Understanding the Jrb Quick Coupler Parts Diagram

In the realm of heavy machinery, the efficiency of operations often hinges on the quality and design of various attachment systems. These systems are critical for seamless transitions between tools and equipment, enhancing productivity and ensuring safety during use. A thorough exploration of these mechanisms reveals intricate designs that facilitate swift and secure connections.

Within this context, it is essential to delve into the specific components that constitute these systems. Each element plays a pivotal role, contributing to the overall functionality and reliability of the connections. Understanding these components not only aids in maintenance but also assists operators in optimizing their equipment for varied tasks.

The ultimate goal of comprehending these mechanisms lies in improving operational efficiency and reducing downtime. By familiarizing oneself with the intricacies of these systems, users can ensure their machinery performs at its best, ultimately leading to enhanced performance in demanding environments.

Understanding JRB Quick Coupler Functionality

The mechanism in question serves a crucial role in enhancing the efficiency of heavy machinery. It allows for the swift attachment and detachment of various tools, making operations more flexible and productive. This innovation simplifies tasks and minimizes downtime, ensuring that equipment can adapt to different demands with ease.

Operational Principles

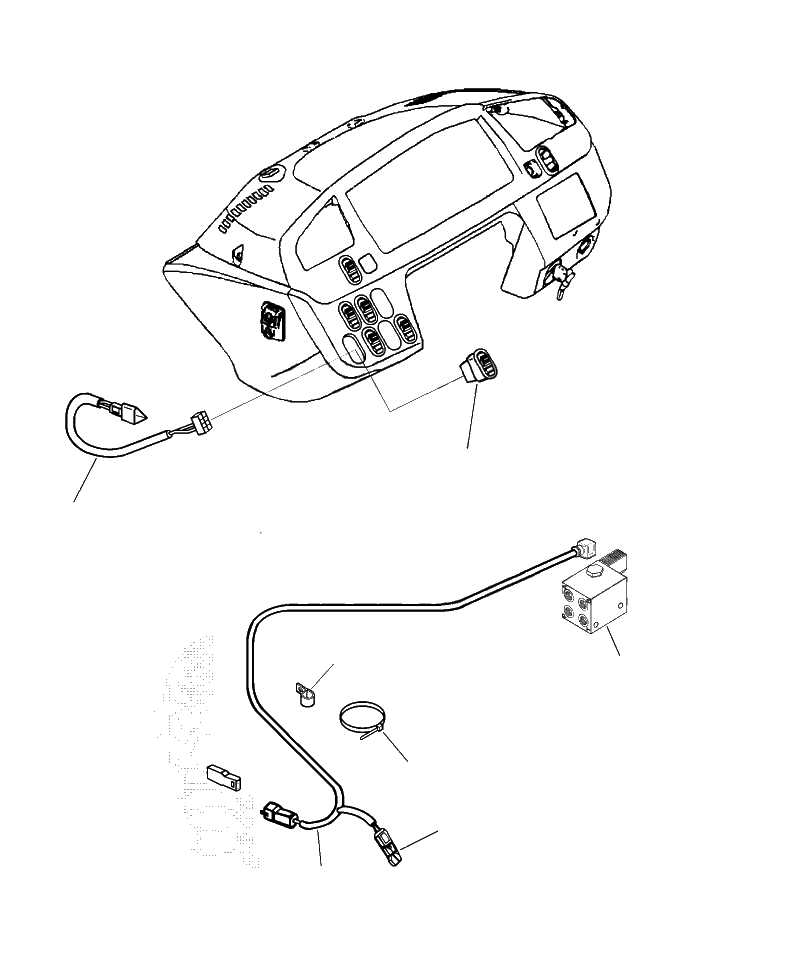

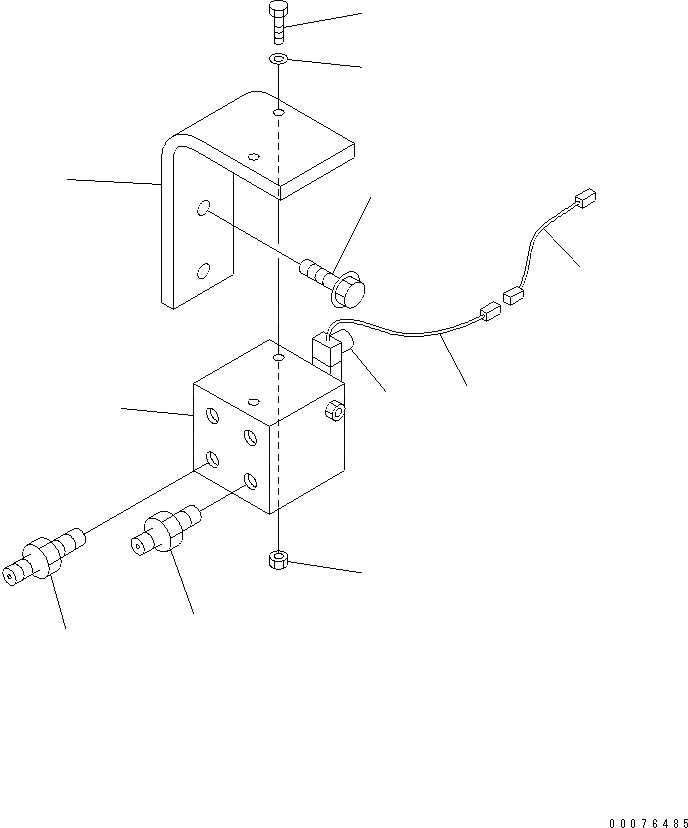

At its core, this system relies on a robust design that facilitates seamless interactions between the machinery and its attachments. Utilizing hydraulic pressure, it engages and releases components effortlessly, enabling operators to switch implements without leaving their cab. This automation enhances precision and reduces the physical strain on users.

Benefits and Applications

The advantages of employing such a system are manifold. It not only accelerates workflow but also improves safety by minimizing manual handling. Industries such as construction, landscaping, and agriculture benefit immensely, as they require rapid changes in tooling to tackle varying tasks. Ultimately, this versatility enhances overall operational productivity.

