Comprehensive Guide to Foodsaver Parts Diagram

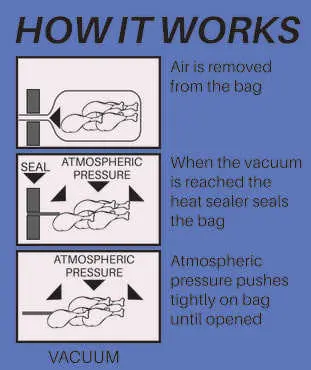

Vacuum sealing systems are essential devices for preserving food and ensuring long-term freshness. These machines work by removing air from specially designed bags or containers, creating a tight seal that helps to lock in flavor and prevent spoilage. Each element of the system plays a crucial role in making sure the process is efficient and reliable. Having a good grasp of the inner workings of these systems can help you troubleshoot issues and maintain optimal performance.

The entire system relies on several interconnected mechanisms working in harmony. From the sealing bar to the vacuum pump, every detail contributes to the device’s efficiency. By exploring these individual components, users can better understand how

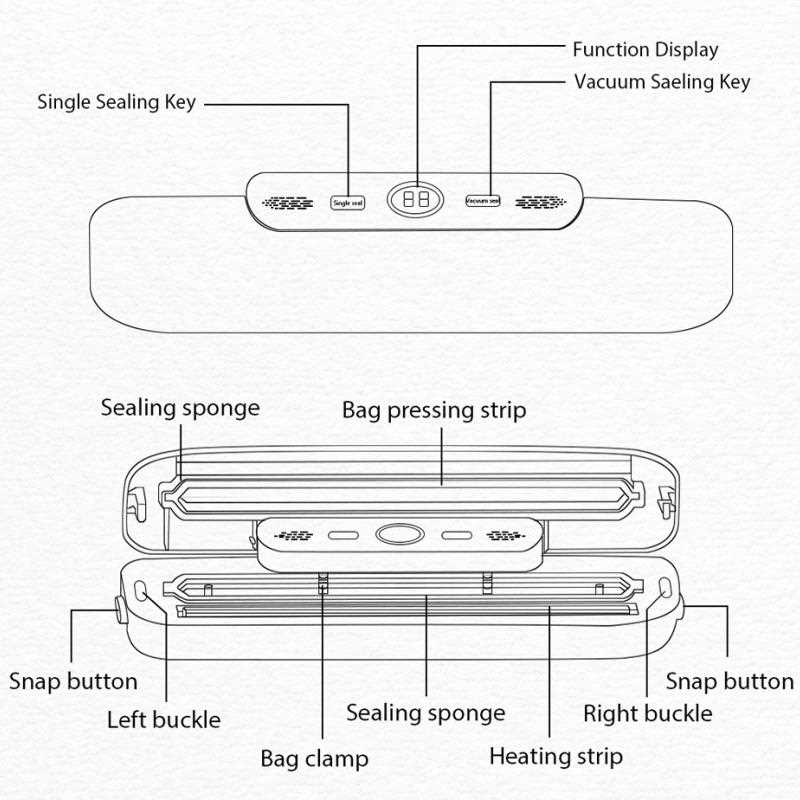

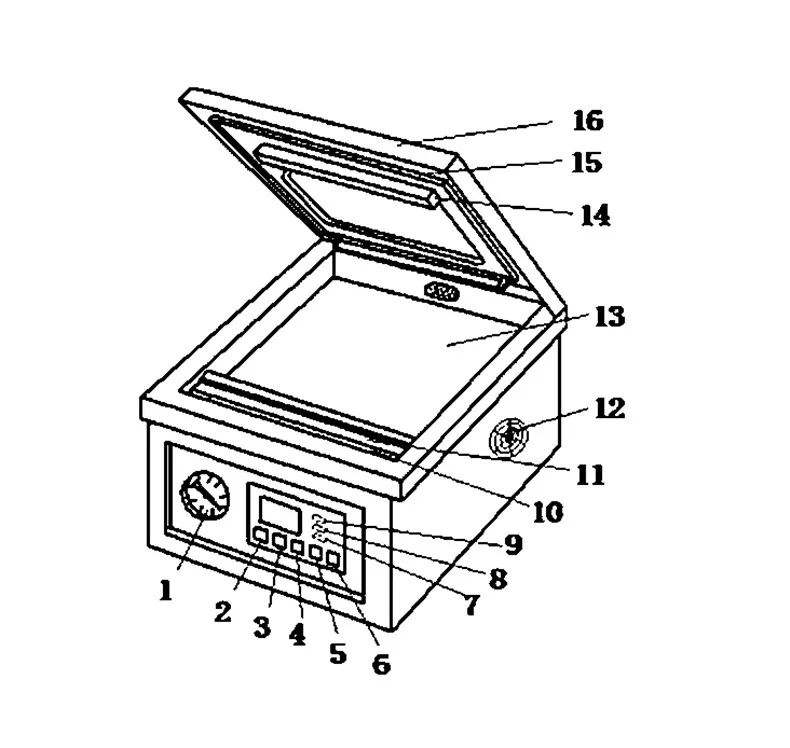

Understanding the Foodsaver Appliance Components

The vacuum sealing system is designed with several key elements that work together to preserve freshness and extend the shelf life of food. Each component plays a vital role in ensuring the machine operates efficiently, creating an airtight seal to lock in flavor and protect against spoilage.

