Hilti te72 parts diagram

When it comes to heavy-duty equipment, having a clear understanding of the internal configurations can significantly enhance maintenance and repair efforts. Each mechanism consists of various elements that work in unison to ensure optimal performance. Familiarity with these structures can streamline troubleshooting and facilitate efficient replacements.

In this section, we will explore the intricate arrangement of components within a specific model of power tools. By delving into the schematics, users can gain valuable insights into the functionality of each piece, allowing for a more effective approach to upkeep. Mastering this knowledge empowers operators to address issues proactively, reducing downtime and extending the tool’s lifespan.

Moreover, comprehending the assembly can assist in identifying wear and tear or potential failures before they escalate into more significant problems. With a thorough grasp of how parts interact, users can enhance their technical skills and make informed decisions regarding repairs and enhancements. This exploration is not only about knowing the components but also understanding their roles in the overall efficiency of the equipment.

Understanding Hilti TE72 Parts

When working with power tools, a comprehensive grasp of their components is essential for effective maintenance and optimal performance. Familiarity with the various elements that comprise a particular device enables users to troubleshoot issues, replace worn parts, and enhance overall functionality. This section aims to provide insights into the critical components of a specific model, highlighting their roles and significance.

Key Components and Their Functions

- Motor: The heart of the tool, responsible for providing the necessary power for operation.

- Gearbox: Transmits energy from the motor to the working end, affecting torque and speed.

- Handle: Essential for user comfort and control, allowing for ease of use during prolonged tasks.

- Bit Holder: A crucial element that secures various attachments for different applications.

- Trigger: The mechanism that initiates operation, offering control over the tool’s performance.

Maintenance Tips for Longevity

- Regularly inspect components for wear and tear.

- Clean the exterior and interior to prevent dust buildup.

- Lubricate moving parts as recommended to ensure smooth operation.

- Replace damaged or worn elements promptly to maintain efficiency.

