Understanding Ingersoll Rand SS3 Parts Diagram for Efficient Maintenance

Exploring the intricate world of air compression machinery reveals a complex network of essential components that work harmoniously to deliver optimal performance. This section aims to illuminate the various elements involved, shedding light on their functions and interrelationships.

Gaining insights into the structure of these devices can significantly enhance maintenance practices and improve overall efficiency. With a clearer understanding of each segment, users can identify issues and implement effective solutions promptly.

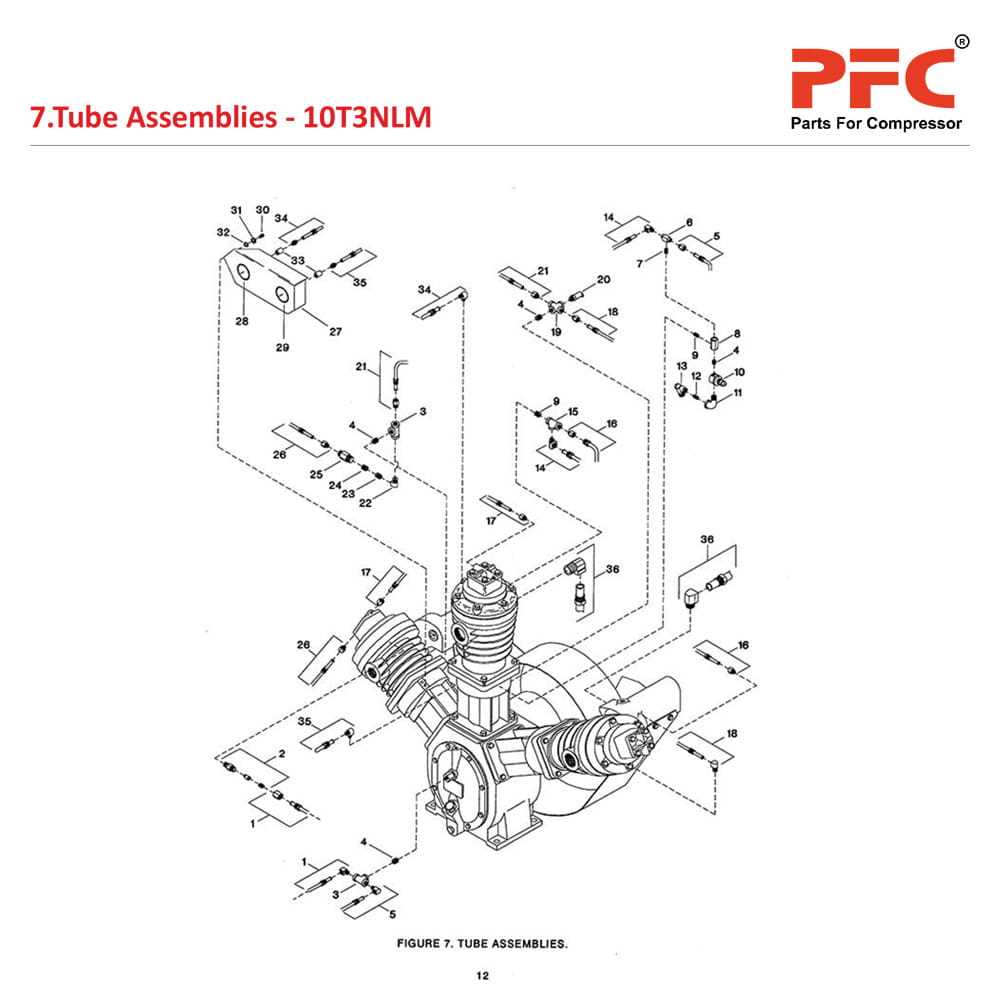

In this context, detailed visual representations serve as valuable tools, allowing individuals to navigate through the complexities of their equipment with confidence. By breaking down the construction and layout, we empower users to delve deeper into the mechanics of their machines, ensuring they achieve the ultimate functionality and longevity.

Understanding Ingersoll Rand SS3 Components

Comprehending the various elements of a specific compressor model is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and efficiency. By familiarizing oneself with these individual parts, one can enhance reliability and troubleshoot issues more effectively.

