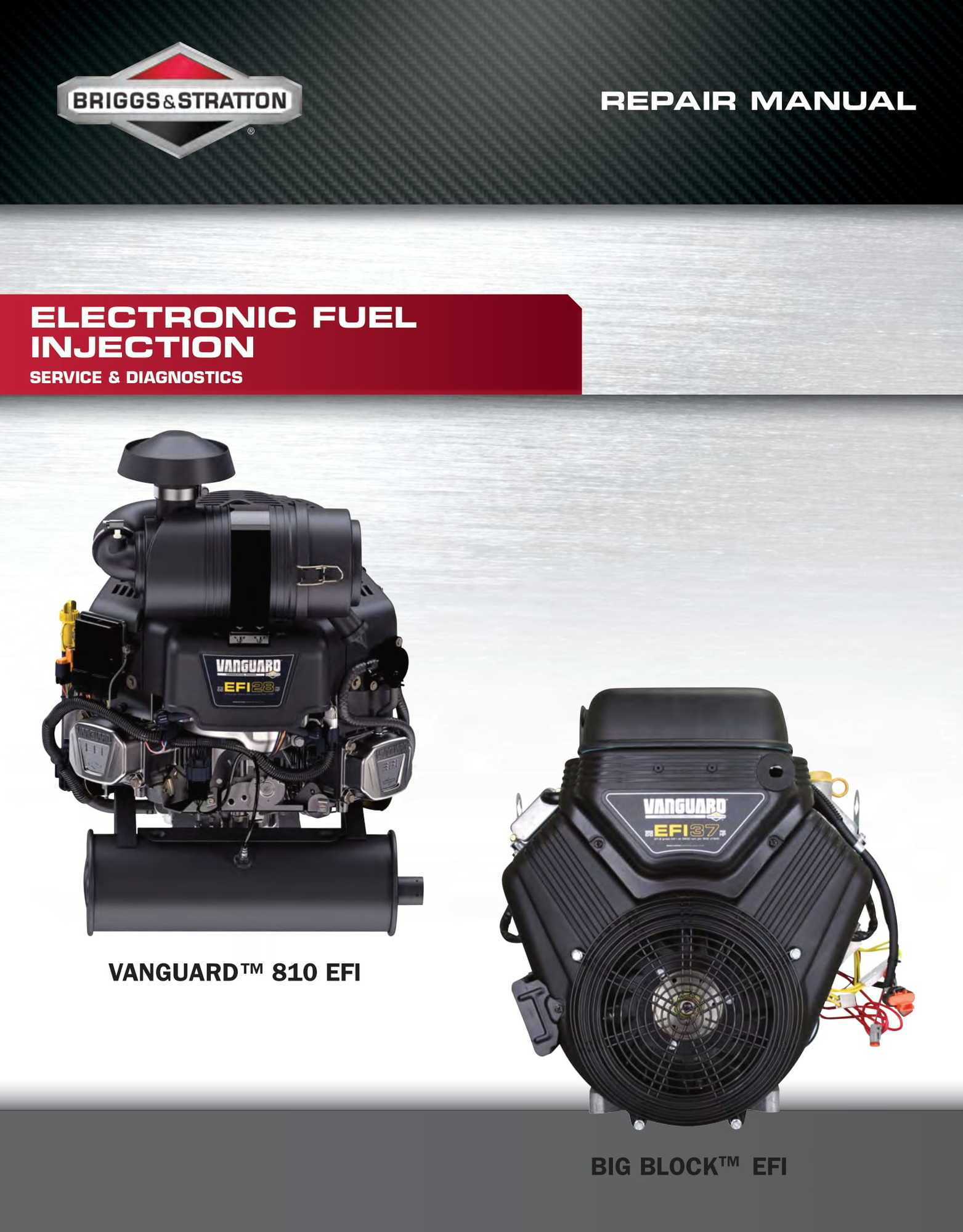

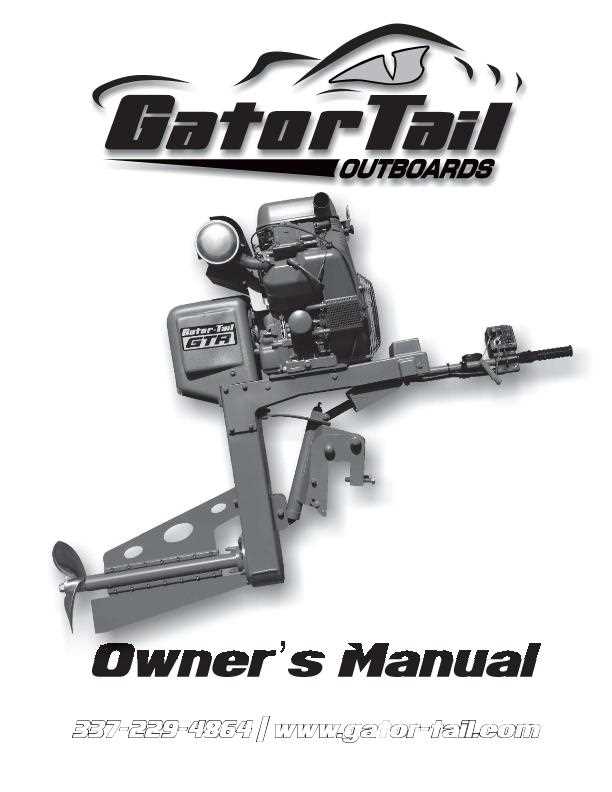

Understanding the Gator Tail Parts Diagram for Better Maintenance

When it comes to maximizing the functionality and longevity of your utility vehicle, a comprehensive understanding of its various components is essential. Each element plays a crucial role in the overall performance and reliability of the machine. Whether you’re a seasoned operator or a newcomer, familiarizing yourself with these essential features can significantly enhance your maintenance routine.

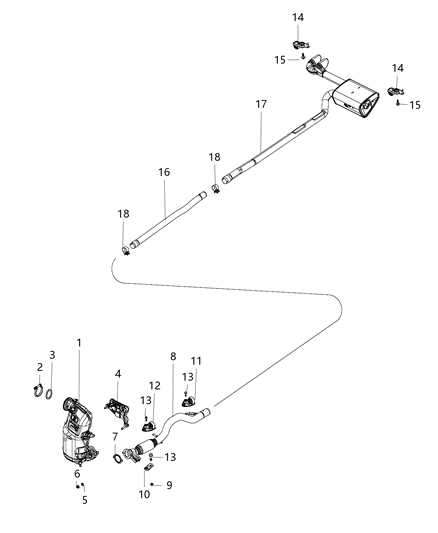

Visual aids can be invaluable tools in grasping the intricate details of your vehicle’s assembly. By breaking down the different sections into manageable parts, operators can quickly identify issues and perform necessary repairs. This knowledge not only empowers users but also fosters a deeper appreciation for the engineering behind these robust machines.

As we delve into the specifics of the individual components, it becomes clear that understanding their arrangement and function is key to effective troubleshooting. By knowing how each piece interacts with the others, you can ensure that your utility vehicle remains in peak condition, ready to tackle any task at hand.

Understanding Gator Tail Parts

In the world of marine propulsion systems, comprehending the various components is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring smooth operation and efficiency, contributing to the overall functionality of the vessel. Gaining insight into these individual elements can help operators troubleshoot issues and enhance their experience on the water.

Key Components Overview

Among the most significant elements are the propulsion unit and steering mechanisms, which work in harmony to deliver agility and responsiveness. Additionally, structural components such as the hull attachment and support frameworks provide stability and durability, ensuring that the system withstands the rigors of aquatic environments. Familiarity with these features allows users to make informed decisions regarding upgrades and repairs.

Maintenance and Troubleshooting

Regular inspection and understanding of the system’s intricacies are vital for longevity. Identifying wear and tear on the individual components can prevent more severe issues down the line. Proper care and attention to detail will not only enhance performance but also extend the life of the entire setup, allowing for countless enjoyable hours on the water.