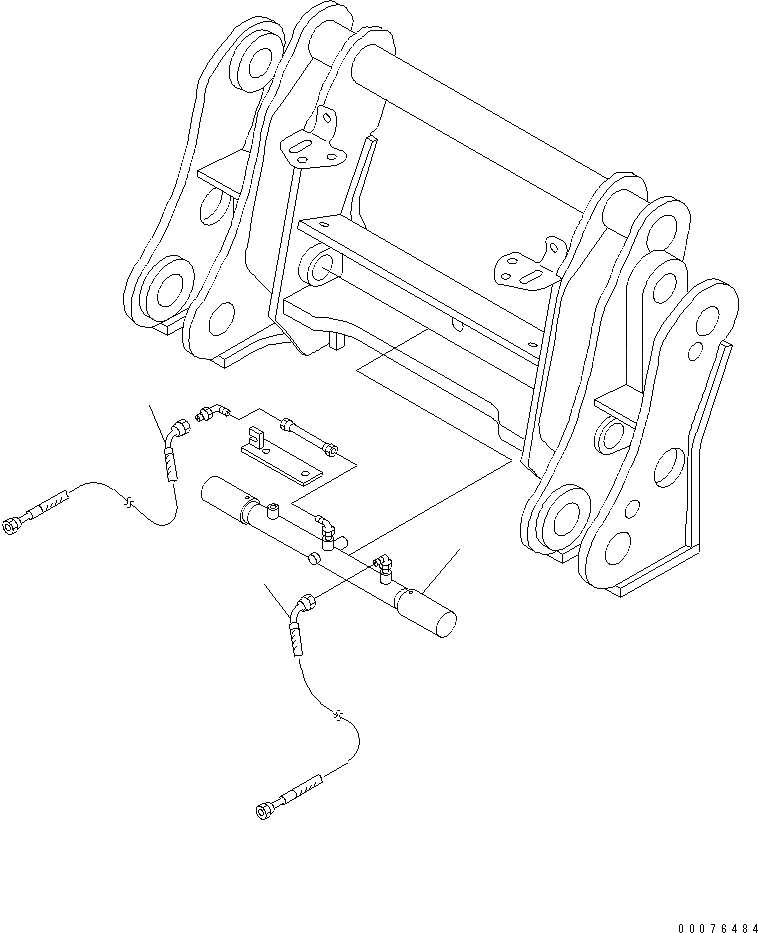

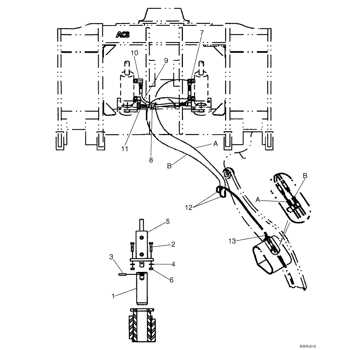

Components of JRB Quick Couplers

This section explores the essential elements that constitute an attachment mechanism designed for seamless interface between various tools and machinery. Each component plays a critical role in ensuring efficiency, safety, and adaptability in heavy equipment operations.

Main Elements

The primary components are crafted to enhance functionality and durability. These elements are designed to withstand significant stress while providing a reliable connection. Understanding these parts is crucial for optimal performance and maintenance.

| Component Name | Function |

|---|---|

| Body | Houses all other components and provides structural integrity. |

| Locking Mechanism | Ensures secure attachment and detachment of tools. |

| Pins | Facilitates the connection between the body and various implements. |

| Hydraulic Cylinder | Operates the locking mechanism, enabling smooth operation. |

Additional Features

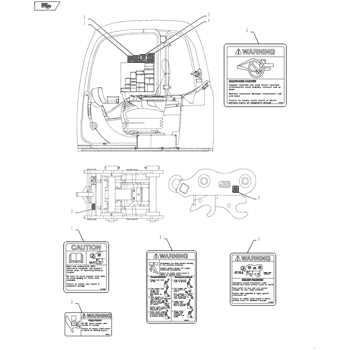

Other supplementary elements contribute to the overall efficiency and safety of the system. These features often include safety locks and indicators that provide operators with immediate feedback on the attachment status. Regular maintenance of these components is essential to prolong the lifespan and ensure reliable operation.

Importance of Coupler Diagrams

Understanding the layout and components of attachment systems is crucial for efficient machinery operation. These visual representations serve as essential tools for both maintenance and assembly, ensuring seamless functionality in various applications.

- Facilitates Maintenance: Clear visuals help technicians identify parts quickly.

- Enhances Training: New operators can learn assembly and disassembly more effectively.

- Improves Safety: Correct understanding reduces the risk of errors during handling.

- Aids in Troubleshooting: Identifying faults becomes simpler with a clear layout.

