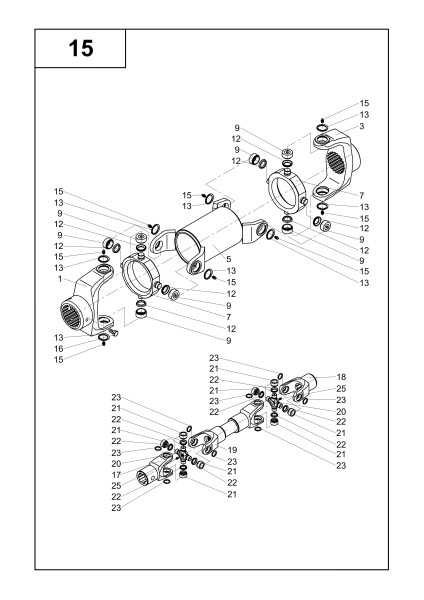

Parts Diagram for Ir 231c Printer

The intricate assembly of a tool is crucial for its optimal performance and longevity. Each element plays a significant role, contributing to the overall functionality and efficiency. By familiarizing oneself with the arrangement and function of these individual elements, users can enhance their understanding of the equipment.

In this section, we will explore the various elements of the specified model. A comprehensive overview of each component will not only assist in identifying parts but also aid in maintenance and troubleshooting. Knowledge of these details empowers users to make informed decisions regarding repairs and enhancements.

Moreover, a clear visual representation of the configuration serves as an invaluable resource. It facilitates easy reference, ensuring that users can efficiently locate and understand the role of each component. This approach promotes effective usage and encourages proactive care, ultimately leading to improved performance and durability of the device.

Detailed Parts Breakdown

This section provides an in-depth exploration of the various components that make up the system. Understanding these elements is essential for effective maintenance and repair. By examining each segment, users can gain insight into the functionality and interrelation of these crucial elements.

Component Overview

The assembly comprises numerous essential elements that work in harmony to ensure optimal performance. Each piece serves a specific function, contributing to the overall efficiency of the machine. Familiarizing oneself with these components will facilitate better troubleshooting and enhance operational understanding.

Functionality of Individual Elements

Examining the functionality of individual pieces reveals how they interact within the assembly. Each component, from the primary mechanisms to the smaller, supporting parts, plays a vital role in achieving the desired output. Knowledge of these functionalities not only aids in effective repairs but also in anticipating potential issues.

Functionality of Key Elements

This section explores the essential roles played by various components within a specific tool, emphasizing their significance in ensuring optimal performance and reliability. Understanding these functions is crucial for effective operation and maintenance.

Core Components and Their Functions

- Motor: Powers the tool and drives its operational capabilities, ensuring sufficient torque and speed.

- Housing: Provides structural integrity, protecting internal mechanisms while facilitating user interaction.

- Trigger Mechanism: Initiates operation, allowing for precise control over the tool’s activation.

- Power Source: Supplies energy, whether electric or pneumatic, crucial for functionality.

Auxiliary Features

- Safety Mechanisms: Designed to prevent accidents and ensure user protection during operation.

- Adjustment Settings: Enable customization for various tasks, enhancing versatility and user experience.

- Maintenance Indicators: Alert users when service is required, promoting longevity and consistent performance.

Identifying Common Issues

When dealing with mechanical devices, recognizing frequent challenges can greatly enhance the maintenance process. Understanding these common malfunctions enables users to address concerns effectively, ensuring optimal performance and longevity of the equipment. This section will explore typical problems that may arise, along with helpful insights for troubleshooting.

Frequent Operational Problems

Users often encounter difficulties related to inconsistent performance. Such issues may manifest as irregular operation or reduced efficiency. Identifying these patterns early can lead to timely interventions, preventing further complications and minimizing downtime.

Maintenance Oversights

Another common concern stems from inadequate upkeep practices. Regular inspections and timely replacements of essential components are crucial for the smooth functioning of the device. Neglecting these aspects can result in wear and tear, leading to more severe operational setbacks.

Replacement Part Specifications

This section provides essential information regarding the specifications of components used in specific equipment. Understanding these details is crucial for ensuring compatibility and optimal performance during the replacement process. Below, we outline key characteristics and standards that should be considered when selecting suitable alternatives.

Key Features

When evaluating components for substitution, it is important to focus on several primary attributes. These include dimensions, material quality, and operational capabilities. Ensuring that these specifications align with the original design is vital for maintaining functionality.

