Iwata Airbrush Parts Diagram

Understanding the intricacies of various device elements is crucial for maintaining performance and achieving precision in detailed tasks. Each component plays a vital role in ensuring that the equipment functions seamlessly, and knowing how these elements interact can greatly improve user experience.

In this section, we will explore the essential structures that make up the core of these tools. By gaining insight into how these parts work together, users can ensure proper maintenance, enhance longevity, and troubleshoot any potential issues that may arise during usage.

We’ll break down each element, highlighting its significance and function, to provide a clear and detailed understanding of the overall system. This guide will serve as a valuable reference for both seasoned professionals and those new to this type of equipment.

An Overview of Components in Iwata Airbrush Systems

In understanding the intricacies of Iwata airbrush equipment, it is essential to delve into the fundamental components that comprise these sophisticated tools. Each element plays a crucial role in the functionality and precision of these devices, contributing to their renowned performance in various artistic and industrial applications.

Key Elements of Iwata Airbrush Systems

- Core Mechanisms: These internal components encompass the primary operational structures, facilitating air and paint flow regulation.

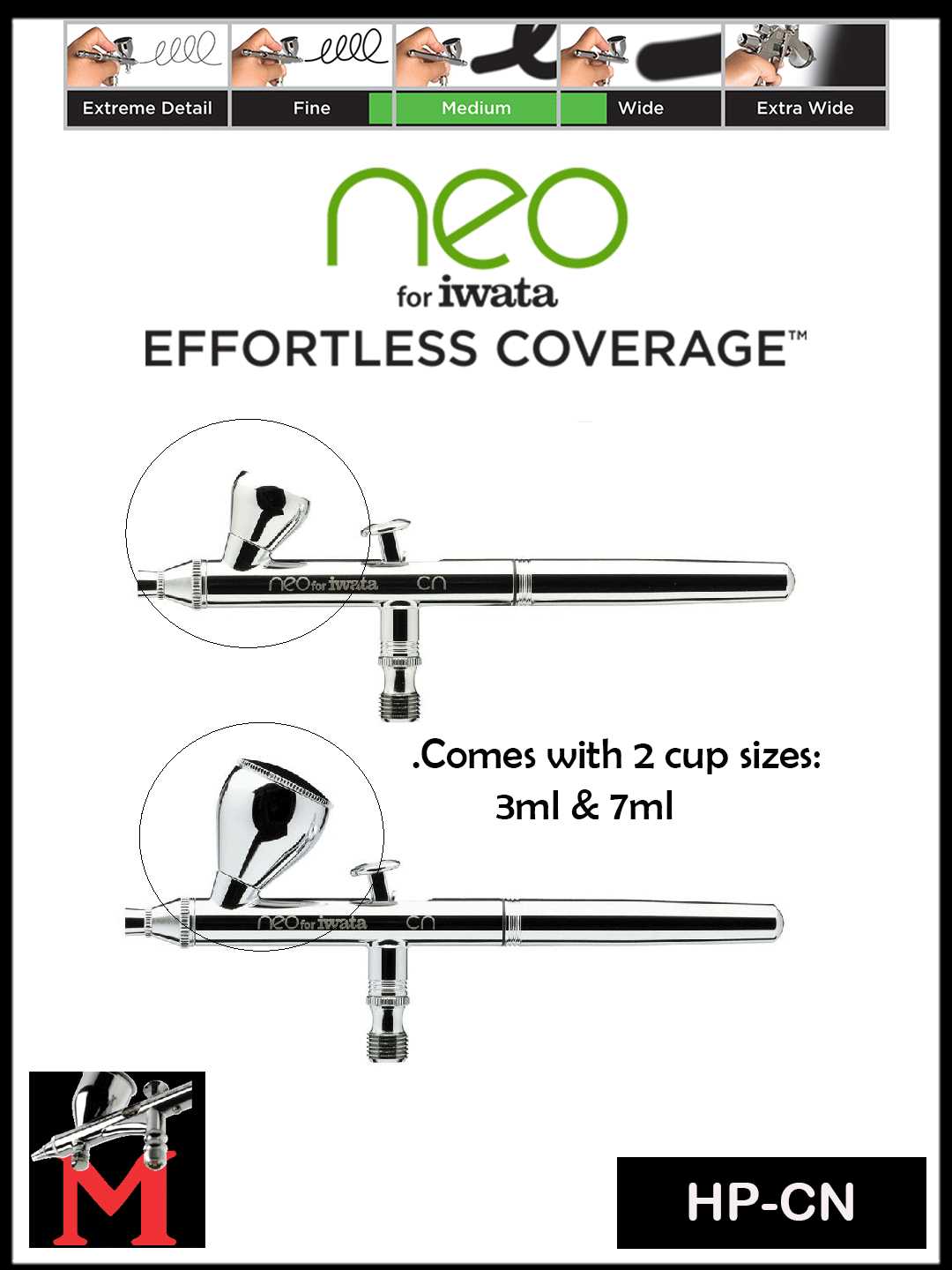

- Nozzle Assemblies: Critical for achieving varying spray patterns, these assemblies include precision-engineered nozzles and needle combinations.

