Comprehensive Guide to Fs38 Parts Diagram

In the world of machinery and tools, a comprehensive understanding of the intricate configurations of their elements is crucial. Each device consists of numerous segments that work in harmony to achieve optimal performance. This section delves into the essential aspects of these configurations, allowing users to familiarize themselves with the various components and their interrelations.

Clarity in identifying each segment is vital for effective maintenance and troubleshooting. By grasping the arrangement of these parts, operators can enhance their ability to diagnose issues swiftly and accurately. This knowledge empowers users to keep their equipment running smoothly and extend its lifespan.

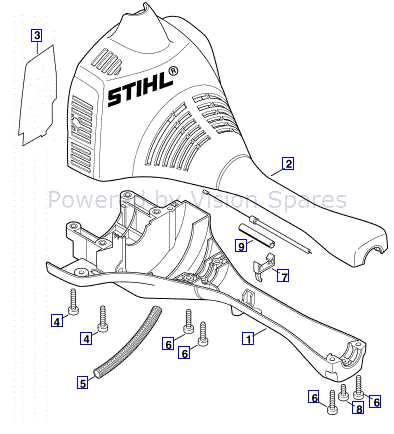

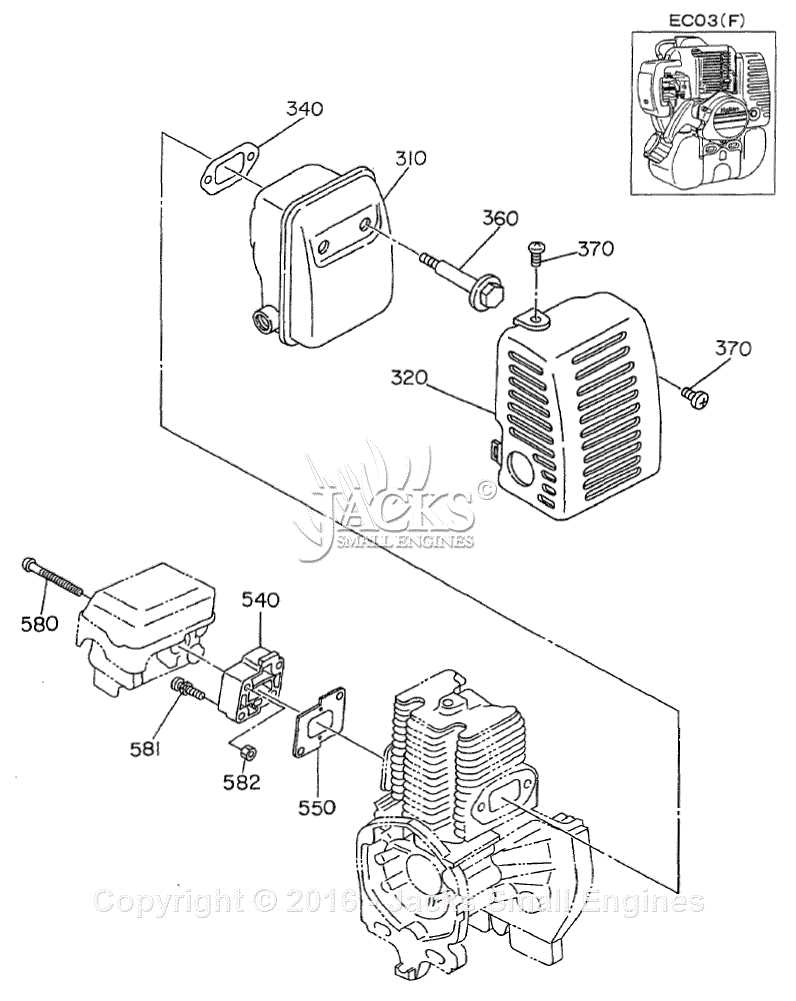

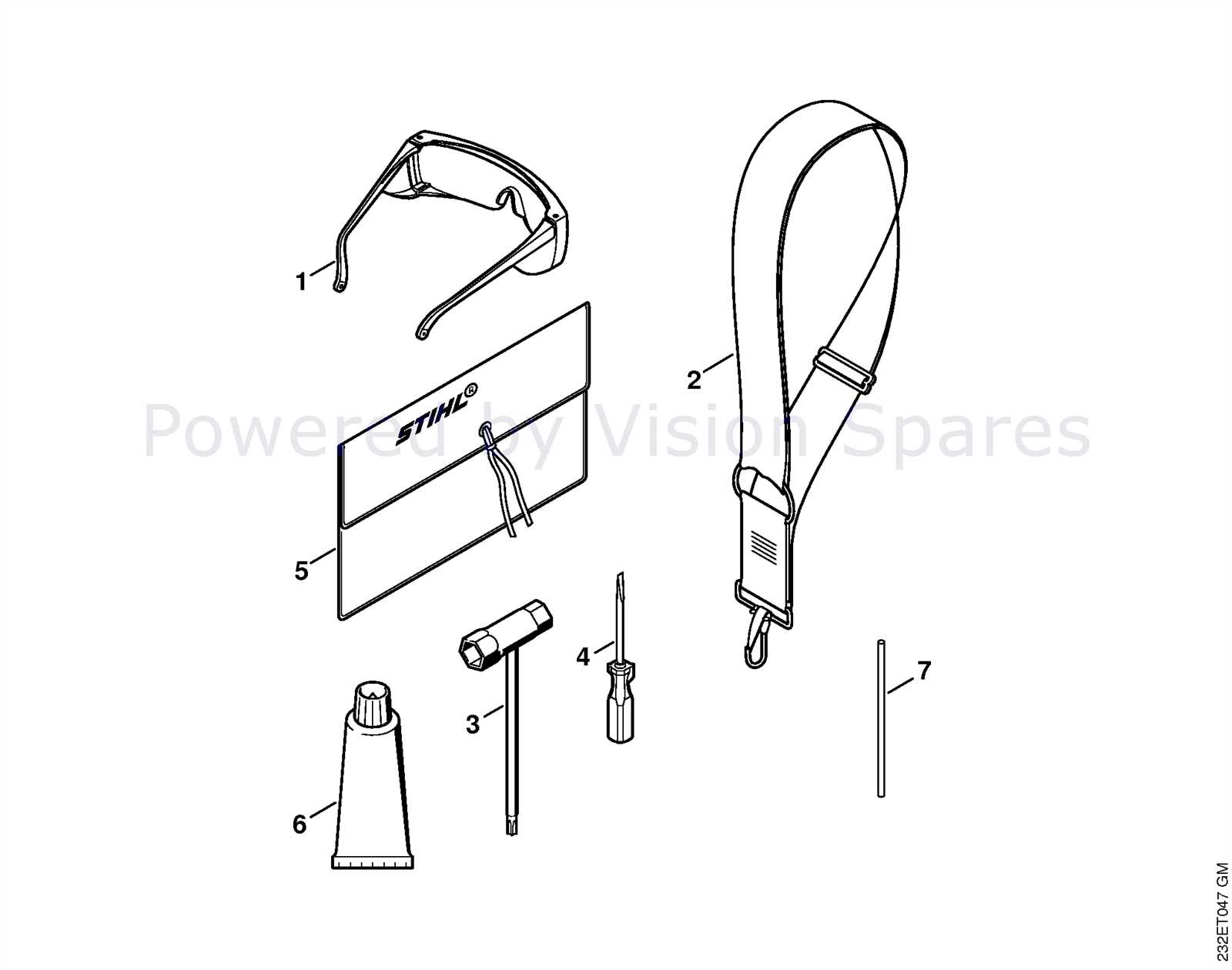

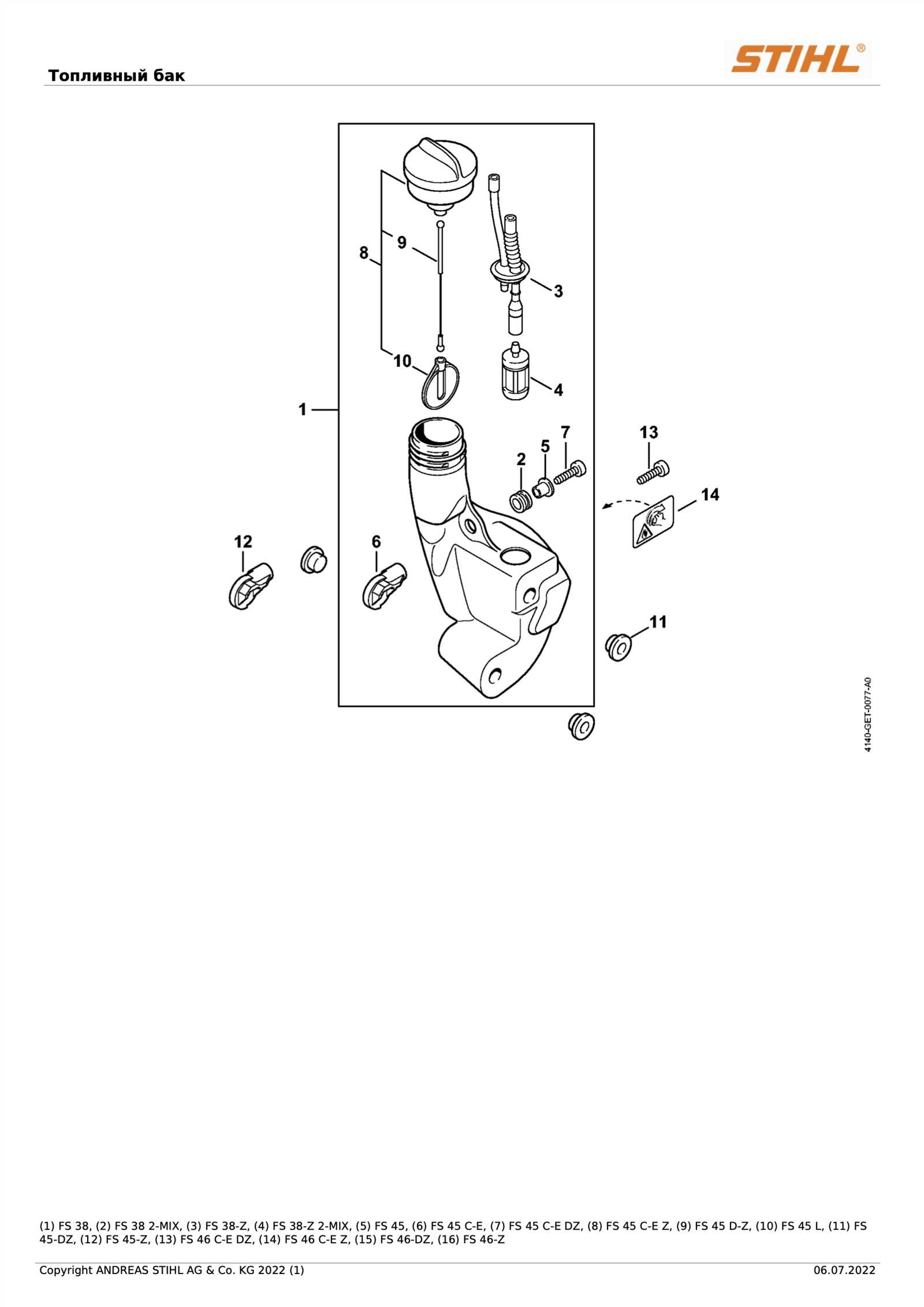

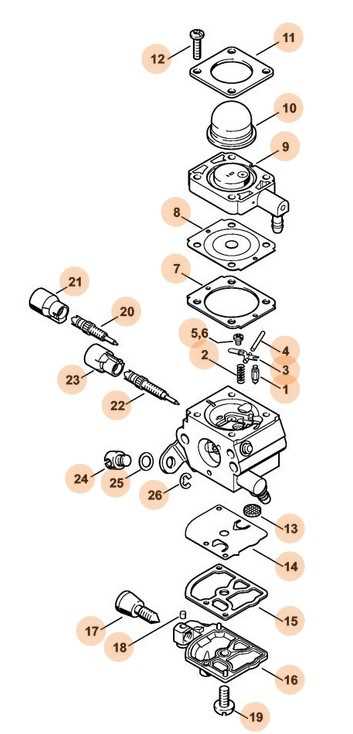

Additionally, visual representations of these configurations play a significant role in facilitating comprehension. Such illustrations offer a clear roadmap, guiding users through the complexity of the machinery. Whether for educational purposes or practical applications, these visual aids are indispensable in mastering the intricate workings of any device.

Understanding the Fs38 Parts Diagram