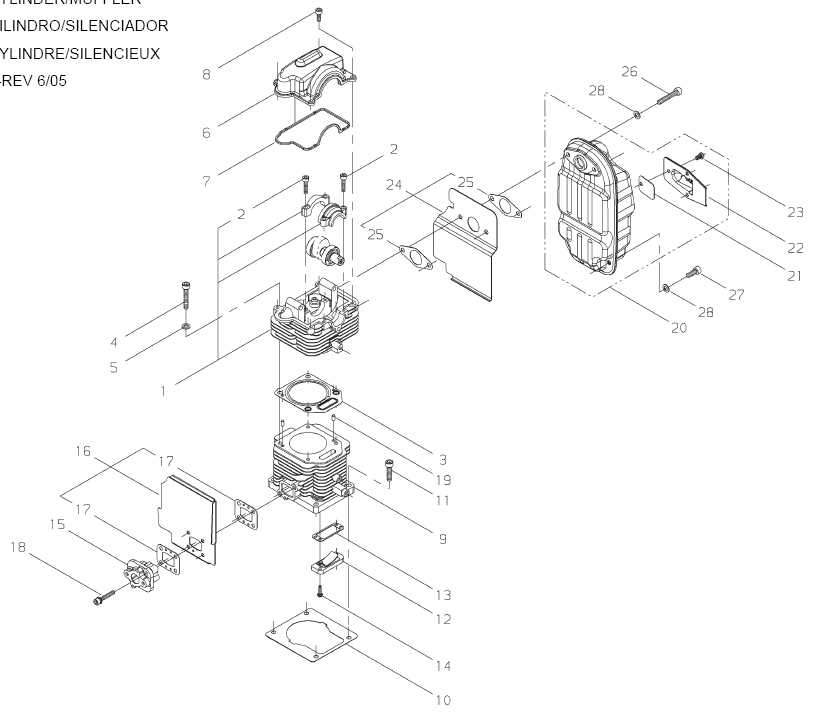

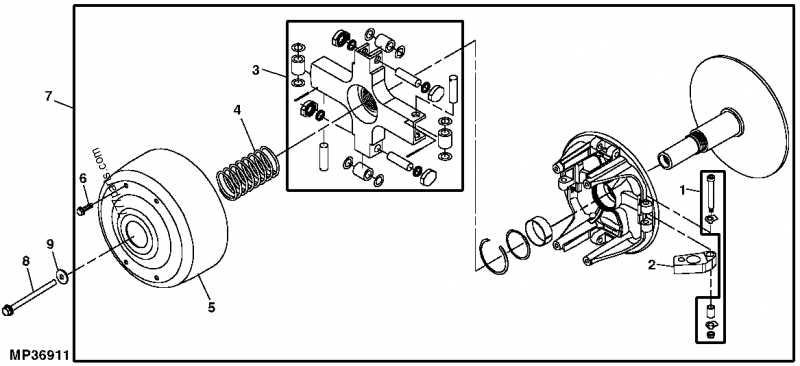

Components of Gator Tail Systems

Understanding the various elements of these propulsion mechanisms is essential for optimizing their performance and maintenance. Each component plays a crucial role in ensuring efficiency and reliability, contributing to the overall functionality of the system.

Key Elements

- Drive Unit: The core of the mechanism that provides the necessary power for movement.

- Propeller: Designed to convert rotational energy into thrust, enhancing propulsion.

- Transom Mount: A critical support structure that connects the assembly to the vessel.

- Shift Lever: Allows for easy gear transitions, ensuring smooth operation.

Additional Components

- Shaft: Transfers power from the drive unit to the propeller.

- Bearings: Provide support and reduce friction for moving parts.

- Fuel System: Supplies the necessary energy to power the unit.

- Electrical Components: Include wiring and connectors essential for ignition and controls.

Each of these components interacts within the system, forming a cohesive unit that ensures optimal functionality and performance.

Importance of Accurate Diagrams

Precision in visual representations is crucial for effective communication and understanding in any technical field. Clear illustrations serve as a universal language, enabling individuals to grasp complex information quickly and efficiently. When details are accurately depicted, users can better interpret instructions and enhance their overall experience.

Clarity is one of the primary benefits of well-crafted visuals. When components are laid out correctly, it minimizes confusion and reduces the likelihood of errors. This clarity allows technicians and users to follow procedures seamlessly, ensuring that every step is executed properly.

Moreover, accuracy in representations fosters greater reliability in operations. When stakeholders can trust the information provided, they are more likely to adhere to guidelines, leading to improved outcomes. In industries where precision is paramount, such as engineering and manufacturing, this reliability can significantly impact efficiency and safety.

In addition, well-defined visuals can enhance training and educational processes. Newcomers benefit from seeing a clear representation of the elements involved, which facilitates faster learning and retention of information. This educational advantage ultimately contributes to a more knowledgeable workforce.

In conclusion, the significance of precise illustrations cannot be overstated. They play an essential role in communication, operational reliability, and educational effectiveness, making them invaluable in any technical discipline.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair. These visuals provide a clear representation of components and their relationships, enabling users to identify and source the necessary elements for their machinery.

