Understanding Graco Paint Sprayer Gun Parts Diagram for Efficient Repairs

In the realm of efficient coating applications, the intricacies of equipment play a pivotal role in achieving optimal results. Knowing the essential elements that contribute to the functionality of these tools can significantly enhance performance and user experience.

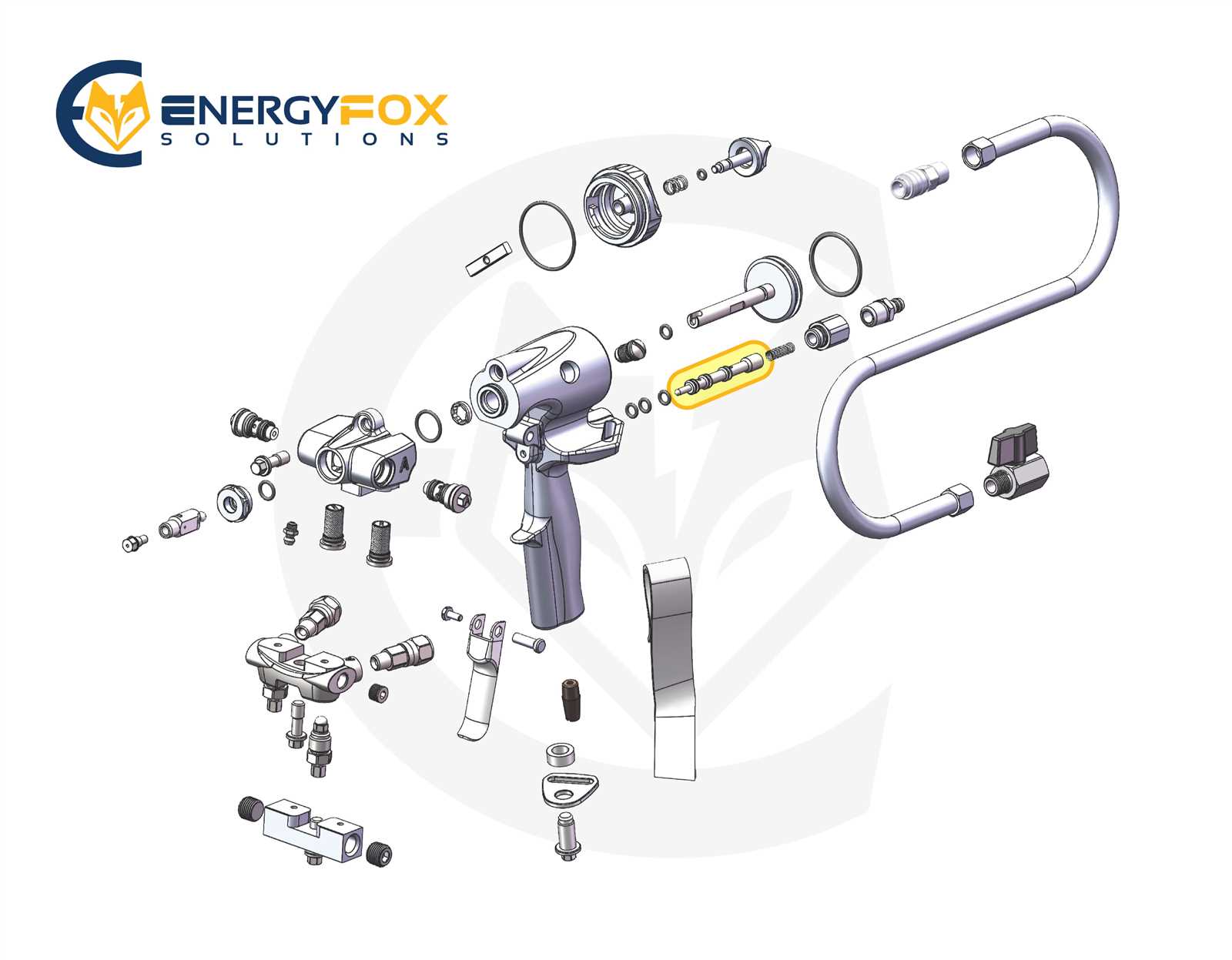

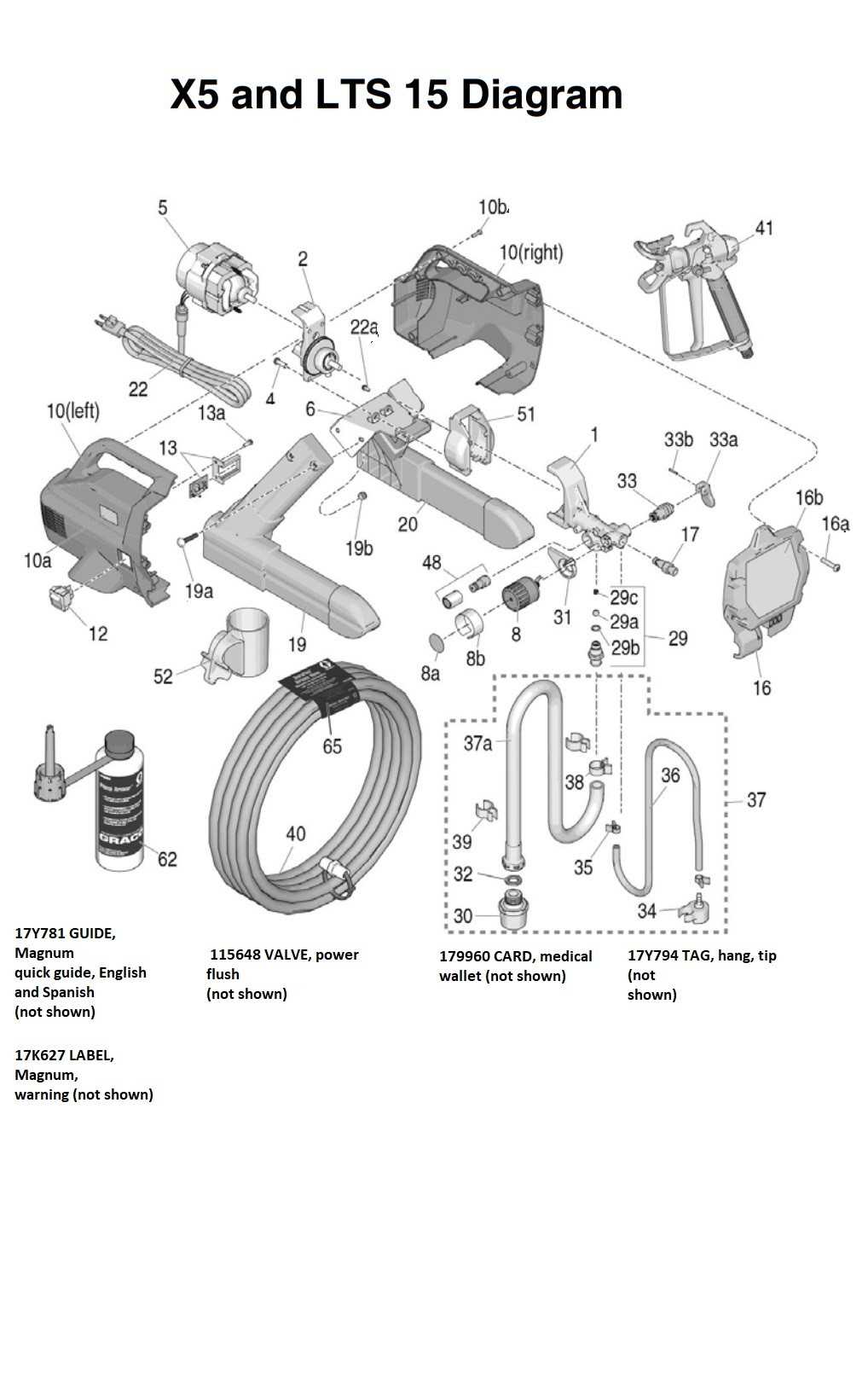

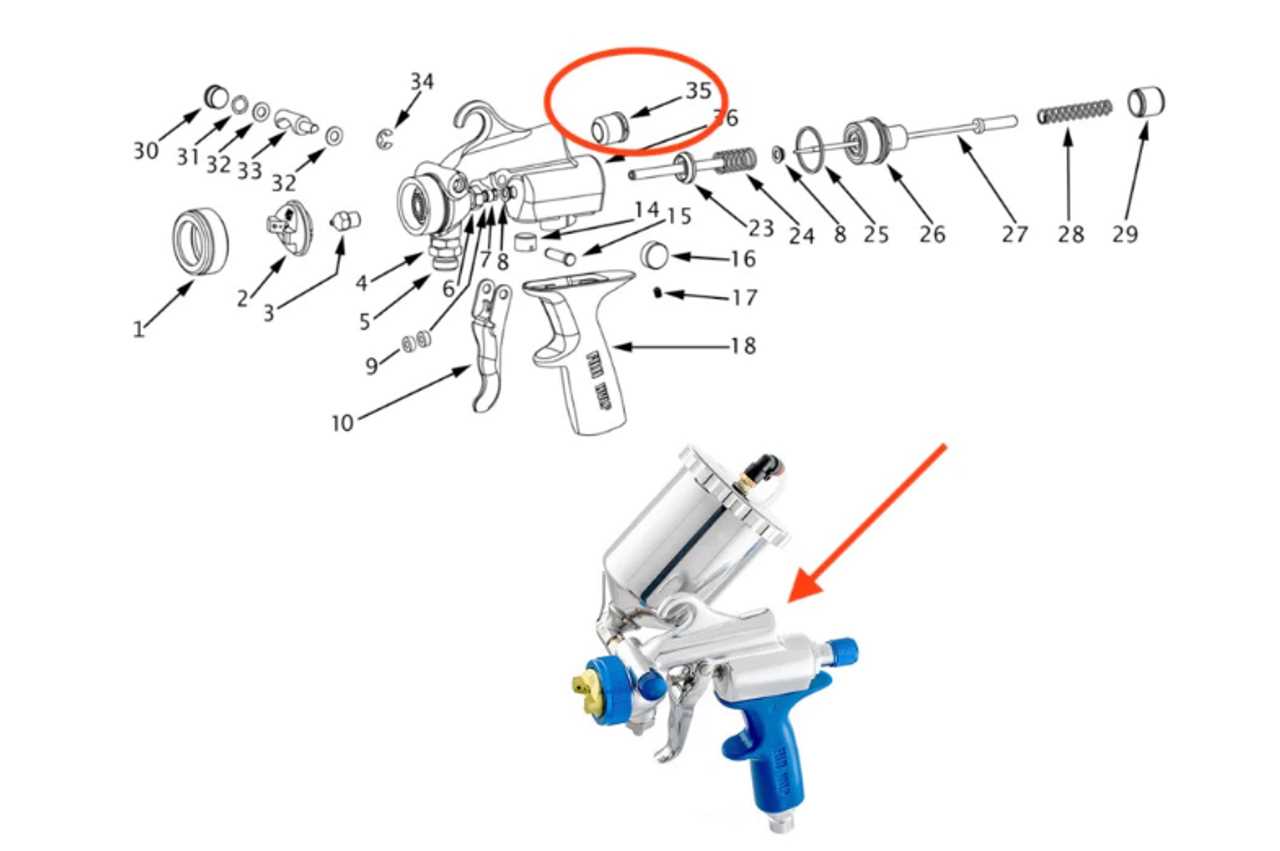

Detailed comprehension of each component enables users to make informed decisions regarding maintenance and upgrades, ensuring longevity and reliability. A visual representation of these crucial elements provides a roadmap for understanding their interconnections and operations.

By exploring the various segments of these sophisticated devices, one can delve into their mechanisms and discover the ultimate way to achieve flawless finishes. Whether you are a professional or a DIY enthusiast, grasping the essentials of these implements will undoubtedly elevate your craftsmanship.

