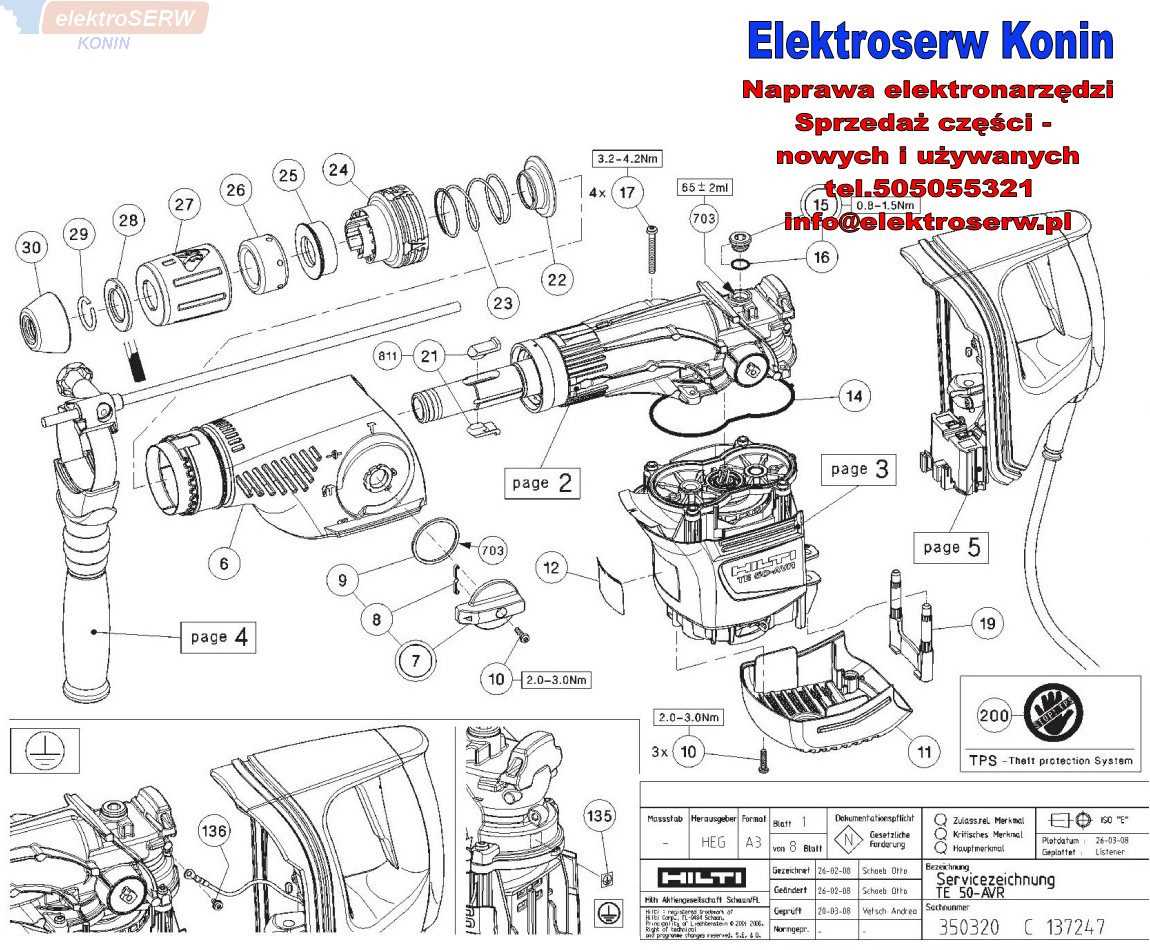

Understanding the Parts Diagram of Hilti TE 50 AVR

In the realm of construction and heavy-duty tasks, mastering the functionality of essential equipment is crucial. Every intricate mechanism plays a vital role in ensuring optimal performance and reliability. By exploring the various elements that contribute to the efficiency of these tools, users can gain valuable insights into their operation and maintenance.

Focusing on the internal structure, enthusiasts can uncover how each piece interconnects, providing the ultimate user experience. A comprehensive breakdown allows for a deeper appreciation of the design, functionality, and potential issues that may arise. Such knowledge not only enhances productivity but also aids in troubleshooting and repairs.

Engaging with detailed illustrations of tool assemblies can illuminate the intricate relationships between components. This exploration is not merely academic; it empowers users to make informed decisions regarding upkeep and modifications. By delving into this aspect, one can ensure the longevity and effectiveness of their trusted equipment.