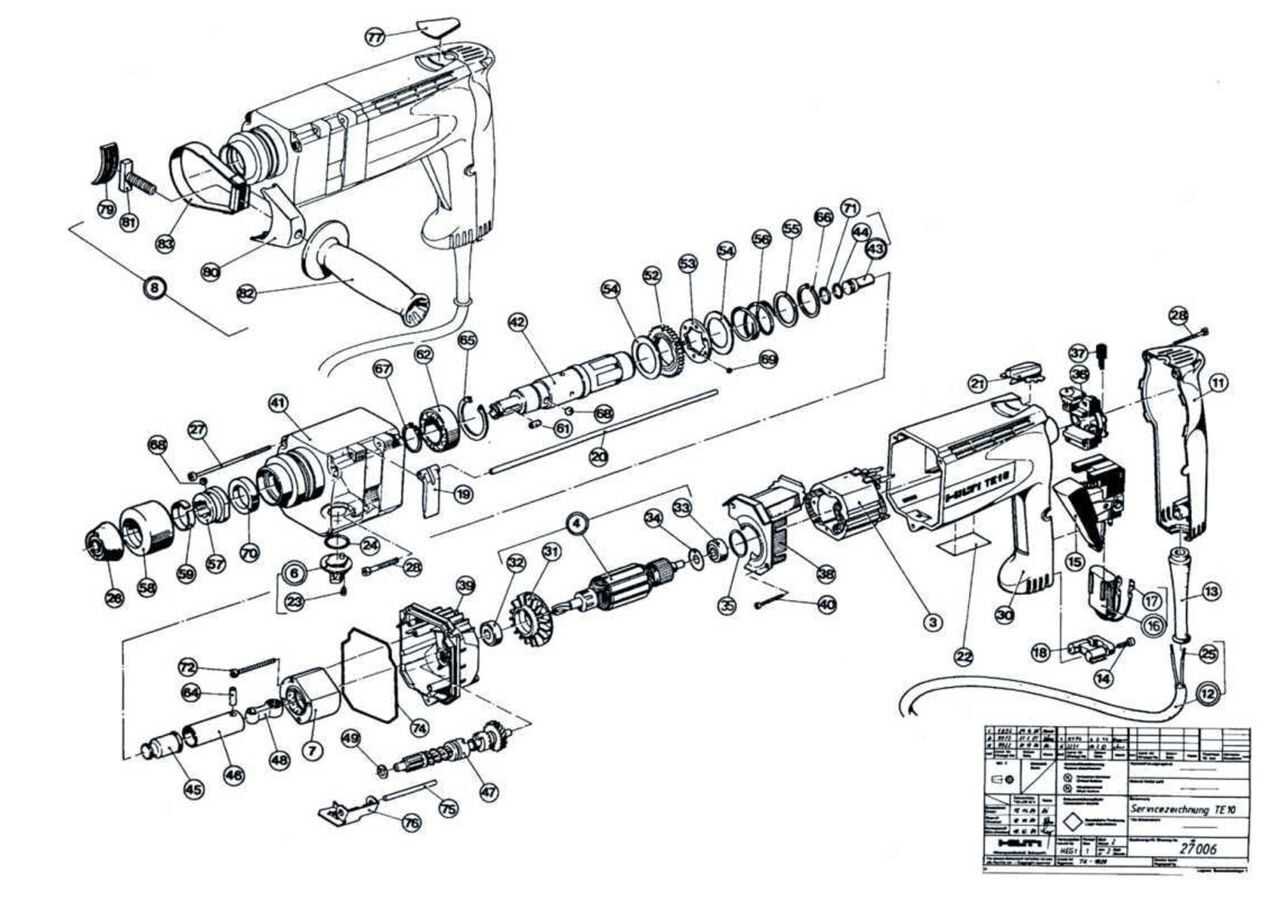

Components of the TE72 Tool

The efficiency of any power tool relies heavily on its individual elements, each designed to perform a specific function. Understanding these components can enhance both the user experience and the longevity of the equipment. In this section, we will explore the key parts that make up this versatile device, highlighting their roles and importance in overall performance.

Motor Assembly: At the heart of the tool lies the motor assembly, which converts electrical energy into mechanical power. This critical component determines the tool’s speed and torque, influencing its effectiveness in various applications.

Gearbox: The gearbox is responsible for transmitting power from the motor to the output shaft. By adjusting the gear ratios, it allows for optimal performance depending on the task, ensuring the right balance between speed and force.

Chisel Holder: This part securely grips the chisel or bit used for demolition or drilling tasks. A reliable chisel holder is essential for maintaining precision and control during operation, reducing the risk of slippage.

Trigger Mechanism: The trigger serves as the user interface, enabling control over the tool’s activation and power output. A well-designed trigger mechanism allows for smooth operation and enhances user comfort.

Vibration Dampening System: To mitigate fatigue during extended use, many tools incorporate a vibration dampening system. This feature minimizes vibrations transmitted to the user’s hands, promoting a more comfortable working experience.

Housing: The outer casing of the tool not only provides structural integrity but also protects internal components from damage. A durable housing is essential for longevity, especially in challenging work environments.

By understanding these essential components, users can better appreciate the engineering that goes into the tool, ultimately leading to improved handling and maintenance practices.

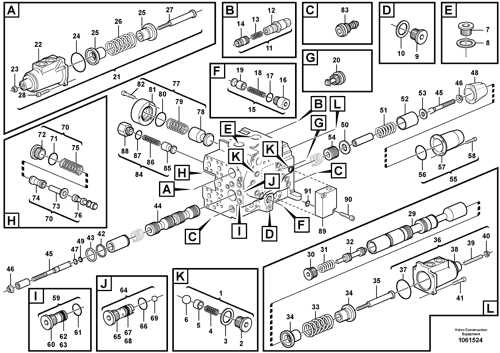

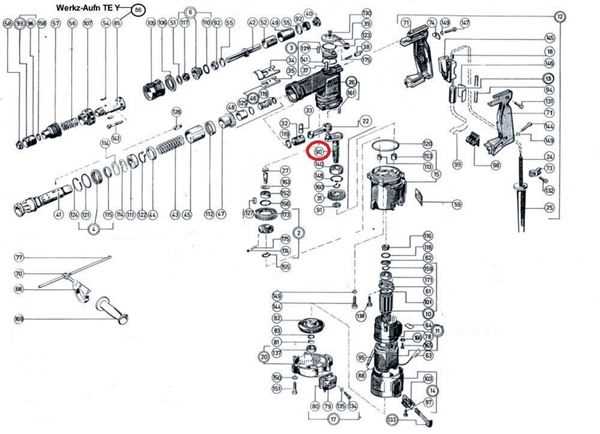

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. This guide provides insights into interpreting the visual layout and symbols that indicate various elements within the system.

To begin, familiarize yourself with the key features of the illustration:

- Legend: Often found at the bottom or side, this section explains symbols used throughout.

- Numbering: Each component typically has a unique identifier that corresponds to a list or inventory.

- Connections: Arrows or lines indicate how parts are linked, showcasing their relationship within the assembly.

By following these steps, you can easily navigate the representation and identify the necessary components for your project.