Understanding Graco Paint Sprayer Components

This section explores the essential elements of a high-performance application tool, highlighting how each component contributes to the overall functionality and efficiency of the device. By examining these components, users can gain insights into their roles, ensuring optimal usage and maintenance.

Key Components

The various elements of the tool work in synergy to achieve smooth and consistent results. Below is a summary of the critical components and their functions.

| Component | Function |

|---|---|

| Motor | Powers the system, ensuring adequate pressure for fluid delivery. |

| Fluid Intake | Draws material from the container for application. |

| Nozzle | Controls the flow and pattern of the material being dispensed. |

| Filter | Prevents clogs by filtering out debris and impurities. |

Maintaining Efficiency

Types of Graco Spray Guns Available

This section explores the various models of spray devices designed for efficient application tasks. Each type serves distinct purposes, catering to different user needs and project requirements.

- Airless Models: Ideal for large surfaces, offering high efficiency and coverage.

- HVLP Options: Perfect for fine finishes, minimizing overspray and providing control.

- Electrostatic Units: Best for metallic coatings, ensuring uniform coverage through charged particles.

- Handheld Variants: Compact and user-friendly, suitable for smaller projects and quick touch-ups.

Understanding these categories can help users select the ultimate tool for their specific tasks, maximizing both quality and efficiency.

Key Parts of a Paint Sprayer

Understanding the essential components of a spraying tool is crucial for achieving optimal results in any coating project. Each element plays a specific role, contributing to the efficiency and effectiveness of the application process. Familiarity with these components can help users troubleshoot issues and maintain their equipment effectively.

Essential Components

The main features include a motor, which powers the device, and a fluid delivery system that transports the coating material from the container to the nozzle. Additionally, the nozzle itself is vital, as it regulates the flow and pattern of the emitted substance, ensuring an even application.

Supportive Elements

Other supportive elements encompass filters, which prevent clogs by removing impurities, and the pressure control system, which allows for adjustments based on the project requirements. Lastly, the handle and trigger mechanism enhance user control, making the operation more comfortable and precise.

How to Read Parts Diagrams

Understanding illustrations that depict component layouts is essential for effective assembly and maintenance. These visuals provide a detailed representation of various elements, making it easier to identify each part’s function and location. Familiarizing yourself with the key features of these schematics can significantly enhance your ability to work with machinery.

| Feature | Description |

|---|---|

| Labels | Clear identifiers next to each component help you know what each part is called. |

| Numbers | Sequential numbers often correlate with a list for easy reference to part names. |

| Sections | Diagrams are usually divided into sections, highlighting different groups of components. |

| Connections | Arrows or lines indicating how components fit together are crucial for proper assembly. |

Common Issues with Spray Gun Parts

Inconsistent operation and performance can be caused by several factors related to the key components of the tool. Understanding these problems helps to ensure smooth and efficient application, reducing downtime and costly repairs.

- Clogging: One of the most frequent problems is blockages, which can interrupt the flow of materials. This often occurs due to improper cleaning or using materials that are too thick for the nozzle.

- Leaking: Leaks around the connections or seals are another common issue, usually caused by worn-out gaskets or improperly tightened fittings.

- Inconsistent Pressure: Fluctuating output pressure can result from blockages or problems with the regulator. This leads to uneven distribution, impacting the overall finish.

- Wear and Tear: Over time, the internal components of the equipment may wear down due to regular use, affecting its overall functionality and precision.

- Improper Adjustment: Incorrect settings or adjustments can cause uneven patterns or spattering. Fine-tuning the controls is essential for optimal performance.

Maintenance Tips for Longevity

Proper upkeep is crucial to ensure the equipment operates smoothly and efficiently for an extended period. Regular care helps prevent potential issues and ensures reliable performance, reducing the need for costly repairs or replacements.

Cleaning and Lubrication

After each use, thoroughly clean all components to remove any debris that could cause blockages or wear. Lubricate moving parts to reduce friction, which can lead to excessive wear and shortened lifespan. Consistent cleaning and lubrication are essential to maintaining functionality over time.

