Understanding the Harman Advance Pellet Stove Parts Diagram

When it comes to ensuring the efficiency and longevity of your heating apparatus, a comprehensive understanding of its individual elements is essential. Each component plays a critical role in the overall performance and reliability of the system. Familiarity with these essential features can help you troubleshoot issues, conduct maintenance, and enhance your heating experience.

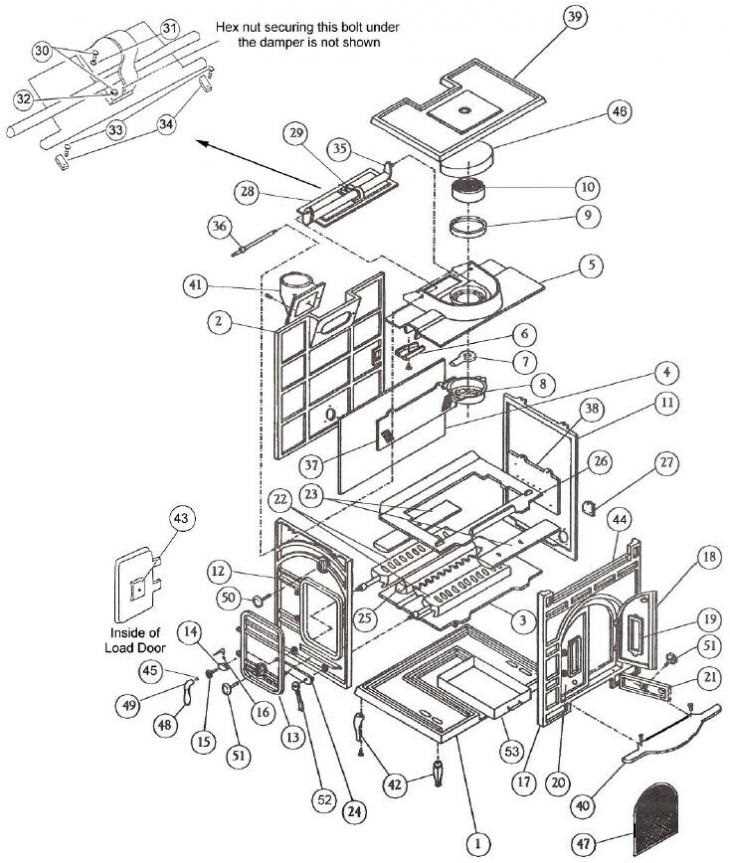

Visual representations of these components can significantly aid in grasping their functions and interconnections. By examining a detailed illustration, one can easily identify where each piece fits and how they contribute to the operational flow. This knowledge empowers users to manage their systems more effectively and make informed decisions regarding repairs and upgrades.

Furthermore, having access to a clear outline of the internal workings allows for better planning during the installation and maintenance processes. Whether you are a novice or an experienced user, being equipped with the right information can lead to a more satisfying and efficient use of your heating solution.

Understanding Harman Pellet Stove Components

Grasping the various elements of a heating appliance is essential for effective operation and maintenance. Each component plays a crucial role in ensuring efficiency and performance, contributing to the overall functionality. Familiarity with these elements enables users to troubleshoot issues and optimize their experience.

Main Elements

At the core of this heating system, the combustion chamber is where the fuel ignites, generating heat. Surrounding it, the heat exchanger efficiently transfers warmth to the air circulating within the space. The fan mechanism assists in distributing this warmth, ensuring consistent temperature throughout the environment.

