Comprehensive Guide to Issc Mk22 Parts Diagram

In the intricate world of weaponry, each model is a harmonious assembly of various elements that contribute to its functionality and reliability. A thorough comprehension of these individual components is crucial for enthusiasts, whether for maintenance, customization, or simply to appreciate the engineering behind the design. This exploration sheds light on the vital aspects that make up a specific firearm, allowing users to grasp its operational mechanics.

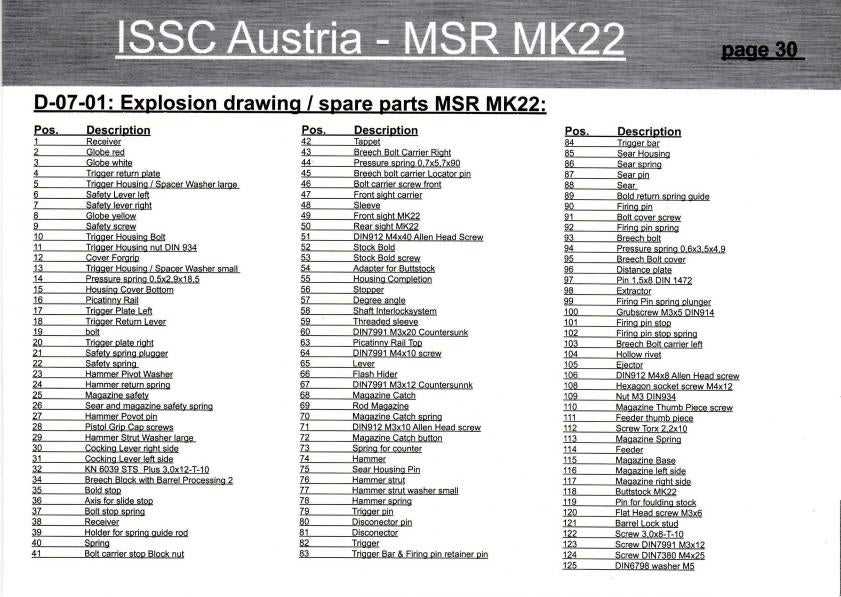

Detailed illustrations serve as valuable tools for those looking to familiarize themselves with the specific arrangement and interaction of these elements. By examining how each part fits together, individuals can enhance their understanding of the overall structure, leading to informed decisions regarding upgrades or repairs. The clarity provided by such visuals simplifies complex systems, making them accessible to both novices and seasoned experts.

Furthermore, knowledge of these components fosters a deeper connection with the firearm itself. Understanding how every piece contributes to performance can transform the experience of ownership, allowing for a more engaged and responsible use. This insight not only aids in practical applications but also ignites a passion for the craftsmanship involved in firearm design and manufacturing.

Understanding Issc Mk22 Components

In the realm of firearms, a comprehensive grasp of individual elements is essential for effective operation and maintenance. Each component plays a critical role in the overall functionality, impacting performance, reliability, and user experience. By delving into the various parts of a specific model, one can appreciate how they interact and contribute to the weapon’s efficiency.

Key Functional Elements

The essential components are designed with precision, ensuring that every piece works harmoniously. From the trigger mechanism to the barrel, each element serves a unique purpose. Understanding the interplay between these parts can enhance the user’s familiarity and confidence with the firearm. Key aspects to focus on include the firing mechanism, magazine, and safety features, all of which are crucial for safe handling and optimal performance.

Maintenance and Care

Proper care and regular inspection of these individual components can significantly extend the lifespan of the firearm. Awareness of how to disassemble and clean each part is vital for maintaining functionality and ensuring safety. Regular maintenance not only improves performance but also helps prevent malfunctions that could arise from neglect. By prioritizing knowledge of these components, users can foster a deeper connection with their equipment.

Importance of Parts Diagrams

Understanding the individual components of any complex system is essential for maintenance, repair, and effective usage. Visual representations that outline the relationships and functions of various elements offer invaluable assistance in these processes. Such illustrations serve as a crucial resource for technicians and enthusiasts alike, ensuring that they can identify, source, and replace necessary elements efficiently.

