Understanding Hitachi Miter Saw Parts Diagram for Efficient Repairs

When it comes to mastering power tools, having a clear understanding of their internal structures is essential for both efficiency and safety. This knowledge enables users to perform maintenance, troubleshoot issues, and optimize their usage effectively. A visual representation can greatly assist in grasping the arrangement and function of each component.

In this section, we will explore the intricacies of a popular cutting instrument, highlighting the various elements that comprise its design. By familiarizing yourself with these components, you can enhance your skills and ensure your equipment operates at peak performance.

Whether you are a seasoned professional or an enthusiastic hobbyist, knowing the layout of your tool can make all the difference. Each segment plays a vital role, and understanding their interrelations can lead to more informed decisions during both usage and repair processes.

Understanding Hitachi Miter Saws

This section aims to provide insight into the intricacies of a particular type of cutting tool designed for precision and versatility. These machines are essential for various woodworking projects, enabling users to create accurate angles and cuts with ease. Mastery of their components and functions can significantly enhance the overall efficiency of tasks, whether in a professional setting or a home workshop.

Key Features

- Precision Angle Adjustments

- Powerful Motor Performance

- Durable Construction Materials

- User-Friendly Controls

Common Applications

- Framing and Trim Work

- Furniture Construction

- Crown Molding Installation

- Cabinetry Projects

Understanding the various aspects of this tool not only aids in selecting the right model but also ensures safe and effective operation. With the right knowledge, users can achieve remarkable results in their woodworking endeavors.

