Understanding the Keihin CVK Carb Parts Diagram

In the realm of engine performance, a crucial aspect lies in the intricate systems responsible for blending fuel and air. This process not only impacts efficiency but also influences overall power output. For enthusiasts and mechanics alike, grasping the nuances of these assemblies is essential.

The various elements involved in these systems play a significant role in maintaining optimal function. From adjustable mechanisms to fixed fixtures, each component contributes to the ultimate goal of seamless operation. A detailed examination reveals the complexity and precision required for effective tuning and repair.

By exploring the structure and interactions of these vital mechanisms, one can gain a deeper insight into performance enhancement. This knowledge equips individuals to tackle maintenance and upgrades, ensuring engines run smoothly and efficiently.

Understanding Keihin CVK Carburetors

This section explores the mechanics and functions of a specific type of fuel delivery device commonly used in various engines. By examining its components and operational principles, one can gain insights into its significance for performance and efficiency.

Key Components

The device consists of several essential elements, including a float chamber, throttle body, and jets. Each component plays a crucial role in regulating fuel flow and air mixture, directly influencing engine performance and response.

Operational Principles

Understanding how this mechanism works involves delving into the interaction between air pressure and fuel flow. Adjustments to specific settings can ultimately optimize performance, making it vital for enthusiasts and mechanics alike to comprehend its intricacies.

Components of Keihin CVK Systems

This section explores the essential elements that contribute to the functionality and efficiency of specific fuel delivery systems. Each component plays a vital role in ensuring optimal performance and reliability, creating a harmonious balance within the entire mechanism.

Fuel Bowl: The reservoir that holds a consistent supply of fuel, maintaining pressure and enabling a steady flow to other parts.

Throttle Valve: This element regulates airflow, directly influencing the engine’s power output and response.

Float Assembly: A crucial component that maintains the fuel level within the bowl, ensuring proper operation and preventing overflow.

Jet System: A series of calibrated orifices that mix fuel with air, allowing for precise control over the air-fuel mixture for efficient combustion.

Needle Valve: This part controls the flow of fuel into the bowl, responding to changes in demand and maintaining system balance.

Choke Mechanism: Facilitating easier starts, this feature enriches the mixture by reducing airflow during initial ignition.

Air Filter: Essential for protecting the system, it prevents contaminants from entering and disrupting the fuel delivery process.

Understanding these components enables enthusiasts and technicians to delve deeper into maintenance and optimization strategies, ultimately enhancing performance and longevity.

Functionality of Carburetor Parts

The intricate design of fuel delivery mechanisms plays a crucial role in the overall performance of an engine. Each component within this system has a specific purpose that contributes to the efficient mixing of air and fuel, ensuring optimal combustion and engine responsiveness.

Key elements include:

- Throttle Valve: Regulates airflow, influencing the engine’s power output.

- Float Chamber: Maintains a consistent fuel level for stable operation.

- Jet Nozzles: Control the amount of fuel that enters the airflow, affecting the air-fuel ratio.

- Needle Valve: Manages fuel flow based on engine demand, ensuring efficiency across various RPMs.

- Choke Mechanism: Aids in starting the engine by enriching the fuel mixture when cold.

Understanding the roles of these components allows for better maintenance and tuning, ultimately enhancing the vehicle’s performance and reliability.

Common Issues with CVK Carburetors

The functionality of fuel delivery systems can be hindered by a variety of complications that impact performance and efficiency. Understanding these common problems is essential for proper maintenance and optimal operation.

Fuel Leaks are one of the most frequent issues encountered. These can arise from worn seals or gaskets, leading to a decrease in performance and potential fire hazards.

Clogged Jets often occur due to impurities in the fuel, resulting in restricted flow and poor acceleration. Regular cleaning is crucial to avoid this issue and maintain smooth operation.

Incorrect Air-Fuel Mixture can lead to stalling or rough idling. This can be attributed to misadjusted settings or blockages, making it necessary to check and adjust the mixture for optimal performance.

Sticky Float can cause flooding, where excess fuel enters the combustion chamber. This problem may stem from debris or improper float height, necessitating inspection and adjustment.

Performance Loss may be experienced if the throttle response becomes sluggish. This can result from various issues, including air leaks or internal wear, requiring thorough diagnostics to identify the cause.

Maintenance Tips for CVK Carbs

Regular upkeep of your fuel delivery system is essential for optimal engine performance. Proper care not only enhances efficiency but also prolongs the lifespan of components. Below are some practical suggestions to ensure your system operates smoothly.

1. Clean Regularly: Keep the fuel delivery components free from dirt and debris. Use a suitable cleaner to maintain clarity and function.