Grasping the intricate layout of components within a machine is essential for effective maintenance and repair. A well-structured visual representation serves as a valuable guide, enabling users to identify various elements and comprehend their relationships. This understanding is crucial for troubleshooting, assembly, and ensuring optimal functionality.

Key Elements of the Visual Representation

To effectively navigate the schematic, it’s important to familiarize oneself with several core features:

- Labels: Each component is typically marked with unique identifiers, simplifying the process of locating and referencing specific parts.

- Connections: Arrows and lines illustrate how different pieces interact and connect with one another, providing clarity on assembly procedures.

- Categories: Components may be grouped based on their functions, helping users to quickly find relevant sections.

Benefits of Utilizing the Visual Guide

Employing this schematic offers numerous advantages:

- Efficiency: Streamlines the identification process, reducing time spent on repairs.

- Accuracy: Minimizes the risk of errors during assembly or disassembly by providing clear visual cues.

- Training Tool: Serves as an educational resource for individuals new to machinery, enhancing their understanding of mechanical systems.

Components Overview of Fs38 Model

This section provides a comprehensive look at the various elements that constitute the operational framework of the model. Understanding these components is essential for effective maintenance and functionality, ensuring optimal performance in various applications.

Key Elements

The primary components play critical roles in the overall efficiency and reliability. Each piece is designed to work in harmony, contributing to the seamless operation of the unit. Regular inspection and timely replacement of these elements can prevent potential failures.

System Integration

Integration of the various segments enhances the model’s effectiveness. The synergy between different components not only improves performance but also extends the lifespan of the equipment. Identifying and addressing wear or damage in these areas is crucial for sustained functionality.

Importance of Accurate Diagrams

Clear representations play a crucial role in understanding complex systems. They serve as visual guides, simplifying intricate information and allowing users to grasp essential components and their interrelations. When these illustrations are precise, they enhance comprehension and facilitate effective communication among users.

Reliability is another vital aspect. When users refer to well-crafted visual aids, they can trust the information presented. This trust minimizes errors during assembly, maintenance, or troubleshooting, ensuring that tasks are completed efficiently and safely.

Furthermore, detailed visuals foster learning and retention. Users are more likely to remember information when it is depicted graphically, allowing for quicker recall when needed. This is especially beneficial in training scenarios, where new users can become familiar with systems faster.

Ultimately, the accuracy of these illustrations directly impacts performance and functionality. When users have access to reliable and clear visual references, they can navigate tasks with confidence, leading to better outcomes and enhanced productivity.

How to Read the Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate and interpret the intricacies of these illustrations, ensuring you can identify and locate each item with ease.

Begin by familiarizing yourself with the layout:

- Orientation: Check the orientation key. Most visuals will have a reference point or a legend indicating the direction and placement of parts.

- Labels: Each element is usually labeled with numbers or letters. Cross-reference these with the accompanying list to find detailed descriptions.

- Grouping: Components may be grouped by function or location. Recognizing these clusters can simplify understanding their roles.

- Color Coding: Pay attention to any color codes that might indicate specific categories or functionalities.

Once you grasp the basic structure, focus on these key aspects:

- Connections: Observe how different elements connect. This can reveal the assembly process and highlight potential points of failure.

- Sizes and Scales: Check if there is a scale provided. Knowing the dimensions can help when ordering replacements.