Understanding the Hilti TE 50 AVR

This section aims to explore a powerful tool designed for heavy-duty applications, highlighting its components and functionality. With its robust engineering, this equipment is tailored for optimal performance in various construction tasks.

To better grasp the essential features, let’s break down the key elements that contribute to its effectiveness:

| Component | Function |

|---|---|

| Motor | Drives the tool with high efficiency |

| Chisel | Enables precise demolition work |

| Handle | Provides stability and control during use |

| Housing | Protects internal mechanisms from dust and debris |

By delving into these components, users can appreciate how this tool achieves its ultimate potential in demanding environments.

Overview of Hilti TE 50 AVR Features

This section explores the key characteristics of a powerful tool designed for efficiency and precision in various applications. It integrates advanced technology to enhance user experience, making it an essential asset for professionals in construction and renovation projects.

Performance and Durability

One of the standout features of this equipment is its robust performance. Engineered to withstand rigorous conditions, it provides exceptional reliability. The high-impact mechanism ensures that even the toughest materials can be handled with ease. Additionally, its durable construction means it can endure frequent use without compromising functionality.

User-Friendly Design

The ergonomic design is another significant aspect, promoting comfort during extended use. Its lightweight nature reduces fatigue, allowing for better control and precision. Advanced vibration reduction technology minimizes strain on the operator, ensuring a safer working environment. These features collectively contribute to enhanced productivity and efficiency on the job site.

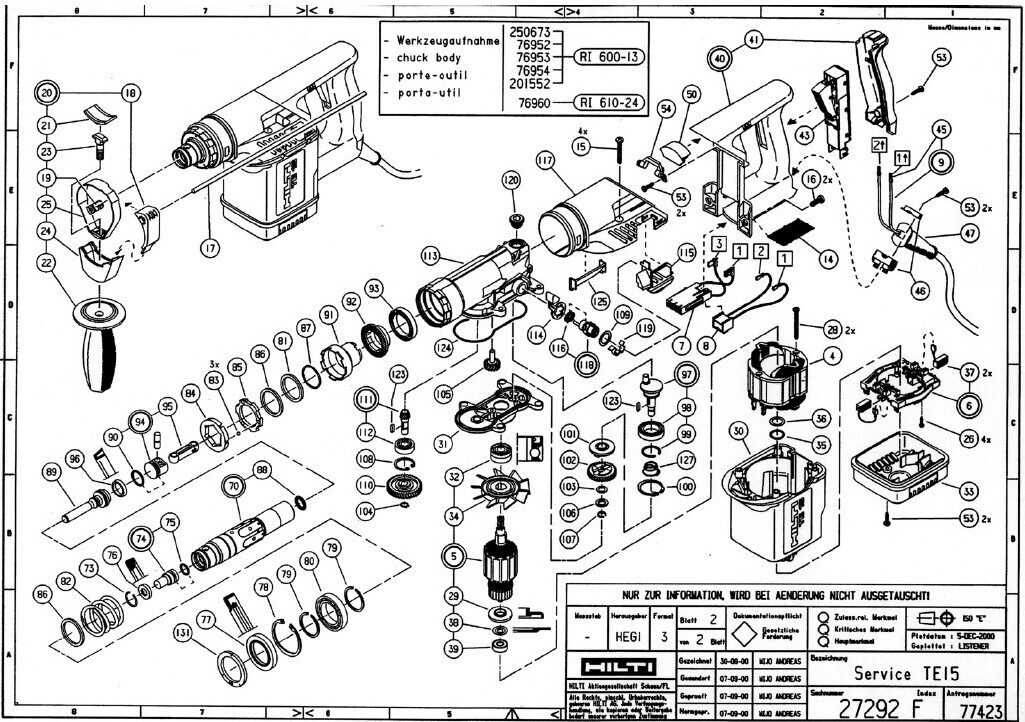

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for maintenance and repair. Visual representations help users identify individual elements, facilitating efficient troubleshooting and assembly. These illustrations serve as essential guides, ensuring that every piece is correctly positioned and functional.

Enhancing User Efficiency

Clear visual aids streamline the repair process. Users can quickly locate necessary items, reducing downtime and improving overall productivity. This efficiency is especially vital in professional settings where time is of the essence.

