Understanding the JCB 930 Parts Diagram for Efficient Maintenance

In the world of construction and agricultural equipment, comprehending the intricate layout of machine components is essential for effective maintenance and operation. Each machine is a complex assembly of parts that work together seamlessly, enabling optimal performance and efficiency. By familiarizing oneself with the arrangement of these elements, operators can better troubleshoot issues and ensure longevity in their equipment.

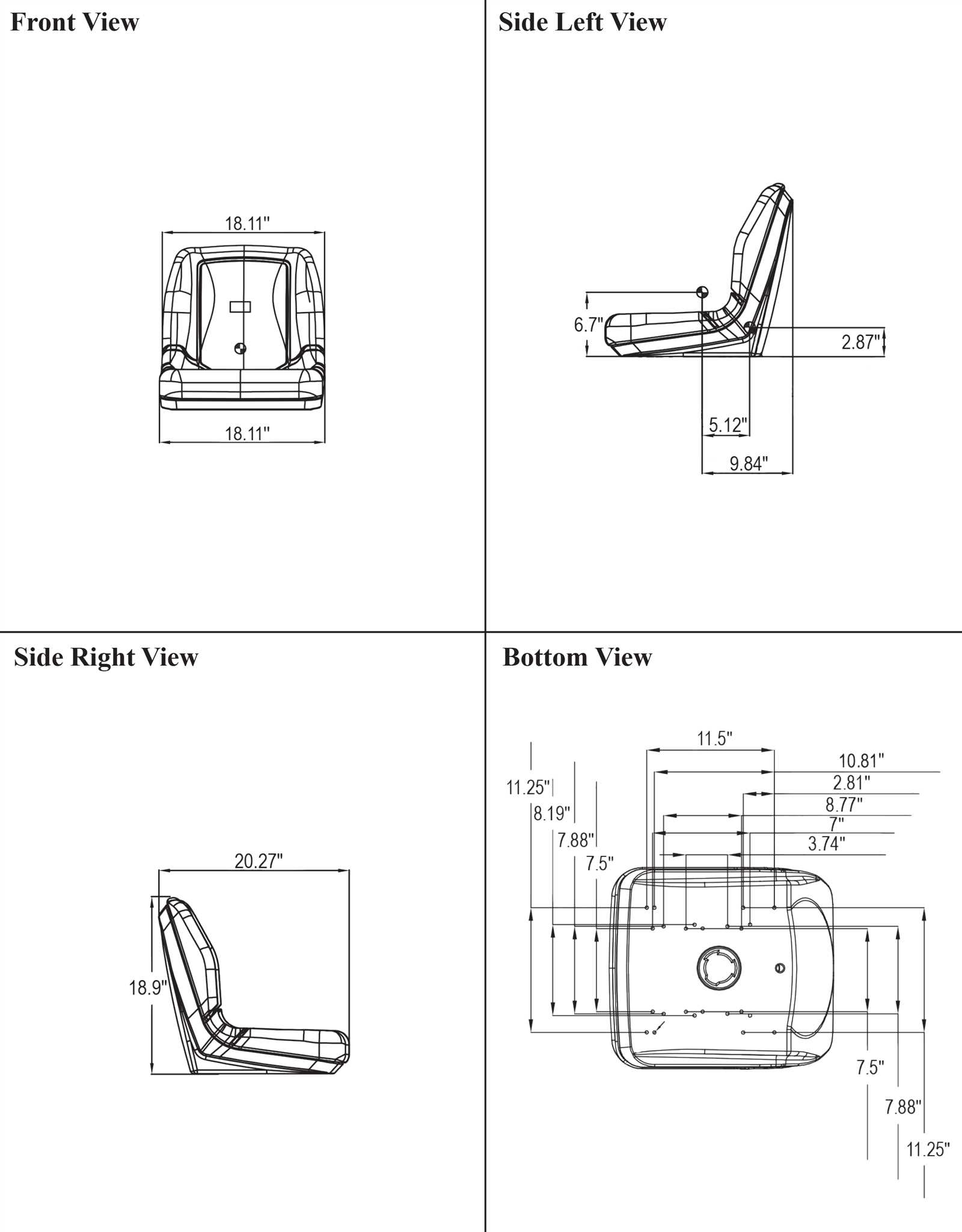

One crucial aspect of this understanding lies in visual representations that illustrate how each component interacts within the overall system. These illustrations serve as valuable guides, providing insights into the positioning and function of various elements. Such knowledge empowers users to undertake repairs and replacements with confidence, minimizing downtime and enhancing productivity.

