Comprehensive Guide to Farmall Parts Diagram

In the realm of farming equipment, the intricate relationship between various elements plays a crucial role in ensuring optimal functionality. This section aims to explore the essential components that constitute these machines, providing clarity on their roles and interactions.

Comprehending the layout and organization of these elements is vital for effective maintenance and troubleshooting. By delving into the specifics, users can better appreciate the complexity behind the machinery that powers agricultural operations.

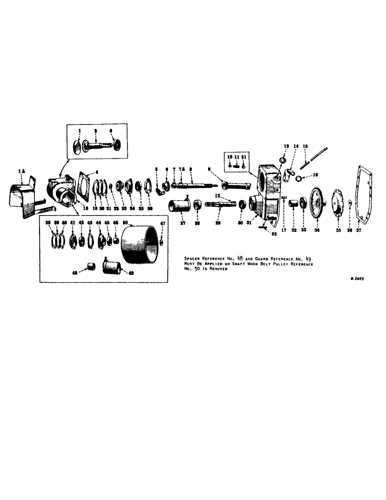

Moreover, having a visual representation of these crucial features can serve as an ultimate guide for enthusiasts and professionals alike. It not only simplifies the understanding of individual units but also enhances the overall efficiency of equipment management.

Understanding Farmall Parts Diagrams

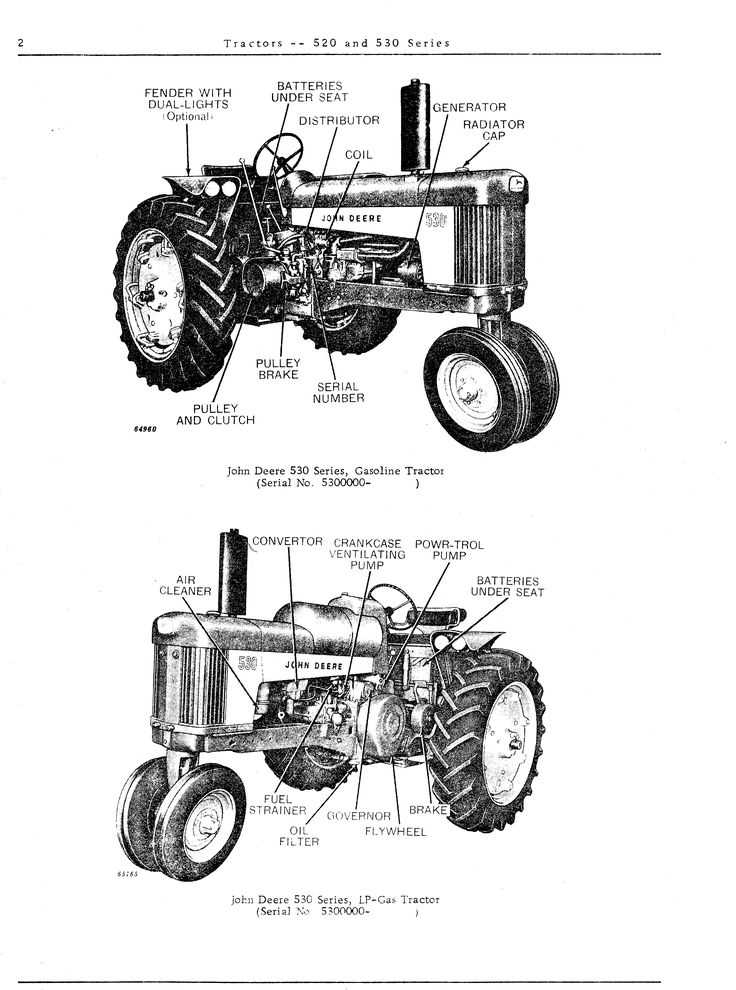

This section explores the visual representations that illustrate the components of agricultural machinery. Such visuals serve as invaluable resources for enthusiasts and professionals, helping to clarify the relationships and functions of various elements within the machinery.

The Importance of Visual Aids

Comprehending these illustrations can significantly enhance maintenance and repair tasks. They provide a clear layout, allowing users to identify and locate specific components efficiently, ultimately improving the overall workflow.

Key Features of the Illustrations

| Feature | Description |

|---|---|

| Labeling | Each component is marked for easy identification. |

| Color Coding | Different colors often indicate various systems or functions. |

| Detail Level | Some representations provide intricate details for advanced tasks. |

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective maintenance and repair tasks. Clear illustrations not only facilitate understanding but also enhance the efficiency of processes. When dealing with complex machinery, the need for reliable visual aids cannot be overstated.