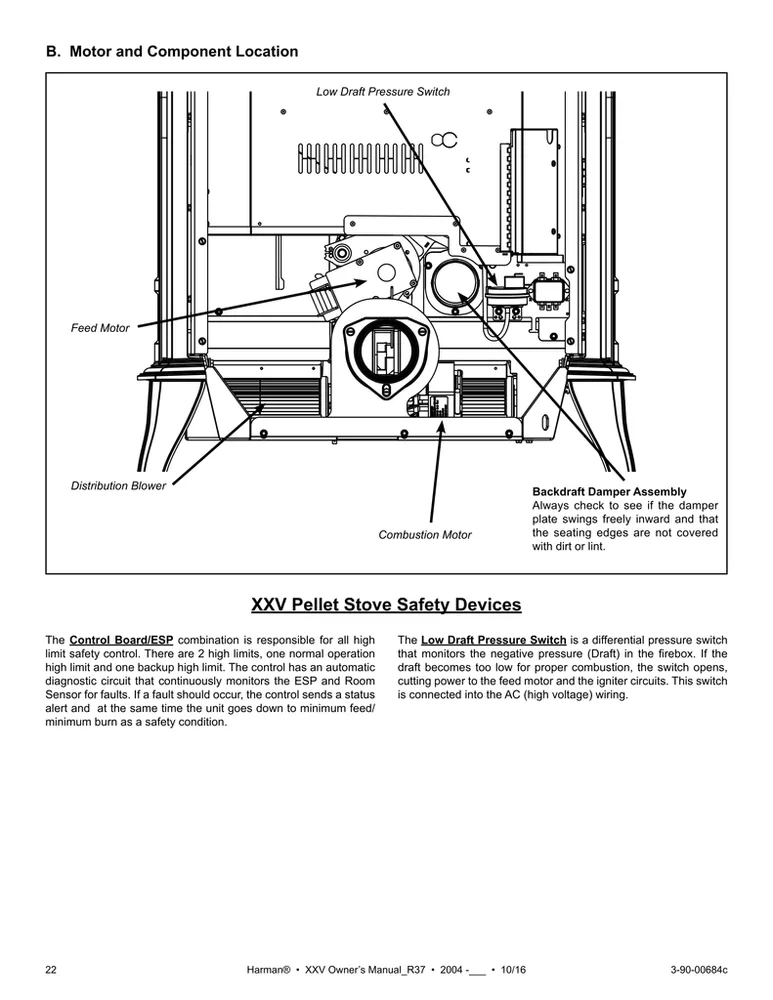

Control panels allow users to adjust settings with ease, providing options for temperature regulation and fuel feed rates. Additionally, safety features, such as temperature sensors and pressure switches, monitor operations to prevent malfunctions. Understanding these control mechanisms is vital for maximizing performance and ensuring safe usage.

Overview of Harman Pellet Stoves

This section provides a comprehensive understanding of a leading brand in the market of home heating solutions. Known for their efficiency and reliability, these devices have become a popular choice for many households seeking sustainable and effective warming methods. With advanced technology and thoughtful design, they cater to various needs while ensuring user satisfaction.

Key Features

- High efficiency and low emissions for eco-friendly operation.

- Smart technology integration for ease of use and convenience.

- Variety of models to suit different space requirements and styles.

- Durability and quality materials for long-lasting performance.

Benefits of Using These Heating Systems

- Cost-effective heating solution, reducing overall energy expenses.

- Environmentally conscious choice, contributing to lower carbon footprint.

- Consistent heat output, providing comfort in all seasons.

- Easy maintenance, ensuring hassle-free operation and longevity.

Key Parts in Pellet Stove Diagrams

Understanding the essential components within heating appliances is crucial for maintenance and troubleshooting. Each element plays a significant role in ensuring efficient operation and safety. This section highlights the main features commonly represented in visual schematics of these heating units.

- Burn Pot: The location where fuel is ignited, allowing for a controlled flame to produce heat.

- Heat Exchanger: A vital section that transfers heat from the combustion process to the surrounding area, enhancing efficiency.

- Fan System: Responsible for distributing warm air throughout the space, ensuring even heating.

- Auger Mechanism: This device feeds fuel from the hopper to the burn pot, maintaining a consistent supply for combustion.

