Comprehensive Guide to Hs81t Parts Diagram

In the realm of machinery and equipment, a comprehensive comprehension of the individual elements is crucial for optimal performance. Each component plays a significant role, contributing to the overall functionality and efficiency of the system. By breaking down these elements, users can gain insights into how everything fits together, ensuring seamless operation.

Exploring these integral pieces allows for enhanced maintenance and troubleshooting. Identifying each section’s purpose aids in addressing potential issues before they escalate, ultimately prolonging the lifespan of the machinery. As enthusiasts and professionals alike seek to deepen their knowledge, a detailed look into the structure becomes invaluable.

With an emphasis on clarity, visual representations serve as powerful tools for understanding. By delving into the intricacies of each segment, one can appreciate the design and engineering that uphold functionality. This journey into the assembly not only enriches expertise but also fosters a sense of confidence in handling machinery.

Understanding the Hs81t Parts Diagram

Comprehending the layout of components in a complex assembly is crucial for effective maintenance and repair. A visual representation helps users identify each element’s role and interconnection, facilitating smoother troubleshooting processes. Mastering this visual guide empowers technicians to execute tasks with confidence and precision.

Key Components Overview

Every intricate system consists of various elements, each serving a specific function. Familiarity with these components is essential for ensuring optimal performance and longevity of the equipment. Below is a table summarizing the primary elements and their descriptions:

| Component Name | Description |

|---|---|

| Element A | Responsible for initial operation and efficiency. |

| Element B | Serves as the connector between different units. |

| Element C | Provides necessary power and stability. |

| Element D | Ensures safety and regulates performance. |

Importance of Accurate Interpretation

Interpreting this visual representation accurately is vital for any maintenance procedure. Misunderstandings can lead to incorrect repairs, resulting in further complications. By developing a thorough understanding of each section, technicians can prevent errors and enhance the efficiency of their work.

Key Components of the Hs81t

This section explores the essential elements that contribute to the overall functionality and efficiency of the system. Understanding these critical parts is vital for effective operation and maintenance, ensuring optimal performance in various applications.

Core Functional Elements

Among the most significant components are the central processing unit and the power supply unit, which serve as the heart and backbone of the mechanism. Their seamless integration allows for enhanced performance and reliability, making them indispensable.

Supporting Structures

Additional structures, such as the housing and connection interfaces, play a pivotal role in safeguarding internal mechanisms while facilitating interaction with external systems. Durability and accessibility of these elements are paramount for sustained operation.

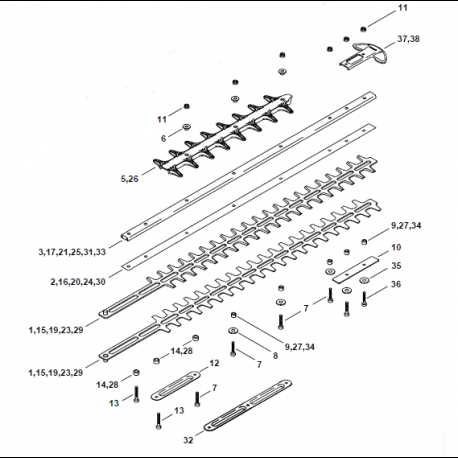

How to Read the Diagram

Understanding a schematic representation of components is essential for effective assembly and troubleshooting. These visual guides often include symbols, labels, and connections that can help you identify the various elements involved in a system. Familiarity with these conventions will enhance your ability to interpret the layout accurately.

Start by examining the overall layout. Note the arrangement of the elements, as this often indicates their relationship and function within the assembly. Look for any legends or keys that explain the symbols used; this will provide clarity on what each component represents. Pay attention to lines and arrows, which can indicate connections and flow, helping you understand how parts interact.

As you analyze the representation, take your time to cross-reference the labeled parts with the actual components you have. This can help in confirming that you are correctly identifying each item and understanding its role in the overall setup. If you encounter any unfamiliar symbols, consulting a reference guide or manual can be invaluable in demystifying these aspects.

Finally, practice is key. The more you work with these visual aids, the more intuitive it will become to interpret them. With patience and persistence, you’ll find that your ability to read these guides improves significantly, making your assembly and maintenance tasks much more manageable.

Common Issues with Hs81t Parts

When dealing with mechanical components, users often encounter a range of common challenges that can impact performance and longevity. Understanding these issues is crucial for effective maintenance and repair, ensuring the equipment operates smoothly and efficiently.

Wear and Tear

Over time, various elements may experience significant degradation due to regular usage. Friction and environmental factors can lead to cracks, breaks, or misalignments, necessitating timely replacements to avoid further damage.