Accurate illustrations serve several key purposes:

- Clarity: They provide a clear view of the components, making it easier to identify each element and its function.

- Efficiency: Well-structured visuals streamline the repair process, reducing the time spent on locating parts and understanding their arrangement.

- Safety: Properly annotated visuals can highlight potential hazards, ensuring that users follow safety protocols during maintenance.

- Guidance: Step-by-step visuals offer guidance for assembly and disassembly, helping to prevent errors that could lead to damage or malfunction.

Investing in high-quality visuals ultimately leads to improved performance and longevity of machinery, showcasing the value of precision in technical documentation.

Common Farmall Models Explained

This section explores various popular models of a well-known agricultural machinery brand, highlighting their characteristics and functionalities. Understanding these models helps farmers and enthusiasts identify which machinery best suits their needs and operational requirements.

Popular Models Overview

- Model A: This model is recognized for its simplicity and reliability. It features a lightweight design, making it suitable for small to medium-sized farms.

- Model B: Known for its versatility, this unit is capable of handling a wide range of implements, from plows to harvesters.

- Model C: This version is appreciated for its powerful engine and enhanced traction, ideal for more demanding tasks in larger fields.

Key Features

- Engine Performance: Most models come equipped with efficient engines designed for longevity and fuel economy.

- Ease of Maintenance: A common trait among these machines is their user-friendly design, facilitating straightforward maintenance routines.

- Attachment Compatibility: These units often support various attachments, allowing for greater flexibility in farm operations.

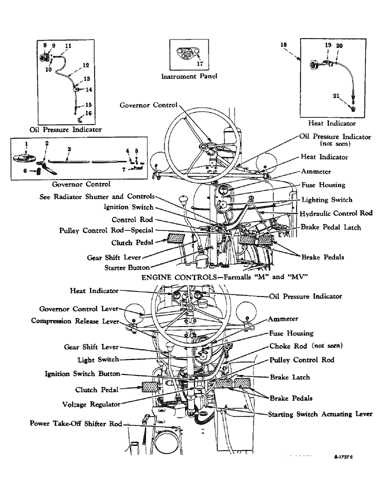

Identifying Key Components Easily

Understanding the essential elements of machinery can significantly enhance maintenance and repair efficiency. By recognizing specific components and their functions, users can troubleshoot issues and optimize performance. This section aims to simplify the identification process, making it accessible for both novices and experienced operators.

Common Elements to Recognize

Familiarity with the most frequently encountered components can lead to quicker resolutions. Here are some vital parts to consider:

- Engine Assembly

- Transmission System

- Hydraulic Mechanisms

- Electrical Wiring

- Chassis Frame

Helpful Tips for Identification

Utilizing certain strategies can streamline the identification process:

- Refer to manuals and technical documents for detailed descriptions.

- Utilize labeling systems to mark each component clearly.

- Group similar items together to simplify searches.

- Take photographs for visual reference during repairs.

- Engage in hands-on training sessions to enhance practical knowledge.

By implementing these methods, recognizing crucial machinery components becomes a straightforward task, allowing for efficient upkeep and operation.

