Understanding the Hilti TE 30 Parts Diagram for Efficient Repairs

In the realm of construction and engineering, a comprehensive grasp of tool mechanisms is essential for both efficiency and safety. This section aims to enhance your knowledge about the intricate elements that contribute to the functionality of these vital instruments.

By examining the structure and relationships of individual components, one can uncover how they work together harmoniously. This exploration not only aids in troubleshooting but also empowers users to make informed decisions regarding maintenance and repairs.

With an ultimate goal of optimizing performance, delving into the specifics of each piece reveals insights that can significantly improve operational capabilities. Understanding these intricacies fosters a deeper appreciation for the tools that facilitate complex tasks in various fields.

Overview of Hilti TE 30

This section provides a comprehensive insight into a powerful tool designed for various construction and demolition tasks. With a focus on efficiency and user comfort, this device stands out for its robust performance and advanced features, catering to the needs of professionals in the industry.

Key Features

The tool boasts a range of functionalities that enhance its versatility. Its ergonomic design ensures ease of use, minimizing fatigue during extended operations. Additionally, the high-impact energy output allows for effective drilling and chiseling in tough materials, making it an essential asset on job sites.

Applications

Ideal for both light and heavy-duty applications, this equipment excels in tasks such as drilling into concrete, masonry, and other hard surfaces. Users appreciate its reliability and precision, which contribute to improved productivity and job quality.

Key Features of TE 30 Model

The TE 30 model is designed to deliver exceptional performance in various applications, combining innovative technology with user-friendly features. This tool stands out for its reliability, efficiency, and versatility, making it a preferred choice for professionals in construction and renovation tasks.

Enhanced Power and Efficiency

One of the defining characteristics of the TE 30 is its powerful motor, which provides the necessary force for heavy-duty tasks. The optimal power-to-weight ratio ensures that users can operate the device with ease, reducing fatigue during prolonged use. Furthermore, the model’s advanced energy management system maximizes performance while minimizing energy consumption.

User-Centric Design

The ergonomic design of the TE 30 model emphasizes comfort and control, featuring a well-balanced structure that allows for extended use without strain. Intuitive controls and vibration reduction technology enhance the overall user experience, enabling precise handling in various working conditions. Additional features, such as an adjustable depth stop, provide greater versatility for different applications.

Understanding Parts and Components

Grasping the various elements and mechanisms within a tool is essential for effective usage and maintenance. Each individual piece plays a crucial role, contributing to the overall functionality and performance of the device. Recognizing these components allows users to troubleshoot issues, enhance their skills, and ensure longevity in their equipment.

Key Elements

Every device consists of multiple key elements, each designed for specific tasks. From the housing that protects internal mechanisms to the operational sections that drive performance, understanding these components helps users appreciate the complexity and engineering behind their tools.

Importance of Knowledge

Having a comprehensive knowledge of these individual pieces can significantly improve one’s ability to manage repairs and replacements. Familiarity with the structure fosters confidence in tackling problems and optimizing the use of the equipment. Ultimately, this understanding leads to better performance and reliability.