Regular Inspection

Inspect the device periodically for any signs of wear or damage. Pay attention to seals, nozzles, and connections, as these areas are prone to deterioration. Early detection of wear can prevent

Replacing Worn Components Effectively

Over time, various tools and devices can experience wear, leading to decreased performance and potential malfunctions. It’s essential to recognize the signs of deterioration early and address them by replacing the affected elements before they cause more significant issues. Proper maintenance and timely component replacement will ensure that the equipment remains in optimal working condition.

To begin, it’s important to assess the condition of key elements regularly. Look for any visible signs of damage, such as cracks or corrosion, as these are clear indicators that replacements are necessary. Pay attention to the performance of the device; if it starts to operate less efficiently or shows inconsistent results, this could point to worn components th

Tools Needed for Assembly

When preparing to put together various mechanical components, it’s essential to have the proper tools on hand. This ensures a smooth and efficient assembly process, allowing each part to be correctly aligned and securely fastened. A well-prepared workspace will save time and prevent potential damage to the equipment.

Basic Hand Tools

For most assembly tasks, having a set of basic hand tools is a must. This includes adjustable wrenches, screwdrivers, and pliers. These tools help with tightening or loosening fasteners and ensuring all elements fit together correctly.

Specialized Equipment

In addition to basic tools, some tasks may require more specialized equipment such as torque wrenches or hex keys. These are vital for precision work, ensuring that all components are secured to the manufacturer’s specifications, preventing over-tightening or stripping of threads

Upgrading Your Graco Sprayer

Improving the efficiency and performance of your equipment can significantly enhance the quality and speed of your work. By implementing new components and optimizing existing features, you ensure that your tool operates more smoothly and reliably, even under heavy use. These adjustments not only prolong the lifespan of the machine but also allow for better precision and control, giving you an edge in challenging projects.

Choose the right enhancements to suit your specific needs, whether it’s about increasing output or gaining finer control over flow. Modern upgrades are designed to be intuitive, with easy integration into older models, ensuring compatibility without compromising functionality. These improvements can reduce the need for frequent maintenance and improve your workflow by offering greater versatility.

By staying up-to-date with the latest technology, you not only increase the durability of your gear but also elevate the quality of your results. Consider adopting features that support efficient operation, helping you handle larger tasks with ease while maintaining consistent performance.

Safety Precautions While Spraying

When using high-pressure equipment, safety should always be a top priority. Understanding and adhering to basic protective measures ensures not only the quality of the work but also the well-being of the operator and others in the surrounding area. It’s important to remain vigilant and prepared for any potential hazards that may arise during the process.

Proper Protective Gear should be worn at all times to shield the user from accidental exposure to harmful substances or physical injuries. This includes, but is not limited to, gloves, goggles, and respiratory masks, which prevent direct contact with chemicals or debris.

Maintaining a well-ventilated workspace is crucial. Many materials emit fumes that can be dangerous when inhaled in confined spaces. Always ensure proper airflow to minimize the risk of inhaling toxic vapors.

Regular inspection of the equipment before each use is essential to avoid malfunctions or leaks. Any signs of wear, such as damaged hoses or faulty connections, should be addressed immediately to prevent accidents.

Finding Replacement Parts Online

When searching for specific components for your equipment, the internet offers a vast array of resources. Online platforms allow users to easily compare products, prices, and availability without the hassle of visiting physical stores. This convenience makes it possible to quickly locate even rare or hard-to-find items.

- Start by visiting specialized websites that focus on machinery or tool components.

- Utilize search filters to narrow down the options based on the model or type of the item you need.

- Check reviews and ratings to ensure the quality and compatibility of the chosen component.

- Some online retailers offer detailed specifications and installation guides, which can be helpful during the purchasing process.

- Don’t forget to compare shipping costs and delivery times, as these can vary significantly depending on the supplier.

By leveraging the power of online marketplaces, you can find the right piece for your equipment efficiently and with confidence.