Comprehensive Jonsered 260 Parts Diagram Guide

Maintaining optimal performance in your cutting tool relies heavily on a thorough understanding of its individual elements. Each section plays a crucial role in ensuring efficiency and longevity. By familiarizing yourself with these components, you can effectively troubleshoot issues and carry out necessary repairs.

In the world of power equipment, a clear visual representation of each part can be invaluable. Such illustrations not only simplify the identification process but also enhance your overall knowledge of how everything fits together. Whether you’re a seasoned user or a newcomer, having access to these insights can significantly improve your hands-on experience.

As you delve into the intricate layout of your machine’s structure, you’ll find that recognizing specific components aids in making informed decisions about maintenance and upgrades. This understanding empowers you to maximize the functionality of your tool, ensuring it serves you well for years to come.

Understanding Jonsered 260 Overview

This section aims to provide a comprehensive insight into a specific model of outdoor power equipment, focusing on its functionality, design, and essential components. Gaining familiarity with this machine is crucial for both operators and enthusiasts, as it enhances the overall experience and efficiency in usage.

Key Features

The featured model boasts a range of characteristics that enhance performance and user convenience. With a robust engine and ergonomic design, it facilitates smooth operation, making it suitable for various tasks in landscaping and maintenance.

Maintenance Considerations

Proper upkeep is vital for longevity and optimal performance. Regular inspections and timely replacements of critical elements can prevent potential issues, ensuring that the equipment remains in peak condition for years to come.