Furthermore, a detailed exploration of these schematics can reveal common wear points and potential areas for improvement. By proactively addressing these factors, operators can maintain their machinery in peak condition, ultimately leading to more efficient operation and reduced costs. Whether for routine checks or significant repairs, a thorough grasp of the layout is indispensable in the realm of heavy machinery.

Understanding JCB 930 Parts Diagram

When working with heavy machinery, comprehending the layout and components is crucial for maintenance and repair. An effective visual representation helps operators and technicians identify each element’s role and location, ensuring optimal performance and safety during operation. Familiarity with these schematics can significantly enhance the efficiency of troubleshooting processes.

Importance of Component Identification

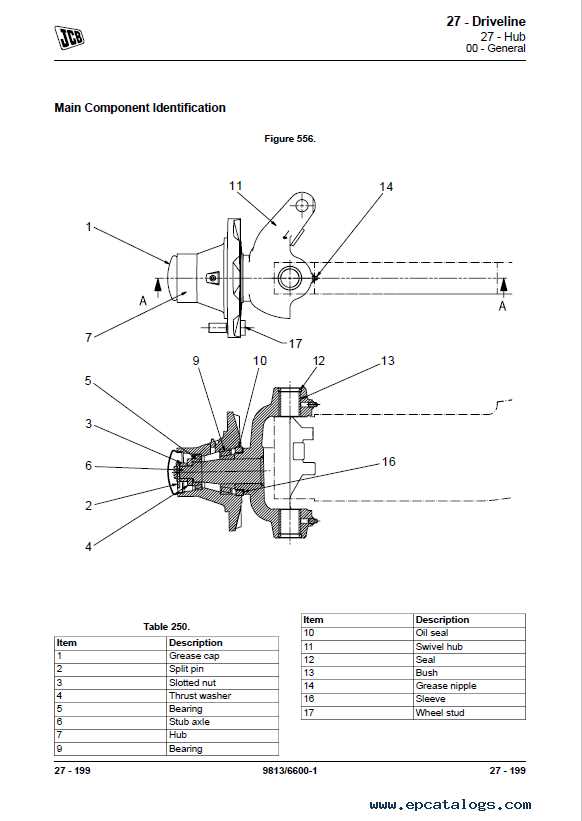

Recognizing individual elements within the mechanical assembly allows for timely replacements and repairs. Each component plays a vital role, and neglecting a faulty part can lead to extensive damage or operational failures. By systematically reviewing the structure, users can better understand how each piece interacts with others, paving the way for informed decision-making.

Utilizing the Visual Representation

Engaging with the visual guide not only facilitates repairs but also supports effective training for new operators. When newcomers grasp the configuration of the machinery, they can operate it more confidently and safely. Moreover, these visuals serve as an invaluable reference tool, aiding in routine inspections and preventive maintenance strategies.

Key Components of JCB 930

The machinery in question is built with several essential elements that contribute to its overall functionality and efficiency. Each component plays a vital role, ensuring that operations run smoothly and effectively.

The engine serves as the powerhouse, delivering the necessary energy to perform various tasks. Its design emphasizes reliability and performance, allowing for prolonged use under demanding conditions.

The transmission system is crucial for power transfer, providing the ability to shift gears seamlessly and maintain optimal control. This feature enhances maneuverability, making it easier to navigate diverse terrains.

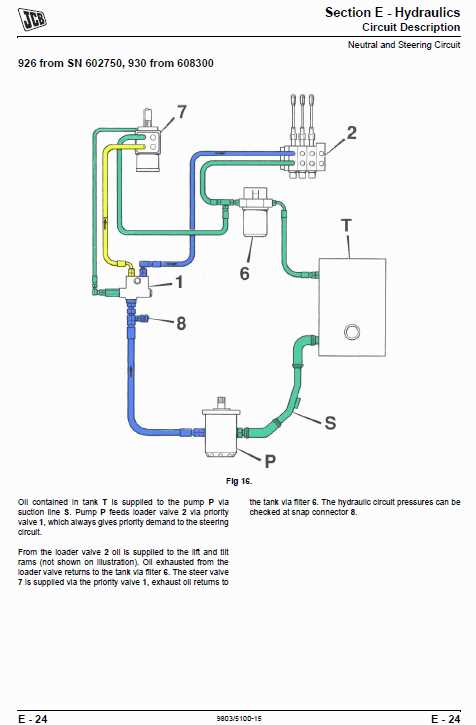

The hydraulic system is another key aspect, enabling the machine to perform heavy lifting and precise movements. This system’s design maximizes efficiency and responsiveness, ensuring that operators can handle loads with confidence.