The main unit houses the motor and vacuum pump, responsible for removing air from the storage bags. A sealing bar is heated to fuse the plastic, forming a tight closure. The control panel allows users to adjust settings for different food types, ensuring the optimal level of suction and sealing. Additional elements, such as the bag storage compartment and cutting mechanism, streamline the process by offering convenient access and precision cutting of bags. Lastly, the drip tray helps collect excess liquid

Key Internal Parts of a Vacuum Sealer

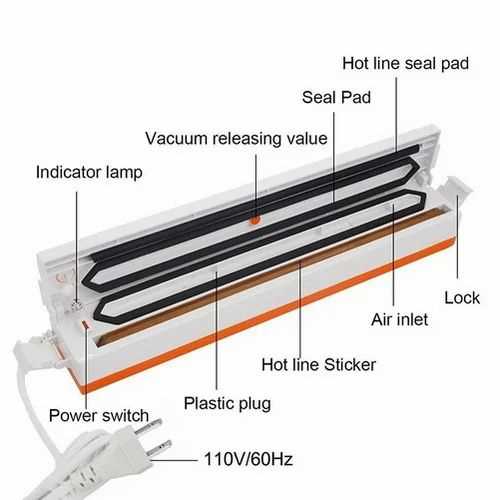

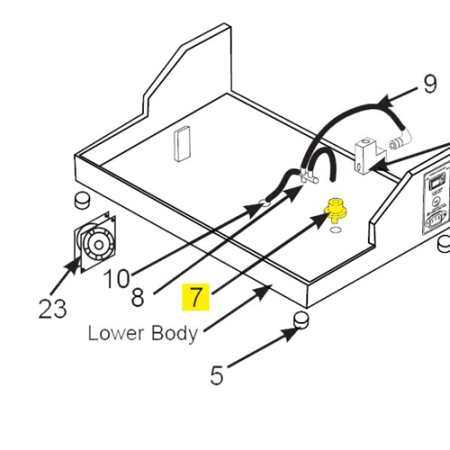

The internal mechanisms of a vacuum sealer play a crucial role in creating an airtight environment. Each component is designed to perform specific tasks that ensure proper sealing, air extraction, and overall functionality.

- Vacuum Pump – Responsible for extracting air from the sealing chamber, creating a vacuum within the packaging.

- Sealing Bar – This heated element ensures that the bag is tightly sealed, preventing air from re-entering after vacuuming.

- Gasket – Provides an airtight seal around the lid, helping to maintain suction during the vacuuming process.

