Jotul F400 Parts Breakdown

When it comes to maintaining the efficiency and longevity of a heating system, familiarity with its key elements is essential. Each component plays a crucial role in ensuring that the device operates safely and effectively. Knowing how these elements function together helps in diagnosing potential issues and performing necessary upkeep.

The internal structure of such units can seem complex at first glance, but breaking it down into smaller sections makes it more approachable. By understanding the various elements, owners can better manage repairs and replacements, keeping their heating systems in top condition.

In the following sections, we will explore the essential aspects of these systems, focusing on the key components that are critical to their smooth operation. Whether you’re looking to address minor issues or are simply curious about how your appliance works, gaining insight into its structure can be invaluable.

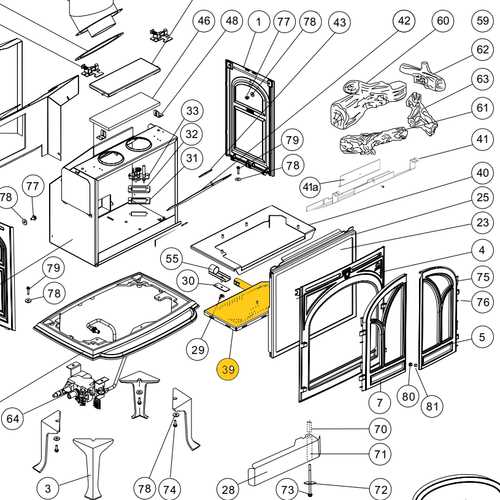

Jotul F400 Components Overview

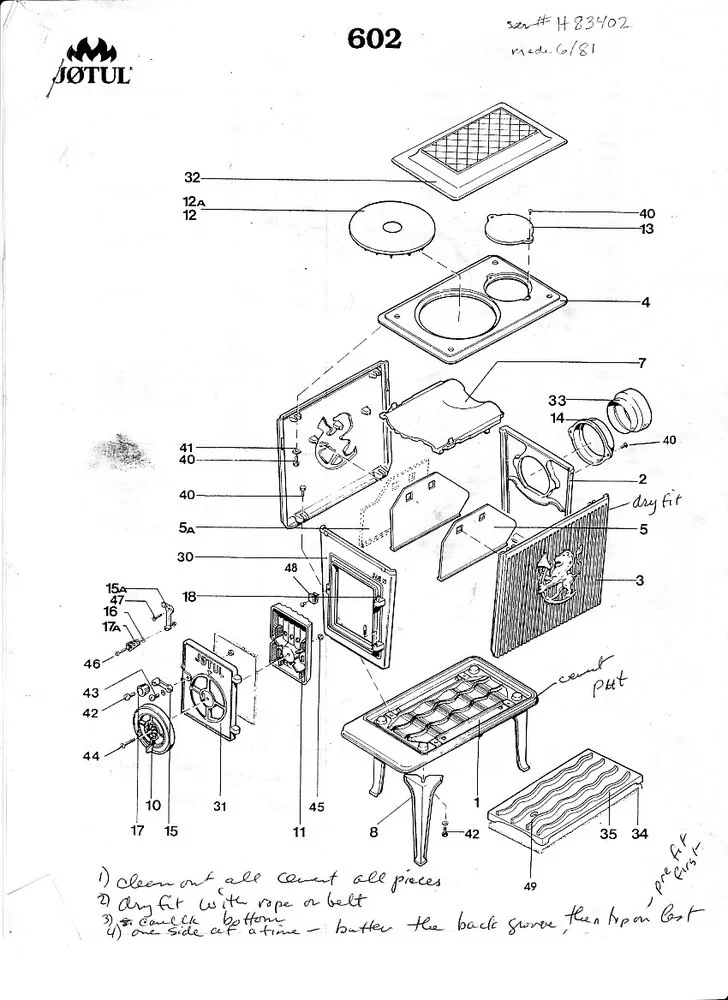

This section provides a detailed exploration of the individual elements that contribute to the efficient operation of the stove. Understanding how each component interacts is essential for maintaining the appliance in optimal condition and ensuring its long-term performance.

Key elements include the heat distribution system, which ensures even warmth throughout the space, and the combustion area, designed to maximize fuel efficiency. Other integral pieces work together to maintain airflow, regulate temperatures, and enhance the overall functionality. Each of these components is engineered to provide both safety and durability during use.

Firebox Construction and Key Elements

The design of the firebox plays a crucial role in the efficiency and durability of any wood-burning system. Its construction not only determines how heat is retained and distributed but also ensures the safety and longevity of the structure. Several key components contribute to the overall performance, making it essential to understand how each element functions.

