Understanding the Hesston 4600 Baler Parts Diagram

In the realm of modern agriculture, the efficiency of harvesting equipment is paramount. A thorough comprehension of the intricate components within these machines is essential for optimal performance and maintenance. Each element plays a vital role in the overall functionality, contributing to the seamless operation of the equipment in various field conditions.

When dealing with complex machinery, having a visual representation of its structure can significantly enhance understanding. By examining the layout of individual components, operators and technicians can identify potential issues and implement timely repairs. This knowledge not only extends the lifespan of the equipment but also improves productivity during the harvesting season.

Furthermore, familiarity with the assembly and arrangement of different elements aids in troubleshooting and replacement processes. Recognizing how each piece interconnects allows users to tackle maintenance challenges with confidence, ensuring that the equipment remains in peak condition throughout its operational life. With the right insights, managing agricultural implements becomes a more straightforward and efficient endeavor.

Key Features of Hesston 4600

This machine is designed to enhance efficiency and performance in agricultural tasks. It combines advanced technology with durable construction, making it a reliable choice for farmers seeking productivity and longevity in their equipment.

One of the standout aspects is its ability to handle various materials with ease. The innovative mechanism ensures consistent operation, reducing downtime and maintenance needs. This feature is crucial for maximizing output during peak seasons.

The ergonomic design contributes to user comfort, allowing for easy operation and adjustments. With a focus on reducing operator fatigue, this equipment is equipped with intuitive controls and accessible maintenance points, ensuring that users can focus on the task at hand.

In addition, the model showcases robust build quality, capable of withstanding challenging field conditions. Its resilience not only prolongs the lifespan of the machine but also ensures optimal performance in diverse environments.

Overall, this agricultural equipment offers a blend of functionality and durability, making it a valuable asset for modern farming operations. Its thoughtful engineering addresses the needs of users, enhancing both productivity and satisfaction in agricultural endeavors.

Importance of Understanding Baler Components

Comprehending the individual elements of a forage compressing machine is essential for efficient operation and maintenance. Familiarity with each component allows operators to identify issues quickly, perform necessary repairs, and ensure optimal performance. A well-rounded understanding can also lead to improved productivity and longevity of the equipment.

Enhanced Operational Efficiency

Knowing how each part contributes to the overall function enables users to:

- Detect malfunctions early.

- Perform timely maintenance tasks.

- Utilize the machine effectively, reducing downtime.

Cost-Effective Maintenance

Understanding the intricacies of the machine leads to:

- Informed decision-making when purchasing replacements.

- Minimized repair costs through proactive care.

- Increased equipment lifespan by adhering to best practices.