- Common Issues: Familiarize yourself with common problem areas that might be indicated within the visual. This knowledge can aid in preventive maintenance.

By mastering these techniques, you’ll be better equipped to diagnose issues and perform repairs confidently, ensuring optimal performance of your equipment.

Common Issues in Fs38 Maintenance

Regular upkeep of gardening equipment is essential to ensure optimal performance and longevity. Neglecting minor problems can lead to more significant complications, making it crucial for users to be aware of common challenges that arise during maintenance.

Engine Troubles

One frequent concern involves engine issues, such as difficulty starting or stalling during operation. Fuel quality and filter clogs are often the culprits. Regular checks and replacements can significantly mitigate these problems, ensuring smoother operation.

Cutting Performance

Another common problem is subpar cutting efficiency, often linked to blade wear or incorrect tensioning. Keeping blades sharp and properly adjusted not only enhances performance but also extends the lifespan of the equipment.

Identifying Replacement Parts Easily

Understanding how to locate necessary components for maintenance can significantly enhance your efficiency and reduce downtime. By familiarizing yourself with the layout and organization of various elements, you can streamline the process of finding what you need. This knowledge not only saves time but also empowers you to make informed decisions when it comes to repairs or upgrades.

First and foremost, having a visual reference is crucial. Diagrams or schematics provide an overview of the entire system, allowing you to pinpoint specific items quickly. These illustrations often categorize components, making it easier to navigate complex machinery or devices.

Moreover, labeling is another effective strategy. When each element is clearly marked, identifying replacements becomes a straightforward task. This practice minimizes confusion and helps ensure that you select the correct items for your needs.

Finally, leveraging online resources can further aid in your search. Many websites offer detailed breakdowns of equipment, complete with images and descriptions. This accessibility allows you to compare options and ensure compatibility, ultimately leading to more efficient maintenance and repair processes.

Benefits of Using Official Diagrams

Utilizing authorized illustrations offers numerous advantages that enhance understanding and efficiency. These resources provide a reliable foundation for maintenance and repair, ensuring users can accurately identify components and their relationships within a system.

Accuracy and Reliability

- Official resources are meticulously crafted, minimizing the chances of errors.

- They reflect the latest updates and revisions, guaranteeing current information.

- Users can trust these visuals for precise component identification.

Improved Efficiency

- Streamlined processes lead to quicker troubleshooting and repairs.

- Clear visual representations reduce confusion and enhance comprehension.

- Time-saving advantages ultimately lead to lower operational costs.

Comparing Fs38 with Other Models

When evaluating a specific model within its category, it is essential to consider its features and performance in relation to similar options. Each design offers unique strengths and weaknesses, which can significantly impact usability and efficiency for the end user. This analysis aims to highlight the distinctive characteristics that set this particular model apart from its peers.

One notable aspect is the engine capacity and power output, which can influence the overall effectiveness in various tasks. While some alternatives may boast higher horsepower, this model often excels in fuel efficiency and ease of handling. Users looking for a balance between power and practicality may find this model particularly appealing.

Furthermore, durability and maintenance requirements play a crucial role in the decision-making process. Compared to other designs, this option may require less frequent servicing, providing an advantage for those who prioritize long-term reliability. The availability of replacement components and accessories also enhances its appeal, ensuring that users can easily maintain and upgrade their equipment.

Another point of comparison is user experience and ergonomics. This model often features a more comfortable grip and intuitive controls, making it suitable for prolonged use. In contrast, some competitors may offer a steeper learning curve, which could deter novice users.

Ultimately, when choosing the right equipment, understanding these comparisons is vital. Prospective buyers should consider their specific needs and preferences, weighing the benefits of each option to find the best fit for their intended tasks.

Maintenance Tips for Fs38 Parts

Ensuring the longevity and efficiency of your equipment requires regular attention and care. Proper upkeep not only enhances performance but also reduces the risk of unexpected breakdowns. Here are some essential guidelines to follow for maintaining your machinery components effectively.

- Regular Cleaning: Keep all surfaces free from dirt and debris. Use appropriate cleaning solutions to avoid damage.

