Understanding the Hendrickson Lift Axle Parts Diagram

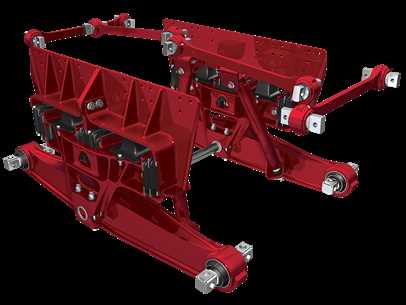

In the world of heavy-duty vehicles, the importance of effective suspension systems cannot be overstated. These mechanisms play a crucial role in ensuring stability, load distribution, and overall performance. A comprehensive grasp of the individual elements that contribute to these systems can significantly enhance maintenance and operational efficiency.

To facilitate this understanding, visual representations serve as valuable tools. They provide insights into how various components interact, showcasing their arrangement and function within the broader system. By examining these illustrations, one can appreciate the complexity and precision involved in the design and functionality of these essential features.

Whether for routine inspections or troubleshooting, having a clear visual guide is indispensable. It aids technicians and operators in identifying wear or damage, ensuring that the vehicle remains in optimal condition. This focus on the intricate details helps in making informed decisions regarding repairs and upgrades, ultimately leading to better performance on the road.

Understanding Hendrickson Lift Axle Functionality

This section explores the mechanics behind specialized suspension components designed to enhance vehicle performance and load management. These systems play a crucial role in optimizing weight distribution and improving stability during operation.

- Mechanism Overview: These components typically include a series of mechanical elements working in tandem.

- Weight Distribution: They allow for better handling of heavy loads by distributing weight evenly.

- Enhanced Stability: Improved balance contributes to safer driving dynamics, especially under challenging conditions.

- Operational Efficiency: These systems can reduce tire wear and improve fuel efficiency.

Understanding how these systems operate can lead to better maintenance practices and overall vehicle longevity.

Components of Lift Axle Systems

Understanding the various elements of an elevation support mechanism is essential for effective maintenance and performance optimization. These systems are designed to enhance load distribution and improve vehicle stability. Each component plays a critical role in ensuring functionality and safety during operation.

Main Elements

The primary components that contribute to the overall efficiency of elevation systems include support structures, hydraulic mechanisms, and control units. Each of these parts interacts seamlessly to provide enhanced performance.

Functionality Overview

These essential components work together to facilitate smooth operation and adjustability, ensuring that the vehicle adapts to varying load conditions. Below is a breakdown of these components:

| Component | Description |

|---|---|

| Support Structure | This is the framework that provides stability and support for the entire system. |

| Hydraulic Cylinder | Utilizes fluid pressure to raise and lower the mechanism as needed. |

| Control System | Manages the operation of the hydraulic components and ensures precise adjustments. |

| Linkage Arms | Connect various parts of the system, facilitating movement and support. |

| Sensor Units | Monitor load conditions and provide feedback to the control system for optimal adjustments. |

Importance of Proper Maintenance

Ensuring the longevity and efficiency of any mechanical system hinges on diligent upkeep. Regular attention not only enhances performance but also prevents unexpected failures, which can lead to costly repairs and downtime. By prioritizing maintenance, operators can significantly improve the reliability of their equipment.

Benefits of Routine Care

Consistent maintenance practices lead to optimal functionality and can reduce the risk of operational disruptions. This proactive approach helps identify potential issues early, allowing for timely interventions that safeguard the entire system’s integrity.

Cost-Effectiveness

Investing in proper maintenance translates into substantial savings over time. By minimizing wear and tear, operators can extend the life cycle of their machinery, ultimately reducing the need for frequent replacements and repairs. This not only enhances productivity but also ensures a more sustainable operation.

Common Issues with Lift Axles

In the realm of commercial transportation, auxiliary suspension components play a crucial role in ensuring stability and load distribution. However, like any mechanical system, these additions can encounter various challenges that may affect their performance and longevity.

Wear and Tear: Over time, these assemblies are subject to significant stress, leading to potential deterioration. Components such as bushings and bearings may wear down, resulting in compromised functionality.

Air System Failures: Many auxiliary systems rely on air pressure for operation. Leaks in the air lines or issues with the compressor can lead to improper inflation, causing uneven weight distribution.

Misalignment: If these systems are not properly aligned during installation or if they shift over time, it can lead to uneven tire wear and reduced handling capabilities. Regular checks and adjustments are necessary to maintain optimal performance.

Electrical Malfunctions: For models equipped with electronic controls, wiring issues or sensor failures can hinder operation. This can lead to unexpected behaviors, such as failing to raise or lower as needed.