Clarity is a significant advantage of these visual guides. They break down intricate assemblies into comprehensible segments, allowing users to easily navigate through the structure. This simplification aids in troubleshooting, as one can quickly pinpoint potential issues by referring to the clear layout of the components.

Moreover, these resources enhance communication between users and service professionals. When discussing specific issues or requirements, having a common reference point helps eliminate misunderstandings and facilitates more productive dialogues. In industries where precision is key, this clarity can lead to improved outcomes.

Additionally, the accessibility of such resources promotes education and learning. Newcomers can familiarize themselves with the intricacies of a system, gaining confidence in their abilities to engage with it effectively. As they learn to interpret these visual aids, their overall competence and understanding grow.

In summary, visual representations of system components are indispensable tools that enhance clarity, improve communication, and foster education, ultimately leading to more effective and informed usage.

Key Features of Issc Mk22

This particular firearm stands out in its category due to several innovative elements that enhance user experience and performance. Its design focuses on combining functionality with ease of use, making it suitable for various applications, from training to recreational shooting.

Ergonomic Design: The shape and texture of the grip are carefully crafted to provide maximum comfort and control. This allows for a more stable hold, contributing to improved accuracy during shooting.

Versatile Caliber: This model accommodates multiple calibers, making it adaptable for different shooting preferences. This versatility appeals to both novice and experienced shooters alike.

Modular System: The construction of this firearm enables easy customization and modification. Users can attach various accessories and upgrades, tailoring the weapon to their specific needs and preferences.

Reliability: Built with high-quality materials, this firearm is designed for durability and consistent performance. Users can depend on it for repeated use without compromising functionality.

Safety Features: Equipped with several safety mechanisms, this model ensures secure handling. Features such as manual safeties and drop safeties provide peace of mind to the user.

Overall, this firearm offers a blend of innovation and reliability, making it a popular choice among enthusiasts and professionals alike.

Commonly Used Replacement Parts

When maintaining or upgrading a firearm, certain components frequently require attention due to wear and tear. Understanding which elements are most commonly replaced can enhance both performance and longevity. Here, we will explore key items that users often seek out to ensure their equipment remains in optimal condition.

Barrels are crucial for accuracy and consistency. Over time, they may become worn or damaged, necessitating replacement for improved precision.

Triggers play a vital role in the shooting experience. Upgrading to a higher-quality trigger can result in a smoother pull and enhanced control.

Recoil springs are essential for proper cycling. A worn spring can lead to malfunctions, making this an important item to consider for replacement.

Sights are integral for aiming. Many users opt for upgraded optics or iron sights to enhance visibility and target acquisition.

Lastly, grips can significantly affect handling and comfort. Swapping out for ergonomic options can lead to a better shooting experience.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective assembly and maintenance. These illustrations serve as a guide, breaking down complex systems into manageable sections, allowing users to easily identify each element’s role and connection.

Start by familiarizing yourself with the overall layout. Each section typically corresponds to a specific area of the object, providing a clear context for where each piece fits. Pay attention to labels that indicate the names or numbers associated with individual items; this will help in locating them in the corresponding documentation or inventory.

Next, notice the relationships between components. Lines or arrows may indicate how parts interact or connect, giving you insight into the assembly process. Take note of any color coding or symbols, as these often convey important information about functionality or compatibility.

Finally, use the visual aid as a reference during disassembly or repair. This resource can significantly reduce errors and streamline the process, ensuring that each piece is correctly installed or replaced. By mastering this skill, you enhance your overall proficiency in working with mechanical systems.

Maintenance Tips for Your Issc Mk22

Proper upkeep of your firearm is essential for optimal performance and longevity. Regular maintenance not only ensures reliability but also enhances safety during use. Here are some key practices to keep in mind for effective care.

Cleaning Routine

A consistent cleaning routine is vital. After each use, ensure that you clean all major components to prevent residue buildup. Utilize appropriate cleaning agents and tools designed for your specific model. A well-maintained barrel and action will improve accuracy and functionality.