Primary Materials

The firebox is typically crafted from heat-resistant materials such as cast iron or steel. These materials are chosen for their ability to withstand extreme temperatures while maintaining structural integrity. Cast iron, for example, offers excellent heat retention, allowing the firebox to radiate warmth long after the fire has died down. Steel, on the other hand, is known for its durability and faster heat transfer.

Internal Components

Within the firebox, elements like baffle plates and burn tubes play vital roles in enhancing combustion efficiency. Baffle plates redirect heat and smoke, increasing the heat exchange inside the unit, while burn tubes help in reigniting unburnt gases, leading to cleaner and more complete combustion. Together, these elements ensure optimal performance while reducing

Air Vent System Functionality

The air vent system plays a crucial role in managing airflow within a heating appliance. By regulating the intake and circulation of air, the system ensures efficient combustion and heat distribution, contributing to overall performance. Understanding its operation can help improve both energy efficiency and user control over temperature.

Air Flow Regulation

Airflow is controlled through adjustable vents that allow the user to manage the intensity of the fire. When the vent is more open, oxygen flows more freely, creating a hotter burn. Conversely, reducing the airflow helps to maintain a slower, more consistent flame. Proper use of these controls can significantly impact fuel consumption and heat output.

Components Overview

The vent system consists of several key components, each working together to optimize air intake and exhaust. The table below highlights these essential elements:

| Component | Function |

|---|---|

| Primary Vent | Regulates the initial oxygen supply for ignition. |

| Secondary Vent | Maintains the air supply for sustained combustion. |

| Exhaust Flue | Channels smoke and gases safely out of the system. |

Door Assembly and Sealing Mechanism

The door system is an essential component that ensures the efficient operation of a heating unit by providing a secure closure. Proper alignment and sealing of the door are critical to maintaining internal heat and preventing air leaks, which can affect both performance and safety. This section explains the key elements of the door structure and the sealing process, emphasizing their role in creating an airtight environment.

The door itself is typically made from durable materials designed to withstand high temperatures. It is mounted on hinges, allowing for easy access when adding fuel or cleaning the interior. A reliable latch mechanism ensures that the door remains securely closed during use, preventing any accidental openings.

Sealing the door is crucial for maintaining energy efficiency. A heat-resistant gasket is fitted around the edges of the door frame, creating a tight seal when the door is closed. Over time, this gasket may wear down and require replacement to preserve its effectiveness in preventing airflow and retaining heat within the unit.

Heat Shields and Safety Features

Heat shields play a crucial role in enhancing the safety and efficiency of heating appliances. These components are designed to minimize the risk of overheating and ensure the safe operation of the system by preventing excess heat from reaching sensitive areas. Additionally, they help to improve the overall durability of the unit.

Functionality of Heat Shields

By creating a barrier between the heating system and nearby surfaces, heat shields reduce the amount of radiant heat escaping into the environment. This not only protects surrounding materials from heat damage but also optimizes the heating performance. Properly installed shields can extend the lifespan of the system while maintaining high safety standards.

Additional Safety Considerations

Beyond heat shields, modern heating systems often incorporate a range of safety features. These include automatic shut-off mechanisms, temperature regulators, and protective barriers to prevent accidental contact with hot surfaces. Regular maintenance and inspections are essential to ensure that these safety features continue to function properly, helping to reduce the risk of hazards in both residential and commercial settings.

Glass Panel Replacement Guide

Replacing the glass panel of your heating appliance is a straightforward task that can enhance its performance and aesthetics. This guide will provide you with step-by-step instructions to ensure a successful replacement process.

Before you begin, gather the necessary tools and materials:

- Replacement glass panel

- Screwdriver

- Gloves

- Protective eyewear

- Sealant or gasket material

Follow these steps for a smooth replacement:

- Ensure Safety: Turn off the appliance and allow it to cool completely before starting.

- Remove the Old Panel: Carefully detach any screws or clips holding the existing glass in place. Gently lift the old panel away.

- Prepare the Frame: Inspect the frame for any damage or debris. Clean the area thoroughly to ensure a proper seal for the new glass.

- Install the New Panel: Place the new glass panel into the frame, ensuring it fits snugly. Use sealant or gasket material as needed to secure it.

- Reattach Fasteners: Secure the new panel by replacing the screws or clips. Ensure everything is tightened appropriately.

- Final Check: Inspect the installation for any gaps or loose fittings. Ensure that the glass is properly seated and secure.

Once the replacement is complete, you can resume using your appliance. Regular maintenance and timely replacements will help maintain efficiency and safety.

Handle and Latch Mechanisms Explained

The mechanisms responsible for handles and latches play a crucial role in ensuring the secure and efficient operation of various appliances. These components not only facilitate ease of access but also contribute to safety and functionality. Understanding their design and operation can help users maintain their equipment more effectively.