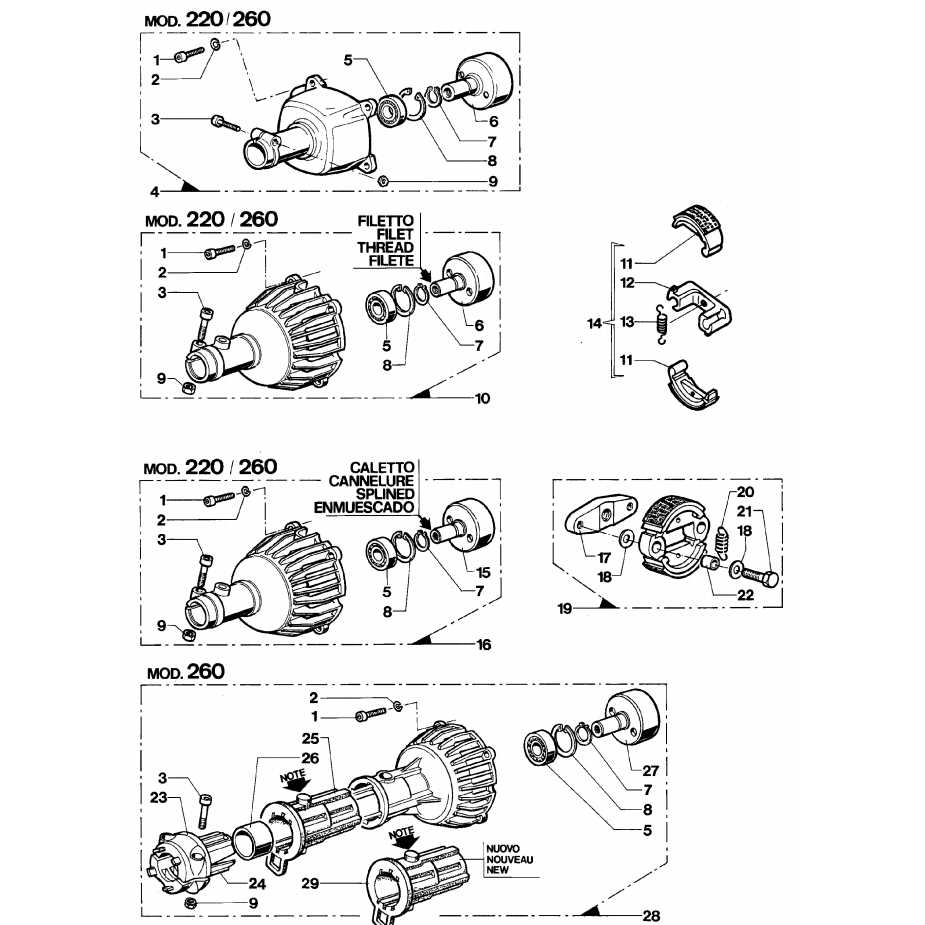

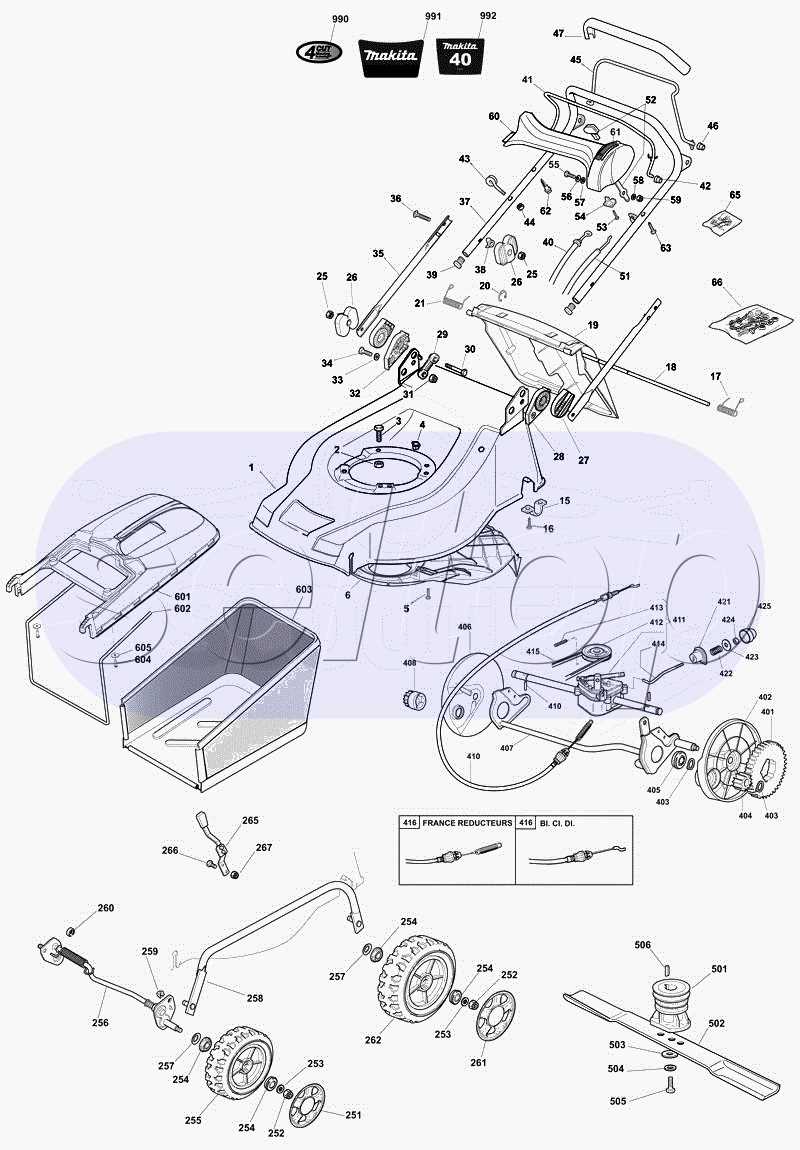

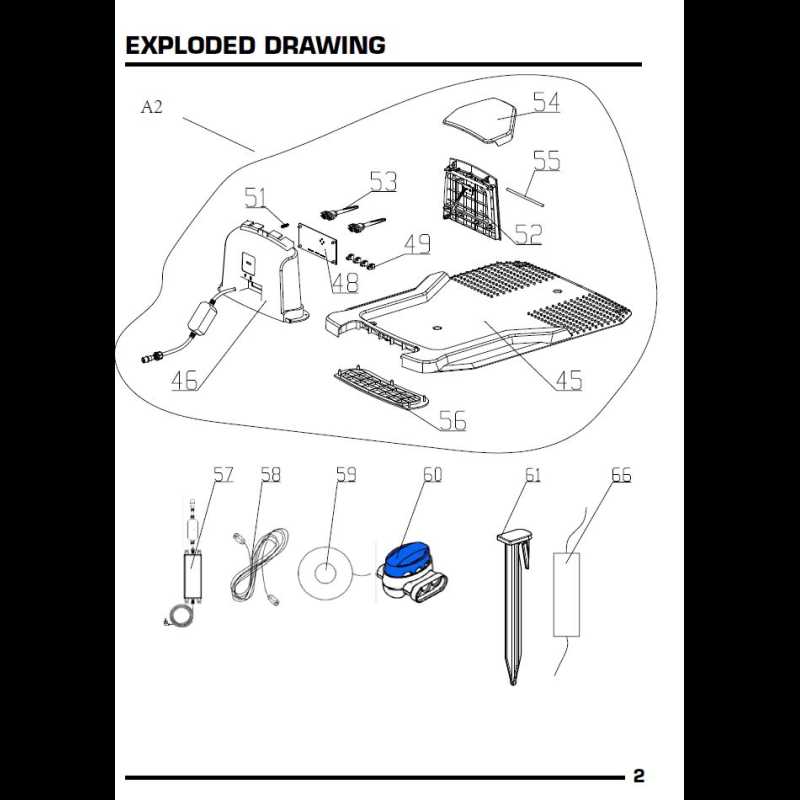

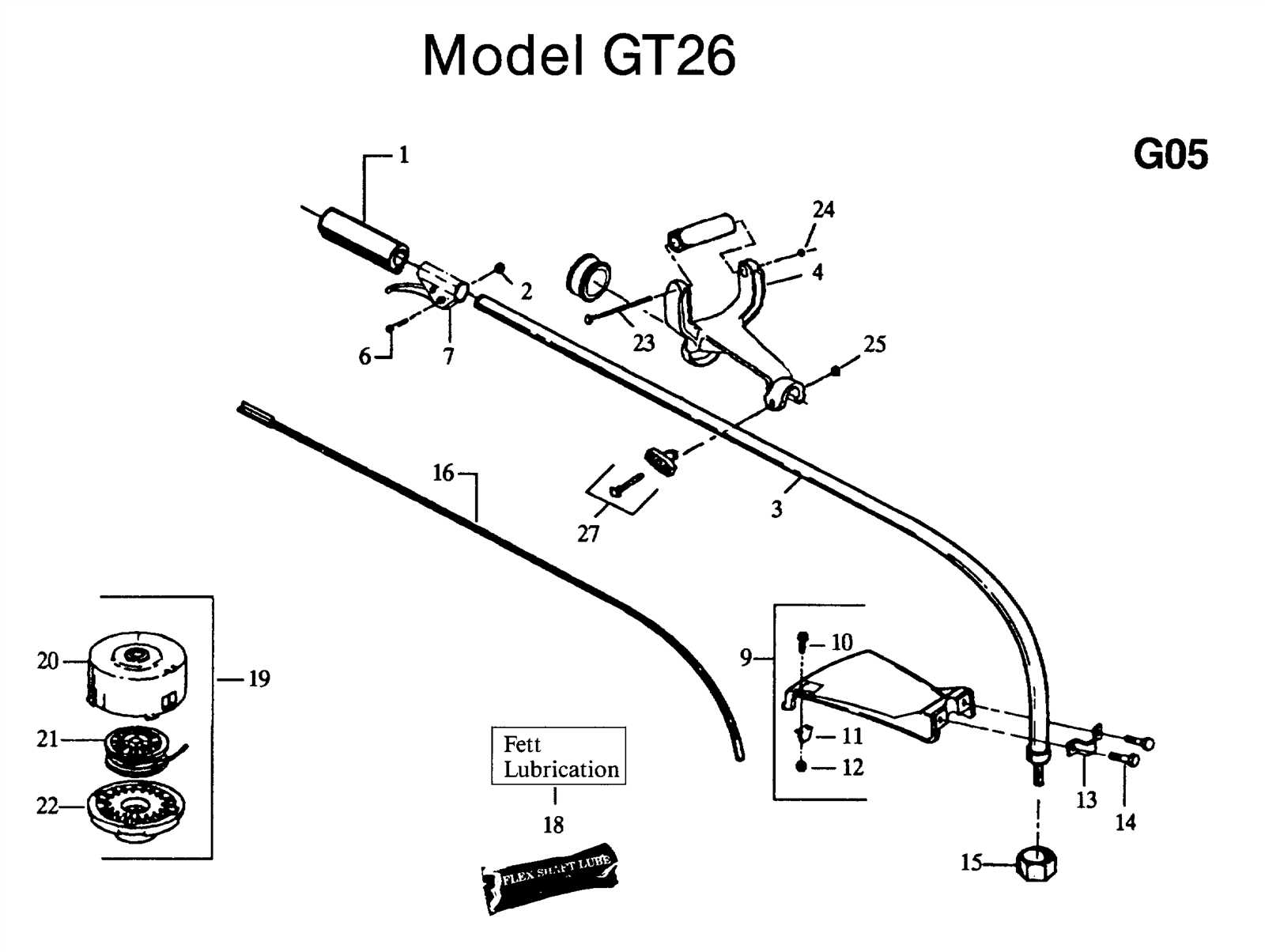

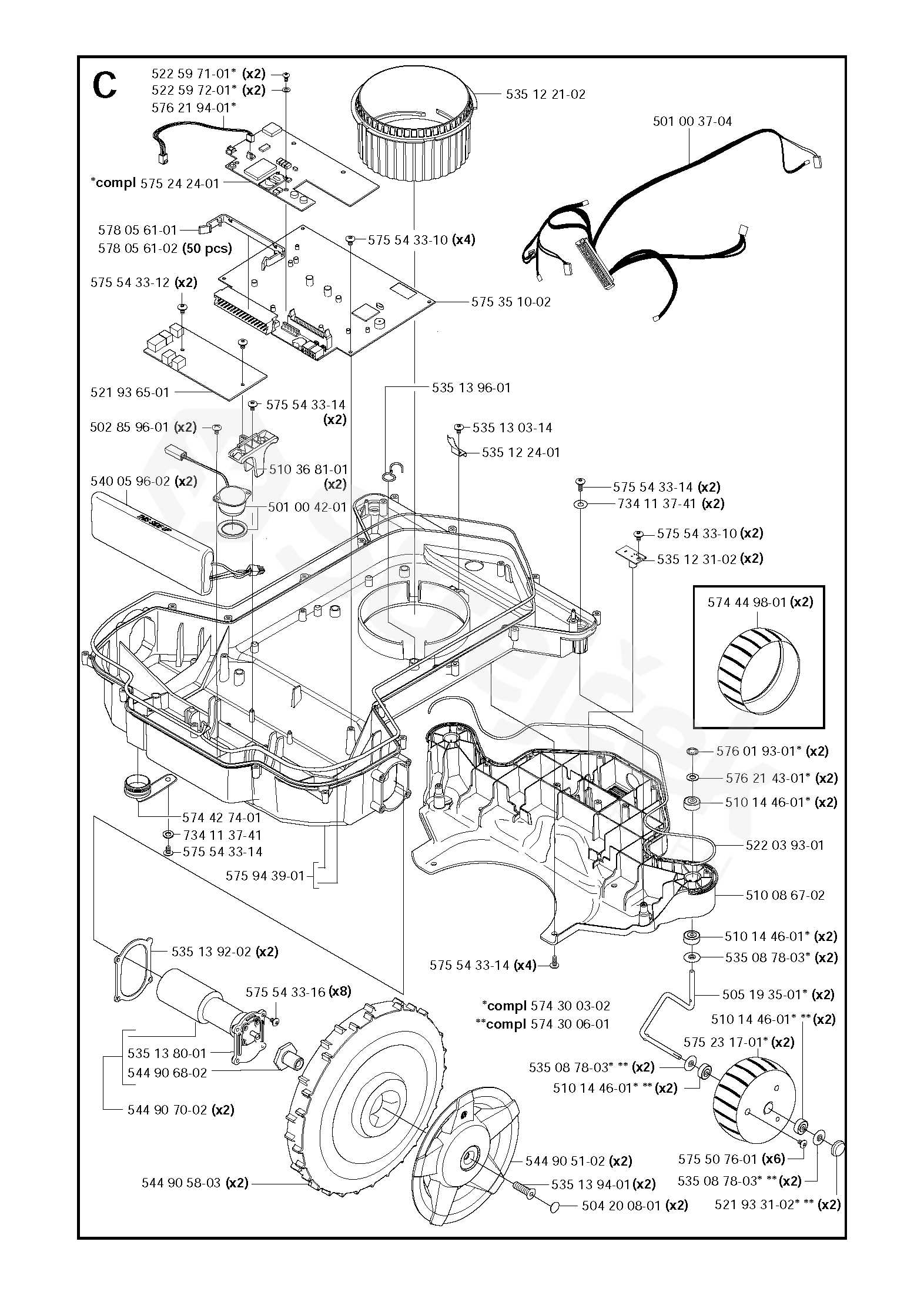

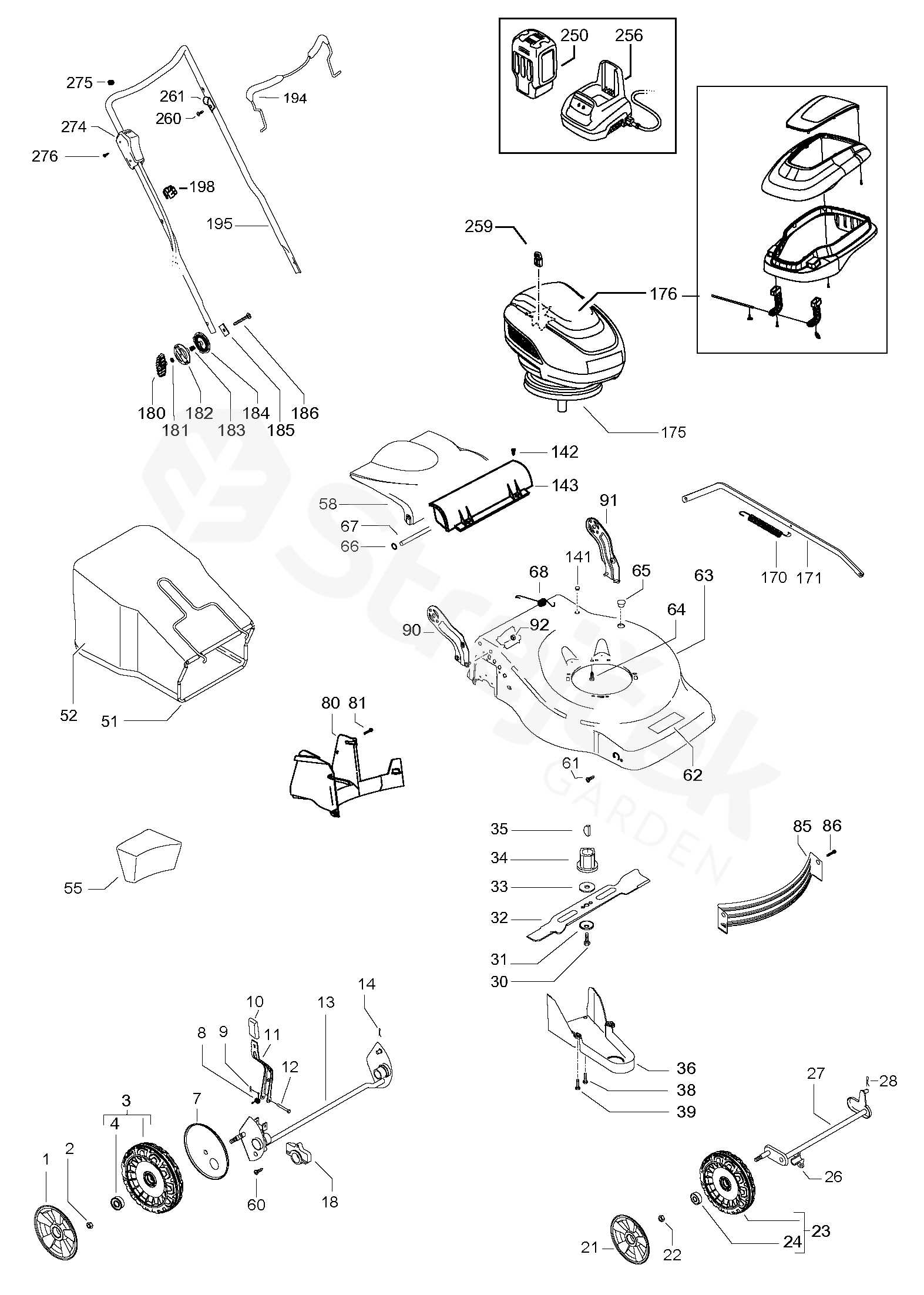

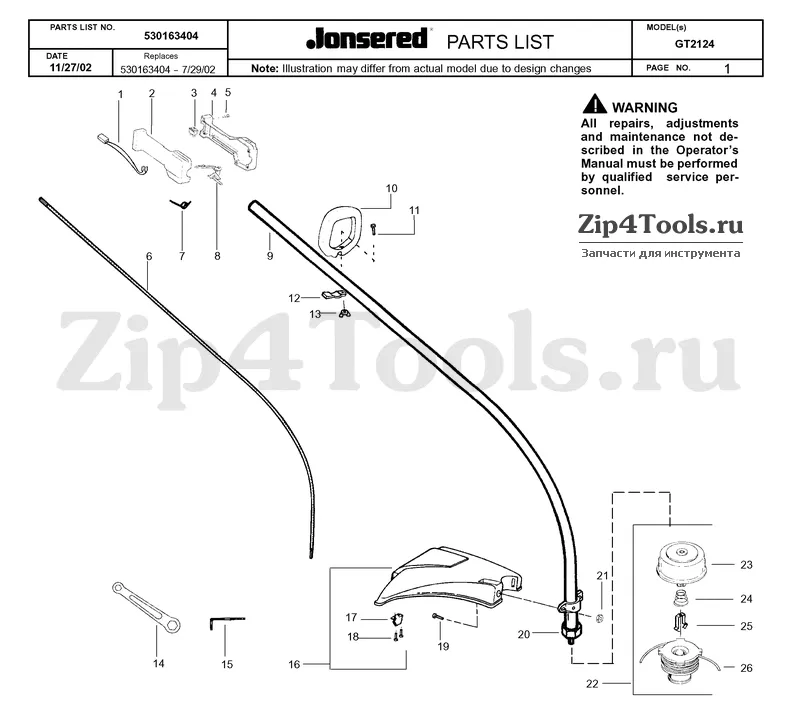

Importance of Parts Diagrams

Understanding the intricate details of mechanical devices is crucial for effective maintenance and repair. Visual representations that outline individual components play a vital role in facilitating this understanding. They provide a clear roadmap, enabling users to identify and locate each element within a complex assembly.

Clarity and Precision are essential when working with machinery. These visual aids break down complicated structures into manageable sections, allowing for easier troubleshooting and assembly. Users can reference these illustrations to ensure that every component is properly installed and functioning as intended.

Moreover, enhanced communication among technicians and hobbyists is another significant benefit. By utilizing a standardized visual format, individuals can discuss issues and solutions more effectively, reducing the likelihood of misunderstandings. This fosters a collaborative environment where knowledge can be shared seamlessly.