Lubrication Techniques

Appropriate lubrication reduces friction and wear. Apply oil to moving parts sparingly, focusing on high-contact areas. Be cautious not to over-lubricate, as excess oil can attract dirt and grime. Regularly inspect and refresh lubrication to maintain smooth operation.

| Maintenance Task | Frequency |

|---|---|

| Clean after use | Every use |

| Inspect for wear | Monthly |

| Lubricate moving parts | Every few uses |

| Check sights and adjustments | Before each use |

Following these maintenance tips will help ensure your firearm remains in excellent working condition, ready for any situation.

Identifying Faulty Components

Recognizing malfunctioning elements in a mechanical assembly is crucial for ensuring optimal performance. Various indicators can signal the need for inspection and potential replacement, allowing for timely maintenance and improved reliability.

Common Symptoms of Malfunction

- Unusual noises during operation

- Inconsistent performance or functionality

- Visible damage or wear

- Leakage of fluids or gases

Steps to Diagnose Issues

- Visual inspection of all components

- Testing with diagnostic tools

- Cross-referencing with operational standards

- Consulting technical documentation for guidance

Assembly Process Explained

Understanding the assembly process is crucial for ensuring optimal performance and longevity of mechanical devices. This section delves into the various stages involved in constructing complex systems, highlighting the significance of precision and accuracy at each step.

The assembly workflow typically follows a structured approach, ensuring that every component is meticulously placed and secured. Key phases include:

- Preparation: Gather all necessary components and tools. Ensure that the workspace is organized to facilitate efficient assembly.

- Component Inspection: Examine each part for defects or irregularities. Quality control at this stage prevents future malfunctions.

- Assembly: Follow a systematic approach to connect parts. This may involve:

- Aligning components accurately

- Using appropriate fasteners

- Applying necessary adhesives or lubricants

Following these stages carefully not only enhances the efficiency of the assembly but also contributes to the overall durability and reliability of the final product.

Aftermarket vs. Original Parts

The choice between aftermarket and original components often sparks debate among enthusiasts and professionals alike. Each option presents distinct advantages and drawbacks that can significantly impact performance, reliability, and cost. Understanding these differences is essential for making informed decisions when upgrading or repairing equipment.

Advantages of Original Components

Original components are typically designed and manufactured by the original equipment producer. They often ensure compatibility and maintain the integrity of the device. Reliability is a key benefit, as these parts usually undergo rigorous testing and quality assurance processes.

Benefits of Aftermarket Options

Aftermarket components can offer enhanced features and often come at a lower price point. Many manufacturers focus on improving performance or providing unique designs. However, it’s crucial to research and ensure that these alternatives meet quality standards, as not all options are created equal. Thorough evaluation can lead to discovering valuable enhancements that align with specific needs.

Safety Considerations in Handling Parts

When working with various components, it is crucial to prioritize safety to prevent accidents and ensure proper functionality. Understanding the risks associated with handling these items can significantly enhance user experience and reduce potential hazards.

Personal Protective Equipment (PPE) should always be worn, including gloves and goggles, to protect against injuries. Additionally, proper lifting techniques are essential to avoid strain or damage while moving heavier items.

It is also important to maintain a clean workspace, as clutter can lead to slips and falls. Regular inspections of tools and equipment will help identify any worn or damaged items that could pose a risk. Lastly, ensure that all individuals involved are trained in safe handling procedures to promote a secure environment.

Where to Find Quality Diagrams

Finding high-quality illustrations that provide detailed breakdowns of various mechanisms can significantly enhance your understanding of their components and functionality. These visual resources are invaluable for enthusiasts, collectors, and professionals alike, enabling them to gain insights into assembly, maintenance, and repair processes. Whether you’re looking for schematics for educational purposes or practical applications, knowing where to source these materials is essential.

Online Resources

The internet offers a wealth of platforms that host comprehensive visual guides. Websites dedicated to firearm enthusiasts, technical forums, and specialty retailers often provide access to these resources. Additionally, social media groups and online communities can be great places to connect with knowledgeable individuals who share their own diagrams and recommendations.

Books and Manuals

Printed materials, such as technical manuals and reference books, can also serve as excellent sources for detailed visual representations. Many manufacturers publish their own guides, which often include annotated illustrations. Libraries or local bookstores may have dedicated sections for such literature, making them valuable spots to explore when seeking reliable information.