Moreover, the chassis provides structural integrity, supporting all components while ensuring stability during operation. Its robust construction allows for durability, making it suitable for various applications in the field.

Finally, the operator’s cabin is designed for comfort and visibility, allowing users to maintain focus while controlling the equipment. Ergonomic features and clear sightlines enhance the overall experience, promoting safety and efficiency.

Importance of Accurate Parts Identification

In the realm of machinery maintenance and repair, ensuring precise identification of components is crucial for optimal performance and longevity. Recognizing the exact specifications and functionalities of each element allows for efficient troubleshooting and effective solutions, minimizing downtime and operational disruptions.

When dealing with equipment, even minor discrepancies in identification can lead to significant issues. Using incorrect components can result in improper fitment, decreased efficiency, and even potential damage to the machinery. Therefore, meticulous attention to detail in recognizing each piece contributes to the overall reliability and safety of operations.

Furthermore, accurate identification aids in sourcing replacements and understanding compatibility. This knowledge empowers technicians to make informed decisions, ensuring that every element used in repairs or upgrades meets the necessary standards. Ultimately, a thorough grasp of component specifications fosters a smoother workflow and enhances the overall effectiveness of maintenance practices.

In conclusion, the significance of precise identification cannot be overstated. It not only supports operational efficiency but also safeguards the investment in equipment, ensuring that it functions at peak performance throughout its lifecycle.

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone involved in maintenance or repair. These illustrations serve as valuable tools, allowing users to identify and locate individual elements within a system. By familiarizing yourself with the symbols and layout, you can navigate these visuals more effectively and streamline your troubleshooting process.

Familiarizing with Symbols

Each representation utilizes specific icons and labels to indicate various parts. Recognizing these symbols is crucial for accurate identification. Common symbols may denote fasteners, connectors, or specific assemblies. Referencing a legend, when available, can greatly enhance comprehension.

Navigating the Layout

The arrangement of components is often systematic. Typically, parts are grouped according to their function or placement within the assembly. Pay attention to the flow of the illustration, as it can guide you in understanding how components interact with one another.

| Symbol | Description |

|---|---|

| ⚙️ | Gear or rotating component |

| Fastener or bolt | |

| Connector or linkage | |

| ️ | Tool or maintenance indication |

By mastering the symbols and layout, you can enhance your understanding of any mechanical system, facilitating more efficient maintenance and repairs.

Common Issues with JCB 930 Parts

When it comes to heavy machinery, the integrity and functionality of components play a crucial role in ensuring optimal performance. Various challenges can arise over time, affecting the efficiency and reliability of these essential elements. Identifying and addressing these common problems is vital for maintaining productivity and minimizing downtime.

One frequent issue involves wear and tear, particularly in high-stress areas such as hydraulic systems and engine components. Regular maintenance can help mitigate these effects, but neglect may lead to significant breakdowns. Another common concern is the availability of replacement components, which can cause delays in repairs if specific parts are hard to find.

Additionally, improper installation or misalignment during repairs can result in further complications, leading to decreased operational efficiency. It’s also important to monitor for signs of corrosion or damage caused by environmental factors, as these can severely impact the lifespan of components. Awareness of these potential issues can aid operators in taking proactive measures to ensure their machinery remains in peak condition.

Maintenance Tips for JCB 930

Regular upkeep is essential for ensuring the longevity and optimal performance of heavy machinery. Implementing a systematic maintenance routine not only prevents unexpected breakdowns but also enhances efficiency and safety on the job site. This section provides valuable insights into best practices for maintaining your equipment effectively.