Additionally, these representations serve as an invaluable resource for education and training. Newcomers to the field can quickly familiarize themselves with the layout and function of various elements, accelerating their learning curve and improving their hands-on skills.

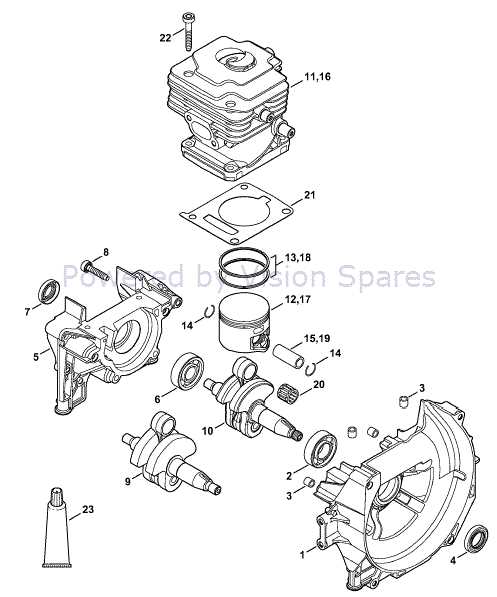

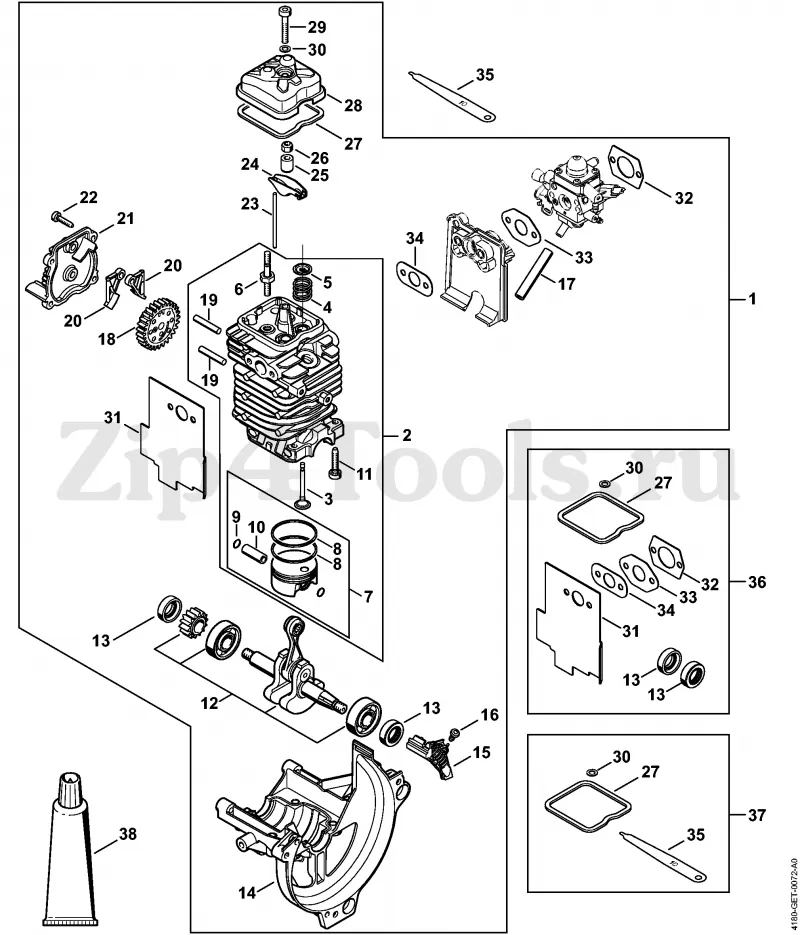

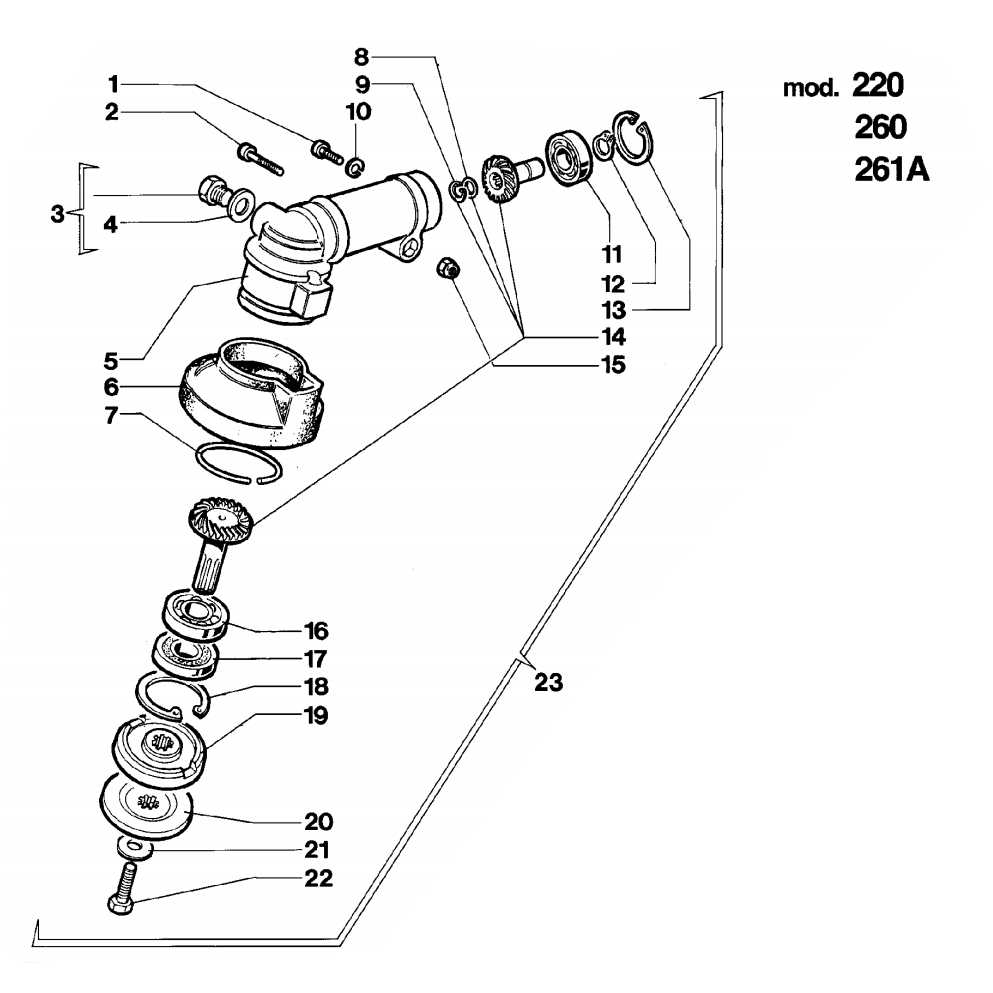

Key Components of Jonsered 260

This section explores the essential elements that contribute to the functionality and performance of a popular outdoor power tool. Understanding these components is crucial for maintenance and effective operation.

- Engine: The heart of the machine, responsible for converting fuel into mechanical energy.

- Bar and Chain: These elements work together to perform cutting tasks efficiently.

- Air Filter: Essential for keeping dirt and debris out of the engine, ensuring optimal performance.

- Fuel Tank: Stores the necessary fuel for operation, designed for easy refueling.

- Starter System: Facilitates the ignition process, allowing the engine to start quickly.

- Throttle Control: Regulates engine speed, giving the user better control during operation.

Each of these components plays a vital role in the overall performance, contributing to the efficiency and longevity of the tool.

How to Read Parts Diagrams

Understanding technical illustrations is essential for efficient maintenance and repair of machinery. These visual representations provide a clear layout of components, enabling users to identify and locate individual items quickly. Mastering the ability to interpret these schematics can greatly enhance one’s troubleshooting skills and overall efficiency.

1. Familiarize Yourself with Symbols: Each illustration uses specific symbols to represent various elements. Take time to learn these conventions, as they streamline the process of identifying parts.

2. Pay Attention to Numbers: Usually, numbers accompany each item, linking them to corresponding descriptions or lists. This reference system is crucial for ordering replacements or understanding assembly procedures.