2. Check for Leaks: Inspect connections and seals frequently. Any signs of leakage can indicate wear and require immediate attention.

3. Adjust Settings: Periodically assess and fine-tune settings for air and fuel mixtures to ensure peak performance.

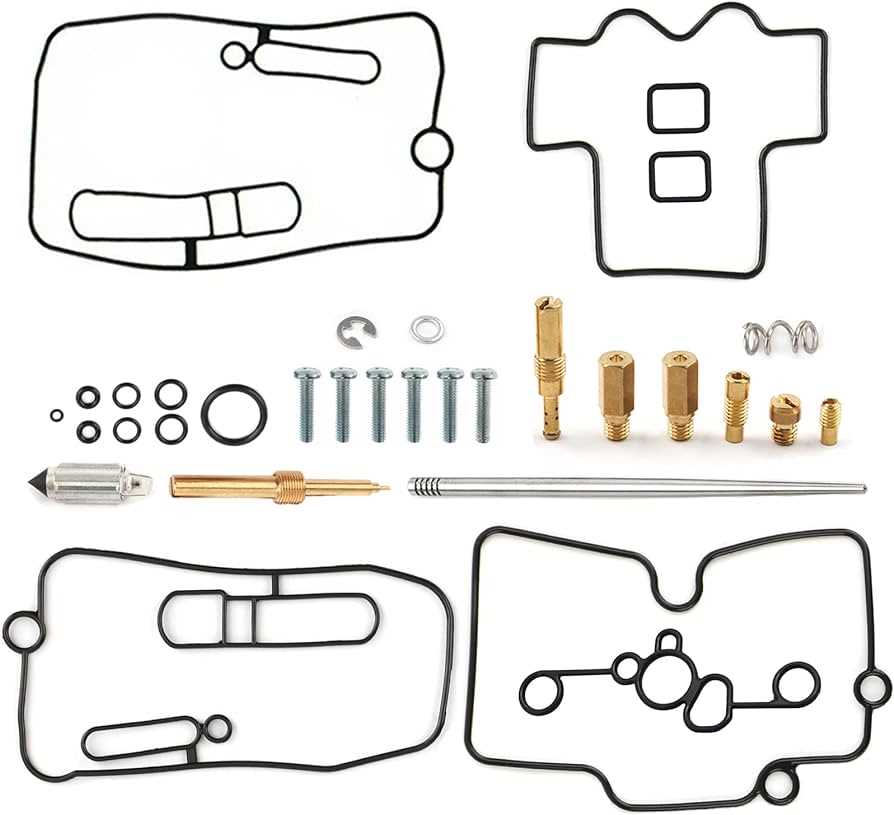

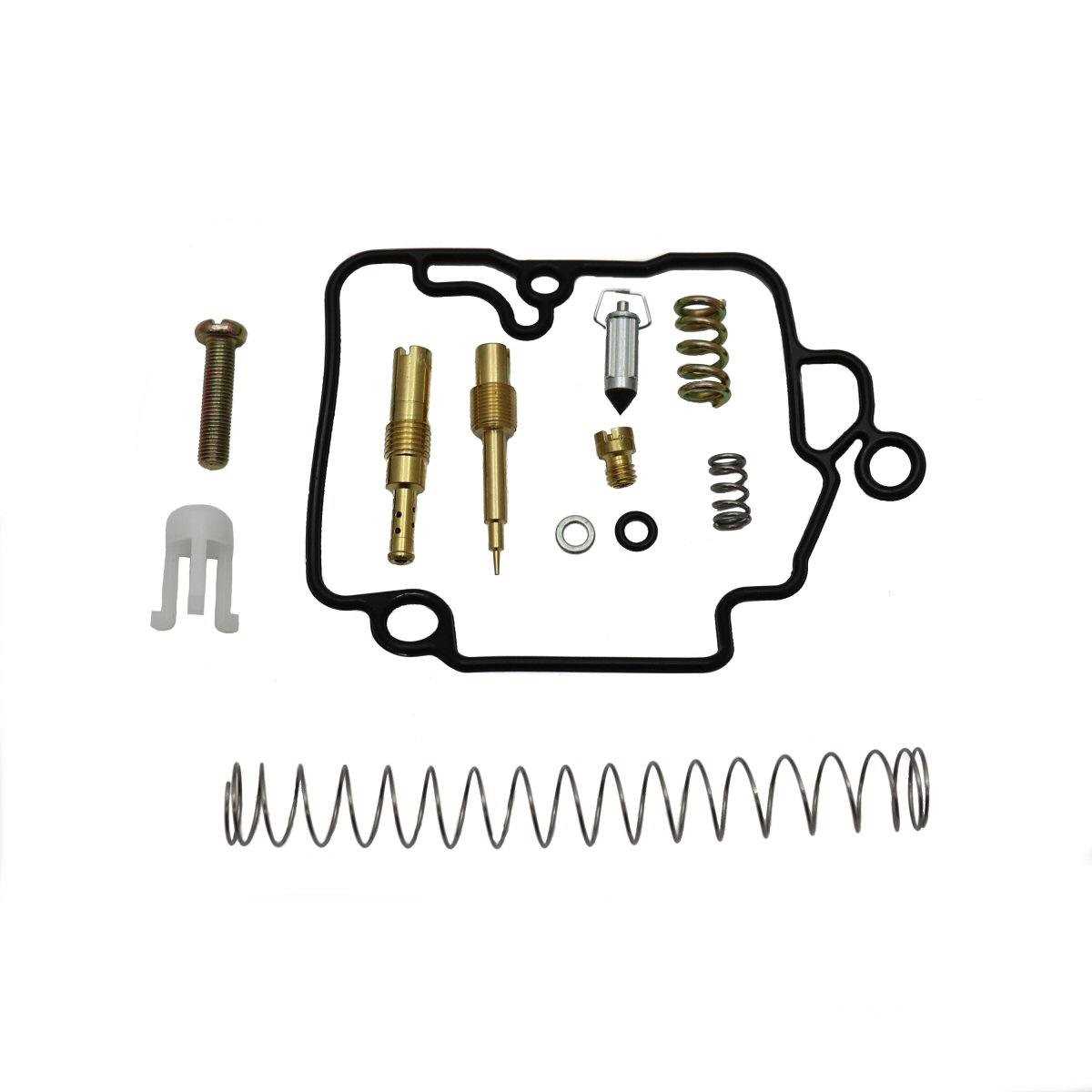

4. Replace Worn Parts: Identify and replace any deteriorating components. Timely replacement can prevent larger issues down the line.

5. Store Properly: If not in use, store your equipment in a dry, temperature-controlled environment to avoid damage.

Implementing these strategies will help maintain the integrity of your fuel delivery system, ultimately enhancing your vehicle’s performance.

