Comprehensive Guide to Gz23n Parts Diagram

In the realm of machinery and engineering, grasping the arrangement of various elements is essential for effective maintenance and repair. A comprehensive visualization of how different units interconnect allows users to navigate complex systems with confidence. This guide delves into the intricacies of these configurations, offering valuable insights for both novices and seasoned professionals.

Analyzing structure enhances our ability to troubleshoot issues, ensuring that every segment functions harmoniously. By breaking down the assembly into its core components, we can identify potential problems before they escalate. This proactive approach fosters a deeper understanding of the machinery, enabling efficient interventions.

Moreover, an organized layout serves as a crucial reference for anyone involved in technical work. Whether for assembly, disassembly, or routine checks, having a clear picture of the configuration simplifies the process. Through careful examination of these visual aids, users can improve their skills and increase the longevity of the equipment they handle.

Understanding Gz23n Components

The intricate assembly of various elements plays a crucial role in the overall functionality of a system. By examining these individual components, one can gain insights into their interrelations and how they contribute to the efficiency and effectiveness of the entire mechanism. A thorough understanding is essential for troubleshooting, maintenance, and enhancement purposes.

Key elements in any system typically include structural parts, connectors, and functional units. Each element serves a specific purpose, and their seamless interaction ensures optimal performance. For instance, structural components provide stability, while connectors facilitate communication between different parts.

Moreover, recognizing the significance of each component can lead to informed decisions during upgrades or repairs. A well-rounded grasp of these individual pieces can ultimately result in improved reliability and longevity of the system.

Importance of Parts Diagrams

Understanding the intricate components of any mechanical system is crucial for effective maintenance and repair. Visual representations serve as essential tools for both professionals and enthusiasts, allowing for a clearer grasp of how various elements interact and function together. These illustrations not only enhance comprehension but also streamline the troubleshooting process, making it easier to identify issues and implement solutions.

Facilitating Maintenance

When it comes to upkeep, having a clear visual reference can significantly simplify the task. Technicians can quickly locate specific elements, determine their condition, and assess what needs attention. This efficiency saves time and reduces the likelihood of errors, ultimately leading to better performance and longevity of the equipment.

Aiding in Training and Education

For those learning about mechanical systems, visual aids are invaluable. They provide a foundational understanding that supports hands-on experience. By examining these representations, learners can connect theoretical knowledge with practical application, fostering a deeper appreciation for the complexity and functionality of the machinery.