Corrosion: Exposure to harsh environmental conditions can cause corrosion of metal components. Regular inspections and maintenance can help identify and address these issues before they escalate.

Addressing these common challenges promptly can extend the lifespan of the auxiliary systems and ensure safer, more efficient operation on the road.

Benefits of Using Lift Axles

Utilizing additional support systems in heavy vehicles offers numerous advantages that enhance performance and efficiency. These systems play a crucial role in improving load distribution, ensuring better traction, and extending the lifespan of tires.

Improved Load Management

- Optimizes weight distribution across the vehicle.

- Reduces wear and tear on primary components.

- Facilitates compliance with weight regulations.

Enhanced Stability and Performance

- Increases overall vehicle stability during transport.

- Improves handling in various driving conditions.

- Offers better fuel efficiency through reduced drag.

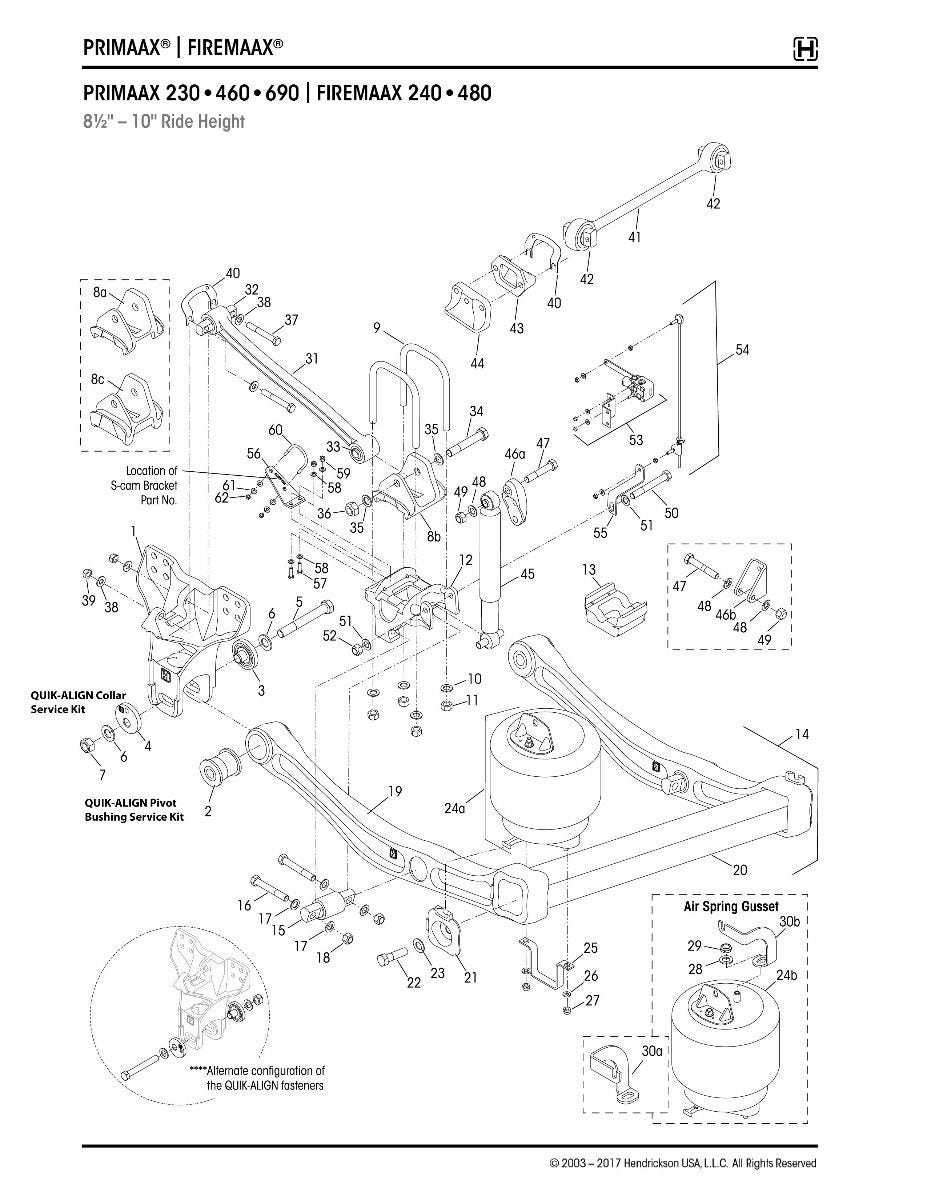

How to Identify Parts in Diagrams

Recognizing components in visual representations is essential for effective maintenance and repair. Familiarity with the symbols and notations used can greatly enhance understanding and efficiency. Here are some strategies to assist in identifying elements within these illustrations.