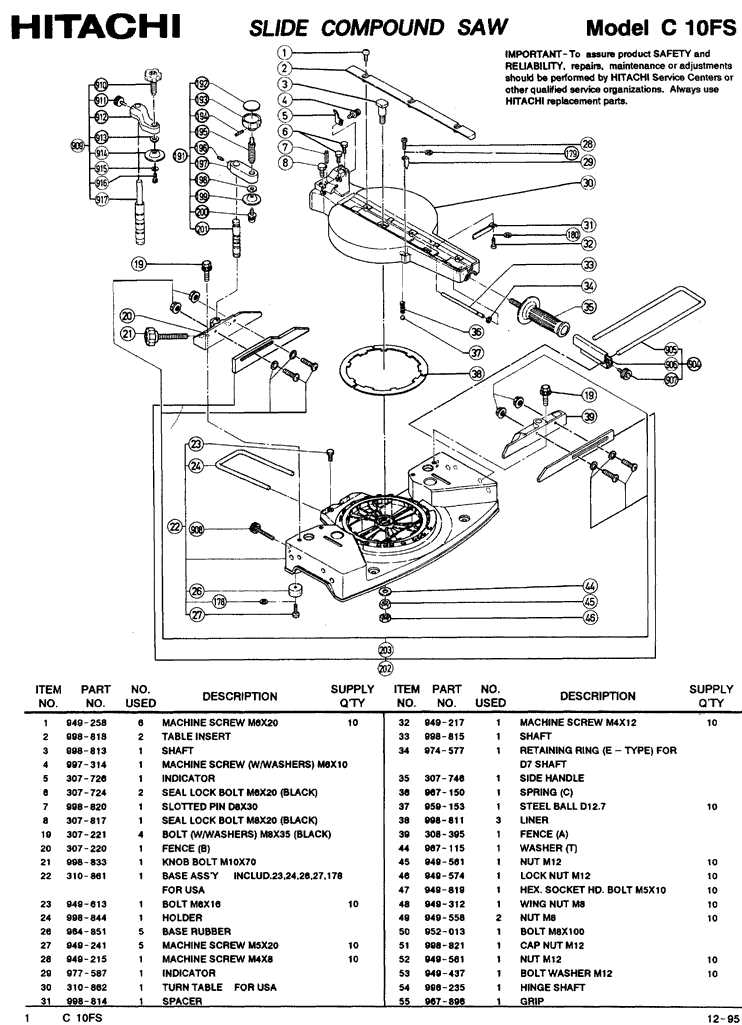

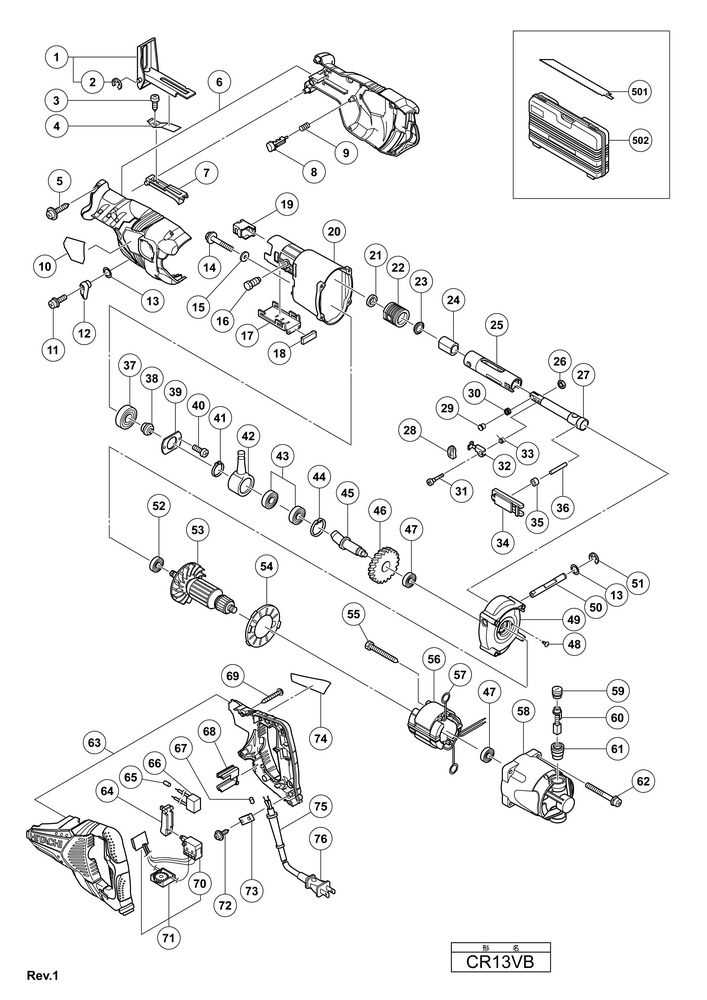

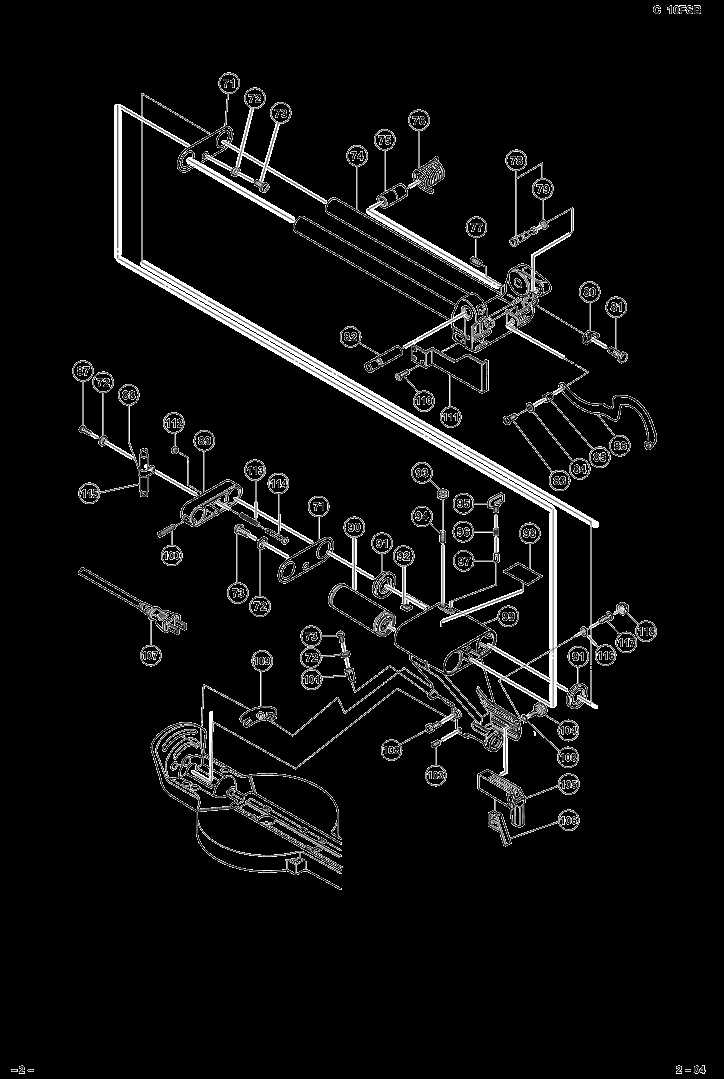

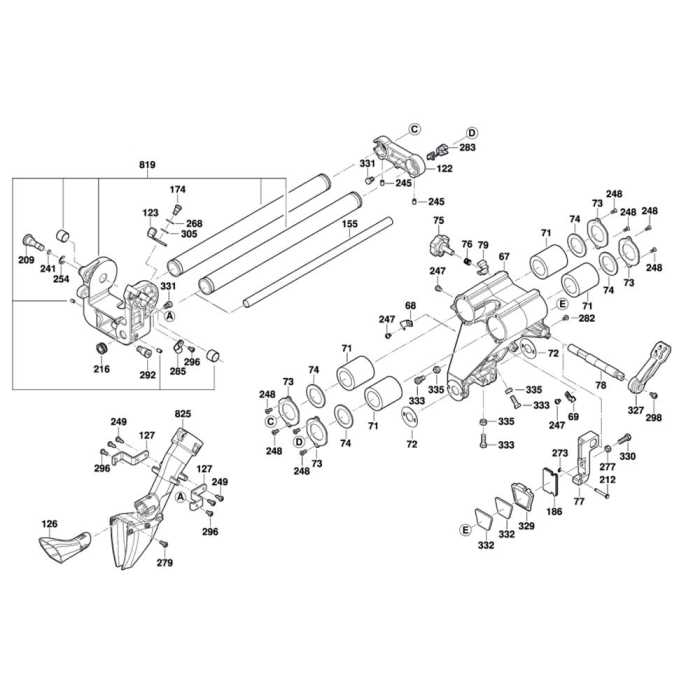

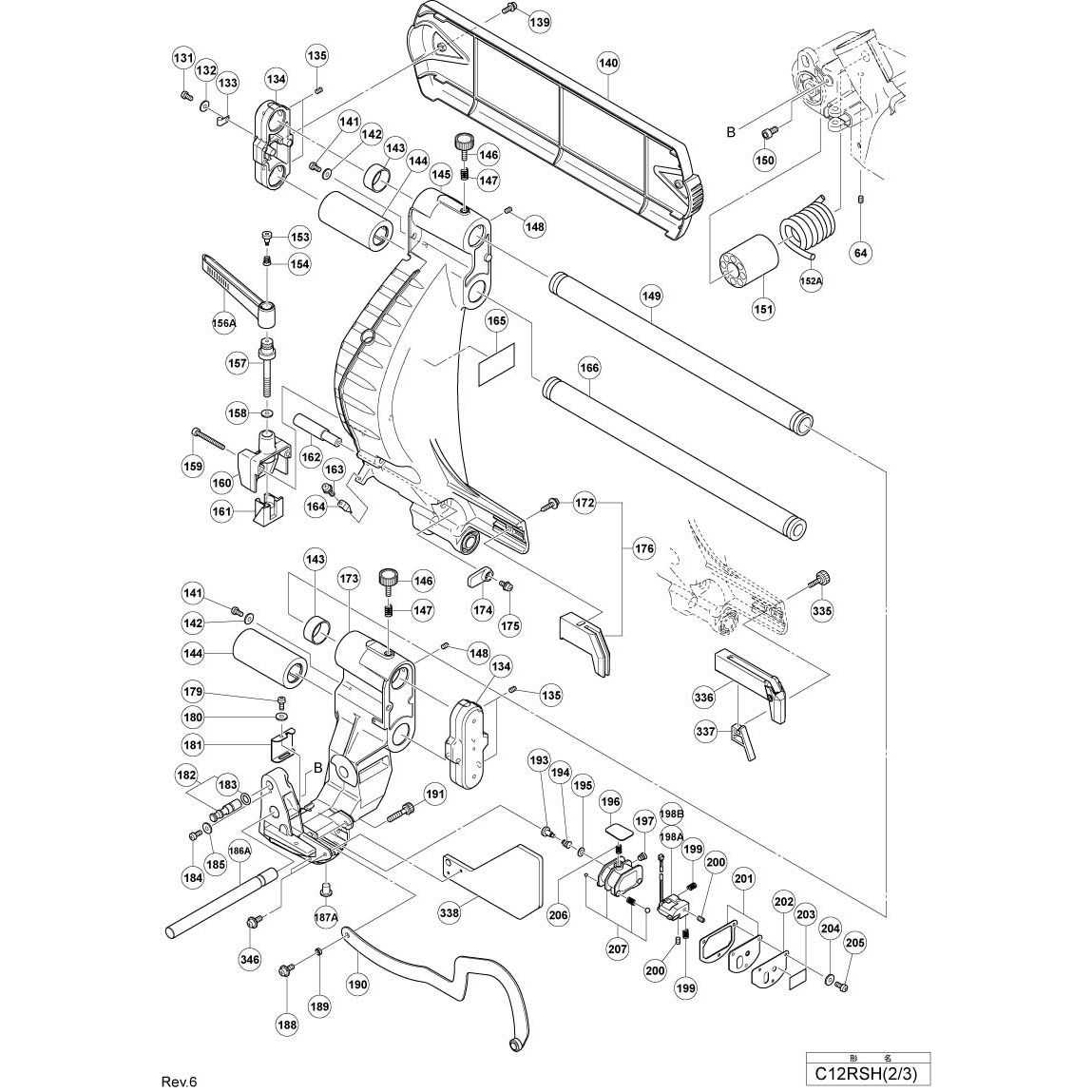

Essential Components of Miter Saws

A precise cutting tool is essential for achieving clean and accurate angles in woodworking projects. Understanding the fundamental elements of this equipment can significantly enhance its usability and performance.

- Base Plate: The stable foundation that supports the entire mechanism and provides a surface for secure placement.

- Table: The flat area where the material is positioned, often adjustable to accommodate various sizes and angles.

- Arm: The pivotal structure that holds the cutting mechanism and allows for angled movements.

- Blade: The cutting edge that determines the tool’s effectiveness, available in different sizes and tooth configurations.

- Fence: The guide that ensures precise alignment of the material, crucial for consistent cuts.

- Motor: The powerhouse that drives the blade, varying in power depending on the tool’s intended use.

- Bevel Adjustment: A mechanism that allows for tilting the blade, enabling compound cuts for more complex angles.

- Dust Collection System: An essential feature for maintaining a clean workspace, minimizing debris during operation.

Familiarity with these components not only aids in maintenance but also improves safety and effectiveness in various cutting tasks.

Importance of Parts Diagrams

Understanding the components of any mechanical device is crucial for effective maintenance and repair. Visual representations of these elements not only aid in identifying specific features but also facilitate a deeper comprehension of how they interact within the overall system. This knowledge is essential for both professionals and enthusiasts alike, ensuring that any tasks undertaken are executed efficiently and accurately.

Enhanced Troubleshooting

One of the primary benefits of having a visual reference is the ability to diagnose issues quickly. When an individual can pinpoint a malfunctioning component, it streamlines the troubleshooting process. Instead of guessing which part might be causing the problem, a clear visual guide allows for immediate identification and resolution, minimizing downtime and frustration.