How to Read a Parts Diagram

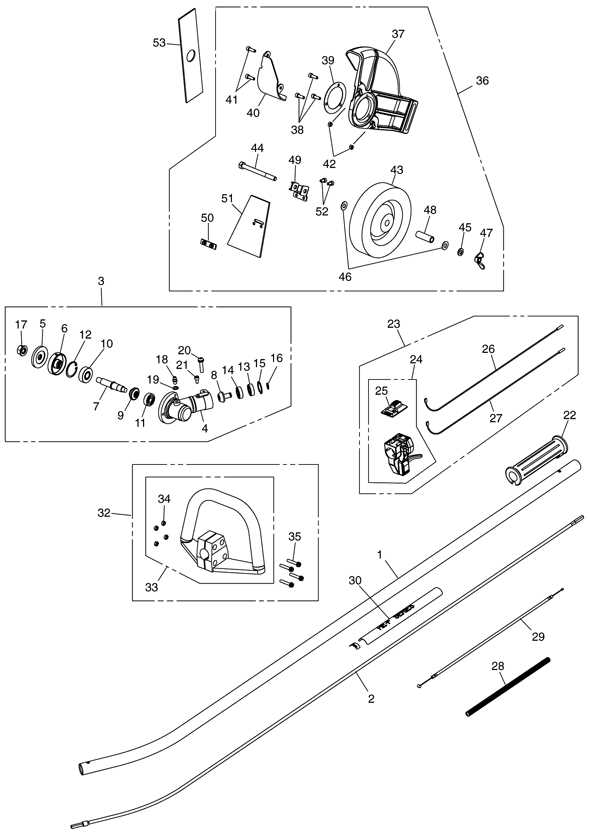

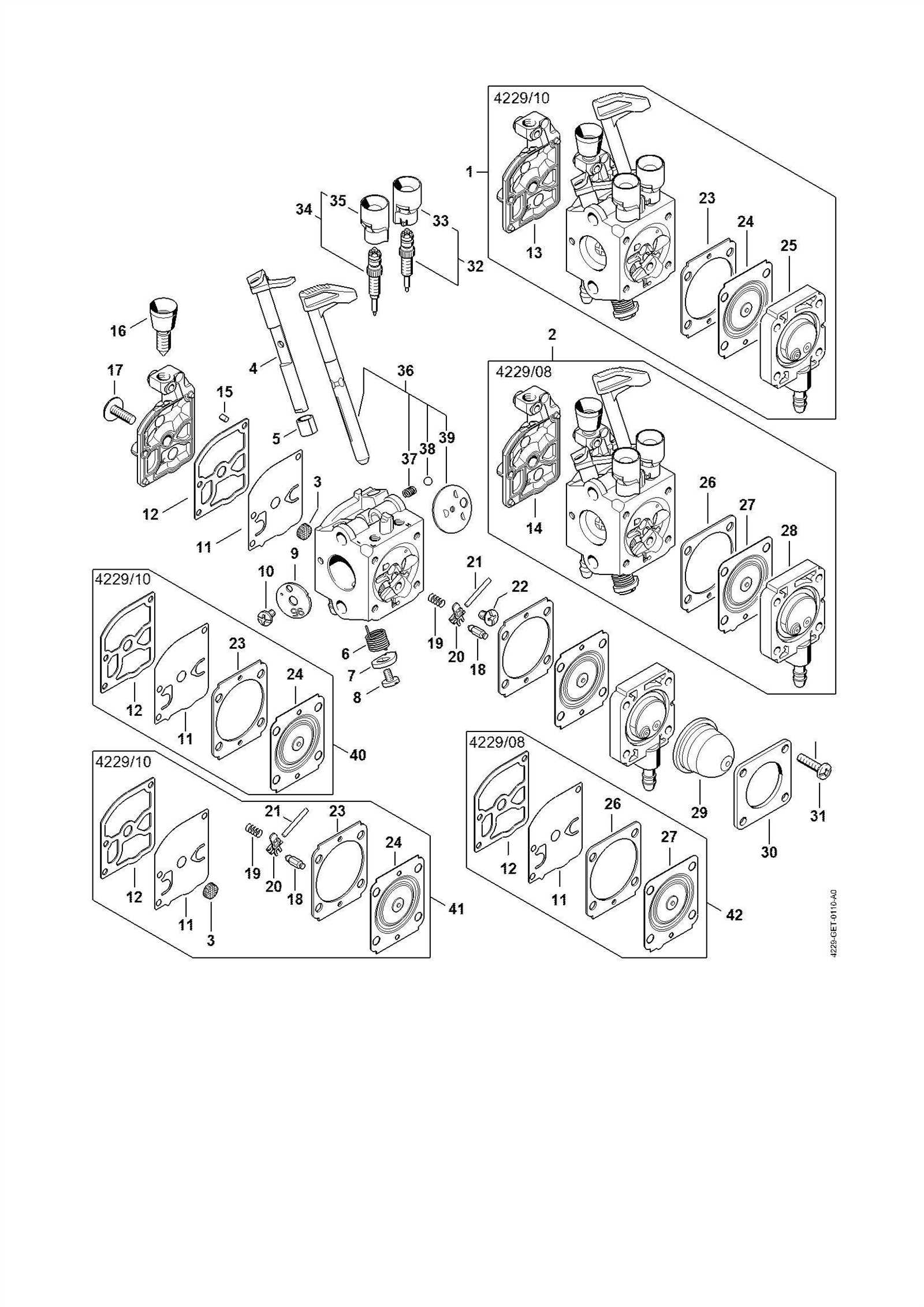

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual aids offer a structured view of elements and their interconnections, allowing users to identify and locate each piece with ease. Mastering this skill can significantly enhance your ability to troubleshoot and assemble mechanical systems.

To effectively interpret such representations, consider the following key aspects:

| Aspect | Description |

|---|---|

| Legend | A guide that explains symbols and markings used, essential for understanding the context. |

| Labels | Clear identifiers for each element, which may include part numbers or descriptions. |

| Connections | Lines and arrows indicating how components are linked or interact with each other. |

| Orientation | Indications of how parts are positioned, often crucial for proper installation. |

By familiarizing yourself with these components, you will gain the confidence to navigate any schematic efficiently, enabling successful repairs and modifications.

Common Issues with Gz23n Parts

When dealing with specific mechanical components, users often encounter a range of challenges that can affect performance and longevity. Understanding these common problems can aid in troubleshooting and maintenance, ensuring efficient operation over time.

Some prevalent issues include:

- Wear and Tear: Regular usage can lead to deterioration, impacting functionality.

- Compatibility: Misalignment or mismatched components can result in operational failures.

- Installation Errors: Incorrect assembly can cause significant malfunctions.

- Material Fatigue: Over time, materials may lose their strength, leading to breakage.

- Corrosion: Exposure to moisture can result in rust and damage, especially in metal components.

Addressing these issues promptly can help maintain optimal performance and prolong the lifespan of the equipment.

Identifying Each Component

Understanding the various elements of a mechanical assembly is crucial for effective maintenance and repair. Each part plays a specific role, contributing to the overall functionality of the system. By familiarizing oneself with these components, one can ensure proper operation and troubleshoot any issues that may arise.

