Understanding the Holley 4150 Parts Diagram for Optimal Performance

In the realm of automotive performance, the intricate assembly of fuel delivery systems plays a crucial role in optimizing engine efficiency and power output. An in-depth exploration of these assemblies reveals the importance of each individual element, contributing to the overall functionality of the unit. Recognizing how these components interact is essential for both enthusiasts and professionals seeking to enhance their vehicles.

Within these systems, the organization and specification of each piece serve as a foundation for successful tuning and maintenance. Knowledge of the various elements not only aids in identifying potential issues but also empowers users to make informed decisions during upgrades or repairs. A comprehensive understanding of the layout and function of these components ensures that every aspect of performance is maximized.

As we delve into the specifics, it becomes clear that a well-structured visual representation can significantly simplify the process of understanding these assemblies. Such illustrations provide clarity, making it easier to navigate the complexity of the system while fostering a deeper appreciation for the engineering behind high-performance applications.

Understanding the Holley 4150 Carburetor

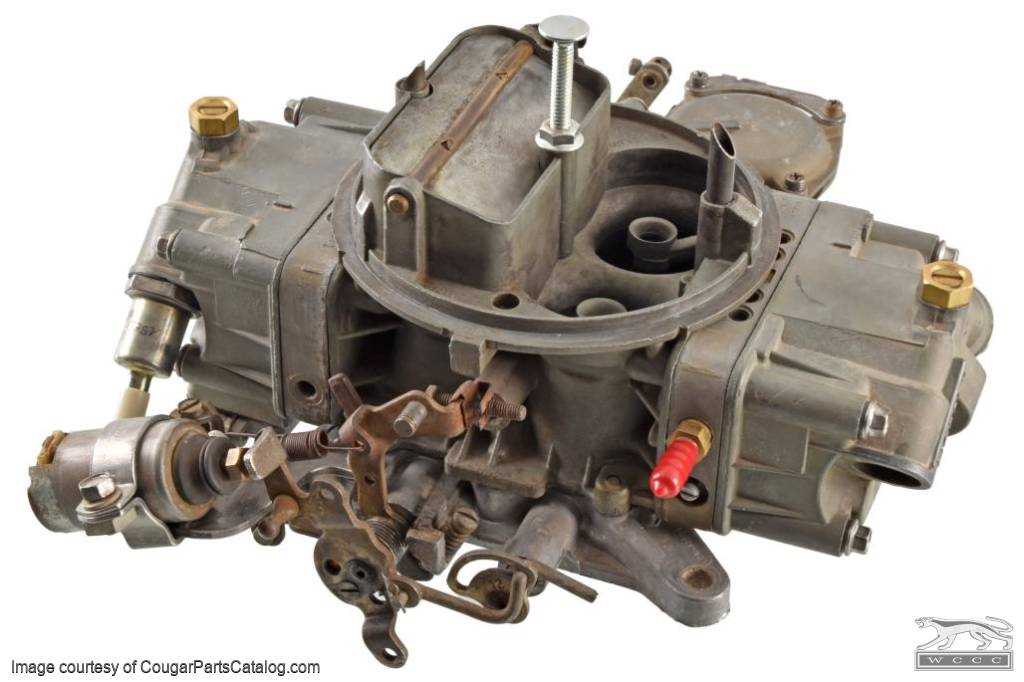

This section delves into the intricacies of a specific type of fuel delivery system that has gained popularity among automotive enthusiasts and professionals alike. With its intricate design and performance capabilities, this component plays a crucial role in optimizing engine function and efficiency.

At its core, this fuel mixture device is engineered to precisely blend air and fuel before delivering it to the combustion chamber. This process is vital for achieving optimal performance, as the right mixture ensures smooth operation and enhanced power output. Understanding the various elements that make up this system is essential for anyone looking to maintain or modify their engine.

The construction of this mechanism includes several key components, such as the throttle body, fuel metering sections, and various adjustments that allow for fine-tuning of performance. Each part works in harmony to ensure that the engine receives the appropriate amount of fuel and air, tailored to specific driving conditions and demands.

Moreover, enthusiasts often appreciate the versatility offered by this design, which allows for customization to suit individual preferences and performance goals. Knowledge of how each component interacts within the system can significantly enhance one’s ability to diagnose issues and make informed modifications.

In conclusion, grasping the fundamentals of this fuel delivery apparatus is essential for both novice and experienced users. It not only aids in maintaining optimal engine performance but also empowers individuals to explore enhancements that can elevate their driving experience.

