts; if they break, they can hinder operation.

- Handle grips: Often become slippery or worn and may need changing for comfort and control.

Maintenance Tips

- Regularly inspect components for signs of damage or wear.

- Clean the equipment after each use to prevent buildup that can lead to wear.

- Store in a dry place to avoid rust and corrosion.

- Refer to the user manual for specific recommendations on replacements and maintenance schedules.

Tools Needed for Repairs

When undertaking maintenance on your equipment, having the right tools is essential for effective repairs. A well-equipped workspace can significantly simplify the process and enhance the quality of your work. Familiarizing yourself with the necessary instruments will ensure you are prepared for any challenges that may arise during the repair process.

Essential tools typically include a variety of wrenches, screwdrivers, and pliers, which allow for the loosening and tightening of components. Additionally, a torque wrench can be valuable for applying the correct amount of force when securing fittings. A socket set can provide the versatility needed for various fasteners, while a multimeter is useful for diagnosing electrical issues. Lastly, safety gear, such as gloves and goggles, should always be on hand to protect yourself during repairs.

Assembly Instructions

This section provides essential guidance for putting together your equipment effectively. Following the instructions carefully will ensure proper functionality and longevity of your device.

Required Tools

Before beginning the assembly process, gather the necessary tools to facilitate a smooth setup. The following items will be helpful:

| Tool | Purpose |

|---|---|

| Screwdriver | To tighten screws and secure components |

| Wrench | For adjusting nuts and bolts |

| Pliers | To hold or bend components as needed |

Step-by-Step Assembly

Follow these steps to assemble your device efficiently:

- Begin by laying out all components on a flat surface.

- Identify the main body and attach the handle securely using the provided screws.

- Connect any additional sections, ensuring that each part aligns properly.

- Tighten all connections firmly to prevent movement during operation.

- Inspect the assembled unit for any loose parts or misalignments before use.

Common Issues and Solutions

When working with agricultural equipment, various challenges may arise that can affect performance and efficiency. Identifying these problems early can help in maintaining optimal operation and extending the lifespan of the machinery. This section explores some frequently encountered difficulties and offers practical solutions.

Frequent Problems

Users often experience issues such as uneven distribution of materials, clogging of mechanisms, or difficulty in adjusting settings. Understanding these common hurdles is the first step towards effective resolution.

Solutions and Recommendations

To address the aforementioned issues, consider the following strategies:

| Issue | Solution |

|---|---|

| Uneven distribution of materials | Check calibration settings and ensure even loading of the material. |

| Clogging of mechanisms | Regularly clean the machine and use materials that are less prone to clogging. |

| Difficulty in adjusting settings | Refer to the user manual for guidance and ensure all components are functioning correctly. |

How to Adjust Settings

Fine-tuning the equipment is essential for optimal performance and achieving desired results. Making the right adjustments ensures even distribution of materials, enhancing efficiency and effectiveness during use.

Follow these steps to modify the settings:

- Identify the Desired Application: Determine the type of material you will be using, as different materials may require varying settings.

- Consult the User Manual: Refer to the instruction guide for specific recommendations on adjustments for various materials.

- Adjust the Flow Rate: Locate the flow control mechanism and set it to the appropriate level based on your material type. Start with a lower setting and gradually increase as needed.

- Modify the Width of Distribution: Depending on your application, adjust the width settings to ensure the material is spread evenly. Wider settings may cover more ground but can lead to uneven distribution.

- Test the Settings: Conduct a small test run to evaluate the effectiveness of your adjustments. Observe the distribution pattern and make further changes if necessary.

- Make Final Adjustments: After testing, finalize your settings based on performance and feedback from the initial run.

Regularly checking and adjusting the settings will help maintain the functionality of the equipment and improve overall results during operation.

Tips for Effective Usage

Maximizing the efficiency of your lawn care equipment requires understanding its operation and maintenance. Implementing best practices can significantly enhance your results and prolong the life of your tools.

Preparation Before Use

- Ensure the device is clean and free from debris to avoid clogs and ensure even distribution.

- Check the calibration settings to ensure the correct application rate of materials.

- Inspect all moving components for wear and tear, replacing any damaged parts as necessary.

During Application

- Maintain a steady pace to achieve uniform coverage across the treated area.

- Overlap each pass slightly to prevent gaps in application.

- Be mindful of environmental conditions, such as wind, which can affect material dispersal.

Cleaning and Storage Practices

Maintaining equipment in top condition is crucial for ensuring its longevity and optimal performance. Proper cleaning and storage techniques play a significant role in preserving functionality and preventing potential issues. This section outlines essential practices to keep your device in excellent shape, ready for the next use.

Cleaning Guidelines

Regular cleaning is vital for removing debris and residues that may accumulate during use. Start by rinsing the unit with water to eliminate loose dirt. For more stubborn residues, a mild detergent solution can be used to scrub surfaces gently. Ensure that all components are thoroughly dried after cleaning to prevent corrosion or mold development.

Storage Recommendations

Proper storage is equally important to protect the equipment from environmental factors. Store the device in a dry, cool location, away from direct sunlight. If possible, keep it indoors during harsh weather conditions. Additionally, consider covering it with a protective tarp to shield it from dust and moisture, which can contribute to wear over time.

Finding Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Whether you’re looking to upgrade or restore functionality, understanding where to seek out these essential items is crucial.

Here are some effective strategies for finding the necessary items:

- Manufacturer’s Website: Visit the official site for accurate information on available components.

- Authorized Retailers: Check with local distributors who specialize in outdoor maintenance tools.

- Online Marketplaces: Utilize platforms that offer a wide range of choices, often at competitive prices.

- Community Forums: Engage with fellow users who may share tips and sources for obtaining the right components.

- Repair Shops: Consult professionals who can assist in sourcing or ordering specific items.

Before making a purchase, ensure compatibility with your existing equipment. This diligence can save time and resources in the long run.