Facilitating Communication

Visual references bridge the gap between technical jargon and practical understanding. They allow technicians and operators to communicate effectively about specific components, minimizing misunderstandings during discussions or training sessions.

| Benefit | Description |

|---|---|

| Time-Saving | Quick identification of components leads to faster repairs. |

| Clarity | Visuals simplify complex information for better comprehension. |

| Collaboration | Enhanced communication aids teamwork in technical environments. |

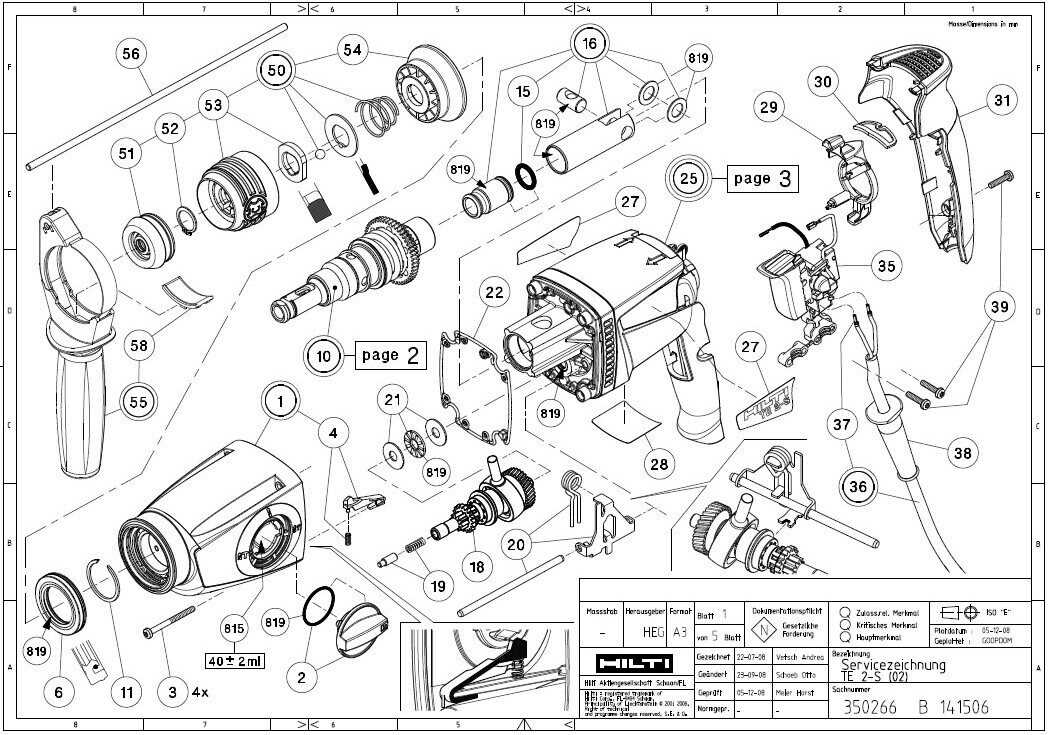

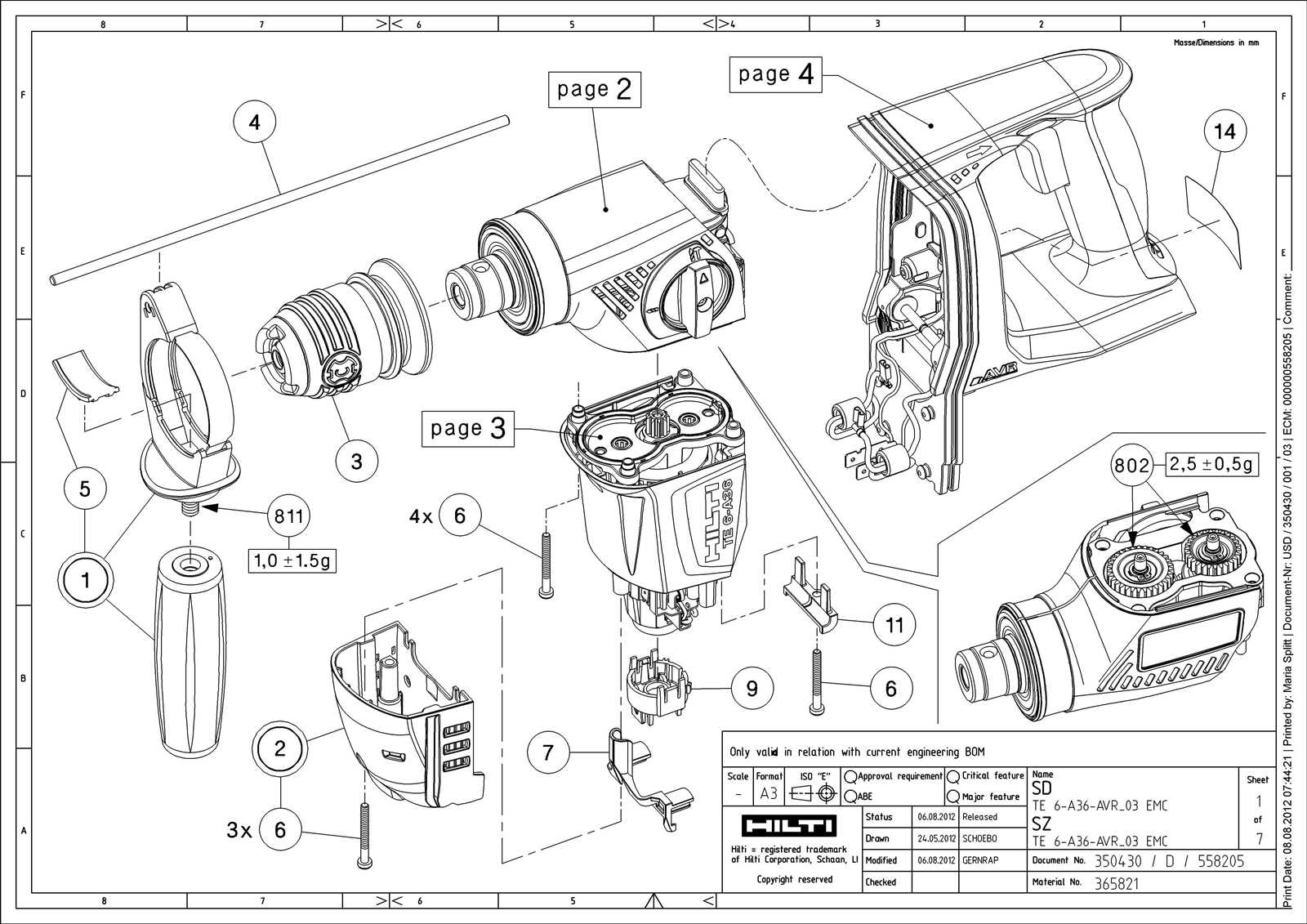

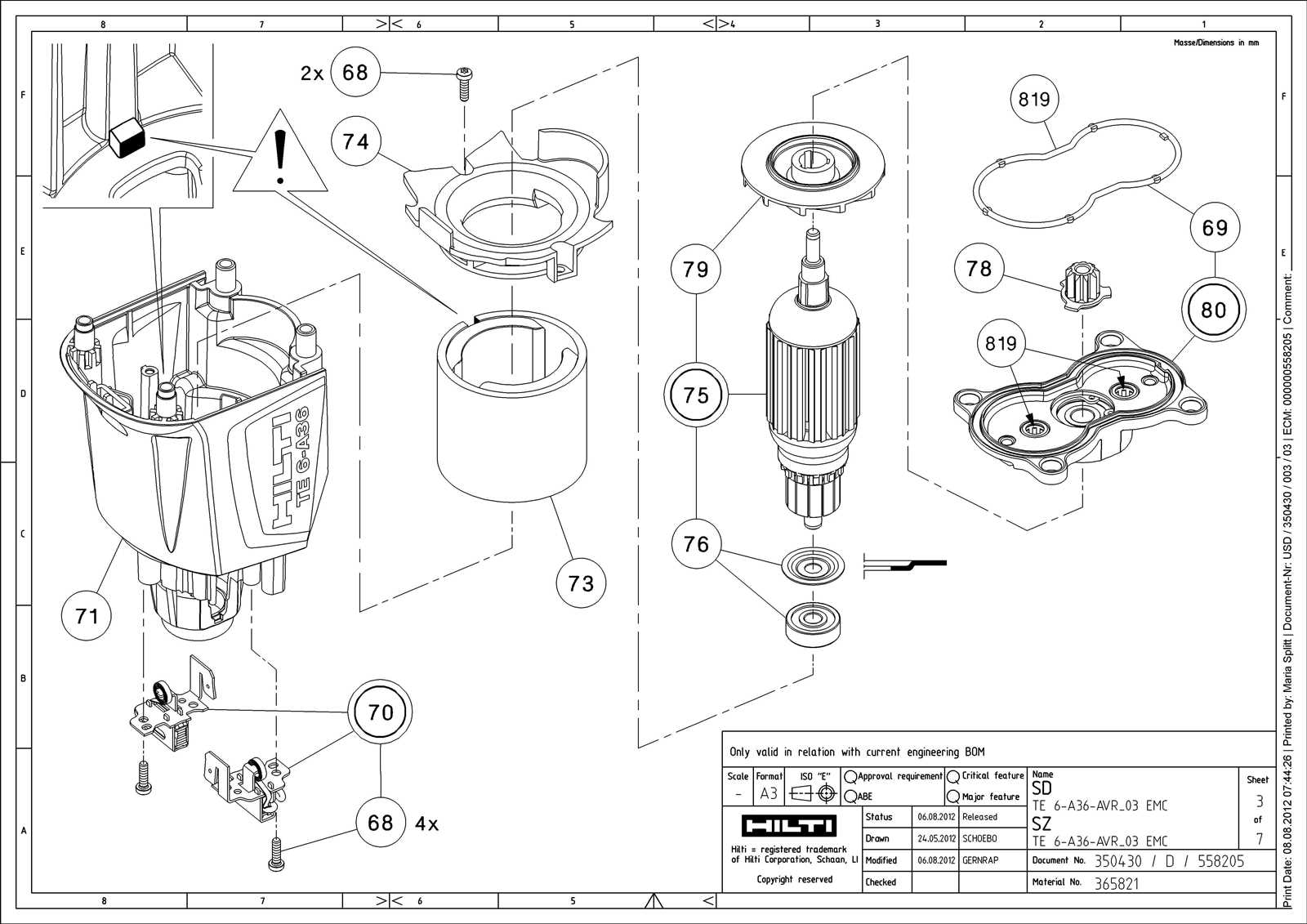

Common Parts of TE 50 AVR

The TE 50 AVR is designed with a variety of essential components that work together to deliver optimal performance. Understanding these elements is crucial for effective maintenance and operation. Each component plays a significant role in the overall functionality, ensuring that the tool operates efficiently in various applications.

One of the key components is the motor, which provides the necessary power for the device to perform tasks such as drilling and chiseling. Its robust design ensures reliability and longevity, making it suitable for demanding work environments.