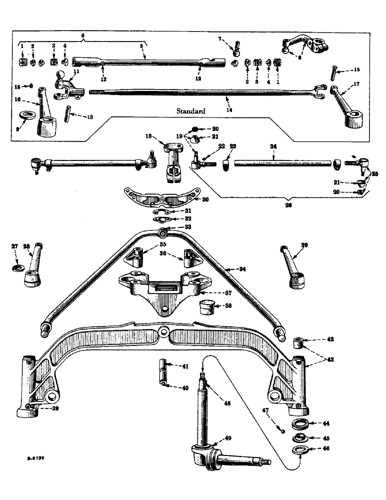

How to Read Parts Diagrams

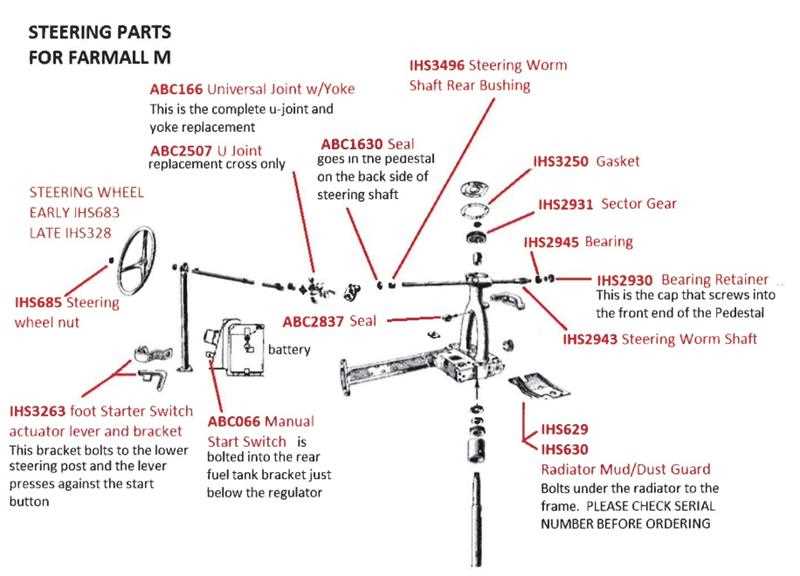

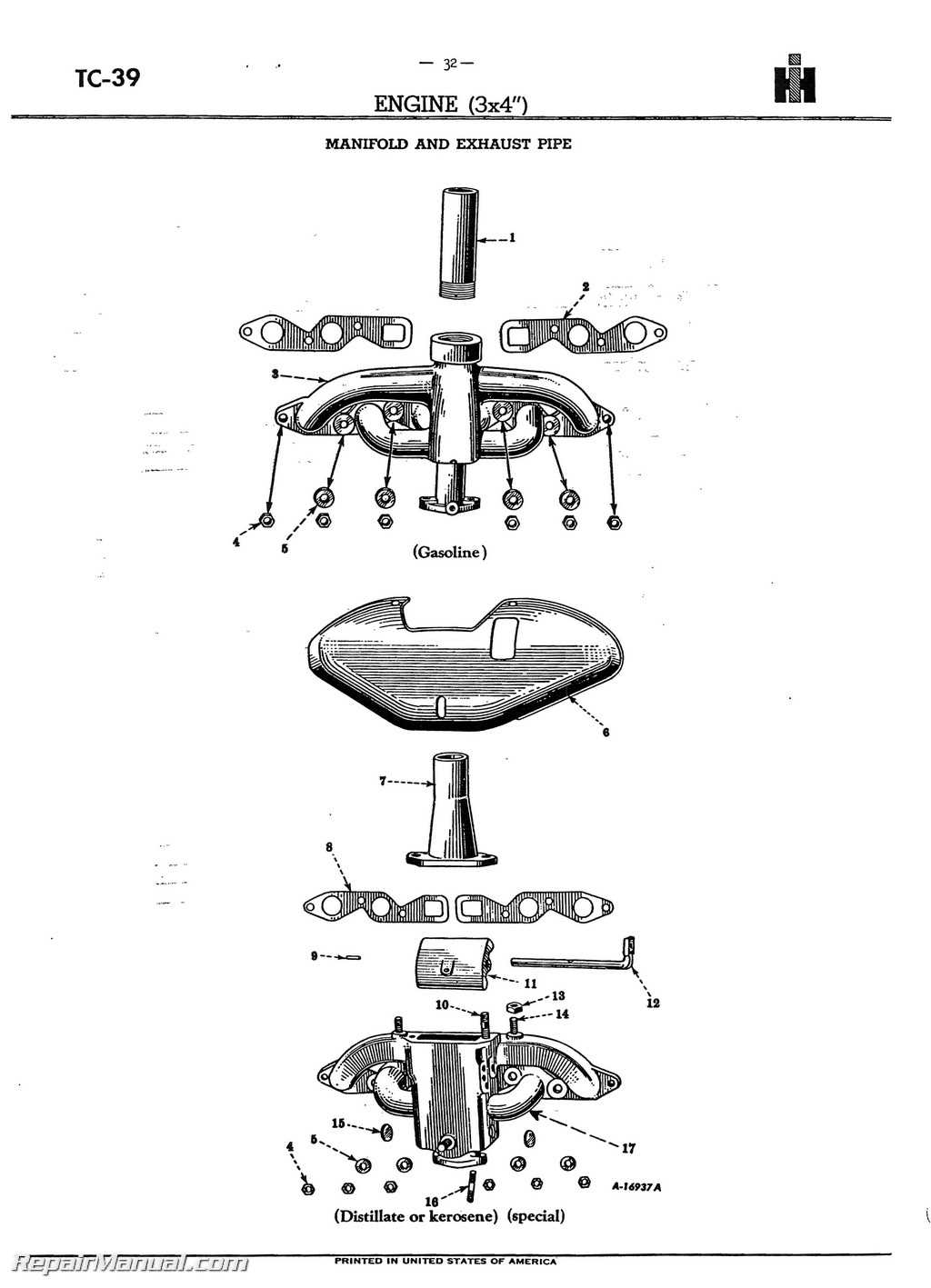

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a detailed view of each item, enabling users to identify and locate individual elements within a larger assembly. Familiarizing yourself with the symbols and layout can significantly enhance your efficiency when working on machinery.

Key Elements to Look For

- Labels: Each part is usually labeled with a specific number or code that corresponds to a reference list.

- Lines and Arrows: These indicate relationships between components, showing how they connect or interact with one another.

- Views: Diagrams may display different angles, such as top, side, or exploded views, to provide clarity.

Steps to Interpret Visual Representations

- Start by examining the overall layout to get a sense of the structure.

- Identify the key elements using the labeled references.

- Follow the lines and arrows to understand the connections and assembly order.

- Consult the accompanying documentation for additional context or specifications.

Tools Needed for Assembly

When undertaking an assembly project, having the right tools is essential for ensuring a smooth and efficient process. Each tool serves a specific purpose, contributing to the overall success of the task at hand. From precision instruments to robust equipment, a well-equipped workspace can significantly enhance productivity and minimize frustration.

Essential Tools

Wrenches and Sockets: These are crucial for tightening and loosening various components. A comprehensive set will allow for better access to different sizes and types of fasteners.

Torque Wrench: This tool is vital for applying the correct amount of force to bolts and screws, preventing damage to the assembly.

Additional Equipment

Drill and Drill Bits: A versatile drill is important for creating holes and driving screws. Having a variety of bits on hand will accommodate different materials and sizes.

Measuring Tools: Accurate measurements are fundamental. A tape measure, caliper, and square will help ensure that all components fit together correctly.

By gathering these essential tools before starting your assembly project, you set the stage for a successful and efficient experience.

Maintenance Tips for Farmall Tractors