- Trigger Mechanisms: Responsible for control and adjustment of airflow and paint release, enhancing user control and versatility.

Exploring these core elements provides a foundational understanding of how Iwata airbrush systems function synergistically, ensuring optimal performance and reliability across diverse creative and industrial environments.

Exploring the Main Sections of the Iwata Airbrush

The intricate structure of professional painting tools consists of several key components, each contributing to the precision and performance artists seek. Understanding these elements allows for better maintenance and operation, ensuring longevity and efficiency during creative work.

First, the handle provides the user with a comfortable grip and stability during use, essential for detailed and controlled strokes. Beneath it, the trigger serves as the main control mechanism, adjusting the flow of the medium and air. This part plays a crucial role in determining how smooth or intense the application is.

Next, the nozzle and needle assembly work together to fine-tune the spray pattern. These two components are responsible for the precision of the application, directly affecting the size and consistency of the lines or shading produced. Proper maintenance of these parts ensures optimal performance and prevents clogging or uneven flow.

Finally, the reservoir or container holds the medium, allowing for continuous work without frequent refilling. It comes in various sizes and materials, catering to different project needs and ensuring the right balance between weight and usability.

Identifying Key Elements in the Iwata Airbrush Design

The structure of this tool is made up of several interconnected components, each playing a crucial role in its overall functionality. Understanding these essential elements helps in both operation and maintenance, ensuring long-lasting performance and precision during usage. Below, we’ll explore the key elements of this design and how they interact with each other to achieve optimal results.

Main Operational Components

The core system includes parts responsible for regulating airflow, liquid flow, and overall control. These elements work together to provide seamless control over the application process, allowing for detailed work across various surfaces.

Connections and Support Mechanisms

Additional mechanisms are responsible for stabilizing and ensuring smooth transitions between different tasks. These support systems are vital for precision and prevent any disruption during continuous use.