Daily Inspection Checklist

Performing a daily inspection is crucial to identify potential issues before they escalate. Here’s a simple checklist to follow:

| Task | Description |

|---|---|

| Fluid Levels | Check engine oil, hydraulic fluid, and coolant levels. |

| Filters | Inspect air and fuel filters for clogs or damage. |

| Tires | Examine tire pressure and tread for wear. |

| Lights | Ensure all lights and indicators are functioning properly. |

| Safety Features | Test alarms and emergency systems to confirm they work. |

Periodic Maintenance Schedule

Establishing a periodic maintenance schedule is vital for comprehensive care. Here’s a suggested timeline:

| Interval | Maintenance Activity |

|---|---|

| Weekly | Grease all pivot points and inspect belts for wear. |

| Monthly | Change engine oil and replace the oil filter. |

| Quarterly | Inspect hydraulic hoses for leaks and wear. |

| Annually | Conduct a comprehensive inspection and replace any worn components. |

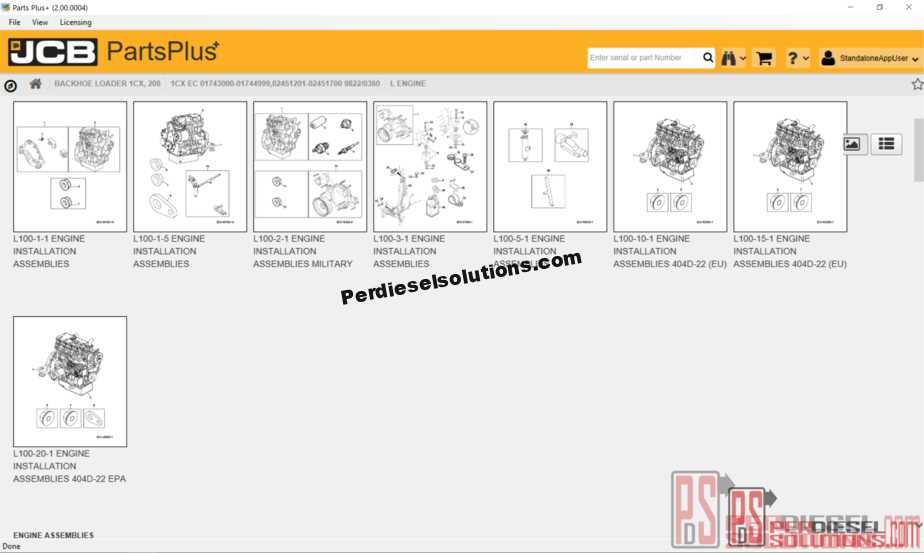

Where to Find Genuine Parts

Locating authentic components for your machinery is essential for maintaining performance and reliability. Whether you are in need of replacements or upgrades, sourcing high-quality items can significantly impact the longevity of your equipment. This section outlines the best avenues to secure genuine items for your heavy machinery.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealerships. These establishments are officially recognized by the manufacturer and offer a wide range of products, ensuring that you receive items that meet the required standards.

Online Marketplaces

The internet provides numerous platforms where you can find genuine components. However, it’s crucial to verify the credibility of the seller. Look for customer reviews and ratings to ensure a safe purchase.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed quality, professional support | Potentially higher prices |

| Online Marketplaces | Convenience, wide selection | Risk of counterfeit items |

Comparing OEM and Aftermarket Parts

When maintaining or repairing heavy machinery, the choice between original equipment manufacturer (OEM) components and alternative solutions can significantly impact performance, durability, and overall cost-effectiveness. Understanding the advantages and disadvantages of each option is crucial for making informed decisions that align with specific needs and budgets.

Benefits of OEM Components

- Quality Assurance: OEM items are designed and manufactured to the exact specifications of the original equipment, ensuring optimal fit and performance.

- Warranty Protection: Many manufacturers offer warranties on their products, providing additional security and peace of mind.

- Reliability: Original components are often tested for durability, which can reduce the likelihood of premature failure.

Advantages of Alternative Solutions

- Cost Savings: Aftermarket solutions typically come at a lower price point, making them attractive for budget-conscious operators.

- Variety: There is a wide range of options available, allowing for more flexibility in sourcing components that meet specific requirements.

- Availability: Alternative items may be easier to find and acquire, reducing downtime during repairs.

Ultimately, the choice between these two types of solutions depends on individual priorities, including budget constraints, performance expectations, and the nature of the intended application.