- Air Intake Valve – Regulates the flow of air into

Exploring the Lid Assembly of a Foodsaver

The upper section of vacuum sealers plays a crucial role in the overall functionality of the device. This component is designed to ensure airtight closure, which is essential for preserving the freshness of stored items. Understanding how this section operates allows for better maintenance and troubleshooting of the machine, contributing to its longevity and performance.

Key elements within the top portion work together to create the necessary suction and secure sealing. These include a sealing strip, valves, and other integral parts that ensure the machine functions properly. Proper alignment and cleanliness of these elements are vital for achieving optimal results when sealing food.

Maintaining and regularly inspecting this section helps in preventing common issues such as incomplete seals or loss of vacuum pressure. By keeping the area free from debris and ensuring all parts are

How the Sealing Strip Works

The sealing mechanism is a crucial component that ensures airtight closure, allowing long-term preservation of various items. It operates by creating a secure bond, preventing external elements from entering and compromising the sealed contents. Understanding its operation helps ensure optimal performance in maintaining freshness and quality.

Material and Structure

The strip is typically made from durable, heat-resistant materials. When activated, it uses heat to fuse together the edges of the bag, creating a tight, impervious seal. The quality of the material plays a vital role in ensuring consistent sealing, especially with different bag thicknesses or materials.

Heat Activation Process

The sealing strip is designed to be activated only at the right moment, ensuring precision in the sealing process. As the heating element generates sufficient warmth, the strip applies pressure