Incorporating these visuals into training programs can ultimately lead to increased efficiency and reduced downtime.

How to Read a Parts Diagram

Understanding a schematic representation is essential for efficient assembly and repair. This guide provides key insights into interpreting these visual tools effectively.

Begin with the following steps:

- Familiarize Yourself with Symbols: Recognize common icons and notations that indicate various components.

- Identify the Layout: Observe how parts are arranged to comprehend their relationships and functions.

- Check the Numbering System: Numbers often indicate assembly order or specific sequences; pay attention to these details.

- Refer to the Legend: Utilize the accompanying key to clarify any unfamiliar terms or symbols.

By following these guidelines, you can delve into the intricacies of any schematic and enhance your understanding of the assembly process.

Common Issues with Quick Couplers

When utilizing attachment mechanisms, several challenges may arise that can hinder performance and efficiency. These complications often stem from wear and tear, improper maintenance, or design flaws, impacting the overall functionality of the equipment.

One prevalent concern is the accumulation of debris and contaminants in the connection points, which can lead to improper seating and disengagement during operation. Additionally, inadequate lubrication may result in increased friction, causing premature wear or even failure of components.

Another issue is the misalignment of parts, often due to operator error or lack of attention during installation. This misalignment can strain the mechanism, leading to breakdowns or decreased efficiency. Regular inspection and proper training can mitigate these risks.

Lastly, environmental factors such as extreme temperatures and exposure to corrosive substances can further exacerbate these problems. Understanding these common challenges can ultimately enhance the longevity and reliability of attachment systems.