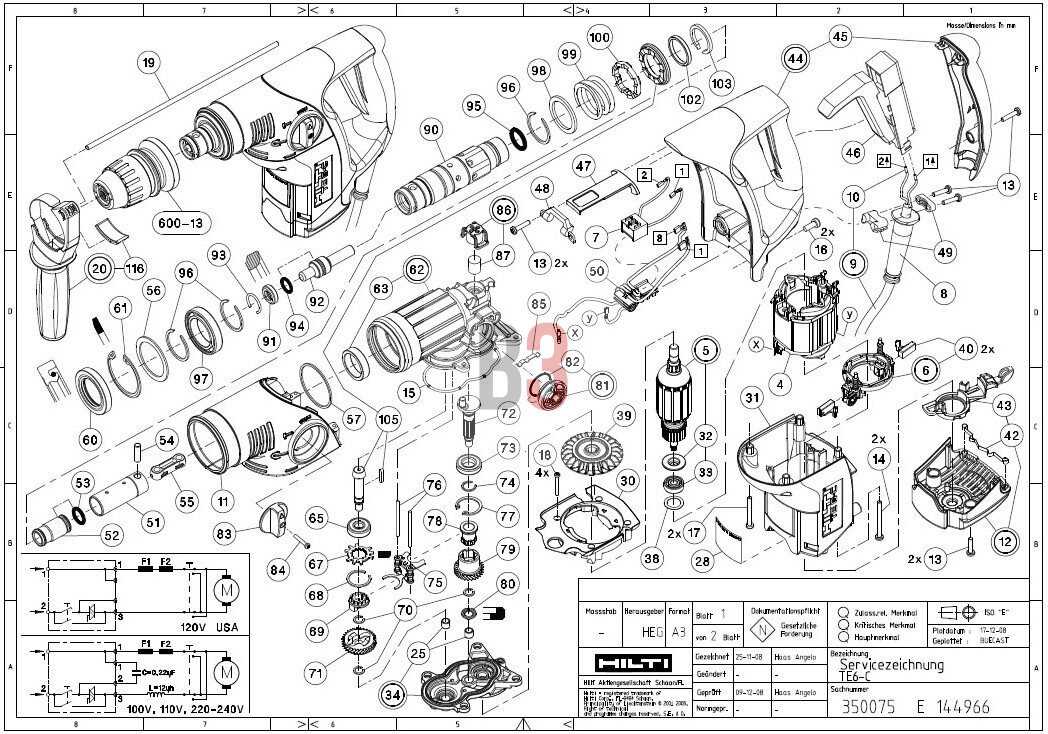

Importance of a Parts Diagram

Understanding the intricate components of a tool is essential for effective maintenance and repair. A visual representation of these elements serves as a valuable guide, ensuring users can identify and access the necessary components with ease. This clarity enhances both the efficiency of repairs and the longevity of the equipment.

Facilitating Maintenance is one of the primary benefits of a visual layout. Users can quickly locate specific elements, reducing the time spent searching for necessary items. This not only streamlines the process but also minimizes the risk of errors during reassembly.

Enhancing Repair Accuracy is another critical aspect. A clear overview helps technicians understand the relationships between different components, leading to more precise repairs. This understanding is crucial when diagnosing issues, as it allows for a systematic approach to troubleshooting.

Moreover, such representations contribute to user training. New users can familiarize themselves with the equipment more effectively, gaining confidence in their ability to perform maintenance tasks. This educational benefit fosters a deeper understanding of the tool’s functionality and encourages responsible usage.

In summary, a visual reference of the equipment’s components not only simplifies maintenance and repair but also enhances training and operational knowledge, ultimately leading to improved performance and reliability.

Common Issues with TE 30 Parts

Understanding the frequent challenges encountered with the TE 30 model can enhance performance and extend its lifespan. Many users face similar concerns that, when addressed, can lead to smoother operations.

- Wear and Tear: Over time, components may deteriorate, impacting functionality.

- Inadequate Lubrication: Insufficient lubrication can lead to overheating and reduced efficiency.

- Improper Assembly: Incorrect assembly can cause misalignment, leading to operational failures.

Regular maintenance and awareness of these common issues can ultimately improve the user experience and ensure optimal performance.

Identifying Replacement Parts Easily

Finding the right components for your tools can often be a challenging task. Understanding how to efficiently identify what you need is essential for maintaining optimal performance. This process involves knowing the various elements involved and having access to clear visual references that simplify the selection process.

Utilizing Visual References

One of the most effective ways to locate the correct items is by using detailed illustrations that break down each element. These guides can help you visually match the component you’re looking for, ensuring that you select the appropriate replacement. Clarity in these resources is key, allowing users to navigate through various options without confusion.