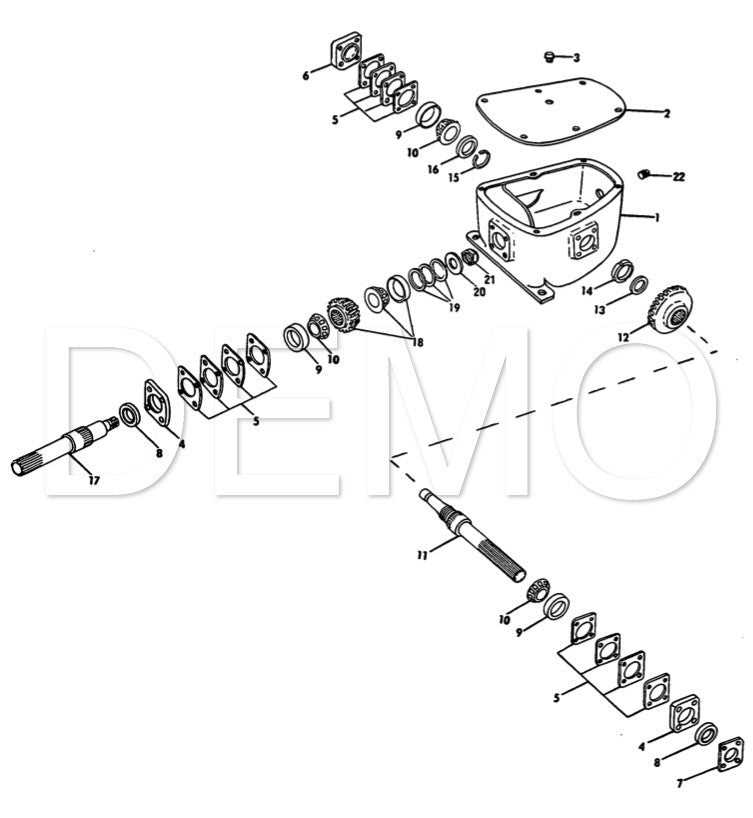

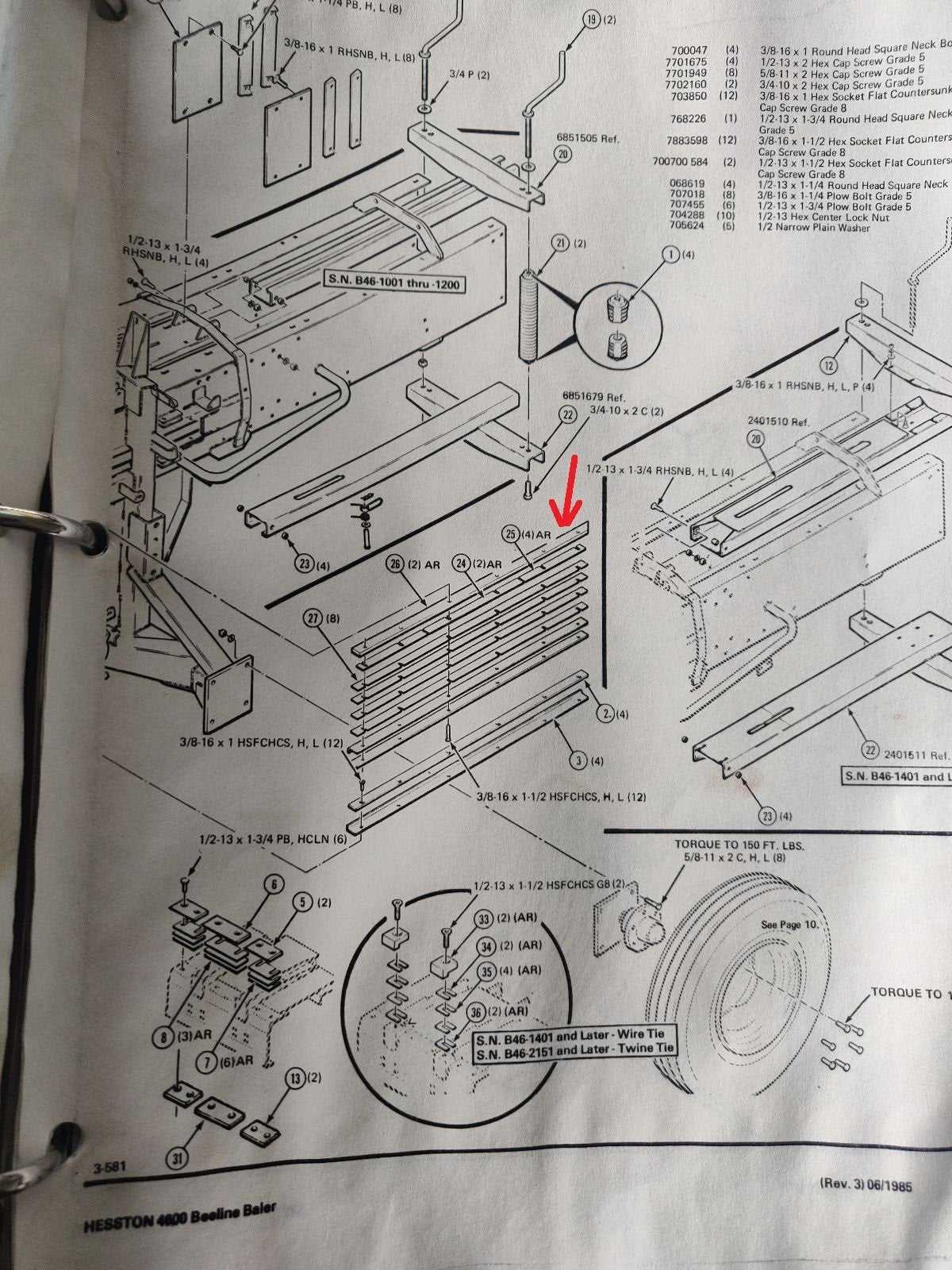

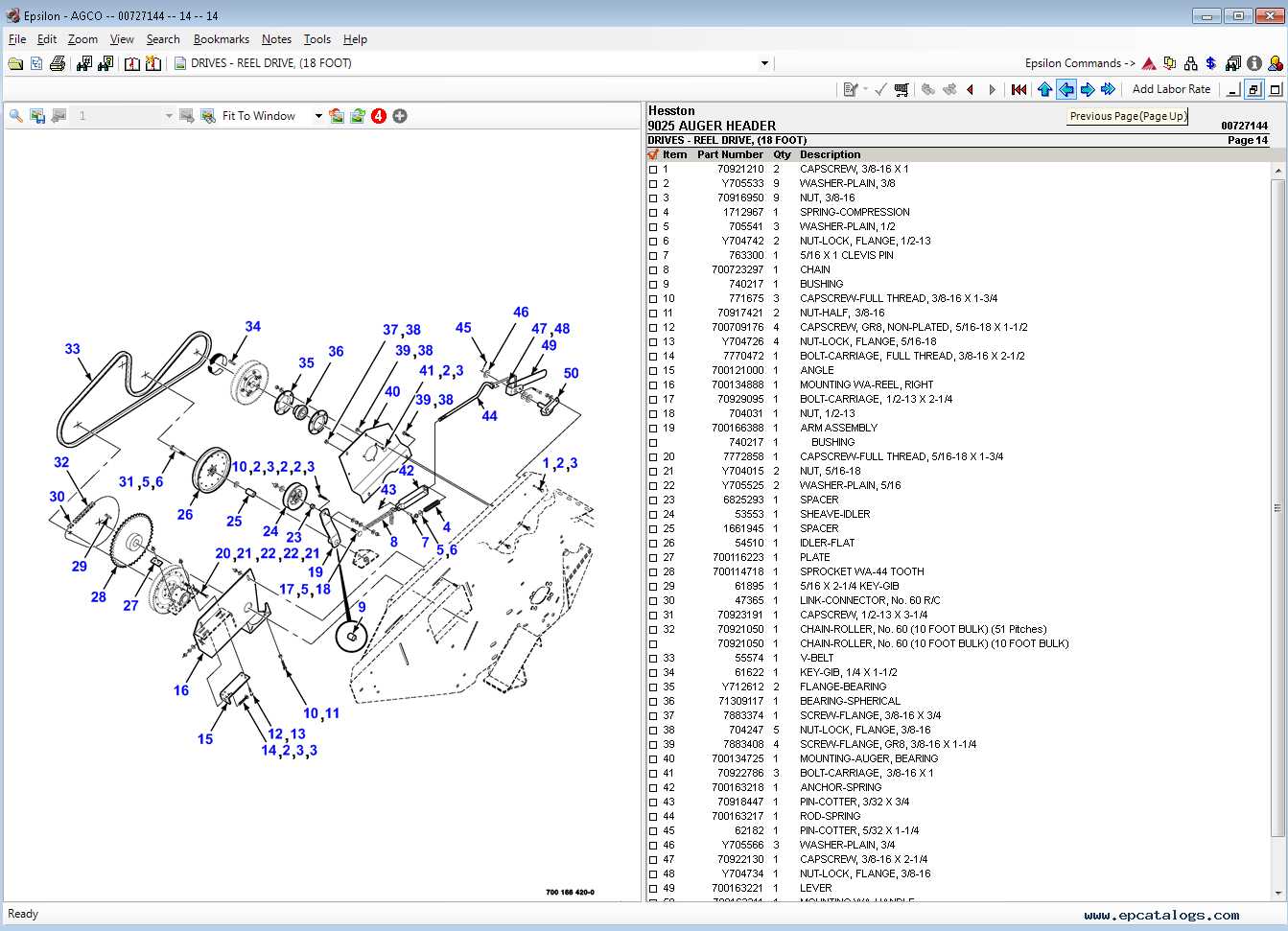

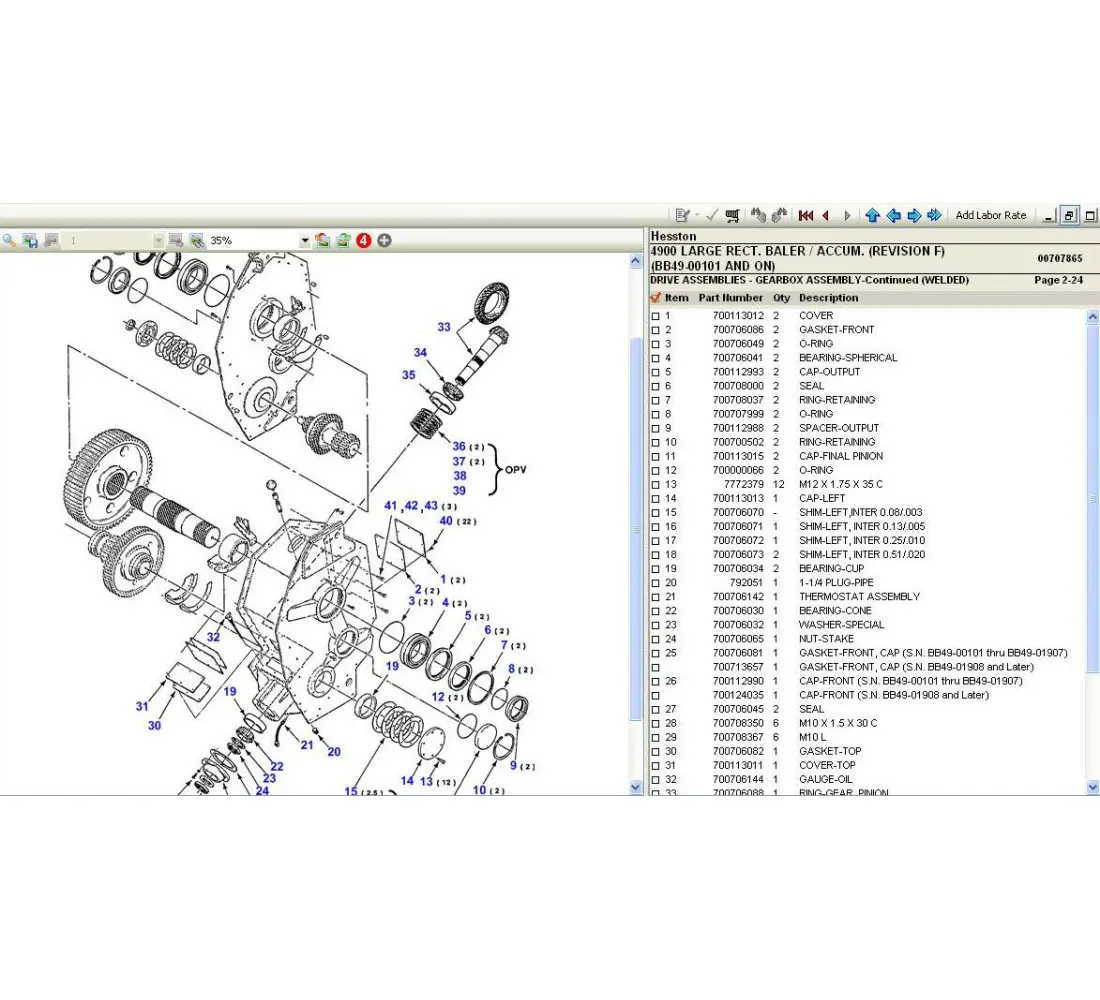

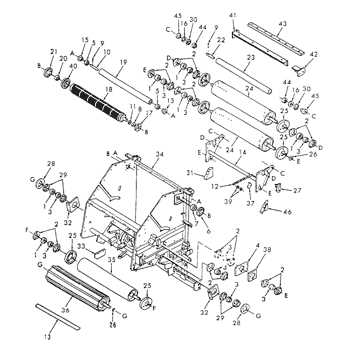

Identifying Major Parts in Diagrams

Understanding the essential components of machinery is crucial for effective maintenance and repair. Recognizing these elements within visual representations aids in troubleshooting and enhances familiarity with the equipment. By focusing on the key sections, operators can gain insights into the overall functionality and potential issues.

When examining a visual schematic, it is important to pay attention to the main assemblies that serve as the backbone of the machine. These units typically include drive systems, operational mechanisms, and control features. Identifying these core components allows users to comprehend how each part interacts within the larger system.

Furthermore, observing the connective elements is essential. These may consist of belts, gears, and other linkages that facilitate movement and energy transfer. Understanding their layout and function can help pinpoint areas that may require adjustments or repairs.