Familiarize Yourself with Common Symbols

- Study frequently used icons and their meanings.

- Refer to a legend or key often provided alongside the visuals.

- Learn the color coding systems, as they can indicate different functions or statuses.

Utilize Reference Materials

- Consult manuals specific to the system or equipment you are examining.

- Use online resources or forums where professionals discuss component identification.

- Take note of manufacturer-specific nuances that may vary from standard practices.

By applying these techniques, one can improve their ability to navigate and interpret complex visuals, ultimately leading to more successful troubleshooting and repairs.

Hendrickson Lift Axle Model Variations

In the realm of specialized suspension systems, variations play a crucial role in meeting diverse operational demands. Each model is designed with specific features and capabilities that cater to various applications, ensuring optimal performance under different conditions. Understanding these differences allows for informed decisions when selecting the appropriate system for specific vehicles and loads.

Design Features and Applications

Different configurations showcase unique design elements, which contribute to their functionality. For instance, some models prioritize enhanced load distribution, while others focus on maximizing maneuverability. The choice of materials and engineering techniques can significantly influence the durability and efficiency of each system, making it vital to assess the requirements of the intended application.

Compatibility and Integration

Another important aspect is compatibility with existing vehicle setups. Variations may offer distinct mounting options and connection interfaces, allowing for seamless integration into various fleets. By evaluating the specific characteristics of each model, operators can ensure that their vehicles achieve the desired balance between stability and agility.

In summary, understanding the distinctions among these suspension configurations enables operators to make strategic choices that enhance vehicle performance and longevity. This knowledge is essential for optimizing fleet efficiency and adapting to evolving industry needs.

Installation Tips for Lift Axles

Proper setup of additional support mechanisms is crucial for optimal performance and safety. Ensuring that every component is aligned and securely fastened can significantly enhance the vehicle’s functionality and longevity. Here are some essential suggestions to guide you through the process.

1. Begin with a thorough inspection of all components before installation. Check for any signs of wear or damage that could affect performance.

2. Follow the manufacturer’s guidelines meticulously to avoid misalignment. Precise measurements during the setup can prevent future complications.

3. Use appropriate tools and equipment to secure each element firmly. Investing in quality tools can make a significant difference in the ease of installation.

4. Once installed, conduct a test run to ensure everything operates smoothly. This will help identify any adjustments needed for optimal performance.

5. Regular maintenance checks after installation are vital. This will help catch any issues early and extend the lifespan of the system.

Safety Considerations with Lift Axles

Ensuring the secure operation of additional support systems is crucial for maintaining vehicle stability and performance. Proper awareness and implementation of safety protocols can significantly reduce the risk of accidents and enhance overall efficiency during transport.

Regular Maintenance and Inspection

Routine checks are essential for identifying wear and tear on components. Regular inspections should encompass all mechanical aspects, including hydraulic systems and control mechanisms, to guarantee optimal functionality. Addressing minor issues before they escalate into major failures can prevent unsafe situations on the road.

Load Distribution Awareness

Understanding how weight is distributed across the vehicle is vital. Uneven loading can lead to instability, increasing the chances of tipping or losing control. Ensuring that the weight is properly balanced not only enhances safety but also extends the lifespan of the vehicle’s components.

Resources for Parts Replacement

Finding reliable resources for component substitution is essential for maintaining optimal performance and safety. Access to accurate information and quality materials can significantly impact the efficiency and longevity of your equipment.

Online Catalogs: Numerous websites offer extensive catalogs that include detailed specifications, enabling you to identify the necessary components quickly. Utilize these digital tools to streamline your search.

Manufacturer Support: Reaching out to manufacturers can provide insights into recommended suppliers and authentic items. Their expertise ensures you receive appropriate guidance tailored to your specific needs.

Forums and Communities: Engaging with online communities can be invaluable. Participants often share experiences and suggestions regarding trusted vendors and alternative solutions, fostering a collaborative environment.

Local Distributors: Don’t overlook local suppliers who may stock essential replacements. Building a relationship with nearby vendors can lead to quicker access to necessary materials and personalized service.

Instructional Resources: Video tutorials and user manuals can offer step-by-step guidance for proper installation and maintenance. These resources help ensure that you perform replacements correctly, minimizing the risk of future issues.

By utilizing these diverse resources, you can effectively manage the process of component replacement and enhance the reliability of your equipment.