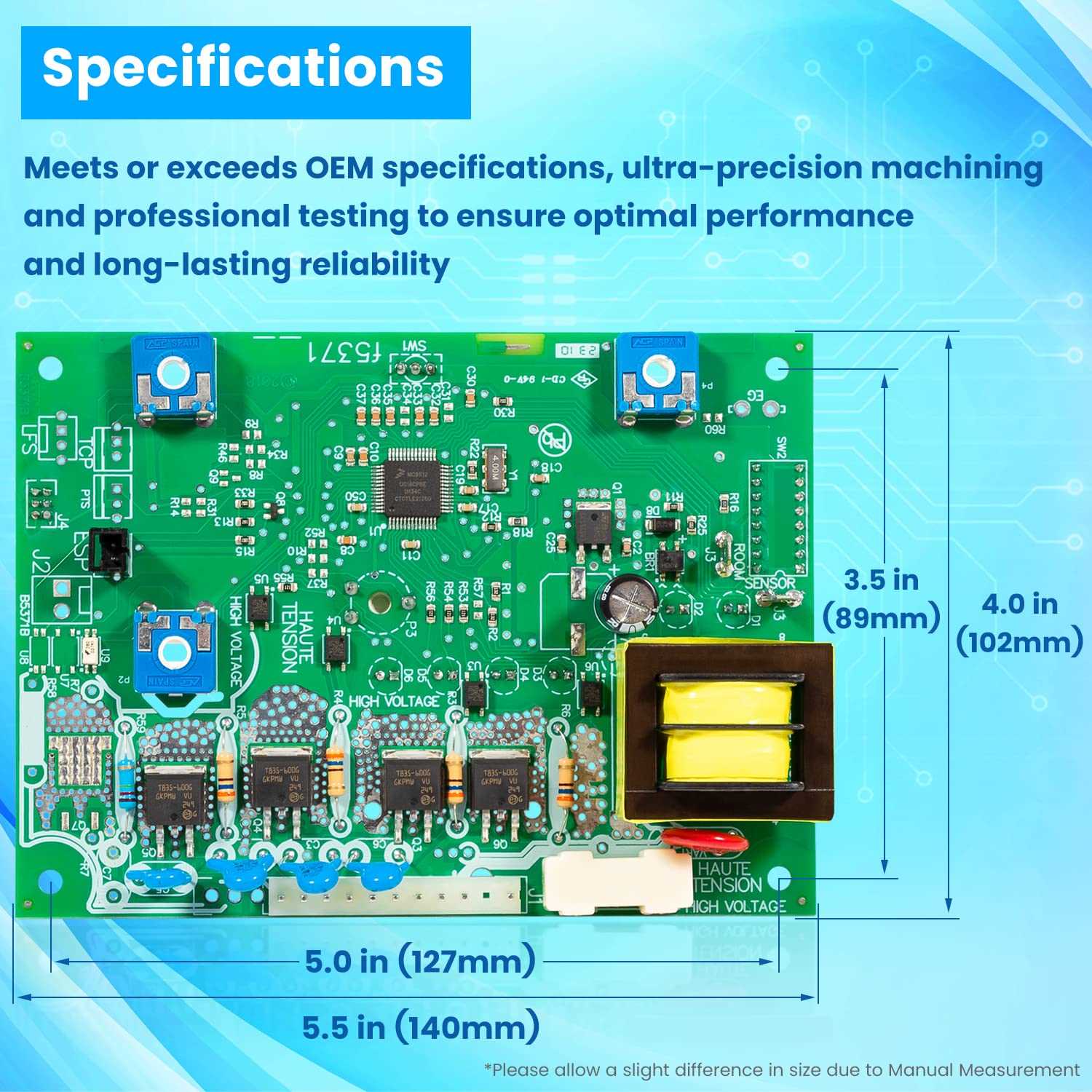

- Control Board: The brain of the system, managing operational settings and safety protocols.

- Exhaust Vent: A crucial pathway for removing gases produced during combustion, ensuring safe operation.

- Hopper: The storage area for fuel, providing a reserve that enables extended operation without frequent refueling.

By familiarizing oneself with these critical components, users can better appreciate the functionality of their heating units and address potential issues that may arise.

Importance of Accurate Parts Identification

Identifying components with precision is crucial for maintaining the efficiency and longevity of any heating appliance. Correctly recognizing each element ensures that repairs and replacements are executed flawlessly, ultimately enhancing the overall performance and safety of the device.

Misidentification can lead to several issues:

- Increased risk of malfunction due to incompatible components.

- Unnecessary expenses from purchasing incorrect items.

- Delays in repairs, causing prolonged downtime.

- Potential safety hazards stemming from improper installations.

To avoid these pitfalls, consider the following strategies for effective identification:

- Refer to the manufacturer’s manual for detailed descriptions.

- Use online resources, including forums and guides, to gain insights from experienced users.

- Take clear photographs of components to compare against reference materials.

- Consult with professionals if uncertain about any element.

Ensuring accurate identification fosters a smoother maintenance process and contributes to the optimal functionality of the equipment.

Common Issues with Pellet Stove Parts

Many users encounter various challenges with their heating appliances, which can significantly affect performance and efficiency. Understanding these common problems can help in maintaining optimal operation and ensuring longevity.