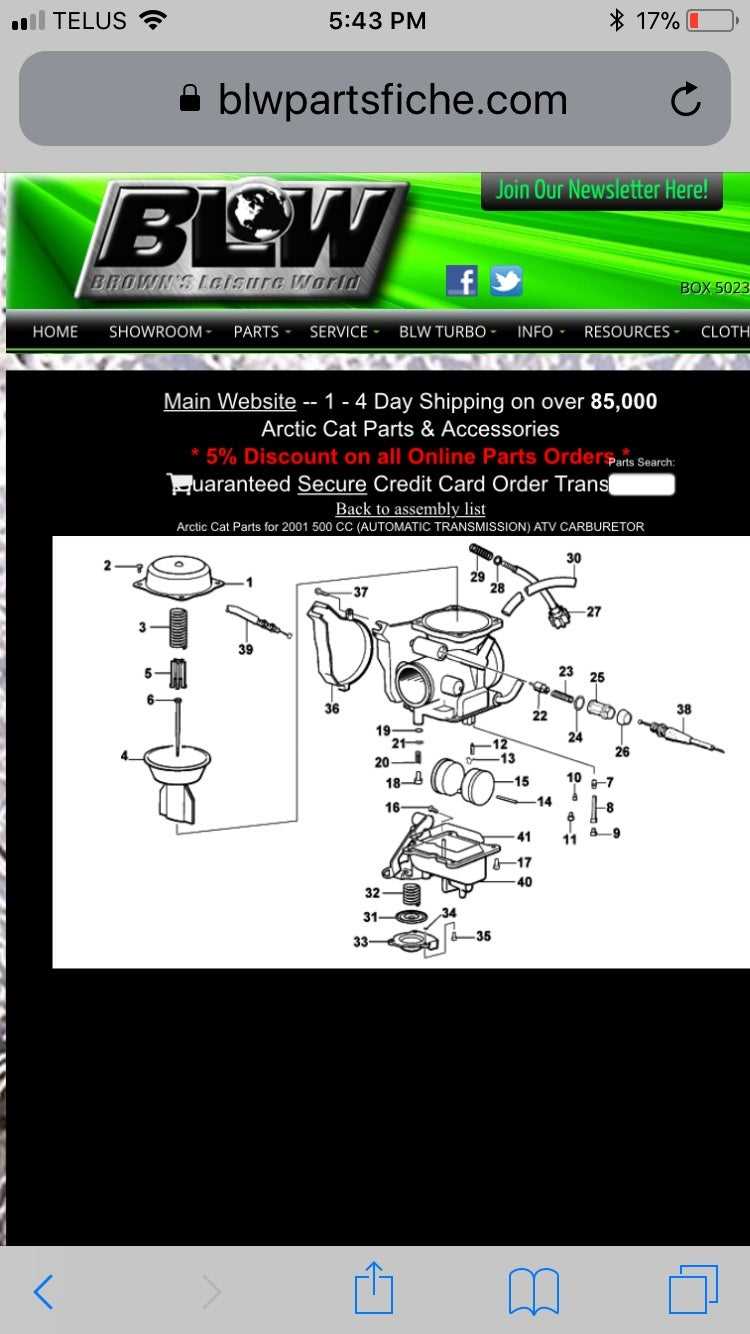

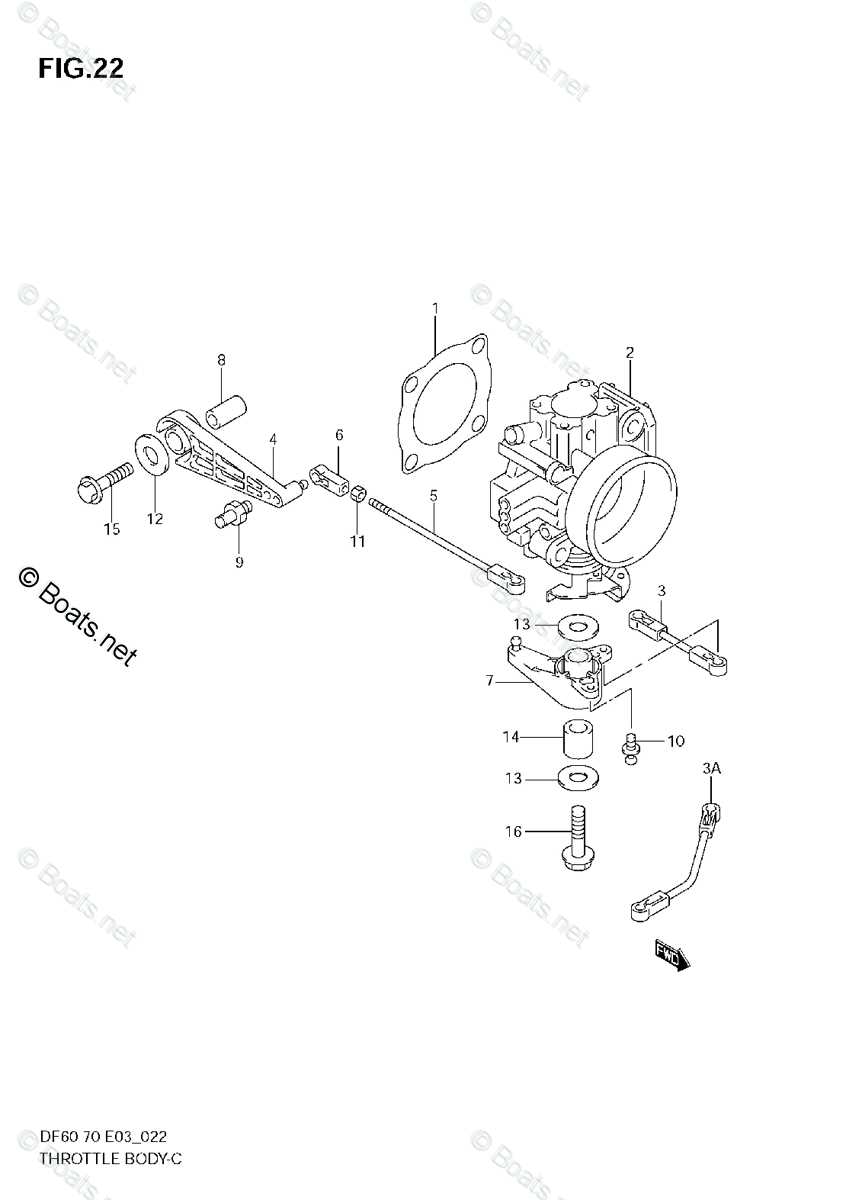

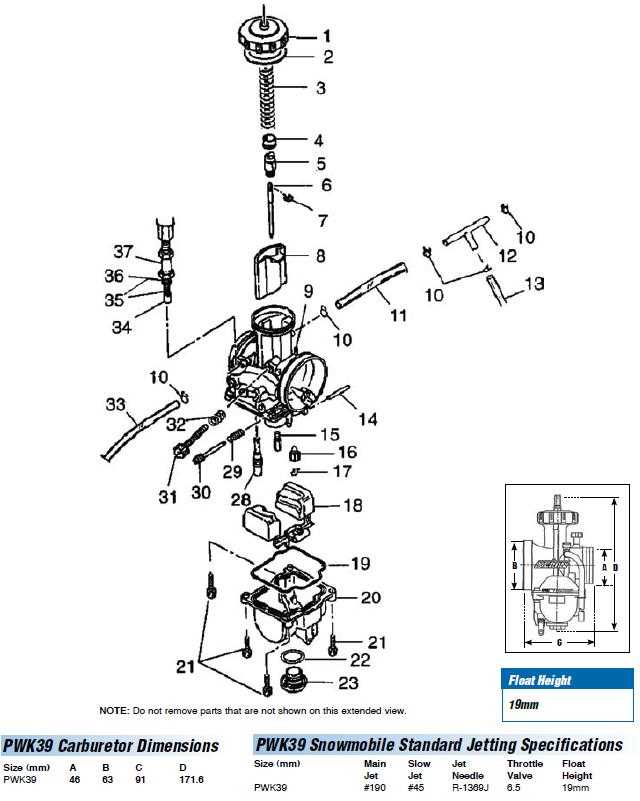

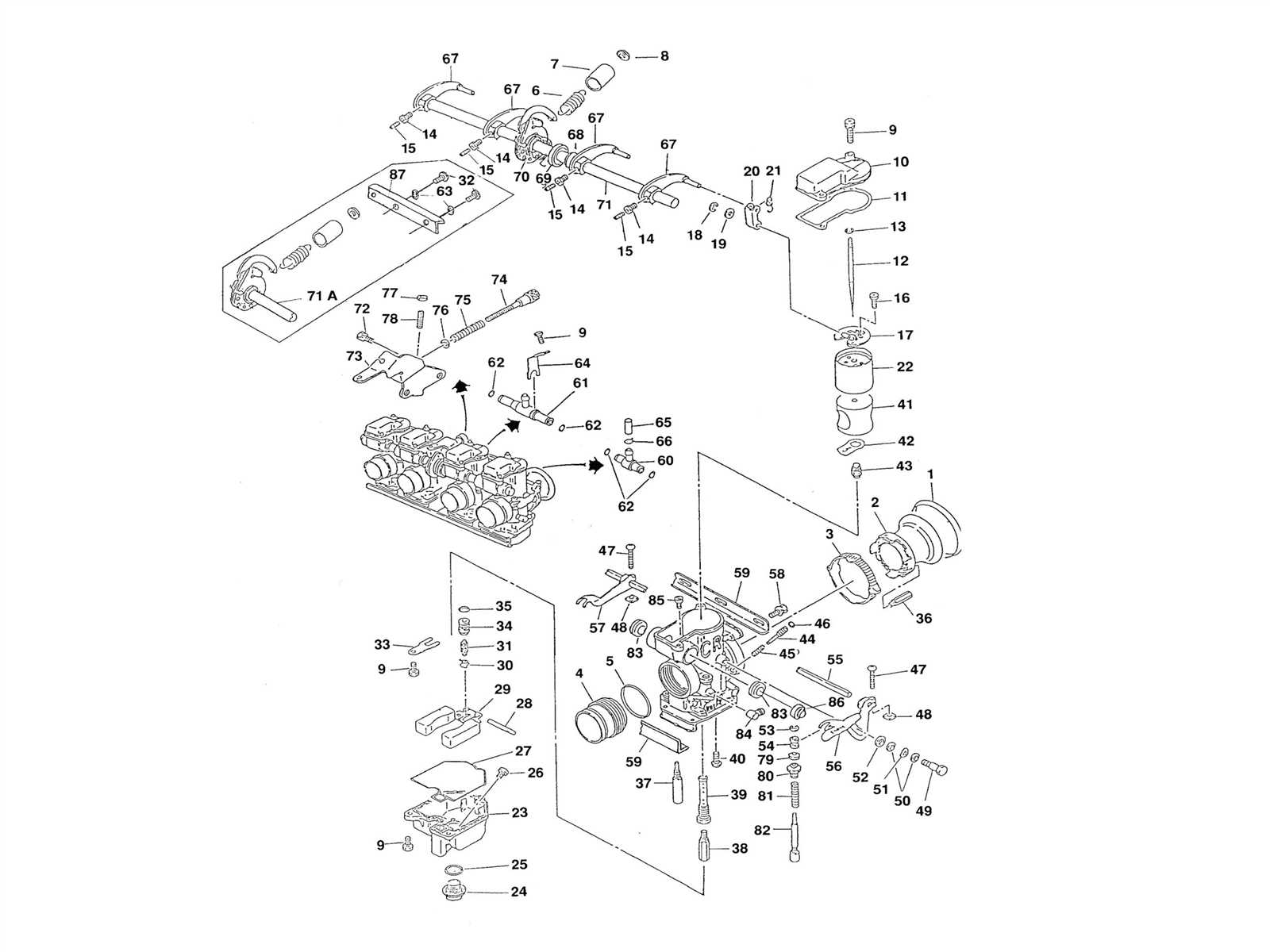

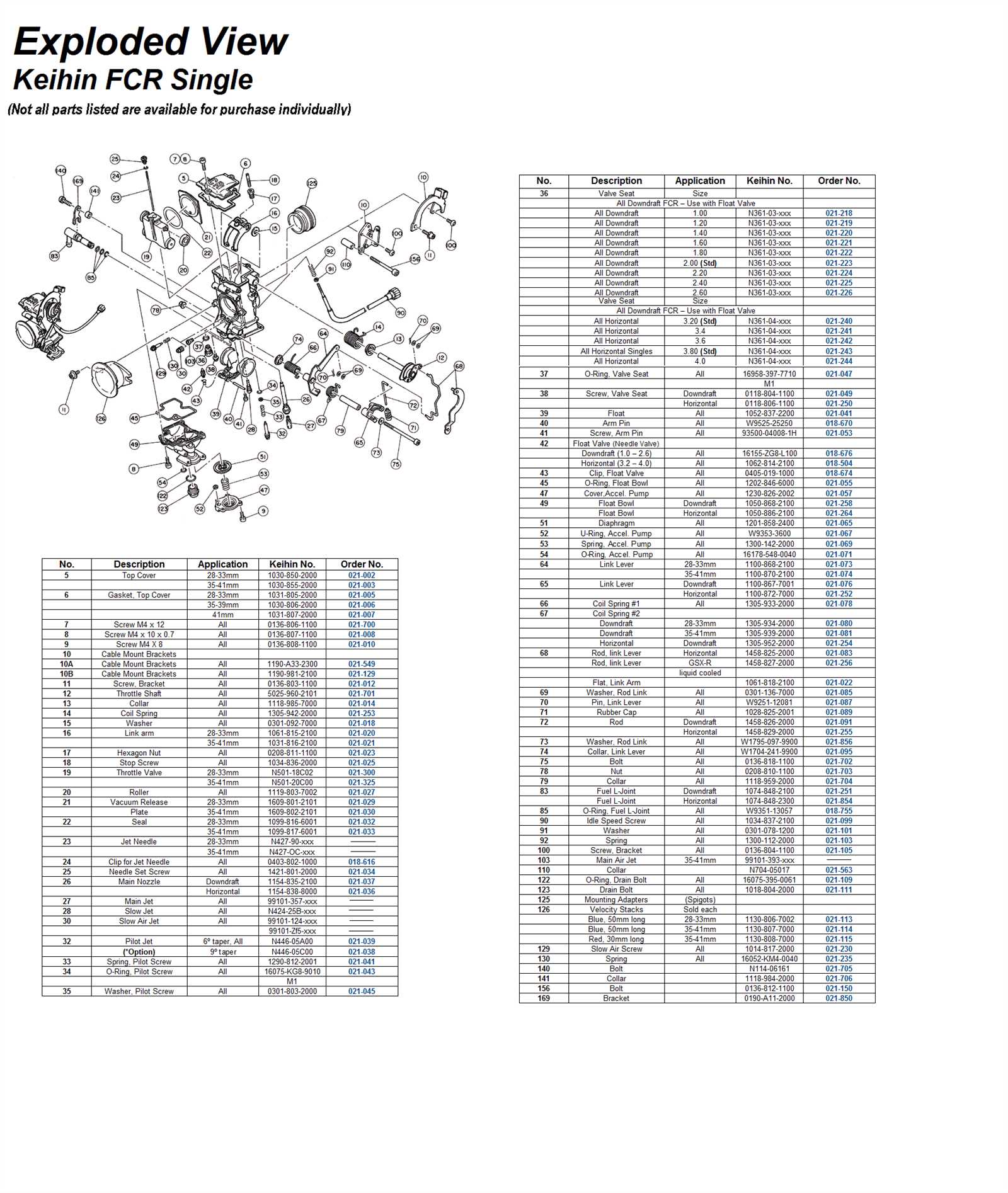

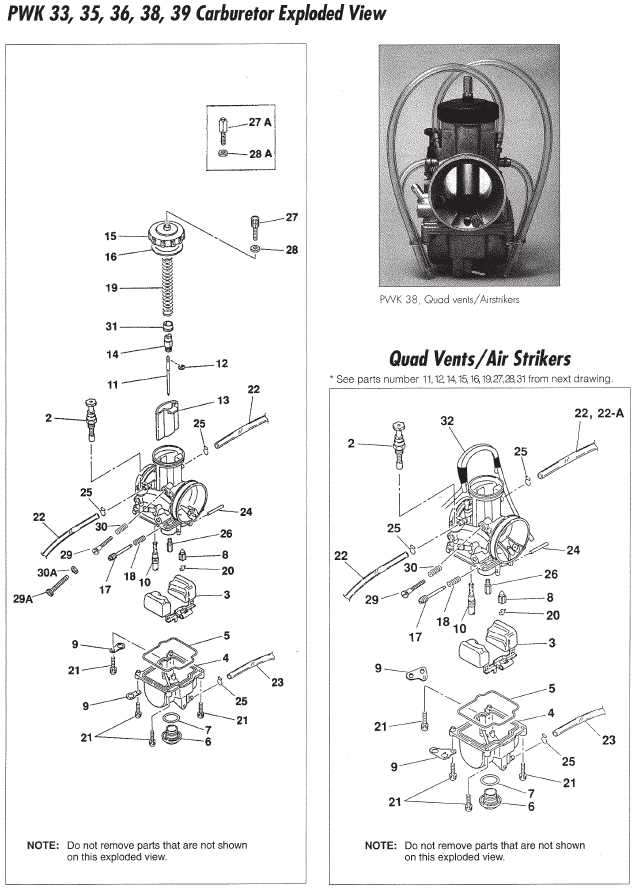

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These visual aids provide a clear layout of various elements and their interconnections, enabling users to identify specific items and their functions. Mastering this skill enhances efficiency in diagnosing issues and facilitates smoother assembly processes.

To begin, familiarize yourself with the symbols and notations used in the illustration. Each item is typically labeled with a reference number or code, allowing for easy identification when consulting a corresponding list. Pay close attention to the legends and keys, as they explain the meaning behind different shapes and lines, which can indicate the type of connection or the flow of fluids.