Another important element is the impact mechanism, which generates the force required for effective drilling into tough materials. This feature enhances the tool’s capability, allowing it to handle a range of applications with ease.

The housing of the tool not only protects internal components but also contributes to user comfort. Its ergonomic design reduces strain during extended use, making it easier to maneuver in various settings.

Additionally, the power supply system is critical for ensuring consistent energy delivery. It integrates seamlessly with other components to maintain optimal performance, enabling users to achieve desired results without interruption.

Finally, the accessory interface allows for easy attachment of different tools, enhancing versatility. This feature enables users to adapt the device for specific tasks, increasing its overall utility in construction and renovation projects.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visuals convey crucial information about components and their relationships within a system.

To grasp the content effectively, consider the following steps:

- Identify Key Symbols: Familiarize yourself with common symbols and notations used in the illustration.

- Study the Layout: Observe how components are arranged, noting connections and positioning.

- Reference the Legend: Check the accompanying legend for explanations of symbols and numbers.

- Follow the Sequence: Understand the flow of assembly or disassembly by following the indicated order.

By honing these skills, you can enhance your ability to interpret technical visuals effectively.

Maintenance Tips for TE 50 AVR

Proper upkeep is essential for ensuring optimal performance and longevity of your equipment. Regular maintenance not only enhances efficiency but also prevents potential issues that may arise from neglect.

- Regularly inspect all components for wear and tear.

- Clean the exterior and interior to remove dust and debris.

- Lubricate moving parts according to manufacturer recommendations.

- Check electrical connections for any signs of damage or corrosion.

- Replace worn-out accessories to maintain peak performance.

Implementing these practices will significantly contribute to the reliability and effectiveness of your tool.