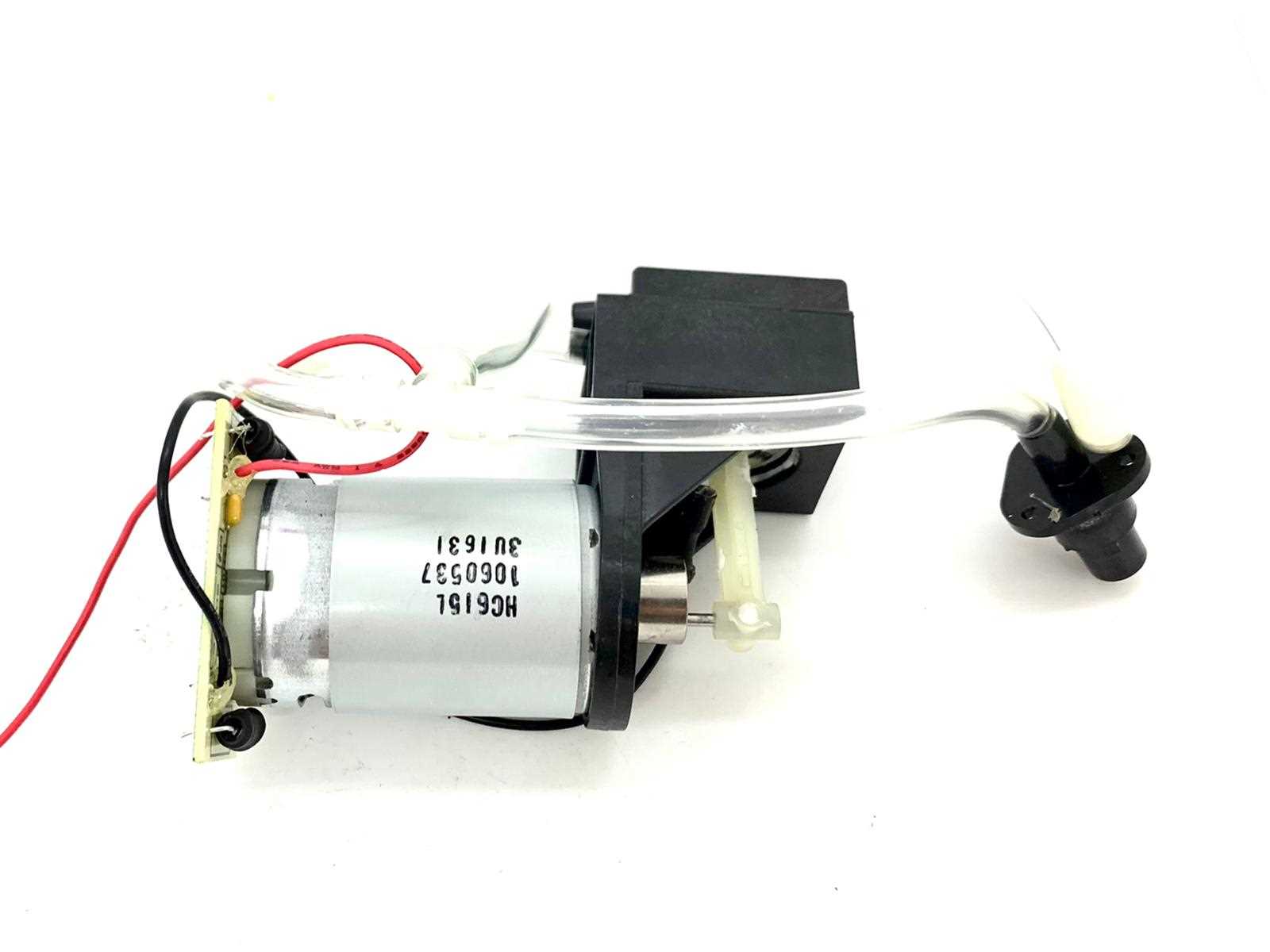

Vacuum Pump Mechanism Breakdown

The vacuum pump is an essential component in maintaining an airtight seal and removing air from storage bags or containers. It works through a precise sequence of movements, ensuring that the environment within the packaging remains as close to a vacuum as possible.

Main components include the pump chamber, valves, and motor, each playing a critical role in the process. The pump chamber creates the negative pressure, while the inlet and outlet valves control the air flow, ensuring one-directional movement. The motor powers the entire system, driving the pump’s functionality.

Proper alignment and synchronization

Role of the Foam Gasket in Sealing

The foam gasket plays a crucial role in ensuring a tight seal in various vacuum sealing systems. Its design and material properties are essential for creating a reliable barrier that prevents air from entering the sealed environment, thereby preserving the freshness of stored items.

Key functions of the foam gasket include:

- Air Leakage Prevention: The primary purpose of the gasket is to eliminate gaps between surfaces, preventing air from entering the sealed area.

- Moisture Resistance: The foam material often exhibits properties that resist moisture, which is vital for maintaining the quality of stored food items.

- Durability: High-quality foam gaskets are designed to withstand repeated use without losing their sealing properties, ensuring long-term effectiveness.

- Easy Replacement: Many sealing systems allow for easy removal and replacement of the gasket, enabling users to maintain optimal sealing performance over time.

In summary, the foam gasket is an integral component in maintaining the integrity of vacuum-sealed environments, directly impacting the preservation of the contents within.

Heating Element Function in Foodsavers

The heating element is a crucial component in vacuum sealing devices, playing a vital role in preserving food by creating an airtight seal. Its primary function involves generating heat to melt the sealing film, allowing it to bond securely to the container or bag. This process is essential for preventing air from entering, which helps extend the shelf life of stored items.

When the machine is activated, the heating element quickly reaches the desired temperature, ensuring an efficient and reliable seal. The design of this component is engineered to deliver consistent heat across the sealing area, preventing any weak points that could compromise the seal. Furthermore, the element’s performance is optimized to minimize energy consumption while maximizing effectiveness, making it an integral part of the preservation process.

Regular maintenance of the heating element is necessary to ensure its longevity and performance. Over time, residues from food products may accumulate, potentially affecting its efficiency. Keeping this component clean not only enhances its functionality but also contributes to the overall reliability of the vacuum sealing unit.