Lastly, being aware of the accessory features can significantly improve operational efficiency. Components like sensors, guards, and storage units enhance the overall effectiveness of the machinery. A thorough grasp of these features not only simplifies maintenance tasks but also promotes a safer working environment.

Maintenance Tips for Hesston 4600

Regular upkeep is essential for ensuring optimal performance and longevity of agricultural machinery. Implementing a consistent maintenance schedule can prevent unexpected breakdowns and enhance efficiency. This section provides essential guidelines for maintaining your equipment effectively.

Daily Checks

Performing routine inspections can help identify potential issues before they escalate. Here are some key areas to focus on:

| Check | Description |

|---|---|

| Fluid Levels | Ensure that all essential fluids are at appropriate levels, including hydraulic fluid and engine oil. |

| Belts and Hoses | Inspect belts for wear and hoses for leaks, replacing them as necessary to prevent failures. |

| Cleaning | Remove debris from all moving parts and surfaces to prevent blockages and ensure smooth operation. |

Seasonal Maintenance

In addition to daily checks, seasonal maintenance is crucial for peak performance during operational periods. Consider the following actions:

| Maintenance Task | Description |

|---|---|

| Lubrication | Apply lubricant to moving parts to minimize friction and wear, enhancing the machinery’s lifespan. |

| Blade Sharpening | Regularly sharpen blades to ensure efficient cutting and reduce strain on the engine. |

| Electrical System | Inspect wiring and connections for corrosion or damage, ensuring a reliable electrical system. |

Common Issues with Baler Parts

Operating agricultural machinery often comes with its own set of challenges. Various components may experience wear and tear, leading to performance issues that can hinder efficiency. Understanding common problems associated with these mechanisms can help in early detection and maintenance, ensuring smoother operation during critical harvest periods.

- Worn Belts: Over time, belts can become frayed or cracked, resulting in reduced tension and potential slippage. Regular inspection is essential to prevent breakdowns.

- Clogged Feed Systems: Debris can accumulate in feeding mechanisms, causing blockages. This can lead to inefficient feeding and may require disassembly for cleaning.

- Faulty Bearings: Bearings can wear out, leading to excessive vibration and noise. Replacing worn bearings promptly can prevent further damage to connected components.

- Hydraulic Leaks: Hydraulic systems are crucial for operation. Any leaks can lead to loss of pressure, resulting in poor functionality. Regular checks for fluid levels and leaks are vital.

- Misalignment: Components that are not properly aligned can cause uneven wear and increase the risk of mechanical failure. Regular alignment checks can mitigate this risk.

Addressing these issues proactively can significantly enhance the longevity and efficiency of the machinery, ultimately leading to better productivity on the farm.