The assembly includes essential elements such as the motor, pump, and pressure switches, each contributing to the overall functionality. Recognizing how these parts interact allows for better insight into operational dynamics. Regular inspection and knowledge of wear patterns can prolong lifespan and prevent unexpected failures.

Additionally, understanding the specifications and features of each component aids in selecting appropriate replacements when necessary. This not only improves performance but also ensures that the system runs smoothly. Knowledge of the assembly fosters confidence in handling repairs and maintenance tasks.

Overview of SS3 Air Compressors

The SS3 series of air compression devices is designed to meet a variety of industrial and commercial needs. These machines offer reliable performance and efficiency, making them a popular choice among professionals. Built to withstand rigorous use, they provide consistent output that is essential for various applications.

Key features include robust construction, user-friendly controls, and energy efficiency. Users appreciate their durability and low maintenance requirements, which contribute to long-term cost savings. Additionally, these compressors are equipped with advanced technologies that enhance operational efficiency.

Overall, the SS3 series stands out in the market for its balance of performance and reliability, making it a preferred option for those seeking effective air compression solutions.

Essential Parts in SS3 Models

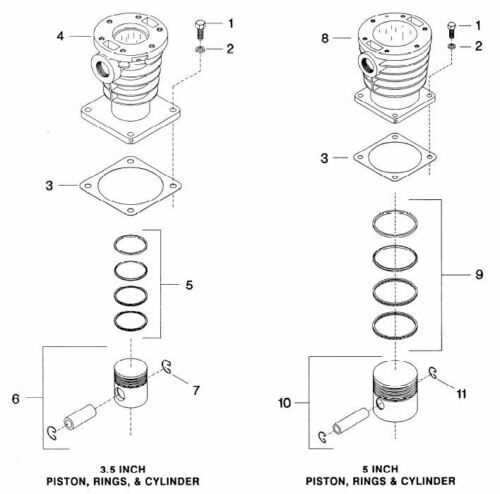

Understanding the key components of these air compressor units is crucial for maintenance and efficiency. Each element plays a vital role in the overall functionality, contributing to optimal performance and reliability.

- Motor: Powers the entire system, ensuring adequate air pressure.

- Compressor Unit: Compresses air, vital for generating the required pressure.

- Tank: Stores compressed air, facilitating a steady supply during operation.

- Pressure Switch: Regulates pressure levels, preventing overload and ensuring safety.

- Valves: Control airflow, contributing to the system’s efficiency and performance.

Each of these components must be regularly inspected and maintained to achieve the ultimate operational effectiveness.

Functionality of Major SS3 Components

The efficiency and performance of any compressed air system largely depend on the key elements that comprise it. Understanding how these components interact and contribute to the overall operation is essential for optimizing functionality and ensuring reliability.

Compressor Unit: This is the heart of the system, responsible for converting mechanical energy into compressed air. It compresses the incoming air, increasing its pressure for various applications.

Air Receiver: Serving as a storage vessel, the air receiver stabilizes pressure fluctuations and provides a reserve of compressed air. It enhances the system’s efficiency by reducing the frequency of compressor cycling.

Pressure Regulator: This component maintains the desired pressure levels within the system, ensuring that the air supplied to tools and machinery is consistent and within specified limits.

Filters: Filters play a critical role in maintaining air quality by removing contaminants and moisture. Clean air is vital for the longevity and optimal performance of downstream equipment.

Lubrication System: Proper lubrication reduces friction and wear within moving parts, ensuring smooth operation and prolonging the lifespan of the compressor.

Control Panel: This unit provides monitoring and control functions, allowing users to manage the system’s performance and troubleshoot any issues that may arise.