Importance of Drip Tray in Vacuum Sealers

The drip tray is a crucial component in vacuum sealing appliances, serving multiple purposes that enhance both functionality and user experience. It plays a significant role in maintaining cleanliness during the sealing process, ensuring that any excess liquid or debris is contained effectively. This not only prevents mess but also prolongs the lifespan of the device by reducing the risk of damage from spills.

Furthermore, the drip tray aids in the efficient operation of the vacuum sealer by facilitating proper air removal and vacuum formation. By capturing unwanted fluids, it ensures that the sealing process is performed optimally, resulting in better preservation of food quality.

Function Benefit Collects excess liquid Reduces mess and cleanup time Protects internal components Extends the lifespan of the appliance Enhances vacuum efficiency Improves food preservation In summary, the drip tray is an essential feature that not only keeps the workspace tidy but also enhances the overall performance of vacuum sealing devices. Understanding its importance can lead to more efficient food storage solutions.

Understanding the Bag Cutter Assembly

The bag cutter assembly plays a crucial role in the efficient operation of vacuum sealing devices. This component is designed to streamline the process of preparing storage bags, ensuring clean and precise cuts for optimal sealing. Understanding its structure and function can enhance the user experience and improve the overall effectiveness of food preservation methods.

Key components of the bag cutter assembly include:

- Cutter Blade: The sharp edge responsible for slicing through material, allowing for custom-sized bags.

- Holder: A fixture that securely supports the cutting blade, ensuring stability during operation.

- Guiding Track: A pathway that directs the bag material as it is fed through the cutter, providing accuracy in cutting.

- Lever Mechanism: A manual or automatic feature that activates the blade for cutting, allowing for ease of use.

To maintain optimal performance of the cutter assembly, consider the following tips:

- Regularly inspect the blade for sharpness; replace if dull.

- Clean the cutting area to prevent buildup of food particles.

- Ensure the holder is secure and free from any obstructions.

- Test the guiding track for smooth operation to prevent jams.

By familiarizing yourself with these elements, you can ensure that the bag cutter assembly functions effectively, enhancing the efficiency of your food storage solutions.

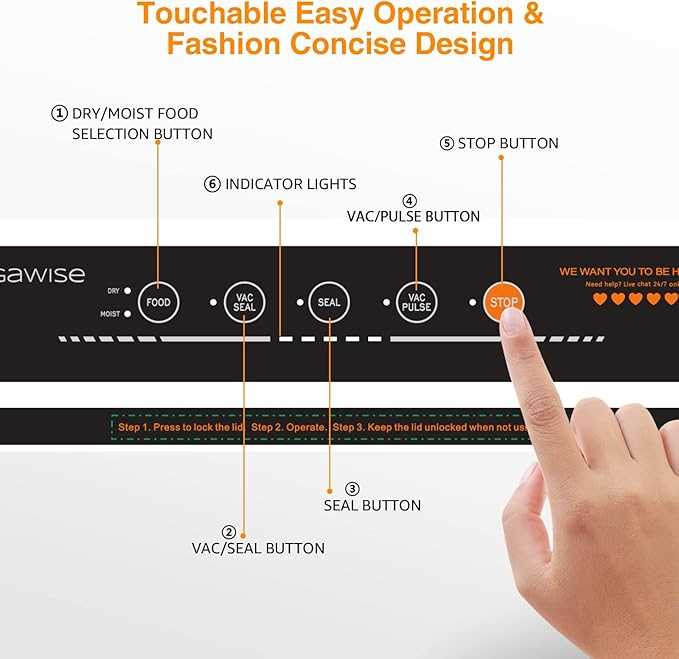

Button and Control Panel Layout Overview

The control interface of a vacuum sealing appliance plays a crucial role in its functionality and user experience. Understanding the arrangement and purpose of each element can significantly enhance the efficiency of the sealing process. This section provides an overview of the control layout, highlighting the various buttons and indicators that facilitate easy operation.

Typically, the interface includes several buttons designated for specific actions, such as sealing, vacuuming, and canceling operations. These controls are strategically placed to ensure intuitive access during use. Additionally, visual indicators may be present to provide feedback on the current status of the device, such as whether it is actively sealing or in standby mode.