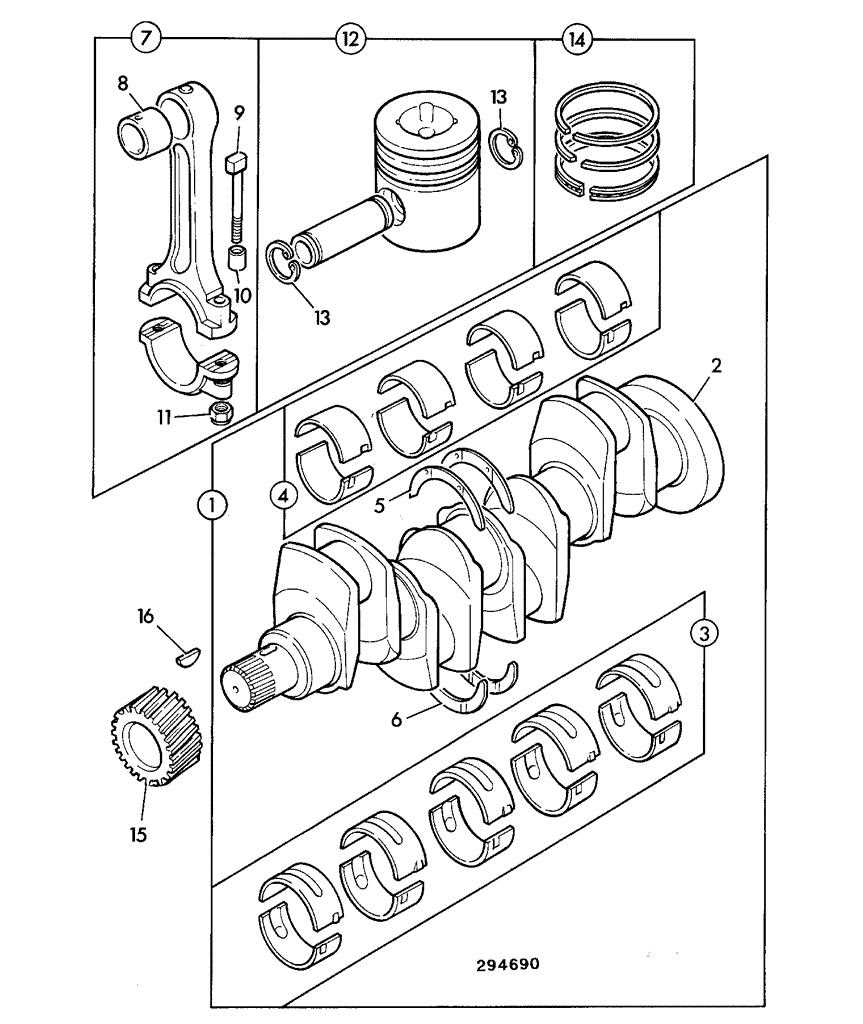

Assembly Process of JCB 930 Components

The assembly of heavy machinery components is a meticulous process that ensures efficiency and reliability. Each piece plays a vital role in the overall functionality of the equipment, requiring careful attention during installation. Understanding the sequence and method of assembly is crucial for optimal performance.

- Preparation of Components:

Before beginning the assembly, all individual elements must be inspected and prepared. This includes:

- Cleaning components to remove any debris or contaminants.

- Checking for wear and tear to ensure each part meets quality standards.

- Organizing components according to their assembly sequence.

- Assembly Sequence:

The order in which components are assembled is critical. A typical sequence may include:

- Assembling the frame to provide structural integrity.

- Attaching the engine and transmission to ensure power transmission.

- Installing hydraulic systems for efficient operation.

- Fastening Techniques:

Securing components properly is essential for durability. Common techniques include:

- Using bolts and nuts to fasten heavy elements.

- Employing welds for a permanent bond in critical areas.

- Utilizing adhesives where appropriate to enhance stability.

- Final Inspection:

Once assembly is complete, a thorough inspection is conducted. This process includes:

- Verifying that all components are properly secured.

- Testing hydraulic and electrical systems for functionality.

- Ensuring compliance with safety and operational standards.

Following this structured assembly process not only enhances the performance of the machinery but also prolongs its lifespan, ensuring that it operates at peak efficiency in various working conditions.