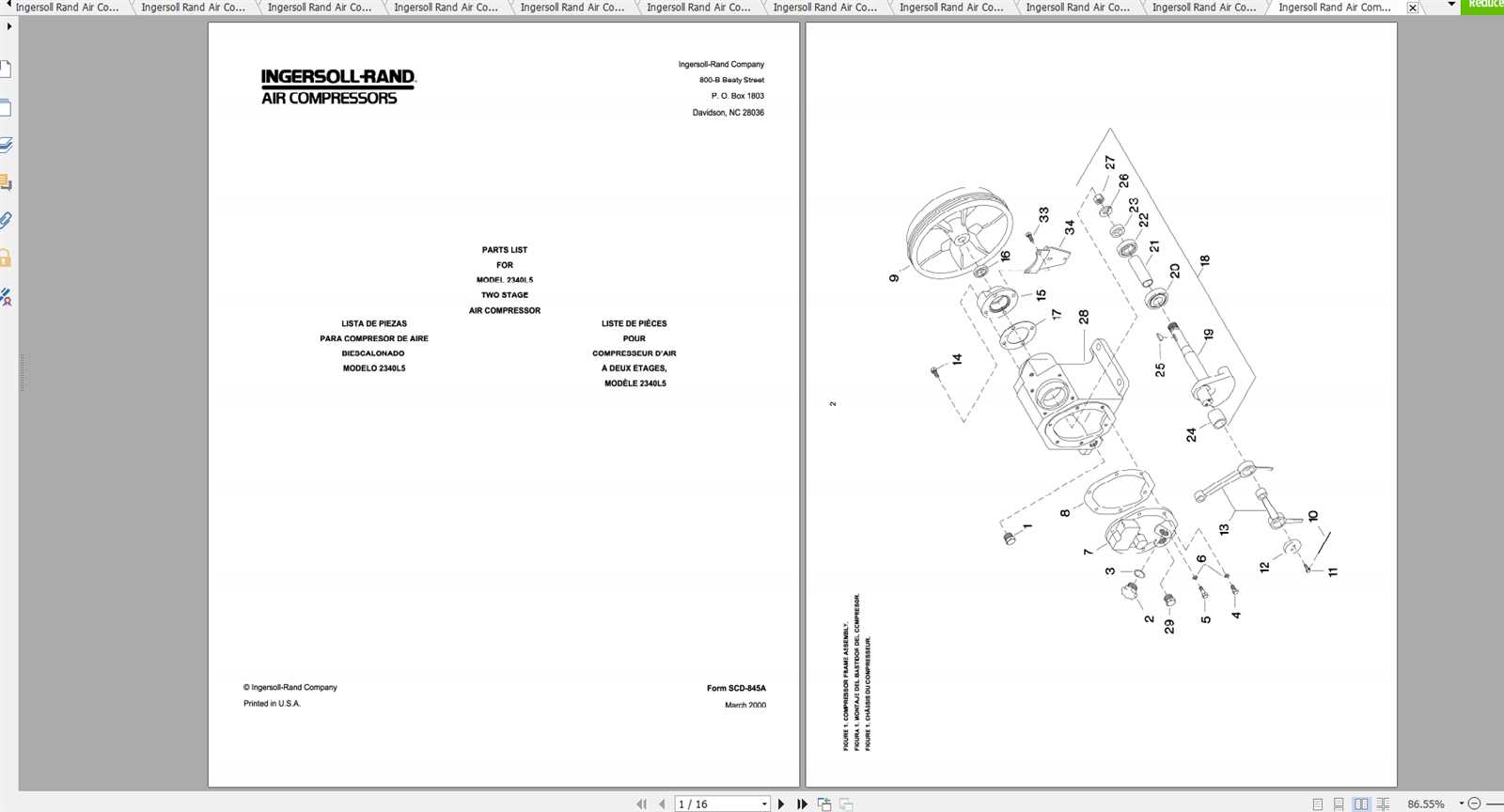

How to Access Parts Diagram

Accessing technical illustrations for equipment can streamline maintenance and repair tasks. Here’s a straightforward guide to help you find the necessary visuals and information.

- Start by visiting the manufacturer’s official website.

- Navigate to the support or resources section.

- Look for a link to technical documentation or manuals.

- Use the search function to enter your equipment’s model number.

Once you locate the appropriate section, you can easily download or view the illustrations you need for efficient troubleshooting.

Importance of Accurate Parts Identification

Precise identification of components is crucial for the seamless operation and longevity of any machinery. When every element is recognized correctly, it ensures efficient maintenance, minimizes downtime, and enhances overall performance.

| Benefits | Description |

|---|---|

| Efficiency | Proper identification leads to quicker repairs and replacements. |

| Cost Savings | Reduces unnecessary expenditures on incorrect items. |

| Safety | Ensures that equipment operates safely and reliably. |

| Performance | Maintains optimal functioning of the entire system. |

In conclusion, ensuring that every component is accurately recognized is fundamental to maintaining machinery efficiency and safety. This vigilance pays off in long-term operational success.