Functionality of Handle Mechanisms

Handles are designed to provide a comfortable grip, allowing users to operate doors or lids smoothly. They can come in various shapes and materials, each influencing the ease of use and durability. A well-designed handle ensures that the user can easily apply the necessary force without compromising safety.

Latch Mechanism Overview

The latch mechanism is essential for securing doors or covers in place. It operates by engaging with a catch or strike plate, preventing unintended openings. Different types of latches, such as slide bolts or cam latches, offer varying levels of security and ease of use, catering to different requirements and preferences.

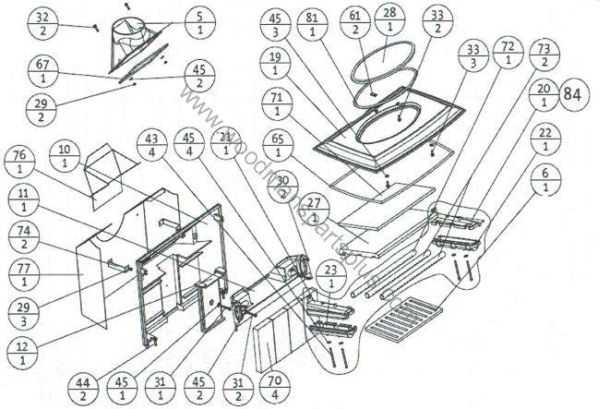

Internal Baffle System Components

The internal baffle system plays a crucial role in the overall efficiency and performance of a heating appliance. This system is designed to optimize airflow, enhancing combustion and ensuring the effective transfer of heat. Understanding its components can provide insight into how the unit operates and contributes to energy efficiency.

Baffle Plates

Baffle plates are the primary elements within the system, guiding the flow of flue gases. These plates are strategically positioned to redirect exhaust gases, allowing for better heat exchange and minimizing the loss of energy. Their design is essential for maintaining optimal temperatures within the combustion chamber.

Insulation Materials

Another key aspect of the internal baffle system is the use of insulation materials. These components help to retain heat and prevent energy loss through the walls of the unit. Proper insulation not only enhances efficiency but also contributes to the longevity of the heating appliance by reducing thermal stress.

Burner Plate and Grate Layout

The arrangement of the burner plate and grates plays a crucial role in optimizing the efficiency of your heating appliance. Understanding how these components fit together can enhance performance and prolong the lifespan of the unit.

Proper installation and maintenance of these elements ensure even heat distribution and effective combustion. Here are key considerations:

- Material: Choose high-quality materials that withstand high temperatures and resist warping.

- Configuration: Ensure the layout allows for optimal airflow, which is essential for efficient burning.

- Cleaning: Regularly remove ash and debris from the grates to maintain proper functionality.

Additionally, paying attention to the specific design of the burner plate can influence heat retention and distribution:

- Ensure that the burner plate sits flush with the base of the unit.

- Check for proper alignment with the grates to avoid gaps that could affect heat efficiency.

- Inspect the grates for any signs of wear and replace them when necessary to maintain optimal performance.

By understanding the importance of these components and their arrangement, users can significantly improve the effectiveness of their heating systems.

Ash Pan Structure and Maintenance

The ash pan is an essential component of a combustion appliance, designed to collect the residue produced during the burning process. Its efficient structure not only facilitates easy cleanup but also plays a vital role in maintaining optimal performance and safety. Understanding its construction and care is crucial for ensuring longevity and functionality.

Construction Details

The ash receptacle typically features a robust design, often made from heat-resistant materials to withstand high temperatures. It is usually positioned at the base of the combustion chamber, allowing for easy access. Some models may include a sliding mechanism or handles to simplify removal and emptying, enhancing user convenience.

Maintenance Practices

Regular upkeep of the ash collection unit is essential for optimal operation. It is advisable to empty the pan frequently to prevent excessive buildup, which can lead to blockages and affect airflow. Cleaning the unit with a damp cloth can help remove residue and prevent corrosion. Additionally, checking for any wear and tear ensures that the component remains in good condition and functions effectively.