Essential Tools for JCB Repairs

Having the right equipment is crucial for effective maintenance and repair of heavy machinery. A well-equipped workshop ensures that tasks can be completed efficiently and safely, reducing downtime and improving overall performance. Below are some key tools that every technician should consider when working on these powerful machines.

Basic Hand Tools

- Wrenches: Adjustable and socket types are essential for loosening and tightening bolts.

- Screwdrivers: A variety of flathead and Phillips head screwdrivers for different fasteners.

- Pliers: Needle-nose and standard pliers are useful for gripping and bending components.

- Hammers: A ball-peen hammer is ideal for driving and shaping metal parts.

Specialized Equipment

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Diagnostic Tools: Electronic devices that help troubleshoot issues and monitor system performance.

- Hydraulic Jacks: Essential for lifting heavy parts safely during repair work.

- Impact Wrench: Provides the necessary power to loosen rusted or tightly secured bolts.

Equipping your workshop with these essential tools will enhance your ability to perform maintenance tasks efficiently, ensuring longevity and reliability of your machinery.

Upgrades for Enhanced Performance

Improving the efficiency and capability of heavy machinery is crucial for optimizing productivity. Various enhancements can lead to better functionality, durability, and overall performance. This section explores essential modifications that can elevate the operation of your equipment, ensuring it meets demanding tasks with ease.

Key Modifications to Consider

- Engine Enhancements: Upgrading the engine can significantly boost power output and fuel efficiency. Options include:

- High-performance air filters

- Advanced fuel injection systems

- Turbochargers for increased power

- Hydraulic System Improvements: A more efficient hydraulic system can enhance lifting capacity and responsiveness. Consider:

- Upgraded hydraulic pumps

- High-pressure hoses for better flow

- Improved valve systems for precise control

Additional Enhancements

- Tire Upgrades: Investing in high-quality tires can improve traction and stability, especially in challenging terrains.

- Cab Comfort: Enhancing the operator’s environment with better seating and controls can lead to increased productivity.

- Monitoring Technology: Implementing advanced telemetry systems can provide real-time performance data and maintenance alerts.

By focusing on these upgrades, operators can ensure their machinery performs at its best, leading to greater efficiency and longevity in the field.

Understanding Warranty and Returns Policy

A comprehensive understanding of warranty and return policies is essential for any consumer. These policies serve as vital safeguards, ensuring that buyers can address issues with their purchases effectively. Knowing the terms and conditions associated with warranties can help users make informed decisions and protect their investments in machinery and components.

Warranties typically cover defects in materials and workmanship, providing customers with assurance that their equipment will function as intended. It is crucial to familiarize yourself with the duration of the warranty and any specific requirements for filing a claim. On the other hand, return policies outline the process for returning items that do not meet customer expectations, detailing acceptable reasons for returns and any associated timeframes.

| Aspect | Details |

|---|---|

| Warranty Duration | Commonly ranges from 6 months to several years depending on the item. |

| Coverage | Usually includes defects in materials and workmanship. |

| Return Timeframe | Typically allows returns within 30 to 90 days of purchase. |

| Conditions for Return | Must be unused and in original packaging, with receipt. |

| Claim Process | Usually requires contacting customer service with details and proof of purchase. |

Understanding these policies not only enhances customer confidence but also fosters a better relationship between buyers and sellers. Always review the specific terms related to any equipment you purchase to ensure a smooth experience should issues arise.

Resources for JCB 930 Owners

Owning heavy machinery comes with its own set of responsibilities and challenges. For operators and enthusiasts, having access to reliable resources is crucial for maintenance, repairs, and overall efficiency. This section provides valuable information and tools that can assist in the upkeep and optimization of your equipment.

Online Communities

Joining online forums and groups can be incredibly beneficial for sharing knowledge and experiences. These platforms often feature discussions on troubleshooting, modifications, and best practices that can enhance the performance of your machine.

Manufacturer Resources

Consulting the manufacturer’s website can provide essential documentation and specifications. Manuals, service guides, and safety protocols are often available for download, offering a wealth of information for proper operation and maintenance.

| Resource Type | Examples |

|---|---|

| Online Forums | Heavy Equipment Forums, Reddit Communities |

| Manufacturer Websites | Official Service Manuals, Technical Support |

| Local Dealerships | Parts Availability, Service Offers |

| Social Media Groups | Facebook Groups, LinkedIn Networks |