Identifying Faulty Components

Recognizing malfunctioning elements within a tool is crucial for effective maintenance and repair. Proper identification not only extends the lifespan of the equipment but also enhances performance. Understanding common issues and their symptoms can help in diagnosing problems swiftly and accurately.

| Component | Common Symptoms | Possible Solutions |

|---|---|---|

| Motor | Overheating, unusual noises | Check for obstructions, replace if damaged |

| Switch | Failure to start, intermittent operation | Inspect connections, replace if necessary |

| Power Cord | Frayed edges, loss of power | Repair or replace the cord |

| Bearings | Excessive vibration, noise | Lubricate or replace bearings |

Where to Find Replacement Parts

Finding components for your tools can be a straightforward process if you know where to look. Several sources can provide you with the necessary elements to keep your equipment functioning optimally.

Authorized Dealers: Start with certified distributors who specialize in these tools. They often carry a wide selection of original components and can offer expert advice.

Online Retailers: Numerous e-commerce platforms list various components. Ensure to verify the seller’s reputation and the authenticity of the items.

Manufacturer’s Website: Check the official site for a dedicated section on replacements. They may offer downloadable catalogs and ordering options.

Local Repair Shops: Skilled technicians can not only assist in identifying the right components but may also have them in stock.

Utilizing these resources can ensure you find the best elements for your machinery, allowing for seamless operation and longevity.

Repairing the Hilti TE 50 AVR

Ensuring optimal performance of your heavy-duty tool is essential for efficient work. When issues arise, timely intervention can prolong its lifespan and enhance functionality. This section will explore effective strategies for troubleshooting and restoring your equipment.

Identifying Issues: Start by assessing the symptoms. Common problems include reduced power, unusual noises, or failure to start. A thorough examination can reveal underlying faults that need addressing.

Necessary Tools: Equip yourself with the right tools for disassembly and inspection. Screwdrivers, wrenches, and a multimeter are essential for diagnosing electrical or mechanical issues.

Disassembly Process: Carefully take apart the device, keeping track of each component. Use a detailed schematic to ensure that you understand the assembly order and part functions.

Replacing Components: If you identify faulty parts, replace them with high-quality alternatives. Ensure compatibility and follow manufacturer recommendations for optimal results.

Reassembly and Testing: Once repairs are complete, reassemble the tool meticulously. Conduct a thorough test to confirm that all functions operate smoothly before returning it to service.

Regular Maintenance: Implementing a routine maintenance schedule will help prevent future issues. Cleaning and lubricating parts can enhance performance and longevity.

Upgrading Your TE 50 AVR

Enhancing the efficiency and functionality of your power tool can significantly improve your productivity on job sites. Upgrading specific components not only boosts performance but also extends the lifespan of the equipment. This section explores various enhancements that can transform your device into a more effective workhorse.

Identifying Key Areas for Improvement

Before initiating upgrades, it’s essential to assess the current condition and capabilities of your tool. Focus on aspects such as vibration control, power delivery, and overall durability. Investing in superior attachments and accessories can lead to smoother operation and greater precision in your tasks.

Recommended Enhancements

Consider replacing worn-out elements with high-quality alternatives designed for increased resilience. Incorporating ergonomic grips can also enhance user comfort, reducing fatigue during prolonged use. Additionally, evaluating and upgrading the motor and impact mechanism can significantly improve drilling and chiseling efficiency, allowing for more robust performance in challenging environments.

Overall, making thoughtful upgrades can transform your power tool, enabling you to tackle a wider range of projects with ease and effectiveness.

Customer Reviews and Feedback

This section highlights the experiences and insights shared by users of a specific tool, emphasizing the importance of customer opinions in shaping product development and reliability. Feedback from users provides valuable perspectives on performance, usability, and overall satisfaction.

Here are some common themes found in user reviews:

- Durability: Many customers praise the robustness and long-lasting nature of the device, noting that it withstands heavy usage.

- Ease of Use: Users often highlight the intuitive design, making it accessible for both professionals and DIY enthusiasts.

- Power: Feedback frequently mentions the impressive power output, allowing for efficient completion of various tasks.

- Support: Customers appreciate the responsive customer service and readily available resources for troubleshooting.

Here are some specific comments from users:

- “This tool has exceeded my expectations in every way. It’s powerful and easy to handle.” – A satisfied customer

- “I appreciate how lightweight it is, making it comfortable to use for extended periods.” – A frequent user

- “The support team was incredibly helpful when I had questions about maintenance.” – A grateful buyer

Overall, user feedback reflects a high level of satisfaction, contributing to a strong reputation in the market. Customer reviews not only help potential buyers make informed decisions but also provide manufacturers with insights for continuous improvement.