Compatibility Problems

Incompatible components can cause serious operational issues. Using incorrect parts may lead to poor fitment or function, affecting overall efficiency and potentially resulting in costly repairs. Always verify specifications before installation.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a proactive approach to care and upkeep. Regular attention to key areas can significantly extend its lifespan, enhancing performance and reliability over time.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep surfaces free from dirt and debris to prevent wear and overheating. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and prevent rust. |

| Inspection | Conduct routine checks for signs of wear or damage to catch issues early. |

| Proper Storage | Store in a dry, protected area to shield from environmental factors that could cause harm. |

Finding Replacement Parts Efficiently

Locating suitable components for your machinery can be a straightforward process if approached with the right strategy. Understanding where to look and how to identify necessary items can save time and effort. The following methods can streamline your search and enhance your overall efficiency.

Utilizing Online Resources

The internet is a treasure trove for sourcing components. Numerous platforms offer comprehensive catalogs and allow for easy comparisons. Here are some key resources:

| Resource Type | Description |

|---|---|

| E-commerce Sites | Online retailers with extensive inventories. |

| Manufacturer Websites | Direct access to original specifications and updates. |

| Forums and Communities | Networking with others for advice and recommendations. |

Consulting Professional Help

In some cases, seeking assistance from professionals can provide invaluable insights. Experts can help identify exact requirements and even suggest alternatives that might be more cost-effective. This collaboration often leads to quicker resolutions and ensures compatibility with your equipment.

Tools Needed for Assembly

When it comes to putting together complex machinery, having the right equipment is crucial for a smooth and efficient process. The appropriate tools not only facilitate assembly but also ensure that each component is fitted correctly and securely. Understanding the necessary instruments can significantly impact the overall success of your project.

Essential Hand Tools

A variety of hand tools will be required for the assembly process. Commonly needed items include screwdrivers, pliers, and wrenches. Each of these tools plays a specific role, allowing you to manipulate screws, tighten fittings, and adjust components with precision. It’s essential to have both standard and metric sizes available to accommodate different specifications.

Power Tools and Accessories

In addition to hand tools, certain power tools can enhance efficiency during assembly. A drill, for example, is invaluable for creating holes and driving screws quickly. Furthermore, using a torque wrench ensures that connections are made with the correct amount of force, reducing the risk of damage. Don’t forget to stock up on accessories such as drill bits and blades to support various tasks.

Comparing Hs81t with Other Models

When evaluating different machinery, it’s essential to analyze various models to understand their strengths and weaknesses. This examination allows users to make informed decisions based on performance, durability, and usability. Each variant may offer distinct features that cater to specific needs, which is crucial for optimizing productivity.

In terms of functionality, some alternatives may excel in speed and efficiency, while others prioritize ease of maintenance and repair. For instance, one model might incorporate advanced technology that enhances precision, whereas another might focus on rugged design suitable for harsh environments. By comparing these attributes, users can identify which machine aligns best with their operational requirements.

Furthermore, compatibility with accessories and support for various tasks can significantly impact the overall user experience. While one variant may offer a broader range of compatible tools, another might provide superior integration with existing systems. Understanding these differences helps in selecting a model that not only meets immediate needs but also supports future growth.

Ultimately, a thorough comparison of various machines enables users to leverage the right combination of features for optimal performance. Whether it’s about efficiency, adaptability, or ease of use, recognizing the nuances among different designs can lead to more effective and satisfying outcomes in various applications.

Cost Analysis of Replacement Parts

Understanding the financial implications of acquiring new components is crucial for effective maintenance and operation. This analysis encompasses various factors that influence expenses, allowing for informed decision-making.

- Initial Costs: Assessing the purchase price of new items.

- Long-Term Savings: Evaluating potential cost reductions through efficiency.

- Installation Expenses: Considering labor costs associated with replacing items.

- Warranty Considerations: Analyzing coverage and its impact on overall costs.

- Supplier Variability: Investigating price differences among vendors.

Each of these aspects plays a vital role in forming a comprehensive understanding of the financial landscape, ultimately guiding effective resource allocation.