Key Components of Holley 4150

The functionality of a carburetor relies on several critical elements that work in harmony to optimize engine performance. Understanding these essential components provides insight into how fuel delivery systems operate effectively within internal combustion engines.

Throttle Body: This component is pivotal in regulating airflow into the engine. It features butterflies that open and close based on the driver’s input, allowing for precise control of air intake.

Float Chamber: This part maintains a consistent fuel level, ensuring that the engine receives a steady supply of fuel. It operates through a float mechanism that adjusts the inlet valve as fuel levels change.

Jets: These are small openings that meter the amount of fuel delivered to the engine. The size and design of the jets influence the air-fuel mixture, which is crucial for achieving optimal combustion.

Venturi: This tapered section creates a difference in pressure that draws fuel into the airstream. The design of the venturi is critical for achieving the correct mixture of air and fuel at various engine speeds.

Accelerator Pump: This component provides a surge of fuel during rapid throttle openings, preventing hesitation and ensuring smooth acceleration. It is vital for enhancing the responsiveness of the engine.

Understanding these fundamental elements helps in recognizing the intricacies involved in tuning and maintaining a carburetor for peak performance, enabling enthusiasts to maximize their engine’s potential.

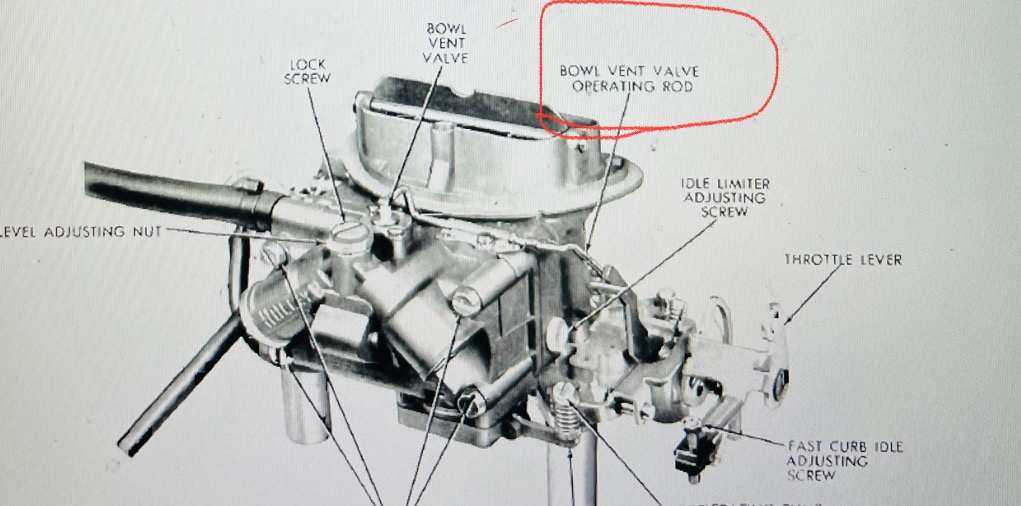

How to Read the Parts Diagram

Understanding the layout of a mechanical assembly is essential for effective maintenance and troubleshooting. A visual representation can help you identify components, their relationships, and how they interact within the overall system. Familiarizing yourself with these illustrations can significantly enhance your ability to work efficiently with the machinery.

Start by familiarizing yourself with the key features of the illustration. Typically, each part is labeled with a unique identifier or number, which corresponds to a list or legend providing detailed descriptions. This connection between the visual and textual information is crucial for accurate interpretation.

Next, pay attention to the arrangement of the elements. Often, the layout will be organized in a logical manner, grouping related components together. This can help you understand how different sections interact with one another, making it easier to locate specific items or troubleshoot issues.

Finally, take note of any symbols or color codes used within the illustration. These can indicate various attributes, such as material types, assembly instructions, or even specific operational functions. Recognizing these cues will aid in a more comprehensive understanding of the assembly.

Common Issues with Holley 4150 Parts

When working with performance carburetors, several frequent challenges can arise that affect their functionality and efficiency. Understanding these issues is essential for maintaining optimal engine performance and longevity. By identifying common problems, enthusiasts can implement effective solutions and ensure a smooth operation.

Fuel Delivery Problems

Inconsistent fuel delivery is a prevalent issue, often leading to poor acceleration and engine stalling. This can result from clogged jets, a malfunctioning fuel pump, or improper tuning. Regular maintenance, including cleaning and inspecting components, can help prevent these complications.