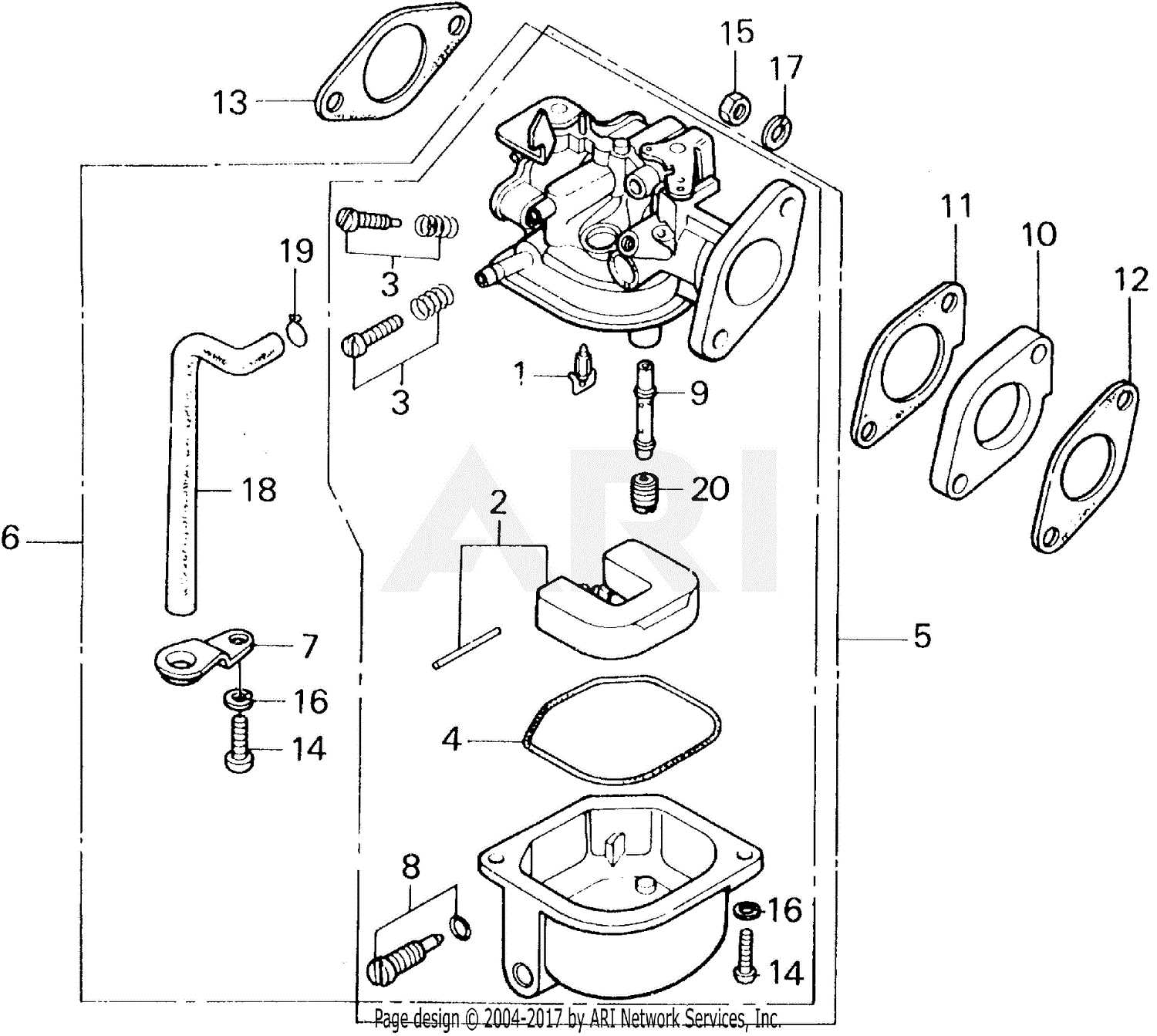

Combustion Air Control Parts

Effective regulation of combustion air is crucial for optimizing performance and efficiency in heating appliances. This section focuses on components that facilitate the management of airflow, ensuring an ideal mixture for combustion processes.

Key Components

- Air Control Damper: Adjusts the volume of air entering the combustion chamber.

- Inlet Grille: Allows fresh air to enter the system, crucial for maintaining proper combustion.

- Ventilation Pipe: Channels air from outside to ensure a consistent supply of oxygen.

Functionality and Importance

Each component plays a significant role in achieving efficient combustion. Properly functioning air control elements help in:

- Enhancing fuel efficiency

- Reducing emissions

- Improving overall appliance longevity

Diagram of Heat Exchange Pathways

Understanding the routes through which heat is transferred is essential for optimizing efficiency in heating appliances. This section outlines the various channels involved in the heat transfer process, providing a clearer insight into how thermal energy circulates within the system.

The heat exchange pathways can be categorized into several components, each playing a crucial role in ensuring effective thermal management:

- Combustion Chamber: The area where fuel is burned, generating heat that initiates the transfer process.

- Heat Exchanger: A device designed to maximize contact between hot gases and surrounding surfaces, allowing for efficient heat transfer.

- Flue System: The route through which exhaust gases exit, ensuring that the heat remains within the appliance as long as possible.

- Surrounding Materials: The materials encasing the heating unit, which absorb and radiate the heat into the environment.

By examining these pathways, users can better understand how heat moves through the appliance and how to enhance its overall performance.