To effectively interpret these illustrations, consider the following steps:

- Familiarize Yourself with Symbols:

- Each symbol corresponds to a specific component or assembly.

- Check the legend for explanations of any unfamiliar markings.

- Identify Key Sections:

- Look for labeled areas that indicate different assemblies or systems.

- Pay attention to any color coding, which may signify particular categories.

- Trace Connections:

- Follow lines that illustrate how components connect and interact.

- Understanding these relationships helps in troubleshooting issues.

- Refer to Part Numbers:

- Each element usually has an associated number for ordering replacements.

- Keep a list of these numbers handy for quick reference.

By following these guidelines, you can navigate technical illustrations with confidence, ensuring that you can identify the components you need for effective repairs and maintenance.

Common Gator Tail Issues

In the world of watercraft propulsion systems, various challenges can arise that affect performance and reliability. Understanding these common problems can help users maintain their equipment effectively and ensure a smooth operation on the water.

Frequent Problems Encountered

- Engine Performance: Issues such as misfires or sluggish acceleration may stem from fuel delivery problems or ignition system failures.

- Exhaust Blockages: Clogs in the exhaust system can lead to overheating and reduced efficiency.

- Control System Malfunctions: Problems with steering or throttle response can significantly hinder maneuverability.

Maintenance Tips

- Regularly inspect and clean the fuel and air filters to ensure optimal engine performance.

- Check for any signs of wear or damage in the control cables and replace them as necessary.

- Periodically examine the exhaust system for blockages and perform necessary cleaning to prevent overheating.

Addressing these concerns promptly can enhance the longevity and functionality of your watercraft’s propulsion system, ensuring enjoyable outings on the water.

Maintenance Tips for Gator Tail

Proper upkeep of your equipment is essential for optimal performance and longevity. Regular attention to various components can prevent potential issues and enhance overall efficiency. Below are key strategies to ensure your system remains in excellent working condition.

- Regular Inspections: Routinely check for any signs of wear or damage. Early detection can save time and resources.

- Cleanliness: Keep all surfaces clean to prevent buildup of debris. This ensures smooth operation and reduces the risk of mechanical failures.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear. Refer to the manufacturer’s guidelines for recommended products.

- Secure Fastenings: Periodically tighten bolts and screws to prevent loosening during use. Vibration can cause components to shift over time.

Additionally, following a structured maintenance schedule can be beneficial:

- Weekly: Check fluid levels and perform visual inspections.

- Monthly: Clean and lubricate critical components.

- Quarterly: Conduct thorough inspections and replace worn items as needed.

By adhering to these maintenance practices, you can ensure that your equipment remains efficient and reliable for years to come.

Upgrading Gator Tail Parts

Enhancing your watercraft’s components can significantly improve performance and efficiency. By focusing on key elements, you can achieve better maneuverability, increased power, and greater durability. Whether you’re a casual user or an avid enthusiast, these upgrades can make a noticeable difference on the water.

Choosing the Right Components is essential for successful enhancements. It’s important to select high-quality replacements that fit well with your existing setup. Consider options that are specifically designed for your model, as compatibility can greatly influence overall performance.

Performance Modifications can include upgrading the propulsion system or refining the hull. Enhancements in these areas can lead to improved speed and handling, allowing for a more enjoyable experience. Additionally, adjusting the weight distribution by using lighter materials can also contribute to better stability and responsiveness.

Finally, regular maintenance of your upgraded features is crucial. Proper care ensures longevity and optimal functioning, making your investment in enhancements worthwhile. Stay informed about best practices to keep everything in peak condition for your next adventure on the water.

Finding Quality Replacement Parts

When it comes to maintaining your equipment, securing high-grade components is crucial for optimal performance and longevity. Quality replacements ensure that your machinery operates smoothly, reducing the risk of breakdowns and costly repairs. This section explores effective strategies to identify and procure superior alternatives that meet your specific needs.

To help you navigate the process, here’s a table outlining essential considerations when searching for reliable replacements:

| Consideration | Description |

|---|---|

| Source Reliability | Choose established suppliers known for their credibility and quality assurance. |

| Material Quality | Opt for components made from durable materials that can withstand demanding conditions. |

| Compatibility | Ensure that replacements are compatible with your machinery to avoid functionality issues. |

| Warranty | Look for parts that come with a warranty, providing peace of mind regarding their performance. |

| Customer Reviews | Research feedback from other users to gauge satisfaction and reliability of the components. |

By considering these factors, you can enhance your chances of finding components that not only meet your operational standards but also contribute to the overall efficiency and durability of your equipment.