Furthermore, some models may feature advanced settings, allowing users to customize their sealing preferences. These settings could include options for different types of bags or varying levels of vacuum pressure. Familiarizing oneself with these controls enables users to maximize the effectiveness of their appliance and achieve optimal results.

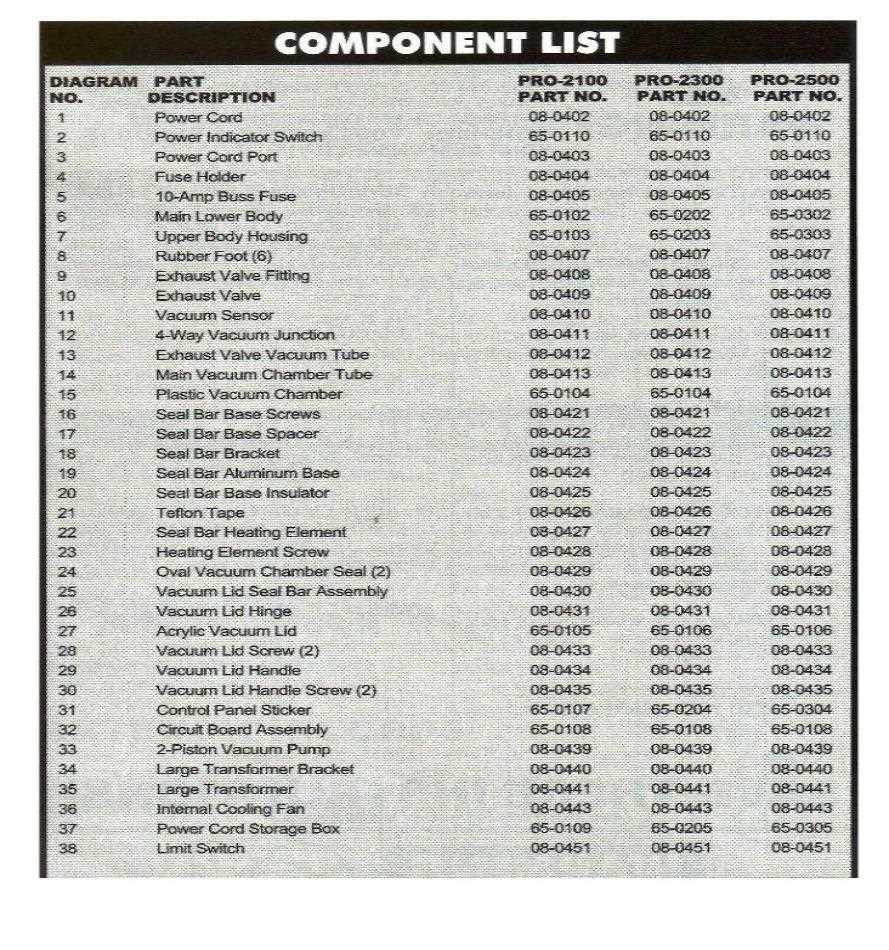

Replacing and Maintaining Foodsaver Parts

Regular upkeep and timely substitution of components are essential for optimal performance and longevity of your vacuum-sealing device. By addressing wear and tear promptly, users can ensure that their unit continues to operate effectively, preserving food freshness and minimizing waste. This section covers key considerations and procedures for maintaining and replacing crucial elements of your appliance.

Essential Components to Monitor

Pay special attention to items such as sealing strips, gaskets, and filters. These elements can degrade over time, affecting the vacuum process and seal integrity. Regular inspection can help identify any signs of damage or wear, enabling proactive maintenance before significant issues arise.

Steps for Replacement

Begin by consulting the manufacturer’s manual for guidance on removing and replacing specific components. Use appropriate tools and follow safety precautions to prevent injury. After replacing parts, perform a test run to verify that the device is functioning correctly and creating a strong seal.