- Inspect for Wear: Frequently check for signs of wear and tear. Early detection can prevent larger issues down the line.

- Lubrication: Apply suitable lubricants to moving parts as recommended by the manufacturer to ensure smooth operation.

- Tightening Fasteners: Periodically check and tighten screws, nuts, and bolts to maintain structural integrity.

- Replace Damaged Components: Promptly replace any broken or worn components to maintain optimal performance.

By adhering to these practices, you can prolong the life of your equipment and ensure it operates at peak efficiency.

Where to Find Quality Diagrams

Accessing high-quality visuals can significantly enhance your understanding of machinery and its components. Reliable resources play a crucial role in ensuring that you have accurate information at your fingertips. Exploring various platforms dedicated to technical information is essential for obtaining these valuable illustrations.

Online Manuals and Guides: Many manufacturers offer detailed manuals online, which often include comprehensive visuals. These can be found on official websites or trusted forums where enthusiasts share insights.

Specialized Communities: Joining forums and social media groups focused on equipment can provide access to user-shared resources. Members often post their findings, including useful illustrations that may not be readily available elsewhere.

Retailers and Suppliers: Some retailers provide downloadable content that includes informative visuals as part of their service. Check the websites of parts suppliers for such resources.

Library Resources: Local libraries often have technical books and manuals. These printed resources can be incredibly beneficial for in-depth research and reference.

Online Marketplaces: Websites that specialize in technical content may offer purchasable or downloadable visuals. Look for those with positive reviews to ensure quality.

Understanding Part Numbers and Codes

In the realm of machinery and equipment, identifiers play a crucial role in ensuring that components are accurately matched with their respective devices. These codes serve as a universal language, simplifying the process of procurement, maintenance, and replacement. Understanding how to read and interpret these identifiers can greatly enhance efficiency and reduce errors.

Each code typically consists of a combination of letters and numbers that convey specific information about the item. The structure of these identifiers can vary, but they generally include details such as the type of component, its size, and even the manufacturing date. Familiarity with this system can empower users to quickly identify the exact part needed for their repair or maintenance tasks.

| Code Structure | Description |

|---|---|

| Letter Prefix | Indicates the category of the component |

| Numerical Sequence | Represents the specific model or size |

| Suffix | May denote a variation or revision of the part |

By breaking down these codes into their individual components, users can gain valuable insights into the functionality and compatibility of various items. This understanding not only aids in selecting the right replacement but also fosters a deeper appreciation of the machinery as a whole.

Tips for Ordering Parts Online

When purchasing components through the internet, ensuring a smooth transaction is essential for a successful experience. Following specific guidelines can help you avoid common pitfalls and make informed choices.

Research Thoroughly: Before finalizing any purchase, investigate the seller’s reputation and reviews. Understanding others’ experiences can provide valuable insights.

Verify Compatibility: Always check that the item you intend to buy matches your requirements. Use model numbers and specifications to confirm fit.

Compare Prices: Take the time to look at various suppliers. This not only helps you find the best deal but also reveals potential alternatives.

Read Descriptions Carefully: Detailed product descriptions can often clarify any doubts. Pay attention to dimensions, materials, and other relevant details.

Consider Shipping Costs: Be mindful of additional expenses that might apply. Sometimes, a lower initial price may lead to higher shipping fees.

Keep Track of Your Orders: Maintain a record of your purchases and any confirmation emails. This will assist in tracking your items and managing returns if necessary.

By following these tips, you can enhance your online shopping experience and ensure you receive the right items efficiently.

FAQs About Fs38 Parts Diagram

This section addresses common inquiries related to the components and their organization within a specific model. Understanding the layout and function of each element can enhance maintenance and troubleshooting processes.

What are the key components I should know about?

Familiarizing yourself with essential elements such as the engine, fuel system, and cutting apparatus is crucial for effective operation and upkeep. Each part plays a significant role in overall functionality.

Where can I find replacement components?

Replacement elements can typically be sourced from authorized dealers, online retailers, or specialized stores. Ensuring you select compatible items is vital for maintaining performance.