Safety Considerations for Gator Tail Use

When operating specialized equipment in aquatic environments, prioritizing safety is crucial to prevent accidents and ensure efficient functioning. Understanding the inherent risks associated with such machinery helps users maintain a secure working atmosphere. Proper precautions can significantly reduce the likelihood of injuries and equipment damage.

Personal Protective Equipment (PPE)

Using the right protective gear is essential for safeguarding operators. The following items are recommended:

- Life jackets or personal flotation devices

- Waterproof boots with slip-resistant soles

- Gloves to protect hands from sharp edges

- Eye protection to shield against debris

Operational Guidelines

Following specific operational guidelines can enhance safety during use:

- Always conduct a pre-operation inspection of the equipment.

- Ensure that all personnel are aware of their roles and positions.

- Maintain a safe distance from obstacles and other vessels.

- Adhere to local regulations regarding watercraft operation.

- Be mindful of weather conditions and adjust operations accordingly.

By integrating these safety measures, operators can significantly mitigate risks and enjoy a more secure experience while using this type of equipment.

Cost Analysis of Gator Tail Repairs

Understanding the financial implications of repair work is crucial for any equipment owner. This section examines the expenses associated with maintenance and restoration, focusing on various components that may require attention. By evaluating these costs, one can make informed decisions about repairs, budgeting, and long-term maintenance strategies.

| Component | Average Cost | Replacement Frequency | Notes |

|---|---|---|---|

| Propeller | $300 | Every 2-3 years | Subject to wear from impacts and corrosion. |

| Drive Shaft | $450 | Every 5 years | Check for bends and damage regularly. |

| Seal Kit | $50 | Annual replacement | Prevent leaks and ensure proper function. |

| Fuel System Components | $200 | Every 3-4 years | Regular maintenance helps avoid costly failures. |

| Electrical Wiring | $100 | As needed | Inspect for frays and corrosion regularly. |

Analyzing these costs allows owners to better prepare for maintenance needs and allocate resources effectively. Awareness of potential expenses can lead to proactive measures, ultimately saving money and enhancing the longevity of the equipment.

Where to Buy Gator Tail Components

Finding reliable sources for components related to your watercraft can greatly enhance your experience on the water. Whether you’re in need of replacements, upgrades, or maintenance items, knowing where to look is essential for ensuring quality and performance.

Here are some recommended places to consider when searching for these essential components:

- Authorized Dealers:

Visit local dealerships that specialize in watercraft equipment. They often carry a range of original equipment manufacturer (OEM) items.

- Online Retailers:

Numerous e-commerce platforms provide a vast selection of parts. Popular sites include:

- Amazon

- eBay

- Specialized watercraft websites

- Aftermarket Suppliers:

Look into companies that offer aftermarket solutions. These suppliers often provide cost-effective alternatives that meet or exceed OEM specifications.

- Local Marine Shops:

Support your local businesses by visiting marine supply stores in your area. They can provide personalized advice and may have the components you need in stock.

Always ensure that you check for warranties and return policies when purchasing components. This can provide peace of mind and protection against any issues that may arise.

DIY vs. Professional Repairs

When it comes to maintaining and fixing equipment, enthusiasts often face the choice between taking on repairs themselves or seeking the expertise of trained professionals. Each approach has its own set of advantages and challenges, which can influence the decision-making process for owners of machinery.

Advantages of DIY Repairs

Taking on repairs personally can provide a sense of accomplishment and save money. Many individuals enjoy the hands-on experience, and it can lead to a deeper understanding of the equipment. Additionally, with the availability of online resources and communities, many find it easier than ever to troubleshoot issues independently.

Benefits of Professional Assistance

On the other hand, enlisting the help of professionals ensures that repairs are conducted with expertise and precision. Professionals are often familiar with common issues and solutions, which can result in faster turnaround times. Furthermore, their knowledge can prevent mistakes that might lead to more significant problems down the line.

| Aspect | DIY | Professional |

|---|---|---|

| Cost | Generally lower | Higher due to labor |

| Time | Variable, may take longer | Often quicker |

| Skill Level | Requires self-assessment | Expertise guaranteed |

| Learning Opportunity | High | Limited |

| Warranty Concerns | May void | Usually maintained |