Clogged Feed Mechanism: A frequent issue is a blockage in the feeding system, which can prevent proper fuel delivery. This often leads to inconsistent heating and can cause the unit to shut down unexpectedly.

Ignition Failures: Problems with ignition components can result in difficulty starting the appliance. This may be due to faulty igniters or inadequate fuel quality, requiring thorough inspection and potential replacement.

Overheating: Excessive temperatures can stem from a malfunctioning thermostat or improper airflow. Regular maintenance of ventilation systems is essential to avoid damage and ensure safe operation.

Unusual Noises: Strange sounds can indicate mechanical issues, such as worn bearings or loose components. Identifying and addressing these noises early can prevent more significant breakdowns.

Smoke Emissions: Inadequate combustion can lead to smoke entering the living space. This often results from clogged exhaust systems or insufficient airflow, necessitating immediate attention to maintain safety.

Maintenance Tips for Harman Stoves

Proper upkeep of your heating appliance ensures optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that may arise over time. Here are some essential practices to keep in mind.

First, it’s crucial to clean the combustion chamber frequently. Removing any ash buildup and debris helps maintain efficient burning and reduces harmful emissions. A clean chamber promotes better airflow and heat distribution.

Next, inspect the air intake and exhaust pathways. Ensuring these areas are free from obstructions is vital for safe operation. Regularly checking and cleaning these components minimizes the risk of malfunction.

Additionally, replacing or cleaning filters on a routine basis is essential. Dirty filters can hinder airflow, causing the unit to work harder and less efficiently. Regular maintenance of filters enhances air quality and reduces energy consumption.

Finally, consider scheduling professional inspections at least once a year. A qualified technician can identify potential issues that may not be visible to the untrained eye, ensuring your appliance operates safely and effectively.

Replacing Worn-out Components Safely

Ensuring the longevity and efficiency of your heating appliance requires timely replacement of deteriorated elements. Properly addressing this maintenance task is crucial for safe operation and optimal performance. Following systematic procedures not only minimizes risks but also enhances the functionality of your unit.

Before beginning the replacement process, it is essential to gather the necessary tools and familiarize yourself with the specific components that require attention. Always prioritize safety by disconnecting the unit from its power source and allowing it to cool down completely. Adhering to these precautions will create a secure environment for your work.

| Step | Action | Tips |

|---|---|---|

| 1 | Disconnect power supply | Ensure all switches are off to prevent accidental activation. |

| 2 | Inspect components | Look for signs of wear or damage. |

| 3 | Remove old components | Use appropriate tools to avoid damage. |

| 4 | Install new components | Follow manufacturer guidelines for proper fitting. |

| 5 | Reconnect power supply | Double-check all connections before turning on. |

By carefully following these steps, you can effectively replace worn-out elements while maintaining a high level of safety. Regular maintenance not only extends the life of your equipment but also ensures a comfortable environment in your space.

Where to Find Replacement Parts

When it comes to maintaining heating appliances, locating suitable components is essential for optimal performance. Understanding where to source these items can save both time and money, ensuring that your equipment runs efficiently. This section will guide you through various avenues to find the necessary replacements.

Online Retailers

One of the most convenient ways to acquire components is through online retailers. Numerous websites specialize in selling heating appliance accessories, providing detailed descriptions and specifications. It’s important to verify the credibility of the seller and ensure that the parts match your specific model.

Local Supply Stores

Visiting local supply stores can be beneficial as well. Many home improvement centers and specialty shops stock components for various heating devices. Engaging with knowledgeable staff can help you identify the correct items and may even provide advice on installation.

| Source | Description | Advantages |

|---|---|---|

| Online Retailers | Websites specializing in heating accessories. | Convenient, wide selection, often detailed specs. |

| Local Supply Stores | Brick-and-mortar shops with physical inventory. | Personal interaction, immediate availability, expert advice. |

| Manufacturer’s Website | Official site offering direct access to components. | Guaranteed compatibility, authentic items, warranty options. |

Understanding the Pellet Stove Layout

Grasping the arrangement of a modern heating appliance is crucial for both optimal performance and maintenance. Each component plays a specific role in ensuring efficiency and safety, creating a harmonious balance that enhances the overall functionality. By familiarizing oneself with the layout, users can troubleshoot issues more effectively and ensure longevity of the unit.