Maintenance Tips for JRB Couplers

Proper upkeep of your attachment system is crucial for ensuring longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected failures. Here are essential practices to keep your equipment in top condition.

Regular Inspections

Conduct routine checks to identify wear and tear. Look for signs of corrosion, cracks, or loose components. Early detection can prevent minor issues from escalating into major repairs. Ensure that all fasteners are tight and that there are no obstructions that could hinder operation.

Lubrication and Cleaning

Keep moving parts well-lubricated to reduce friction and prevent premature wear. Use high-quality grease recommended by the manufacturer. Regularly clean the attachment to remove dirt and debris, which can cause damage over time. Establish a maintenance schedule to ensure these tasks are performed consistently.

Choosing the Right Quick Coupler

Selecting the appropriate connector for your machinery is crucial for ensuring efficiency and safety. With various options available, understanding the specific requirements of your tasks is essential to make an informed decision.

First, assess the compatibility of the connector with your equipment. Consider factors such as size, weight capacity, and the type of attachments you will use. This will help avoid potential operational issues and enhance overall performance.

Next, evaluate the materials used in the construction of the connector. High-quality materials will provide durability and withstand harsh working conditions. Investing in robust options can lead to long-term cost savings.

Lastly, consult user reviews and expert recommendations. Real-world experiences can guide you toward reliable choices that suit your specific needs. By delving into feedback, you can find the ultimate solution for your requirements.

Installation Process Explained

The process of setting up connection mechanisms is crucial for ensuring optimal performance and safety in various applications. A clear understanding of the steps involved can greatly enhance efficiency and reduce the likelihood of errors during installation. This section outlines the essential stages and considerations necessary for a successful assembly.

Preparation Steps

Before beginning the installation, it is vital to gather all necessary tools and components. Ensure that the work area is clean and organized to prevent any interruptions. Reviewing the manufacturer’s guidelines and verifying compatibility with existing equipment will help in identifying the specific requirements and avoiding potential pitfalls.

Installation Procedure

Start by securely positioning the components, aligning them according to the specified instructions. Gradually tighten any fastening mechanisms, ensuring a snug fit without over-torquing. After the initial setup, conduct a thorough inspection to confirm that all elements are correctly placed. Finally, perform a functional test to verify that the assembly operates smoothly and meets all performance standards.

Upgrading Your Coupler System

Enhancing your attachment system can significantly improve the efficiency and versatility of your machinery. With advancements in technology and design, modern solutions offer better performance, easier operation, and increased durability. This section explores essential considerations and components necessary for upgrading your attachment mechanism.

Key Considerations for Improvement

When contemplating an upgrade, several factors should be evaluated to ensure the best fit for your equipment. Consider the compatibility with existing systems, the type of tasks you aim to accomplish, and the overall cost-effectiveness of the new components. Additionally, it’s crucial to assess the reliability and maintenance requirements of the new system.

Essential Components for Modernization

Upgrading your attachment mechanism often involves integrating new components designed for enhanced functionality. Below is a table listing common elements that can contribute to a more efficient system:

| Component | Description | Benefits |

|---|---|---|

| Interface Plate | Connects the attachment securely to the machine. | Improved stability and reduced wear. |

| Locking Mechanism | Ensures secure attachment during operation. | Enhanced safety and ease of use. |

| Hydraulic System | Provides power for movement and adjustments. | Increased precision and responsiveness. |

| Durable Materials | High-strength components that resist wear. | Longer lifespan and reduced maintenance costs. |

Frequently Asked Questions About Couplers

This section addresses common inquiries regarding attachment systems used in construction and heavy machinery. Understanding these components is crucial for efficient operations and maintenance.

- What is the primary function of these systems?

These mechanisms enable quick and secure connections between equipment and attachments, enhancing versatility and productivity. - How do I maintain these systems?

Regular inspections, cleaning, and lubrication are essential to ensure optimal performance and longevity. - What are the common issues associated with these mechanisms?

Typical problems include wear and tear, misalignment, and difficulty in disengagement. - Are there different types available?

Yes, various designs cater to specific needs, including manual and hydraulic options. - How can I choose the right system for my equipment?

Consider compatibility, load requirements, and operational environment when selecting a suitable model.