First and foremost, it’s essential to recognize the primary structures that form the foundation of the assembly. These are often the most visible and serve as the backbone for other elements. Next, secondary components, which may include fasteners and connectors, facilitate the integration of the primary parts, enhancing stability and performance.

Additionally, auxiliary elements, such as sensors and actuators, are vital for monitoring and controlling operations. Understanding their placement and function can significantly impact the effectiveness of the entire system. Ultimately, a comprehensive grasp of each component’s role not only aids in efficient assembly but also fosters proactive maintenance practices.

Tools Needed for Assembly

When embarking on a project involving intricate components, having the right instruments at hand is crucial for a smooth assembly process. These tools not only facilitate efficient handling of each element but also ensure precision and reliability in the final structure.

Essential items typically include screwdrivers of various sizes, which allow for easy fastening of screws and adjustments. A set of pliers can be invaluable for gripping and bending materials, while a wrench is often necessary for tightening nuts and bolts securely. Additionally, a utility knife or scissors may be required for cutting through packaging or materials during the setup.

Measuring tools, such as a tape measure or ruler, play a significant role in ensuring that all components are aligned correctly. A level can help maintain balance and proper positioning throughout the assembly. Finally, a sturdy work surface is essential to keep everything organized and within reach, promoting an efficient workflow.

Maintenance Tips for Gz23n

Proper upkeep of machinery is essential for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents potential breakdowns and costly repairs. Adopting a systematic approach to care can yield significant benefits over time.

Regular Inspections

Conducting frequent assessments of components is crucial. Look for signs of wear, corrosion, or any unusual noises during operation. Early detection of issues can save time and resources. Make a checklist to ensure all areas are thoroughly examined.

Lubrication and Cleaning

Keep all moving elements well-lubricated to minimize friction and wear. Use appropriate lubricants as specified in the manual. Additionally, regular cleaning of surfaces helps prevent the buildup of debris, which can interfere with functionality. A clean environment contributes to a smoother operation and extends the lifespan of the equipment.

In summary, maintaining machinery involves routine inspections, proper lubrication, and cleanliness. These practices will ensure your equipment runs efficiently and remains in good condition for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. Whether you are dealing with maintenance, repairs, or upgrades, various sources offer reliable alternatives to keep your machinery running smoothly.

Online Retailers

One of the most convenient options is to explore online marketplaces. Numerous e-commerce platforms specialize in a wide range of components, providing detailed descriptions and user reviews to help you make informed choices.

Local Suppliers

For those who prefer a hands-on approach, visiting local suppliers can be beneficial. These establishments often carry a variety of items and can offer personalized assistance in finding what you need.

| Source Type | Advantages | Disadvantages |

|---|---|---|

| Online Retailers | Convenience, wide selection, user reviews | Shipping times, potential for errors |

| Local Suppliers | Immediate availability, expert advice | Limited selection, possibly higher prices |

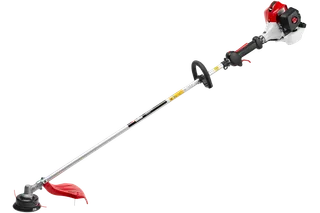

Comparing Gz23n Models

In the realm of machinery, variations in design can lead to distinct functionalities and performance characteristics. Understanding these differences is crucial for users aiming to optimize their experience and achieve specific outcomes. This section delves into the nuances among different versions of a popular device, highlighting their respective features and benefits.

Performance Differences

Each variant presents unique capabilities, often tailored to meet diverse operational needs. While some models may excel in efficiency, others might focus on enhanced durability or user-friendliness. By examining these traits, potential buyers can align their choices with their operational requirements, ensuring they select a model that fits their specific tasks.

Design and Features

The aesthetic and functional aspects of each model also vary significantly. From ergonomic enhancements to advanced technology integrations, these features can greatly influence user satisfaction. By assessing the design elements, users can make informed decisions based on comfort, usability, and adaptability to their work environments.

Expert Insights on Performance

Understanding the intricacies of mechanical systems is essential for optimizing functionality and enhancing overall efficiency. This section delves into expert analyses that highlight key factors influencing performance, providing valuable guidance for enthusiasts and professionals alike.

Key Factors Impacting Efficiency

- Material Quality: The choice of materials significantly affects durability and responsiveness. High-grade components ensure longevity and minimize wear.

- Precision Engineering: Accurate manufacturing processes lead to better alignment and reduced friction, enhancing operational effectiveness.

- Maintenance Practices: Regular upkeep is crucial. Implementing a consistent maintenance schedule can prevent costly breakdowns and maintain peak performance.

Optimizing Performance Through Upgrades

- Component Replacement: Upgrading to modern alternatives can provide substantial improvements in efficiency and power output.

- Enhanced Calibration: Fine-tuning systems can yield noticeable gains in responsiveness and overall effectiveness.

- Utilizing Technology: Incorporating advanced monitoring tools allows for real-time assessments, enabling informed adjustments to enhance performance.