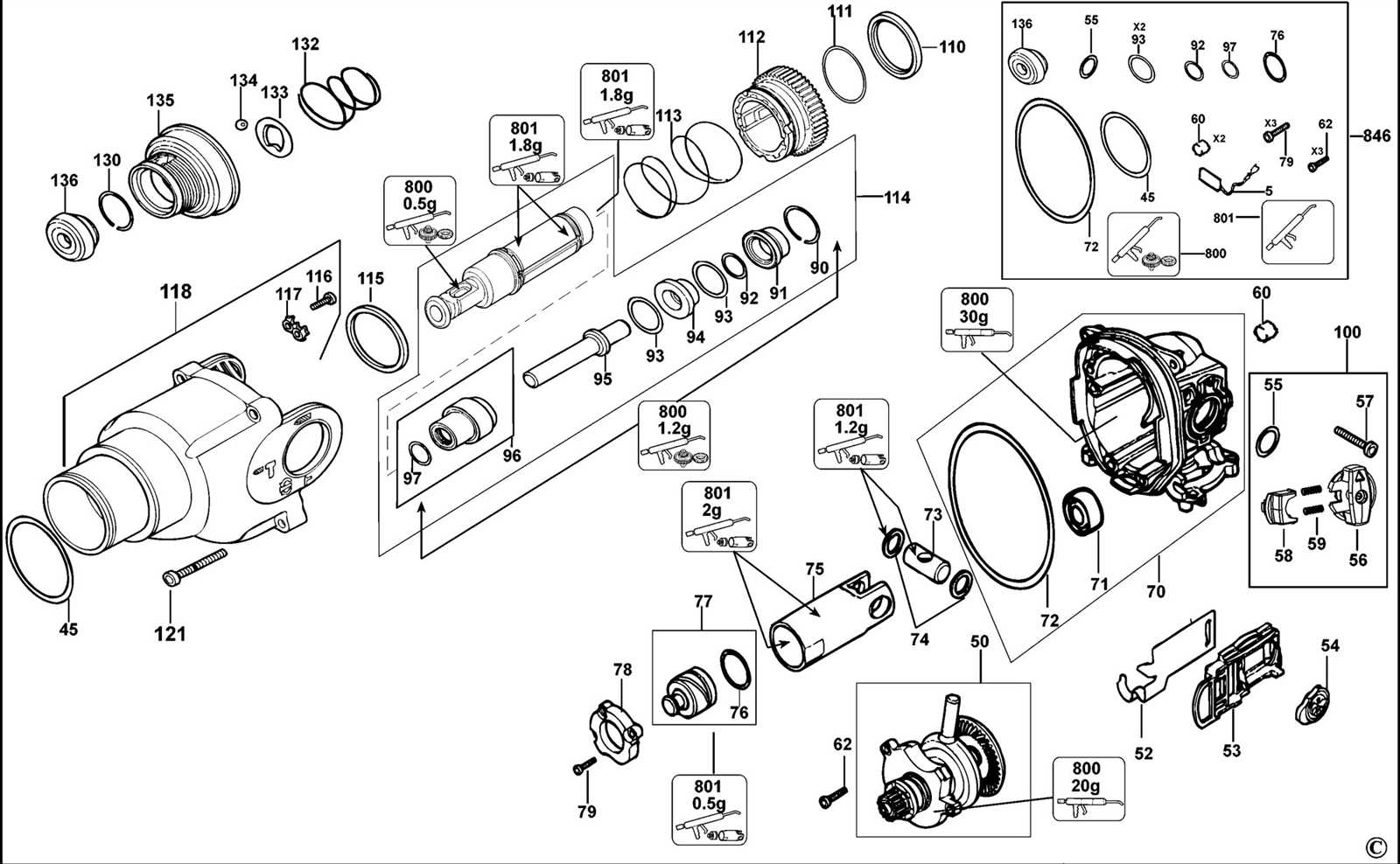

Common TE72 Replacement Parts

In any robust tool, certain components often require substitution due to wear and tear. Understanding which elements are prone to degradation can enhance the longevity and efficiency of your equipment. Below, we explore the essential items typically replaced to maintain optimal performance.

Key Components for Replacement

- Drill Bits

- O-Rings

- Chuck Assemblies

- Brushes

Maintenance Tips

- Regularly inspect components for signs of wear.

- Keep replacement items on hand to minimize downtime.

- Consult your manual for specific replacement intervals.

Maintenance Tips for Hilti TE72

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a structured maintenance routine can prevent breakdowns and enhance efficiency.

- Inspect components regularly for wear and tear.

- Clean the machine after each use to remove debris.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Check electrical connections and replace any damaged wires.

By adhering to these practices, users can significantly reduce downtime and extend the life of their tools.

Identifying Parts by Diagram

Understanding the components of a tool or machine is essential for efficient maintenance and repairs. Visual representations serve as valuable resources, allowing users to quickly locate and identify various elements. This section explores effective methods for recognizing individual parts through illustrative guides.