Common Issues with SS3 Parts

When dealing with specific mechanical components, several frequent challenges may arise that can affect performance and longevity. Understanding these issues is crucial for effective maintenance and troubleshooting.

- Wear and Tear: Over time, components can degrade due to constant use, leading to decreased efficiency.

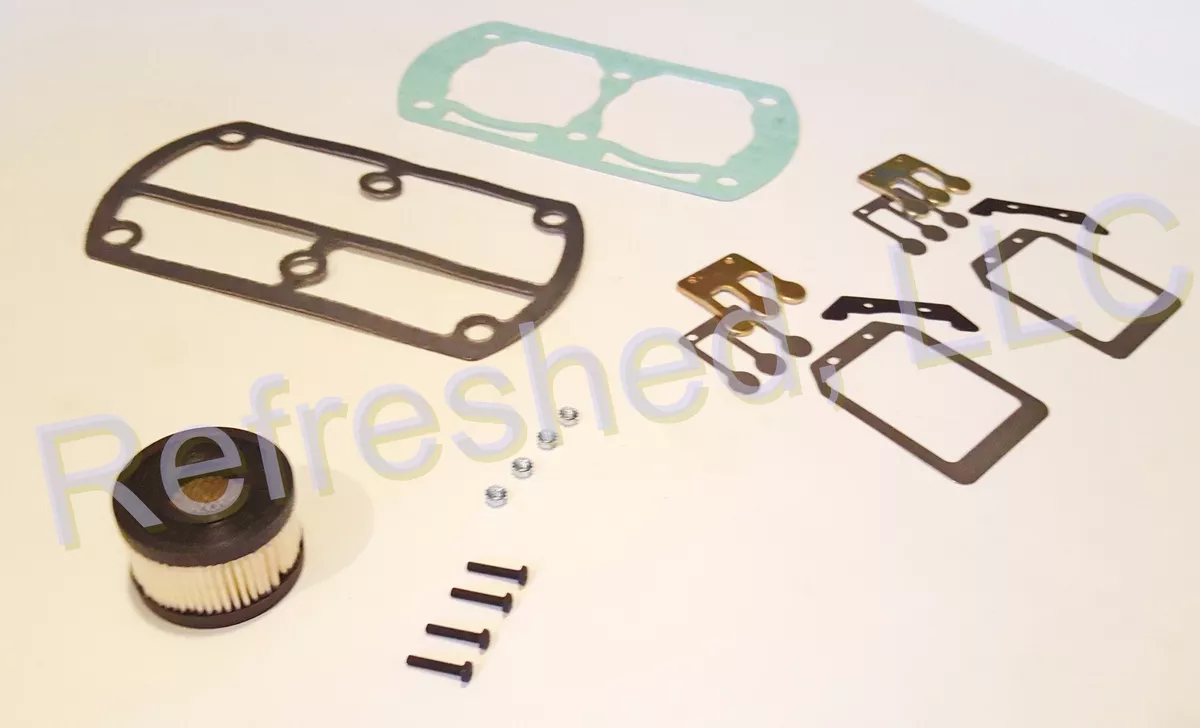

- Sealing Failures: Gaskets and seals may wear out, causing leaks that compromise the entire system.

- Corrosion: Exposure to moisture and other elements can lead to rust, impacting both function and safety.

- Misalignment: Improper installation can result in misalignment, causing excessive strain on parts and potential breakdowns.

Addressing these concerns promptly can enhance the performance and reliability of the equipment, ensuring it operates smoothly and efficiently.

- Regular inspections should be conducted to identify signs of wear.

- Replace worn seals to prevent leaks and maintain pressure.

- Utilize corrosion-resistant materials where possible.

- Ensure proper alignment during installation and routine maintenance.

By being aware of these common issues and taking proactive measures, users can significantly extend the lifespan of their mechanical systems.

Maintenance Tips for SS3 Systems

Ensuring the longevity and efficiency of your air compression systems requires regular attention and care. Implementing a structured maintenance routine can prevent unexpected failures and enhance performance.

Regular Inspection

- Check for any signs of wear or damage in hoses and connections.

- Inspect filters regularly to ensure they are clean and functioning.