Regular upkeep is essential for ensuring the longevity and optimal performance of agricultural machinery. Proper maintenance practices not only enhance efficiency but also reduce the risk of unexpected breakdowns. This guide provides valuable insights into effective care routines that can keep your equipment running smoothly.

Routine Inspections

- Check fluid levels regularly, including oil, coolant, and hydraulic fluids.

- Inspect belts and hoses for signs of wear or damage.

- Examine tires for proper inflation and tread wear.

- Clean air filters to ensure efficient airflow to the engine.

Seasonal Maintenance

- Spring: Change oil and replace filters to prepare for the busy season.

- Summer: Monitor cooling systems to prevent overheating during high-use periods.

- Fall: Inspect and clean fuel systems to prepare for storage.

- Winter: Store machinery in a dry, sheltered area to protect against harsh conditions.

Adhering to these maintenance strategies can significantly extend the lifespan of your agricultural equipment while enhancing productivity on the field.

Where to Find Reliable Diagrams

Finding trustworthy visual guides is crucial for anyone involved in maintenance and repair work. Accessing accurate resources ensures that you can complete tasks effectively and safely, reducing the likelihood of errors.

Online Resources

- Manufacturer websites: Often provide official documentation.

- Dedicated forums: Communities sharing experiences and resources.

- Online marketplaces: Vendors offering manuals and schematics.

Printed Materials

- Local libraries: Often have technical books and guides.

- Specialty bookstores: Focused on agricultural equipment literature.

- Trade shows: Opportunities to collect materials directly from experts.

Using Diagrams for Troubleshooting

Visual representations are invaluable tools when diagnosing issues in complex machinery. They provide a clear layout of components, allowing users to pinpoint faults and understand the interconnections between parts. By leveraging these illustrations, one can streamline the troubleshooting process, saving both time and effort.

Benefits of Visual Aids

- Enhanced Understanding: Diagrams break down intricate systems into manageable sections, making it easier to grasp how each element functions.

- Quick Reference: A visual guide serves as an immediate reference during inspections, helping identify which components need attention.