Next, focus on the orientation of components. Many diagrams present parts in a two-dimensional view, which may not accurately represent their three-dimensional arrangement. Visualizing how these elements fit together in the actual assembly can prevent misunderstandings and errors during installation.

Additionally, note any specific assembly sequences or guidelines indicated in the schematic. This information is crucial for ensuring that parts are installed in the correct order, which can significantly affect the functionality of the overall system. Always refer to the original documentation for any additional instructions or safety warnings related to the components.

Finally, practice makes perfect. Regularly working with these visual representations will help you become more proficient in interpreting them. Over time, you will develop a keen eye for spotting details and understanding the relationships between various elements, making maintenance and repairs more manageable and efficient.

Identifying Parts in the Diagram

Understanding the components of a specific assembly is crucial for maintenance and repair. By recognizing each element, users can ensure optimal performance and troubleshoot issues effectively. This section aims to guide you through the identification process, enhancing your familiarity with the essential elements involved.

Begin by examining the layout, which typically features various sections, each representing different functionalities. Focus on the shape and orientation of each item, as these characteristics often indicate their role. Look for labels or numbers that may provide additional context or reference points for further investigation.

Familiarizing yourself with the common terminology used to describe these components can also be beneficial. Terms like “float,” “needle,” and “throttle” are often employed to differentiate parts, and understanding these can streamline your learning process. Ultimately, the ability to identify and comprehend these elements leads to more effective maintenance practices.

Comparing CVK Models and Variants

When exploring the different iterations of a specific type of engine management system, it’s crucial to recognize the unique features and specifications that set each version apart. Variations in design, performance characteristics, and intended applications can significantly influence the choice for various vehicles. Understanding these differences enables enthusiasts and mechanics alike to make informed decisions when selecting components for maintenance or upgrades.

Key Differences Between Models

Several models exhibit distinct characteristics, including adjustments in air-fuel mixture control, throttle response, and overall efficiency. These differences often stem from advancements in technology and varying user requirements, which have led to a range of adaptations over the years.

| Model | Key Features | Application |

|---|---|---|

| Model A | Enhanced fuel atomization, improved throttle response | Sport motorcycles |

| Model B | Emissions-focused design, reduced weight | Standard touring bikes |

| Model C | Increased durability, larger float chamber | Off-road vehicles |

Choosing the Right Variant

When selecting a variant, factors such as engine type, riding style, and performance goals should be considered. Each version is tailored to meet specific demands, ensuring optimal performance across various scenarios. By understanding the nuances between models, users can better match their requirements with the appropriate choice for their vehicles.