Key Components Overview

At the heart of the system lies the combustion chamber, where the magic of heat generation occurs. Surrounding this area are various elements such as the fuel feed mechanism and the ventilation system, which work in unison to regulate airflow and temperature. Understanding how these components interact can lead to more efficient operation and reduced fuel consumption.

Importance of Maintenance

Regular upkeep of these essential elements is vital for preventing malfunctions. Neglecting any part of the setup can lead to decreased efficiency and potential hazards. By regularly inspecting and cleaning the different sections, users can ensure that their heating unit remains reliable and effective throughout the colder months.

Pellet Stove Operation Explained

Understanding the functionality of modern heating appliances can enhance user experience and efficiency. These devices utilize a unique combustion process that transforms organic materials into heat, providing a reliable and eco-friendly source of warmth.

At the core of this system is a controlled feed mechanism that delivers the fuel to the combustion chamber. This ensures a consistent supply, allowing for optimal burning conditions. The ignition process is typically initiated electronically, producing minimal emissions while maximizing energy output.

Once ignited, the air supply is carefully regulated to maintain an ideal burn rate. This balance is crucial for achieving high efficiency and reducing waste. The heat generated is then circulated through the living space, often with the help of a fan that distributes warmth evenly.

Additionally, most appliances are equipped with a monitoring system that tracks performance metrics, such as temperature and fuel levels. This allows users to maintain optimal operation and make adjustments as necessary, enhancing both safety and comfort.

In summary, the effective operation of these heating units combines advanced technology with user-friendly features, resulting in an efficient and sustainable heating solution for modern homes.

Enhancing Efficiency with Proper Parts

Optimizing the performance of heating appliances requires a keen understanding of their components. Each element plays a crucial role in ensuring effective energy utilization, leading to improved overall functionality. By focusing on the quality and compatibility of these essential pieces, users can significantly enhance their system’s efficiency and longevity.

Understanding Component Roles

Every individual element contributes uniquely to the operation of the unit. For instance, the ignition mechanism is vital for prompt heating, while the combustion chamber influences fuel consumption. A thorough grasp of how these components interact allows for better maintenance practices, ultimately translating into cost savings and reduced environmental impact.

Importance of Regular Maintenance

Regular inspections and timely replacements of worn-out elements are key to maintaining optimal performance. Failure to address minor issues can lead to major inefficiencies, increased energy costs, and even safety hazards. Emphasizing the importance of preventive care ensures that each component functions harmoniously, providing a seamless heating experience.

Visual Guides for Assembly and Repair

When it comes to maintenance and troubleshooting of heating appliances, visual resources can significantly enhance understanding and execution. These guides serve as invaluable tools for both novice and experienced users, providing clear illustrations and step-by-step instructions that simplify complex tasks.

Comprehensive illustrations help users identify components and understand their functions, making it easier to follow along with repair or assembly procedures. By visually breaking down each step, these guides reduce the likelihood of errors, ensuring that every part is correctly placed and secured.

Step-by-step tutorials often accompany these visuals, offering detailed explanations that complement the diagrams. Users can easily navigate through various stages of the process, gaining confidence as they work through each task methodically. This combination of images and written instructions fosters a more intuitive approach to maintenance, enhancing the overall user experience.

Ultimately, leveraging visual aids not only facilitates repairs but also promotes a deeper understanding of how these systems operate, empowering users to take control of their equipment’s functionality.

Safety Precautions During Repairs

When undertaking maintenance on heating appliances, it is essential to prioritize safety to prevent accidents and ensure efficient operation. Proper precautions can help mitigate risks associated with electrical components, heat, and potential hazards from fuel sources.

Before beginning any repair work, disconnect the unit from its power source to avoid electrical shock. Additionally, allow the appliance to cool down completely if it has been in use. Wearing appropriate personal protective equipment, such as gloves and goggles, can shield against debris and sharp edges during the process.

It is advisable to work in a well-ventilated area, especially when dealing with components that may release harmful fumes. Keep a fire extinguisher nearby, as a precaution against any unforeseen incidents. Always refer to the manufacturer’s guidelines for specific safety recommendations relevant to the model being serviced.

Lastly, if uncertain about any repair, seeking professional assistance is a wise choice. Ensuring both personal safety and the proper functioning of the appliance should always be the top priority during maintenance activities.