Benefits of Visual Guides

- Enhances comprehension of complex assemblies.

- Facilitates quicker troubleshooting and repairs.

- Reduces the likelihood of misplacing or damaging components.

- Serves as a reference for reassembly after maintenance.

Steps to Identify Components

- Begin by familiarizing yourself with the overall layout of the tool.

- Refer to the visual guide to locate specific sections of interest.

- Match the identified section with the corresponding labels or numbers.

- Verify the identification by cross-referencing with available specifications.

By following these guidelines, users can ensure efficient management of their equipment, making it easier to maintain functionality and extend the lifespan of the machine.

Where to Buy TE72 Parts

Finding the right components for your equipment can be crucial for maintaining its efficiency and performance. Fortunately, there are several reliable sources where you can acquire the necessary items to keep your tools in top condition. Whether you prefer purchasing online or visiting a local store, options abound to suit your needs.

| Source Type | Description | Advantages |

|---|---|---|

| Online Retailers | Websites that specialize in tool components. | Convenience and often a wide selection. |

| Authorized Dealers | Official distributors with a full range of items. | Genuine quality and expert advice. |

| Local Hardware Stores | Community shops that may stock various components. | Immediate access and support from local staff. |

| Second-Hand Marketplaces | Platforms for buying used items from other users. | Potential for lower prices and rare finds. |

Each option has its benefits, so consider your preferences and requirements when deciding where to purchase. With the right approach, you can easily find what you need to keep your tools operating smoothly.

Tools for TE72 Disassembly

Proper disassembly of power tools requires a specific set of instruments to ensure efficiency and safety. Utilizing the right tools not only facilitates the process but also minimizes the risk of damaging components. Understanding the necessary equipment is crucial for anyone looking to perform maintenance or repairs.

Essential Instruments

When preparing for disassembly, several key instruments are recommended:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing screws of various sizes and types. |

| Hex Key Wrench | Used for loosening hex screws and bolts. |

| Pliers | Assists in gripping and pulling components apart. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Plastic Pry Tools | For gently separating plastic components without damage. |

Safety Gear

In addition to tools, personal protective equipment is vital. Wearing safety glasses, gloves, and appropriate clothing helps prevent injuries during the disassembly process. Ensuring a safe work environment will lead to a more successful and efficient task completion.

Typical TE72 Issues and Solutions

In the realm of construction tools, various challenges can arise during operation, impacting efficiency and performance. Understanding common malfunctions and their corresponding solutions can greatly enhance the user experience and prolong the lifespan of the equipment.

Common Problems

- Insufficient Power: Users may encounter situations where the tool lacks the necessary power to perform tasks effectively.

- Overheating: Extended use may lead to excessive heat buildup, causing the tool to shut down.

- Vibration Issues: Excessive vibrations can indicate a malfunction, affecting precision and comfort.

- Faulty Switch: Problems with the power switch can lead to intermittent operation or complete failure to start.

Recommended Solutions

- Power Supply Check: Ensure that the electrical source is stable and that the power cord is in good condition.

- Cooling Periods: Allow the tool to cool down during prolonged usage to prevent overheating.

- Regular Maintenance: Schedule routine checks to assess and tighten any loose components that may contribute to vibration.

- Switch Replacement: If the power switch fails, consider replacing it with a compatible part to restore functionality.

By addressing these typical concerns, users can optimize their equipment’s performance and ensure reliable operation on the job site.

Upgrading Your Hilti Equipment

Enhancing your tools can significantly improve efficiency and performance on the job site. By investing in modern components and technology, you can ensure your machinery operates at its best, leading to increased productivity and reliability.

| Upgrade Type | Benefits |

|---|---|

| Power Supply | Improved energy efficiency and extended runtime |

| Attachments | Versatility in applications and enhanced functionality |

| Control Systems | Greater precision and user-friendly interfaces |

| Safety Features | Increased protection for operators and compliance with regulations |

Ultimately, focusing on upgrades will help you maintain a competitive edge in your industry and ensure your tools are ready for any challenge.

Benefits of Using Genuine Parts

Opting for authentic components ensures optimal performance and longevity of your equipment. These elements are designed specifically to meet the highest standards, providing reliability and peace of mind.

- Quality Assurance: Genuine components undergo rigorous testing to ensure durability and effectiveness.

- Perfect Fit: Designed to match your equipment precisely, reducing the risk of malfunctions.

- Enhanced Performance: Authentic parts contribute to the overall efficiency and capability of your tools.

- Warranty Protection: Using original elements often maintains the manufacturer’s warranty, safeguarding your investment.

- Safety: Genuine components are built to comply with safety regulations, minimizing risks during operation.