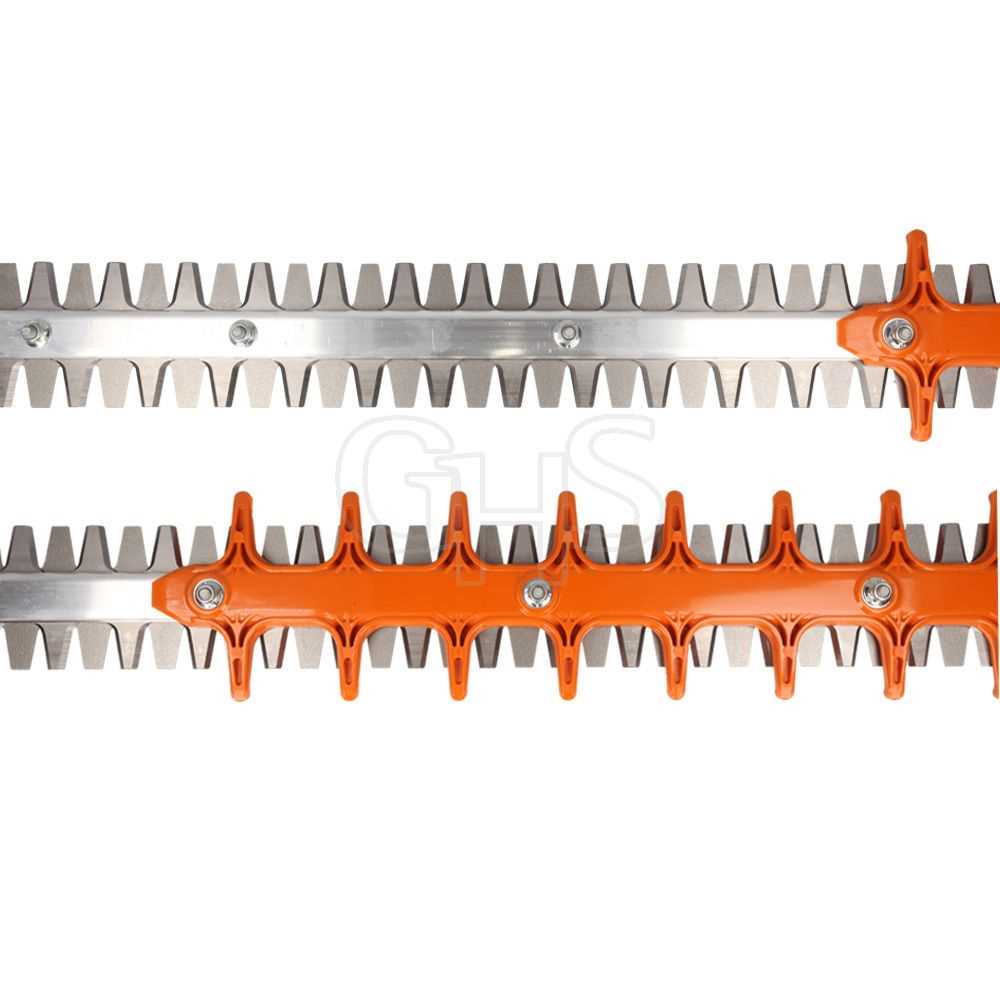

Visual Identification of Components

Recognizing various elements within a mechanical system is crucial for effective maintenance and repair. A clear understanding of these components allows for quicker troubleshooting and enhances overall efficiency. This section will provide insight into how to visually identify key parts, facilitating easier navigation and management of your equipment.

| Component | Visual Characteristics | Function |

|---|---|---|

| Gear | Toothed wheel, often metallic | Transmits torque and rotational motion |

| Connector | Small, usually cylindrical; may have pins | Links different sections of the system |

| Housing | Outer shell; typically rectangular or circular | Protects internal components from damage |

| Sensor | Compact device, often with a lens or opening | Monitors various operational parameters |

Expert Recommendations for Repairs

When it comes to maintenance and restoration of machinery, understanding key components and their interactions is essential. Experienced technicians emphasize a systematic approach to ensure longevity and optimal performance. Here are some crucial strategies to consider.

Essential Tips for Effective Repairs

- Always refer to reliable manuals and schematics to understand the assembly and function of each part.

- Utilize quality tools to avoid damaging sensitive components during disassembly and reassembly.

- Maintain a clean workspace to prevent contamination and ensure that small parts are not lost.

Common Mistakes to Avoid

- Neglecting to perform regular inspections can lead to overlooked wear and tear.

- Using incorrect replacement items can compromise the entire system’s functionality.

- Rushing through repairs may result in improper reassembly, causing future issues.

Resources for Further Learning

Expanding your knowledge in a specialized field can greatly enhance your understanding and skills. A variety of resources are available to help deepen your expertise and provide insights into complex systems and components. Whether you’re a beginner or looking to refine your skills, these materials can serve as valuable tools for your learning journey.

Online Courses and Tutorials

Many platforms offer comprehensive courses designed to cater to various skill levels. These interactive sessions often include video lectures, quizzes, and forums for discussion, allowing learners to engage actively with the material. Websites like Coursera, Udemy, and Khan Academy can be excellent starting points for structured learning.

Books and Manuals

Literature, including textbooks and specialized manuals, remains a cornerstone of in-depth knowledge. Look for publications that cover theoretical foundations as well as practical applications. These resources often provide diagrams, case studies, and detailed explanations that can help solidify your understanding of intricate systems.