- Efficient Problem-Solving: By visualizing potential failure points, users can focus their efforts on specific areas, reducing guesswork.

Effective Troubleshooting Strategies

- Identify Symptoms: Start by noting any irregular behaviors or signs of malfunction.

- Consult the Visual Aid: Use the illustration to locate the components associated with the identified issues.

- Isolate and Test: Focus on specific parts as indicated in the diagram and conduct tests to determine functionality.

- Document Findings: Keep a record of any discovered faults or successful repairs for future reference.

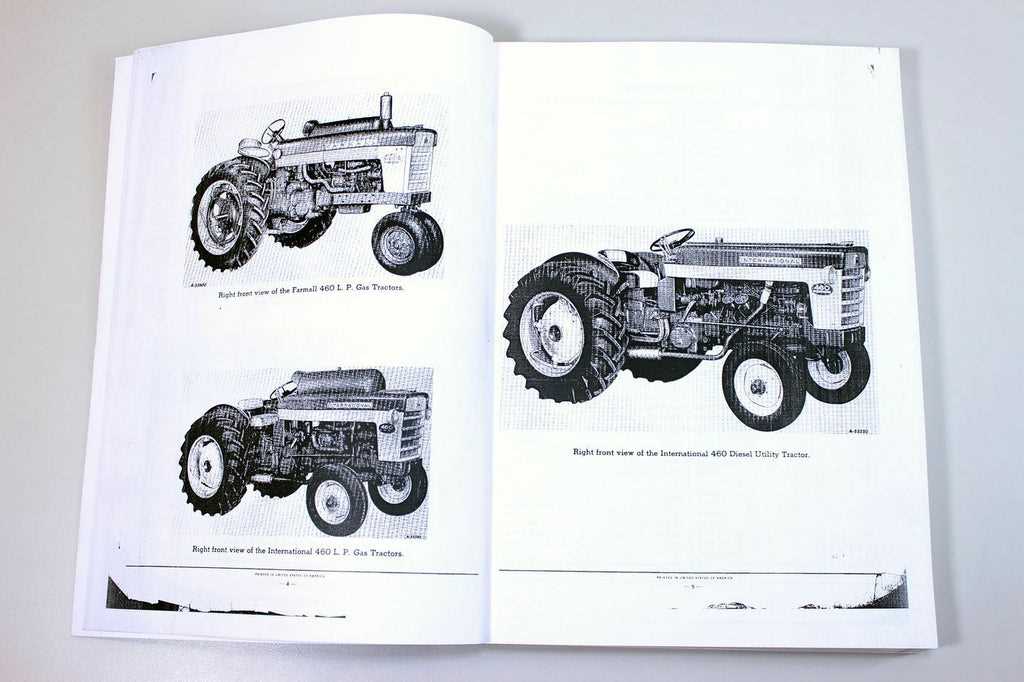

Comparing Diagrams Across Models

When analyzing technical illustrations for various agricultural machinery models, it’s crucial to recognize the differences and similarities that can impact maintenance and repair tasks. Each version may have unique features that require a tailored approach, yet understanding commonalities can streamline processes for technicians and enthusiasts alike.

By examining these illustrations side by side, users can identify key components, assembly configurations, and potential areas for cross-reference. This comparative analysis not only aids in troubleshooting but also enhances the overall comprehension of machinery functions across different designs.

| Model | Component Similarities | Distinct Features |

|---|---|---|

| Model A | Engine layout, transmission | Hydraulic system configuration |

| Model B | Transmission, wheel assembly | Steering mechanism design |

| Model C | Engine type, frame structure | Control panel interface |

This structured approach not only facilitates effective repairs but also enriches the knowledge base of users who engage with multiple machinery types. Understanding these relationships allows for informed decision-making regarding repairs and upgrades across various models.

Future of Farmall Parts Documentation

The evolution of documentation for machinery components is essential for enhancing user experience and operational efficiency. As technology advances, new methods of organizing and accessing information will transform how enthusiasts and professionals interact with their equipment.

Innovative Approaches

- Utilization of augmented reality to visualize components in real-time.

- Development of interactive platforms for user-generated content and troubleshooting.

- Integration of artificial intelligence for personalized recommendations and guidance.

Accessibility and Sustainability

- Emphasis on cloud-based solutions for easy access to documentation from anywhere.

- Creation of digital archives to preserve historical data and facilitate research.

- Commitment to sustainability by reducing printed materials and promoting eco-friendly practices.