Compatibility Standards

Adhering to compatibility guidelines is essential for effective replacements. Below is a summary of the key specifications to consider:

| Specification | Description |

|---|---|

| Size | Measurements of the component, ensuring it fits within the designated area. |

| Material | Type of substance used, which affects durability and performance. |

| Functionality | Operational parameters that define how the component interacts with the system. |

| Manufacturer Standards | Certifications and quality assurance from the original producer. |

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular attention and care can prevent unnecessary wear and tear, enhancing performance and reliability over time.

Regular Cleaning

Keeping your machinery clean is a fundamental step in maintenance. Dust and debris can accumulate and lead to operational issues. Follow these tips:

- Use a soft brush or compressed air to remove dirt from hard-to-reach areas.

- Wipe down surfaces with a damp cloth to eliminate grime.

- Inspect filters regularly and clean or replace them as needed.

Periodic Inspections

Conducting regular inspections helps identify potential problems before they escalate. Consider the following actions:

- Check for any signs of wear or damage in crucial components.

- Test all moving parts to ensure they function smoothly.

- Monitor fluid levels and top up or change them according to the manufacturer’s recommendations.

Assembly Instructions for Components

Proper assembly of various elements is crucial for ensuring the functionality and longevity of the equipment. Understanding the sequence and method of combining these components can significantly enhance performance. This section provides clear instructions to facilitate a smooth assembly process.

Preparation Steps

- Gather all necessary components and tools.

- Ensure the workspace is clean and organized.

- Review any accompanying manuals for reference.

Assembly Process

- Begin by securing the base component on a flat surface.

- Attach the first auxiliary part, aligning it with the designated slots.

- Use screws or fasteners to secure the component firmly in place.

- Continue adding components in the specified order, ensuring each is tightly connected.

- After all parts are assembled, conduct a thorough inspection to confirm stability.

Tools Required for Repairs

Having the right instruments is crucial for effective maintenance and restoration tasks. Proper tools not only facilitate the repair process but also ensure safety and efficiency during the job. Below is a list of essential equipment that can help in carrying out repairs effectively.

- Wrenches: Various sizes are needed to fit different fasteners.

- Screwdrivers: A set of flat-head and Phillips screwdrivers is essential for removing and tightening screws.

- Pliers: These are useful for gripping, twisting, and cutting wires and small components.

- Socket Set: A comprehensive socket set is important for loosening and tightening nuts and bolts.

- Torque Wrench: This tool ensures that fasteners are tightened to the correct specifications.

- Utility Knife: A sharp blade is helpful for cutting materials and stripping wires.

- Safety Gear: Protective eyewear and gloves should always be worn to prevent injuries.

By gathering these tools before starting any repair project, you can streamline the process and reduce the likelihood of complications. Preparation is key to achieving successful outcomes in maintenance tasks.

Safety Guidelines During Maintenance

When performing maintenance on equipment, adhering to safety protocols is crucial to ensure both personal well-being and the longevity of the machinery. Understanding potential hazards and taking the necessary precautions can significantly reduce the risk of accidents.

Preparation and Equipment Inspection

Before beginning any maintenance tasks, it is essential to prepare adequately. Inspect tools and equipment to ensure they are in proper working condition. Look for any signs of wear or damage that could pose a risk during the maintenance process. Additionally, ensure that the workspace is clean and free of obstructions to prevent slips or falls.

Use of Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is a fundamental aspect of maintaining safety standards. This may include gloves, goggles, and hearing protection, depending on the nature of the work being carried out. Always prioritize safety by ensuring that all personnel involved are equipped with the necessary gear to mitigate potential hazards.

Where to Find Quality Parts

Finding reliable components for your equipment is essential for maintaining optimal performance and longevity. Quality parts ensure that your machinery operates smoothly and effectively, minimizing the risk of breakdowns and costly repairs. This guide will help you navigate the best sources for high-grade replacements.

One of the best places to start your search is authorized dealers or distributors who specialize in your specific model. These suppliers typically offer genuine items that are specifically designed for your machine, guaranteeing compatibility and reliability. Additionally, they often provide valuable support and expertise to assist with your purchase.

Online marketplaces can also be a great resource for quality replacements. Websites dedicated to tools and machinery often feature extensive catalogs, allowing you to compare various options. Be sure to read customer reviews and ratings to ensure you are selecting reputable sellers who offer dependable components.

Local hardware stores and specialty shops may carry quality options as well. Establishing a relationship with these businesses can lead to personalized service and advice tailored to your needs. Furthermore, they may have insights into local sourcing or repair services that could enhance your overall experience.

Lastly, consider joining online forums or communities related to your equipment. Engaging with other users can provide recommendations on where to find high-quality replacements and help you learn from their experiences. Networking in these groups can be invaluable for discovering trusted sources and maximizing the efficiency of your machinery.