3. Use a Legend: Many illustrations include a legend that clarifies the meaning of symbols and numbers. Referencing this can save time and prevent confusion.

4. Focus on the Layout: The arrangement of components often indicates their relationships. Observing how parts connect can provide insight into how they function together.

5. Cross-Reference with Manuals: For the ultimate understanding, consult product manuals or service guides alongside the visuals. This comprehensive approach will deepen your knowledge and improve repair accuracy.

Common Issues with Jonsered 260

When operating a powerful outdoor tool, users often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems is crucial for effective maintenance and ensuring longevity. From fuel system troubles to mechanical wear, each issue requires attention to keep the equipment functioning optimally.

Fuel System Challenges

One frequent concern involves the fuel delivery mechanism. Clogs in the fuel filter or lines can lead to poor engine performance, causing the machine to stall or run inconsistently. Ensuring that the fuel is clean and the system is free from obstructions is vital for smooth operation. Additionally, issues with the carburetor, such as incorrect adjustment or wear, can hinder the power output and responsiveness.

Mechanical Wear and Tear

Over time, components may experience wear that impacts the overall functionality. Common symptoms include reduced power, unusual vibrations, or difficulty starting. Regular inspection of the chain, bar, and drive mechanisms can help identify early signs of deterioration. Addressing these issues promptly can prevent more extensive damage and costly repairs down the line.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your outdoor power equipment requires regular care and attention. By following a few essential practices, you can enhance performance and extend the lifespan of your tools. These tips focus on routine maintenance tasks that help prevent wear and tear, ensuring reliable operation for years to come.