Understanding Component Functions

Another crucial aspect is having a solid grasp of the functions of each element within your tool. Familiarity with how each piece contributes to the overall operation enables quicker identification. When you recognize which components are critical for your specific needs, the replacement process becomes significantly more efficient, minimizing downtime and maximizing productivity.

How to Read the Diagram

Understanding the visual representation of components is essential for effective assembly and maintenance. This guide will help you navigate the essential features and symbols used in the schematic, ensuring you can interpret it with confidence.

Follow these steps to enhance your comprehension:

- Familiarize Yourself with Symbols:

- Identify common icons that represent various elements.

- Learn what each symbol indicates regarding function and positioning.

- Study the Layout:

- Observe the overall structure to understand the relationships between different components.

- Pay attention to directional arrows that may indicate flow or movement.

- Refer to Annotations:

- Look for labels or notes that provide additional context.

- Use these annotations to clarify any uncertainties about specific parts.

By mastering these elements, you will be equipped to navigate the schematic with ease and ensure optimal performance of your equipment.

Tools Required for Maintenance

Ensuring optimal performance and longevity of your equipment necessitates specific instruments for effective upkeep. Having the right tools on hand can streamline maintenance tasks and enhance overall efficiency.

- Wrenches: Essential for tightening and loosening various components.

- Screwdrivers: Necessary for removing and securing screws in different sizes.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Lubricants: Important for reducing friction and ensuring smooth operation.

- Cleaning Supplies: Required for maintaining cleanliness and preventing debris buildup.

By equipping yourself with these essential items, you can effectively address maintenance needs and ensure the equipment operates at its best.

Tips for Effective Repairs

Ensuring successful fixes requires a strategic approach and understanding of the tools and materials at hand. By following a few essential guidelines, you can enhance your repair process and achieve lasting results.

Assess the Situation

Before diving into repairs, carefully evaluate the damage. Identifying the underlying issues will help you choose the right techniques and materials for the job. Take notes on what you observe to avoid missing crucial details.

Gather Quality Materials

Using high-quality components is vital for durability. Always opt for reliable brands and ensure compatibility with the item being repaired. Investing in good materials can prevent future problems and save time in the long run.

Where to Buy Genuine Parts

When seeking authentic components for your tools, it is crucial to know where to find reliable sources. Quality assurance plays a significant role in maintaining performance and longevity, so choosing the right vendors is essential.

Here are some trusted options for acquiring genuine components:

- Official Retailers: Check authorized dealers who specialize in the brand. They often have the latest inventory and can provide guidance on compatibility.

- Manufacturer’s Website: The brand’s official site usually offers a direct purchasing option, ensuring you receive the correct items.

- Online Marketplaces: Established e-commerce platforms may carry authentic items. Look for sellers with high ratings and positive reviews.

- Local Service Centers: Many repair shops are authorized by the brand to sell original items. Visiting these centers can also give you insight into proper installation and maintenance.

Always verify the authenticity of the components before purchasing. This can include checking for certification seals or comparing prices with official sources to ensure you are not overpaying for counterfeit alternatives.

Benefits of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring longevity and optimal performance. By adhering to a scheduled maintenance routine, users can significantly enhance the reliability and efficiency of their tools, ultimately leading to reduced downtime and improved productivity.

Enhanced Performance

Regular check-ups and servicing prevent potential issues from escalating, allowing machinery to function at peak levels. This proactive approach not only boosts performance but also ensures safety during operation.

Cost Efficiency

Investing in routine maintenance can lead to substantial savings in the long run. Addressing minor repairs before they develop into major failures reduces unexpected expenses and prolongs the life of equipment.

| Benefit | Description |

|---|---|

| Increased Reliability | Minimizes unexpected breakdowns. |

| Improved Safety | Ensures safer working conditions. |

| Longer Lifespan | Extends the life of equipment. |

| Better Efficiency | Maximizes tool performance. |