Streamlined Repairs and Replacements

Another significant advantage is the ease with which repairs and replacements can be carried out. A visual aid provides a roadmap for disassembly and reassembly, ensuring that all necessary components are accounted for. This level of organization not only simplifies the repair process but also reduces the risk of errors, ultimately prolonging the lifespan of the equipment.

Common Hitachi Miter Saw Models

Various models from a renowned brand in the woodworking industry cater to different user needs. These tools are designed for precision and efficiency, making them suitable for both professionals and DIY enthusiasts.

- Model C10FCE2

This unit is known for its lightweight design and powerful motor, ideal for quick cuts and portability.

- Model C12RSH2

Featuring a sliding mechanism, this variant allows for wider crosscuts while maintaining accuracy.

- Model C10FCG

This model combines a compact design with a robust build, making it perfect for tight spaces and demanding tasks.

- Model C12LSH

A reliable option for larger projects, this unit offers enhanced cutting capabilities and user-friendly features.

Choosing the right model depends on the specific requirements of each project, ensuring optimal performance and results.

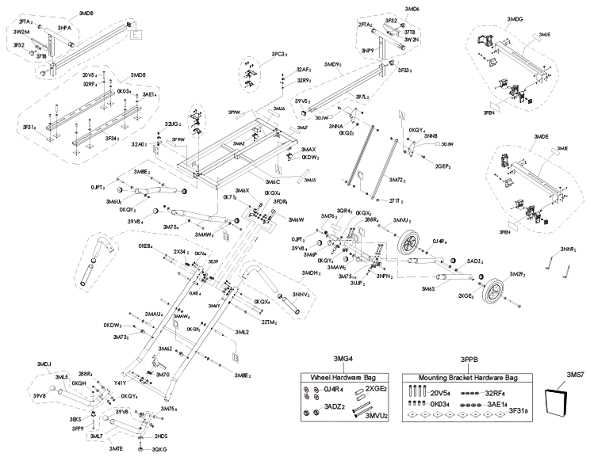

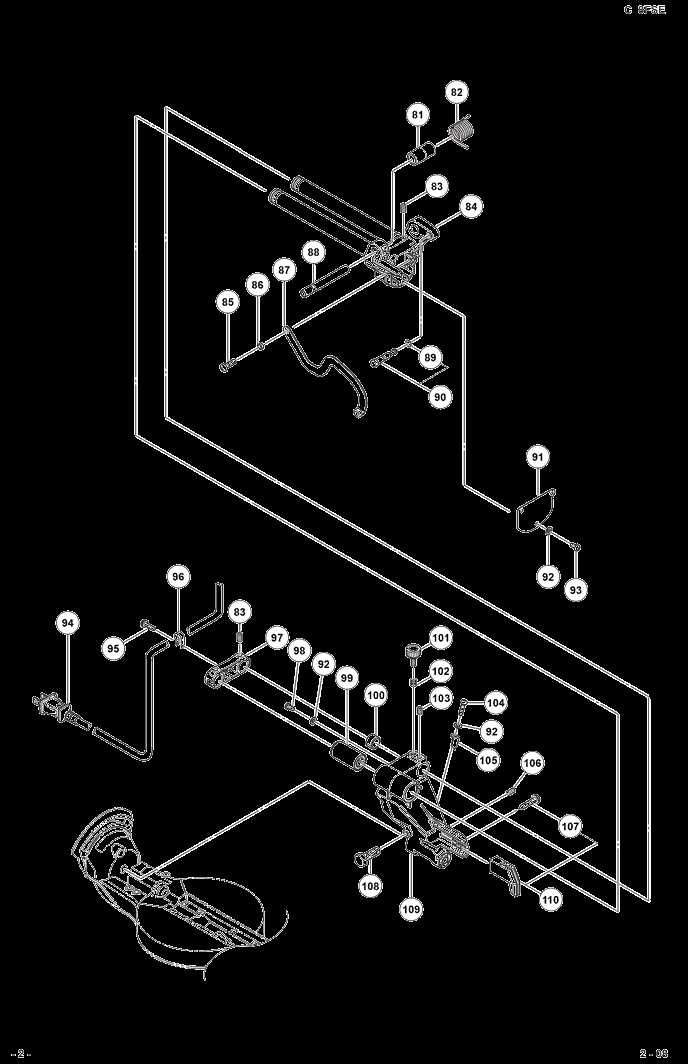

Identifying Parts in Diagrams

Understanding the components illustrated in technical schematics is crucial for effective maintenance and repairs. These visual representations provide a roadmap to the inner workings of machinery, allowing users to pinpoint specific elements with ease. Familiarity with the layout enhances one’s ability to troubleshoot issues efficiently and ensures accurate reassembly after any disassembly.