Replacement Parts for Efficient Operation

Ensuring optimal performance of agricultural machinery relies heavily on the timely replacement of essential components. Maintaining equipment efficiency is crucial for maximizing productivity and minimizing downtime. Regularly updating worn-out elements not only enhances functionality but also extends the lifespan of the machinery.

Identifying the correct components for your specific model can significantly improve operational efficiency. Below is a table outlining some common replacements that contribute to the seamless functioning of your equipment.

| Component | Description | Function |

|---|---|---|

| Roller Assembly | Essential for the compression and shaping of material. | Ensures uniformity in baling process. |

| Knife Kit | Includes sharp blades for cutting crops. | Facilitates effective material entry and processing. |

| Drive Belts | Transmits power from the engine to the working parts. | Maintains efficient movement of the machinery. |

| Feed Mechanism | Aids in guiding material into the working chamber. | Enhances the intake process, reducing blockages. |

| Hydraulic Cylinders | Controls the movement of various machine parts. | Ensures smooth operation and precise adjustments. |

Where to Find Hesston Parts

When it comes to sourcing components for your agricultural machinery, it’s crucial to know where to look. The availability of high-quality replacements can significantly enhance the efficiency and longevity of your equipment. Various options exist for obtaining these essential items, from online retailers to local dealers, ensuring that you can keep your machinery in optimal condition.

Online Retailers

Numerous online platforms specialize in agricultural machinery supplies. These websites often provide detailed catalogs that allow you to search for specific components by model or function. By utilizing filters and search tools, you can easily locate the necessary items without the hassle of in-person shopping. Additionally, many online vendors offer competitive pricing and fast shipping options, making them a convenient choice for procurement.

Local Dealerships

Visiting nearby dealerships can also be an effective way to acquire the components you need. Local sellers typically have knowledgeable staff who can assist you in identifying the right items for your machinery. Furthermore, purchasing locally can often provide immediate access to parts, reducing downtime and keeping your operations running smoothly. Establishing a relationship with your local dealer can lead to valuable insights and recommendations for maintaining your equipment.

Comparing Hesston 4600 to Other Models

This section explores the characteristics and features of a specific hay-making machine in comparison to its counterparts in the market. By examining various models, users can understand the strengths and weaknesses of each, ultimately aiding in the decision-making process for agricultural needs.

When evaluating the chosen model against similar equipment, several factors come into play. Performance is a primary concern; the efficiency of hay processing and the quality of the final product are critical in determining value. Additionally, durability and maintenance requirements play significant roles, as operators seek machinery that withstands rigorous use and demands minimal upkeep.

Another vital aspect is the technological features incorporated into the machinery. Innovations such as automated systems and improved safety mechanisms can enhance usability and streamline operations. Furthermore, cost-effectiveness is always a crucial element; prospective buyers must consider initial investment versus long-term operational costs.

Ultimately, comparing this model to others in the industry provides a comprehensive view of its capabilities. By understanding how it stacks up against its peers, users can make informed choices that align with their agricultural objectives.

Benefits of Using Quality Components

Utilizing high-grade components in machinery significantly enhances performance and reliability. Quality materials not only improve the overall efficiency of equipment but also contribute to longevity, minimizing the need for frequent replacements. This investment often leads to reduced operational costs over time, making it a wise choice for any operator.

Durability is a key advantage of superior components. When machinery is built with robust materials, it withstands the rigors of demanding tasks, thereby decreasing the likelihood of breakdowns. Operators can rely on their equipment to perform consistently under pressure.

Another vital aspect is performance optimization. Well-crafted parts function seamlessly, ensuring that all systems work together efficiently. This synergy translates into smoother operations and enhanced output, ultimately boosting productivity.

Furthermore, using quality elements fosters safety. Inferior components may fail unexpectedly, posing risks to both operators and surrounding personnel. By prioritizing high standards, operators can ensure a safer working environment.

Lastly, investing in premium components often enhances resale value. Equipment that is well-maintained and constructed from top-quality materials typically attracts higher offers on the market. This financial benefit can be crucial when considering upgrades or expansions in the future.