Air-Fuel Mixture Imbalance

An incorrect air-fuel mixture can lead to various performance issues, such as rough idling or excessive fuel consumption. This imbalance might stem from worn gaskets, damaged diaphragms, or incorrect adjustments. Ensuring proper calibration and regular checks can alleviate these problems and enhance overall performance.

Maintenance Tips for Holley 4150

Regular upkeep is essential for ensuring optimal performance and longevity of your fuel delivery system. Proper maintenance not only enhances efficiency but also prevents potential issues that could arise from neglect. Following a few straightforward guidelines can help keep your system in top condition.

1. Regular Cleaning: It’s crucial to keep the components clean. Periodically remove dirt and debris, as they can affect performance. Use a suitable cleaner and soft brush to gently scrub the surfaces, ensuring no residue remains.

2. Check Seals and Gaskets: Inspect all seals and gaskets for wear or damage. Replacing these components promptly can prevent leaks and maintain the integrity of the system.

3. Monitor Fuel Quality: Using high-quality fuel is vital. Contaminated or low-grade fuel can lead to clogs and inefficiencies. Regularly check for any signs of fuel deterioration.

4. Adjust Settings: Ensure that the adjustment settings are calibrated according to the manufacturer’s recommendations. This can significantly impact performance and fuel efficiency.

5. Inspect for Leaks: Regularly examine the entire assembly for any signs of leakage. Addressing leaks immediately can save on repairs and ensure safety during operation.

6. Consult the Manual: Always refer to the manufacturer’s manual for specific maintenance guidelines tailored to your system. Following these recommendations can provide additional insights into proper care.

By adhering to these maintenance tips, you can enhance the reliability and efficiency of your fuel delivery setup, ensuring smooth operation for years to come.

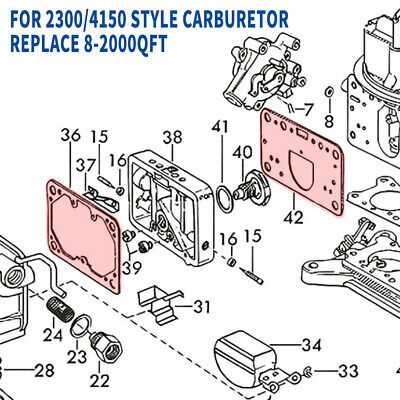

Choosing Replacement Parts Effectively

When it comes to maintaining or upgrading your vehicle’s performance, selecting the right components is crucial. The right choices not only enhance efficiency but also ensure longevity and reliability. Understanding the nuances of each element can significantly impact overall functionality.

Assessing Compatibility

Before making any replacements, it’s essential to evaluate the compatibility of the components with your specific system. Researching specifications and understanding the requirements of your engine will help in making informed decisions. Always cross-reference manufacturer recommendations to avoid any discrepancies.

Quality Over Cost

While it may be tempting to opt for cheaper alternatives, prioritizing quality can save time and resources in the long run. Investing in high-grade materials often results in better performance and fewer issues. Consider well-reviewed brands and consult forums or expert opinions for insights into durability and effectiveness.

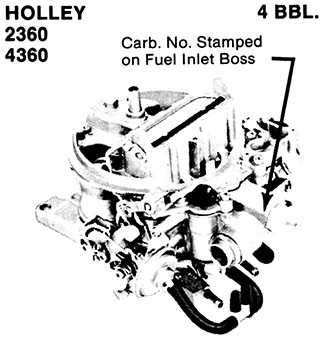

Differences Between Holley 4150 Models

Understanding the variations among different carburetor designs is crucial for enthusiasts seeking optimal performance. Each model brings its own unique features and specifications, catering to diverse engine setups and driving styles. This section delves into the distinguishing characteristics that set each variant apart.

Key Variations

- Cfm Ratings: Different models offer varying cubic feet per minute (cfm) ratings, affecting airflow and engine responsiveness.

- Venturi Sizes: The size of the venturis can influence fuel mixture and throttle response, with larger sizes typically providing higher power output.

- Accelerator Pump Configurations: Some designs feature distinct accelerator pump setups, enhancing fuel delivery during rapid throttle movements.

- Adjustment Options: Certain variants come equipped with more advanced tuning capabilities, allowing for fine-tuning of air-fuel mixtures.

Material Differences

- Body Construction: Models may differ in material, such as aluminum versus zinc, impacting durability and weight.

- Finish Types: Some carburetors are coated with special finishes for added protection against corrosion, affecting longevity.

- Gasket Materials: Variations in gaskets can influence sealing capabilities and overall performance reliability.

In summary, understanding these differences is essential for selecting the right carburetor for specific applications, ensuring optimal performance and efficiency in various automotive setups.