Familiarization with common symbols and terminologies is the first step towards mastering these visuals. Each component is often represented by a unique shape or label, which can indicate its function or location within the overall structure. Recognizing these features will aid in understanding how parts interact and contribute to the machine’s performance.

Furthermore, diagrams may include numerical references or color coding to distinguish between various elements, making identification even more straightforward. Paying attention to these details can significantly reduce confusion during repair tasks and enhance the overall user experience.

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. A well-structured illustration provides insights into the assembly and functionality of various elements within a machine. Here’s how to navigate such visual aids with ease.

Start by familiarizing yourself with the layout:

- Orientation: Identify the orientation of the drawing. Ensure you are viewing it from the correct angle to accurately interpret the relationships between parts.

- Labels: Look for labels accompanying each component. These annotations typically include part numbers and descriptions, helping to clarify their function.

- Legend: Check for a legend or key that explains symbols or colors used in the illustration. This can provide additional context for the components depicted.

Next, analyze the relationships:

- Connections: Observe how parts connect to one another. Pay attention to lines or arrows indicating movement or attachment points.

- Grouping: Note any grouped components that may function together, as understanding these relationships can simplify troubleshooting.

- Sequential Order: Follow the logical sequence of assembly. This will aid in both understanding the operation and in any repair tasks.

Finally, cross-reference with documentation:

- Manuals: Utilize user manuals or service guides that may accompany the illustration for additional details on each component.

- Online Resources: Search for online resources or forums where others discuss similar diagrams for insights and tips.

By mastering these techniques, you can effectively interpret a visual representation of components, leading to more efficient maintenance and a deeper understanding of your equipment.

Replacement Parts for Hitachi Saws

Maintaining tools in peak condition is essential for optimal performance. When components wear out or become damaged, timely replacement is crucial to ensure continued reliability and efficiency. This section focuses on the various options available for restoring functionality to these essential devices.

Common Components for Replacement

Here are some frequently needed components that may require substitution over time:

- Blades

- Motor brushes

- Drive belts

- Switch assemblies

- Base plates

Where to Find Quality Replacements

Finding reliable components is vital for maintaining tool performance. Consider these sources:

- Authorized retailers

- Online marketplaces

- Specialty tool shops

- Manufacturer’s website

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your cutting tool requires regular upkeep and attention. By implementing simple maintenance practices, you can extend its lifespan and maintain optimal functionality. This section outlines essential tips that will help you preserve the integrity of your equipment over time.

Regular Cleaning

Keep your tool free from debris and dust accumulation. After each use, wipe down the surfaces with a soft cloth and ensure that any particles are removed from moving parts. For deeper cleaning, periodically disassemble accessible components and use compressed air to clear out fine dust that may hinder performance.

Lubrication and Inspection

Proper lubrication is crucial for smooth operation. Apply appropriate lubricants to moving parts as specified in the user manual. Additionally, conduct regular inspections for wear and tear, checking for any signs of damage or misalignment. Addressing minor issues early can prevent more significant problems in the future.

Tools Needed for Repair

When it comes to servicing your equipment, having the right tools is essential for ensuring a smooth and efficient process. This section will outline the necessary instruments and materials to help you tackle repairs effectively, minimizing downtime and maximizing performance.

Essential Instruments

Start with a reliable set of screwdrivers, as various fasteners will need to be removed. Both flathead and Phillips types are crucial for accessing internal components. Additionally, a quality wrench set will help you tighten or loosen bolts securely. Don’t forget a pair of pliers for gripping and twisting when needed, as well as a measuring tape for precise measurements during assembly.