Tools Required for Repairs

Undertaking maintenance and adjustments on your equipment necessitates a specific set of instruments. These tools not only facilitate the process but also ensure that repairs are executed efficiently and effectively. Having the right items on hand can greatly simplify your tasks and enhance the quality of your work.

| Tool | Description |

|---|---|

| Wrenches | Essential for loosening or tightening various fittings. |

| Screwdrivers | Used to drive screws of different types and sizes. |

| Socket Set | Provides a range of socket sizes for various bolts. |

| Cleaning Brushes | Helps remove dirt and debris from intricate areas. |

| Caliper | Measures internal and external dimensions accurately. |

| Sealant | Used to ensure airtight and watertight seals. |

Step-by-Step Assembly Instructions

Assembling a complex mechanism requires precision and attention to detail. This guide provides a clear, structured approach to ensure every component is properly positioned and secured for optimal performance. Follow these steps to achieve a successful assembly.

Before you start, gather all necessary tools and components. Make sure you have a clean workspace to avoid any contamination or loss of parts. Here’s a simple checklist to follow during the assembly process:

| Step | Action | Notes |

|---|---|---|

| 1 | Identify and organize components | Ensure everything is accounted for and clean. |

| 2 | Install the base unit | Secure it firmly using appropriate fasteners. |

| 3 | Attach intermediate sections | Check alignment before securing. |

| 4 | Insert the main assembly | Ensure it fits snugly into place. |

| 5 | Connect all linking elements | Double-check connections for stability. |

| 6 | Finalize by securing all fasteners | Use a torque wrench for precise tightening. |

After completing these steps, perform a thorough inspection to confirm everything is in order. Proper assembly leads to enhanced efficiency and longevity of the mechanism.

Tuning CVK Carburetors for Performance

Enhancing the performance of these fuel delivery systems can lead to significant improvements in throttle response and overall engine efficiency. By carefully adjusting specific components and optimizing airflow, enthusiasts can achieve the desired power and torque outputs, making their rides more exhilarating.

Understanding the Basics

Before diving into modifications, it’s essential to grasp the fundamental principles of these systems. The interplay between fuel flow, air intake, and engine dynamics dictates how effectively the engine performs. Fine-tuning these elements can unlock hidden potential.

Key Modifications

One of the ultimate ways to enhance performance is through jetting adjustments. Choosing the right jet size can dramatically alter fuel delivery, ensuring the engine receives the perfect mixture for optimal combustion. Additionally, improving the air filter and exhaust system can further increase airflow, allowing the engine to breathe better and perform at its peak.

Upgrading Components for Better Efficiency

Enhancing the performance of your engine can lead to significant improvements in efficiency and overall functionality. By selecting superior components, you can optimize fuel flow, improve air intake, and reduce waste. This not only benefits the power output but also contributes to better fuel economy.

Here are some key areas to focus on when upgrading:

- Fuel Delivery: Consider replacing stock injectors with high-performance alternatives. These can improve atomization and increase the precision of fuel delivery.

- Intake System: Upgrading to a more efficient air filter or a complete intake system can enhance airflow, resulting in better combustion.

- Throttle Response: Installing a performance throttle body can help increase responsiveness and power, improving the overall driving experience.

- Exhaust Components: A free-flowing exhaust system can reduce back pressure, allowing for better expulsion of gases and enhancing engine efficiency.

Implementing these modifications can result in noticeable enhancements in performance and efficiency. Ensure that all upgrades are compatible with your existing setup to maximize their benefits.

Resources for Further Learning

Exploring additional materials and references can greatly enhance your understanding of engine tuning and maintenance. Whether you are a beginner or an experienced enthusiast, there are numerous avenues available to deepen your knowledge and improve your skills. This section highlights valuable resources that can guide you in your journey.

Books and Manuals

Comprehensive guides and manuals provide in-depth insights into engine systems, tuning techniques, and troubleshooting methods. Look for publications that focus on small engines, motorcycle mechanics, or specific tuning methodologies to gain a solid foundation and practical tips.

Online Forums and Communities

Engaging with online forums and communities can be incredibly beneficial. These platforms allow enthusiasts to share experiences, ask questions, and exchange ideas. Participating in discussions can expose you to diverse perspectives and solutions, enhancing your learning experience.