| Component | Function |

|---|---|

| Flow Regulator | Controls the amount of liquid released. |

| Nozzle | Directs the spray to the desired area. |

| Trigger | Enables precise control over both air and liquid flow. |

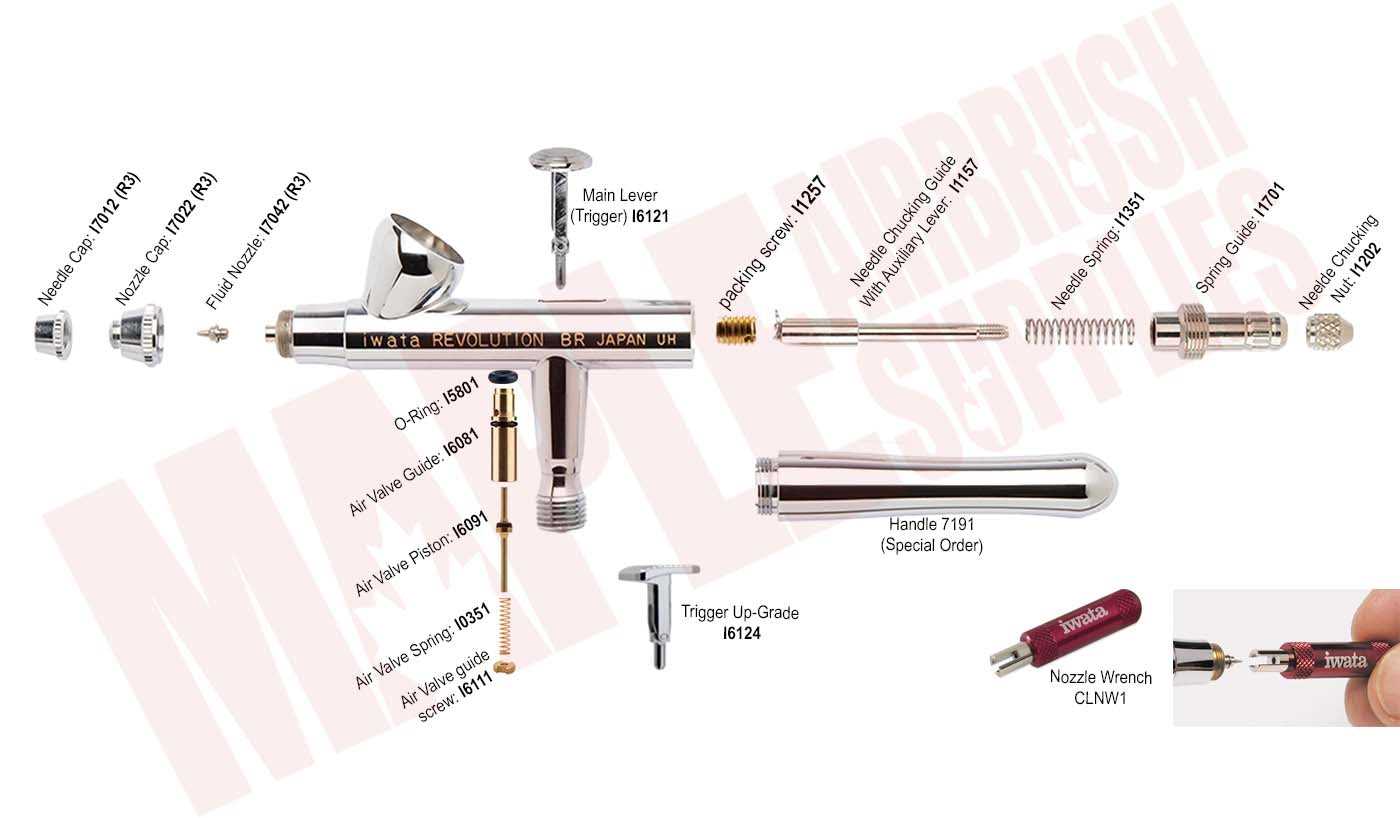

Detailed Breakdown of Iwata Airbrush Parts

Understanding the individual components of this tool is crucial for both maintenance and effective use. Each element plays a specific role in ensuring smooth performance, from the trigger mechanism to the nozzle system. This guide provides an in-depth look at how these elements work together, offering a clear understanding for users at all levels.

Key Components Overview

The primary sections of this device include various mechanisms responsible for controlling airflow and paint mixture. These parts work together in harmony to deliver precise results, whether for detailed artwork or broader applications.

Component Table

| Component | Description | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Trigger | Controls the flow of air and fluid with adjustable pressure sensitivity. | ||||||||||||||||||||||||

| Nozzle | Regulates the spray pattern by adjusting the paint flow and atomization. | ||||||||||||||||||||||||

| Needle | Moves within the nozzle to fine-tune the fluid output. | ||||||||||||||||||||||||

| Air Valve | Manages the intake of air, essential for consistent operation. | ||||||||||||||||||||||||

| Paint Cup | Holds the fluid

Functional Anatomy of an Iwata AirbrushThe functional anatomy of this device is based on precision engineering, designed to offer users complete control over airflow and fluid adjustment. At its core, this tool integrates several components that work together to ensure smooth performance, creating fine mist patterns essential for detail work. Understanding the role of each element is crucial for optimal usage, as well as for troubleshooting common issues. Each component has a specific function, which contributes to both the efficiency and versatility of the tool. Internal Mechanism and Fluid FlowThe internal workings are centered around a system of valves and regulators. The needle and nozzle work in tandem to control paint flow and spray pattern, with the needle ensuring that the liquid is atomized correctly. The air valve regulates the airflow, which combines with the paint at the nozzle, delivering a controlled spray pattern. Maintaining these components in optimal condition is key to achieving precision during usage, as even slight wear can cause inconsistencies. External Controls and AdjustmentsOn the exterior, controls such as the trigger and adjustment knob provide the user with the ability to fine-tune the output. The trigger connects to the needle and allows for dynamic control over paint release, while the adjustment knob ensures that the flow of material remains consistent. Regular checks and maintenance of these parts can significantly improve longevity and performance, reducing the chances of malfunction or clogging. Components That Ensure Precision in Iwata AirbrushesHigh-performance spray tools rely on several key elements that work together to achieve optimal accuracy. Each part is designed with meticulous attention to detail, ensuring smooth operation and consistent results. Whether you’re aiming for detailed artistry or even coatings, the individual components contribute to the overall efficiency of the tool. Nozzle and needle systems play a crucial role in regulating the flow of materials, offering precise control over the amount and direction. These elements are finely tuned to prevent clogging and ensure an even output. Additionally, the mechanism responsible for air pressure adjustment guarantees that the tool performs reliably under various conditions, contributing to the overall performance. Key Differences Among Various ModelsWhen exploring the diverse options available in these precision tools, it’s essential to understand how each model caters to specific artistic or technical needs. Each version offers unique features that make it suitable for different tasks, whether focused on intricate detailing or covering larger areas. By comparing various characteristics, one can better decide which tool will enhance their workflow Common Upgrades and Replacements for Precision Spray Tools

Maintaining and improving your precision spray tool is key to achieving consistent results. Over time, various components may wear out or benefit from enhancements, ensuring optimal performance and longevity. There are several areas where upgrades or replacements can provide noticeable improvements in efficiency and functionality. Nozzle and Needle EnhancementsOne of the most common upgrades involves replacing the nozzle and needle. These elements are essential for controlling the flow and detail of your work. Over time, they may become worn or damaged, and upgrading to higher-quality or specialized versions can greatly improve precision and control.

Improving Air Flow ComponentsAnother area where replacements are often needed is in the air flow system. Upgrading air valves or seals can help ensure a smoother and more consistent delivery, reducing fluctuations Essential Maintenance Tips for Iwata Airbrush ComponentsProper care and regular upkeep of your painting tool’s key elements can significantly extend its lifespan and maintain optimal performance. Routine cleaning, lubrication, and inspection are critical to ensuring that each part works smoothly and consistently over time. Below are some essential steps for maintaining the key components of your equipment. Cleaning the Internal MechanismKeeping the inner workings free of debris is one of the most important steps in maintaining efficiency. This includes flushing out any leftover paint and ensuring that no blockages form in the system.

Lubrication of Moving PartsLubricating the moving parts ensures that the mechanism functions smoothly without friction or wear over time.

|