Safety Equipment

Safety should always be a priority. Equip yourself with protective eyewear to shield your eyes from debris and dust. A pair of durable gloves will protect your hands while working with sharp or rough components. Lastly, having a first-aid kit on hand is wise, ensuring you’re prepared for any minor accidents that may occur during repairs.

Where to Find Replacement Parts

Finding suitable components for your tools can be a straightforward process if you know where to look. Various resources are available to help you source the necessary items, whether for routine maintenance or repair. Here are some reliable options to consider when searching for these essential elements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides detailed listings of available components, along with diagrams to assist in identification. |

| Authorized Dealers | Local retailers that specialize in tool sales usually carry a selection of components or can order them for you. |

| Online Marketplaces | Websites like eBay or Amazon feature various sellers offering a wide range of components, often at competitive prices. |

| Specialty Repair Shops | These shops not only provide repair services but often stock or can obtain hard-to-find components. |

| Community Forums | Online forums dedicated to tool enthusiasts can be a great resource for advice on where to find specific items. |

By exploring these avenues, you can enhance the longevity and performance of your equipment, ensuring it remains in optimal condition for all your projects.

FAQs About Hitachi Miter Saws

This section addresses common inquiries regarding a popular type of cutting tool used in woodworking and construction. Understanding the intricacies of these tools can enhance your experience and ensure safe and efficient operation.

What are the key features to consider when choosing a cutting tool?

When selecting a cutting instrument, it’s essential to evaluate several features such as blade size, motor power, and the tool’s weight. Additionally, consider the presence of a laser guide for precision cuts and adjustable bevel settings for versatile angles. These elements significantly influence performance and usability.

How can I maintain my cutting instrument for optimal performance?

Regular maintenance is crucial for longevity and efficiency. Ensure the blade is sharp and clean, as a dull blade can lead to poor cuts and increased strain on the motor. Lubricate moving parts as needed and regularly check for any loose screws or components. Always refer to the user manual for specific maintenance guidelines.

Common Issues and Solutions

When working with precision cutting tools, users often encounter various challenges that can impact performance and accuracy. Understanding these common problems and their respective solutions can greatly enhance efficiency and extend the lifespan of the equipment.

| Issue | Description | Solution |

|---|---|---|

| Blade Dullness | A dull blade can lead to rough cuts and increased strain on the motor. | Regularly sharpen or replace the blade to ensure clean and efficient cuts. |

| Misalignment | Improper alignment can result in inaccurate cuts. | Check and adjust the alignment according to the manufacturer’s specifications. |

| Excessive Vibration | Excessive movement during operation can affect precision. | Ensure all components are securely tightened and inspect for any wear or damage. |

| Motor Overheating | Overheating can occur due to prolonged use or blockage. | Allow the tool to cool down periodically and ensure ventilation is not obstructed. |

| Dust Buildup | Accumulated dust can impede performance and visibility. | Regularly clean the tool and surrounding area to maintain optimal working conditions. |

Upgrading Your Miter Saw Components

Enhancing the functionality of your cutting tool can significantly improve your woodworking experience. By replacing or upgrading specific elements, you can achieve greater precision, efficiency, and durability in your projects. This section will explore various components you might consider enhancing to maximize performance.

- Blades: Investing in high-quality blades can greatly influence the quality of cuts. Consider options like carbide-tipped or specialty blades for different materials.

- Laser Guides: Adding a laser guide can improve accuracy by providing a clear cutting line, making it easier to align your workpiece.

- Fences: Upgrading to a more robust and adjustable fence can enhance stability and precision, allowing for more accurate cuts.

- Dust Collection: Improving the dust collection system will keep your workspace clean and enhance visibility while cutting.

- Motor Upgrade: If you require more power, consider upgrading the motor for improved performance during heavy-duty tasks.

Each of these enhancements can contribute to a more effective and enjoyable woodworking experience. Carefully assess your needs and the specific improvements that would benefit your workflow the most.