Regular Cleaning

Keeping your equipment clean is crucial for optimal performance. Dirt and debris can cause overheating and mechanical issues. After each use, wipe down surfaces and remove any accumulated residue. Pay special attention to air filters and cooling fins, as they can significantly impact efficiency.

Routine Inspections

Conducting periodic inspections is vital for identifying potential problems before they escalate. Check components for wear, ensuring that all parts are securely attached and functioning correctly. Look for signs of damage or fatigue, and address any issues promptly to maintain operational integrity.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Clean exterior surfaces | After each use | Prevents overheating and improves efficiency |

| Inspect components | Monthly | Identifies wear and prevents breakdowns |

| Replace filters | Every season | Enhances performance and extends engine life |

| Check fuel system | Before use | Ensures reliable starts and smooth operation |

Finding Replacement Parts Online

Locating suitable components for outdoor equipment can be a daunting task. However, the internet offers a plethora of resources to simplify this process. By utilizing various online platforms, users can effectively identify and acquire the necessary items to ensure their tools operate at peak performance.

Here are some strategies to enhance your search:

- Specialized Retailers: Many websites focus specifically on outdoor machinery. These retailers often have extensive inventories and knowledgeable customer service teams.

- Manufacturer Websites: Visiting the official website of the manufacturer can provide access to original components, ensuring quality and compatibility.

- Marketplace Platforms: Websites like eBay and Amazon feature numerous sellers offering new and used items, sometimes at discounted prices.

- Online Forums and Communities: Engaging with online groups can provide valuable insights and recommendations for sourcing items.

Before making a purchase, consider the following tips:

- Verify Compatibility: Always confirm that the item is suitable for your specific equipment model.

- Check Reviews: Read feedback from other customers to gauge the reliability of the seller and the quality of the products.

- Compare Prices: Take the time to compare costs across different platforms to ensure you’re getting the best deal.

- Review Return Policies: Understanding the return policy can save you from potential issues if the item doesn’t meet your expectations.

By following these guidelines, you can confidently navigate the vast online marketplace and find the components you need to keep your equipment running smoothly.

Comparing Jonsered Models

This section explores the nuances and differences among various models from a renowned manufacturer in the outdoor power equipment sector. By examining their features, capabilities, and performance metrics, users can make informed choices based on their specific needs and preferences.

Performance and Efficiency

When assessing different machines, it’s essential to consider their operational efficiency and power output. Some models boast enhanced engines that offer superior torque and speed, making them suitable for heavy-duty tasks. Others may prioritize fuel economy, providing longer run times for less demanding applications.

Features and Usability

Each variant presents unique characteristics that cater to different user requirements. While some machines may include advanced safety features and ergonomic designs for comfort, others focus on simplicity and ease of maintenance. Understanding these aspects can significantly impact user experience and overall satisfaction.

Repair Techniques for DIY Enthusiasts

For those who take pride in fixing their own equipment, understanding various repair methods is essential. This section provides insights into effective strategies and techniques that can empower hobbyists to tackle maintenance and restoration projects confidently.

Whether dealing with mechanical failures or routine upkeep, mastering certain approaches can greatly enhance your skills. Here are some fundamental techniques that every DIY enthusiast should consider:

| Technique | Description |

|---|---|

| Disassembly | Carefully taking apart the machinery to access internal components for inspection and repair. |

| Cleaning | Removing dirt, debris, and buildup to ensure smooth operation and prevent future issues. |

| Lubrication | Applying appropriate oils or greases to moving parts to reduce friction and wear. |

| Replacement | Identifying worn or damaged components and substituting them with new or refurbished parts. |

| Reassembly | Putting all components back together methodically, ensuring everything is secured properly. |

By incorporating these techniques into your repair process, you can not only extend the life of your equipment but also gain valuable experience in mechanical skills and problem-solving.

Expert Recommendations for Users

For enthusiasts and operators, understanding the intricacies of their equipment is crucial for optimal performance and longevity. Expert insights can significantly enhance user experience by ensuring maintenance is both effective and efficient.

Essential Maintenance Tips

Regular upkeep is vital for sustained operation. Consider the following recommendations:

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 25 hours | Use high-quality lubricant for best results. |

| Filter Inspection | Every 50 hours | Replace if clogged or damaged. |

| General Cleaning | After each use | Remove debris and check for wear. |

Safety Precautions

Ensuring safety is paramount during operation. Adhere to the following guidelines:

- Always wear appropriate protective gear.

- Conduct a pre-use inspection.

- Follow manufacturer’s safety recommendations.