- Look for any unusual noises or vibrations during operation.

Lubrication and Cleaning

- Maintain proper lubrication levels to reduce friction and wear.

- Clean the exterior regularly to prevent dust accumulation.

- Replace oil and filters as recommended by the manufacturer.

Where to Find Replacement Parts

Finding suitable components for your machinery can be essential for maintaining performance and reliability. Fortunately, there are several reliable sources to consider when searching for these essential items.

- Authorized Dealers: Many manufacturers have certified distributors who offer genuine items. These outlets ensure you receive high-quality replacements that match original specifications.

- Online Retailers: Numerous e-commerce platforms specialize in industrial supplies. Websites often feature detailed descriptions, customer reviews, and comparison options, making it easier to select the right component.

- Local Hardware Stores: Many community hardware stores stock a variety of components. Staff members can assist you in finding the right item, and you can often get immediate access without shipping delays.

- Aftermarket Suppliers: For those seeking cost-effective alternatives, aftermarket companies produce compatible components that can serve as substitutes. Research their reliability and compatibility with your specific model.

- Forums and Online Communities: Engaging with fellow enthusiasts in online forums can provide valuable insights. Members often share their experiences with sourcing components and may recommend trustworthy suppliers.

By exploring these options, you can ensure that your machinery remains operational and efficient, allowing for continued productivity and performance.

DIY Repairs: Step-by-Step Guide

Engaging in self-repair projects can be both rewarding and economical. By following a structured approach, you can tackle common issues with your equipment effectively. This guide outlines essential steps to help you navigate the repair process confidently.

Preparation

Before diving into any repair task, proper preparation is crucial. Here’s what you should do:

- Gather necessary tools: Ensure you have all required instruments handy, such as wrenches, screwdrivers, and pliers.

- Review the user manual: Familiarize yourself with the device’s components and specifications.

- Clear your workspace: A tidy environment enhances focus and safety.

Repair Process

Follow these steps for a systematic approach to repairs:

- Identify the issue: Determine what is malfunctioning and how it affects performance.

- Disassemble the device: Carefully remove parts as necessary, keeping track of screws and components.

- Inspect components: Look for wear, damage, or blockages that need attention.

- Replace or repair parts: Depending on your assessment, either fix the existing components or install new ones.

- Reassemble the device: Put all parts back together in reverse order, ensuring everything is secure.

- Test functionality: After reassembly, power on the device to ensure it operates correctly.

By following this guide, you can gain confidence in your ability to perform repairs, ultimately extending the life of your equipment while saving money.

Comparing SS3 to Other Models

This section explores the distinctions and similarities between the featured compressor model and its counterparts, highlighting performance, efficiency, and design nuances. Understanding these aspects can aid potential buyers in making informed decisions based on their specific requirements.

Performance Metrics

When evaluating compressors, key performance indicators such as horsepower, air delivery rate, and tank capacity come into play. This model excels in providing a balanced output while maintaining energy efficiency, making it suitable for both light and heavy-duty tasks. Comparatively, some alternatives may offer higher outputs but at the cost of increased power consumption.

Design and Usability

Design elements significantly influence user experience. The examined model features a compact build, enhancing portability and ease of use in various settings. In contrast, other models may prioritize raw power over convenience, resulting in bulkier designs that can hinder mobility. A thorough assessment of these factors can lead to the ultimate choice for both novice and experienced users.

Upgrades and Modifications for Efficiency

Enhancing the performance of your air compressor can significantly boost its operational efficiency. By implementing strategic upgrades and modifications, you can optimize functionality, reduce energy consumption, and extend the lifespan of the equipment. This approach not only maximizes productivity but also ensures a more sustainable operation.

Common Upgrades

One effective method is to invest in advanced filtration systems. These upgrades help maintain air quality, reducing wear on internal components. Additionally, incorporating variable speed drives can enhance energy efficiency by adjusting motor speed based on demand, thus minimizing unnecessary power usage.

Essential Modifications

Another vital modification involves regular maintenance practices, such as replacing old hoses and seals. This simple action can prevent air leaks, which often lead to significant energy losses. Furthermore, installing a programmable control system allows for precise monitoring and scheduling, ensuring that the compressor runs only when needed, ultimately leading to cost savings.