Upgrading Your Holley 4150 System

Enhancing your carburetor system can significantly improve performance and efficiency. By carefully selecting and installing upgraded components, you can achieve better throttle response, fuel delivery, and overall engine dynamics. This guide will provide insights into key areas for improvement and potential modifications to consider.

One of the primary upgrades involves optimizing the air-fuel mixture through advanced jets and metering blocks. These components are crucial for achieving the right balance, especially in high-performance applications. Additionally, enhancing the fuel system can lead to more reliable operation and increased horsepower.

| Component | Upgrade Option | Benefits |

|---|---|---|

| Jets | Adjustable Jets | Fine-tune air-fuel ratio for specific conditions |

| Metering Blocks | High-Performance Blocks | Improved fuel flow and consistency |

| Throttle Linkage | Aftermarket Linkage Kits | Better response and control |

| Fuel Pump | High-Volume Pump | Ensures adequate fuel supply for high-demand scenarios |

Incorporating these upgrades can transform your system, providing enhanced performance and responsiveness. Each modification plays a vital role in the overall efficiency and power output of your engine, making it essential to consider each element carefully.

Compatibility with Other Carburetors

When considering performance enhancements for your engine, understanding the interchangeability of different fuel delivery systems is crucial. Many enthusiasts seek to combine or replace components to optimize efficiency and power output. This section will explore how various models align with each other, providing insights for potential upgrades or modifications.

Several factors influence compatibility, including design features, dimensions, and mounting configurations. Here are key points to consider:

- Flange Style: Different carburetors may have unique flange designs that affect fitment on intake manifolds.

- Throttle Linkage: Ensure that the linkage system aligns correctly for smooth operation and proper throttle response.

- Jetting Options: Similarities in jetting can facilitate tuning between models, allowing for easier adjustments.

- Fuel Inlet Position: The location of fuel inlets can vary, impacting the installation process and fuel line routing.

Many enthusiasts have successfully integrated parts from alternative systems, benefiting from performance gains. Consider the following compatibility tips:

- Research models that share similar specifications and configurations.

- Consult community forums and expert opinions for successful combinations.

- Test fit components before final installation to ensure compatibility.

- Be aware of tuning requirements post-installation to achieve optimal performance.

By thoroughly understanding the nuances of various fuel delivery systems, you can make informed decisions that enhance your vehicle’s performance while maintaining reliability.

Tools Needed for Holley 4150 Repairs

When it comes to maintaining and repairing performance fuel delivery systems, having the right tools is essential. The following list outlines the necessary equipment that will help ensure efficient and effective repairs, allowing you to get your engine running optimally.

Essential Hand Tools

- Socket Set: A comprehensive set will cover various sizes for different fasteners.

- Wrenches: Both open-end and box-end wrenches are crucial for tight spaces.

- Screwdrivers: A selection of flathead and Phillips screwdrivers is necessary for various screws.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small components.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to manufacturer specifications.

- Fuel Pressure Gauge: Helps diagnose fuel delivery issues by measuring system pressure.

- Cleaning Kit: A set specifically designed for intricate components will keep parts in optimal condition.

- Vacuum Gauge: Useful for diagnosing issues related to air and fuel mixtures.

Equipping yourself with these tools will facilitate a smoother repair process, enabling you to tackle common issues with confidence and precision.

Online Resources for Parts and Diagrams

In today’s digital age, accessing information about automotive components has become more straightforward than ever. Enthusiasts and professionals alike can find a wealth of resources online, making it easier to obtain detailed visuals and specifications for various systems. Whether you’re looking for specific components or general overviews, numerous platforms cater to these needs.

Here are some valuable online sources to consider:

- Manufacturer Websites: Many manufacturers provide extensive catalogs and technical documentation on their official sites. This is often the most reliable source for accurate and up-to-date information.

- Online Retailers: E-commerce platforms often feature detailed listings that include images and descriptions of individual components. They may also provide user reviews that can offer insight into quality and compatibility.

- Forums and Community Sites: Enthusiast forums are treasure troves of shared knowledge. Users frequently post images, guides, and personal experiences that can help you understand the intricacies of various systems.

- Social Media Groups: Platforms like Facebook and Reddit host groups dedicated to automotive topics. These communities can be a great place to ask for recommendations or find links to useful resources.

- Video Tutorials: Websites such as YouTube offer a vast array of tutorial videos, where experts break down systems and components, often providing visual references that can enhance understanding.

lessCopy code

Utilizing these resources will empower you to make informed decisions and locate the precise information you need for your automotive projects.