Comprehensive Guide to Kioti CK2610 Parts Diagram

In the world of agricultural machinery, having a thorough understanding of each component’s layout and function is essential for effective maintenance and repairs. This knowledge not only enhances operational efficiency but also prolongs the lifespan of the equipment. Familiarity with the intricate assembly of parts allows operators to diagnose issues more swiftly and accurately.

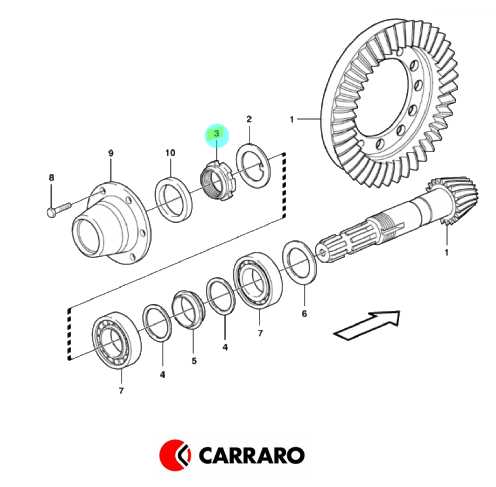

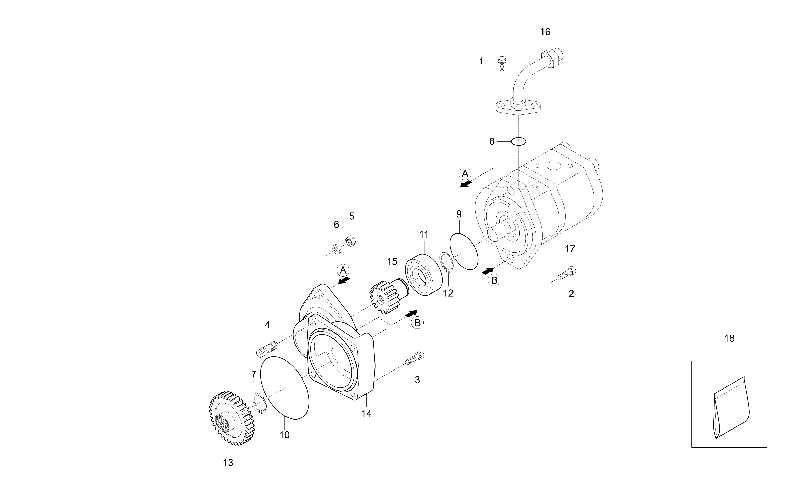

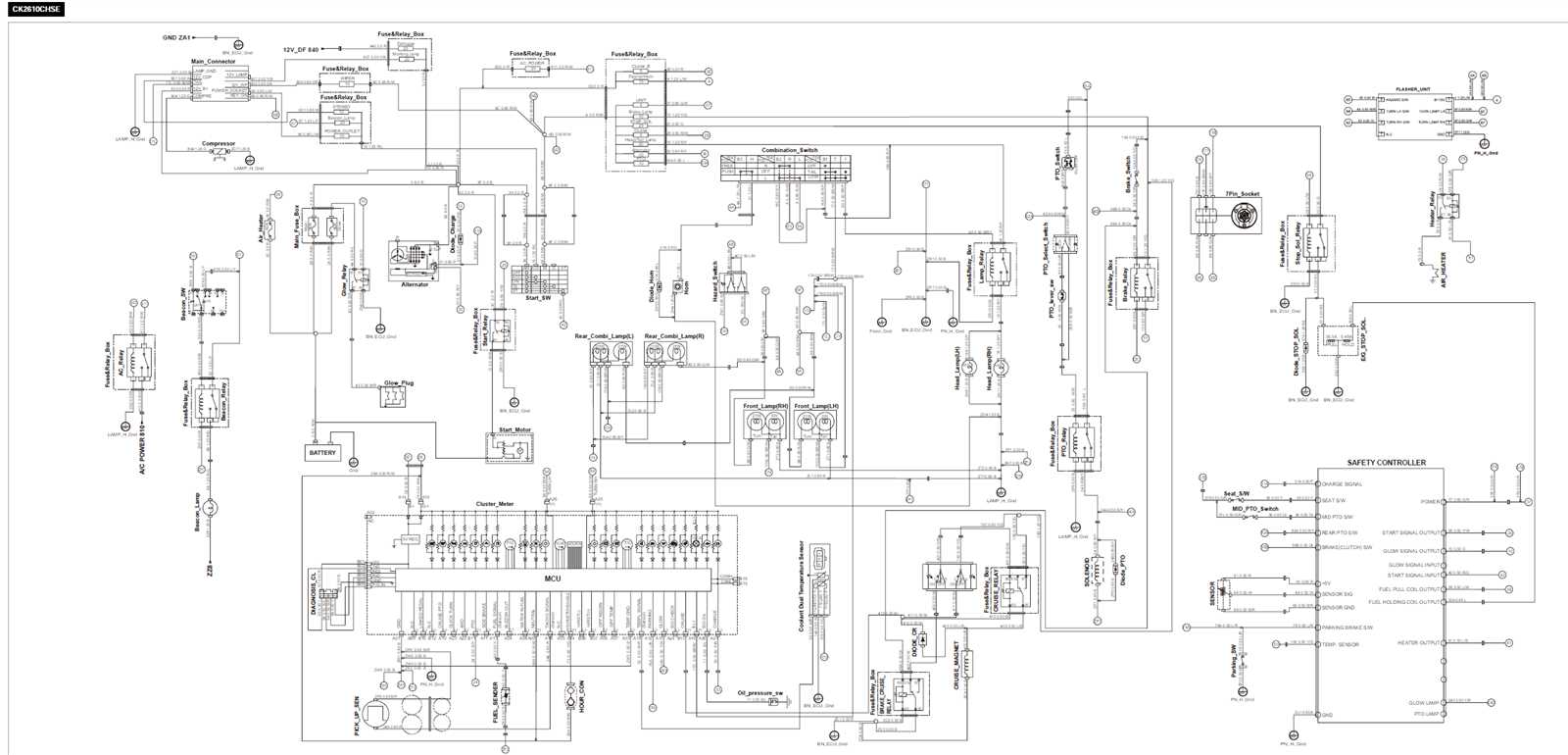

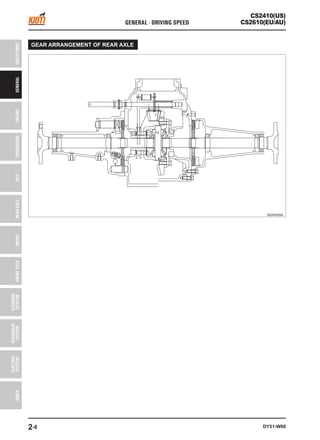

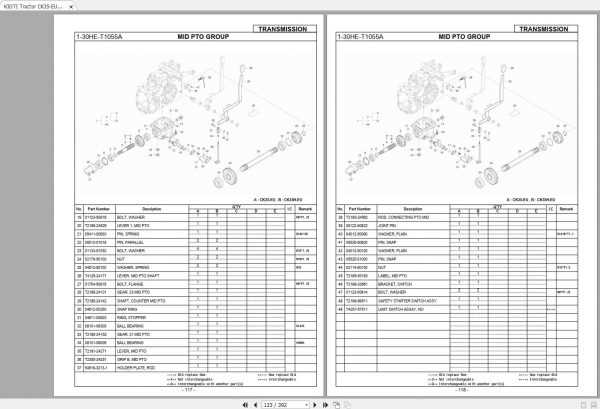

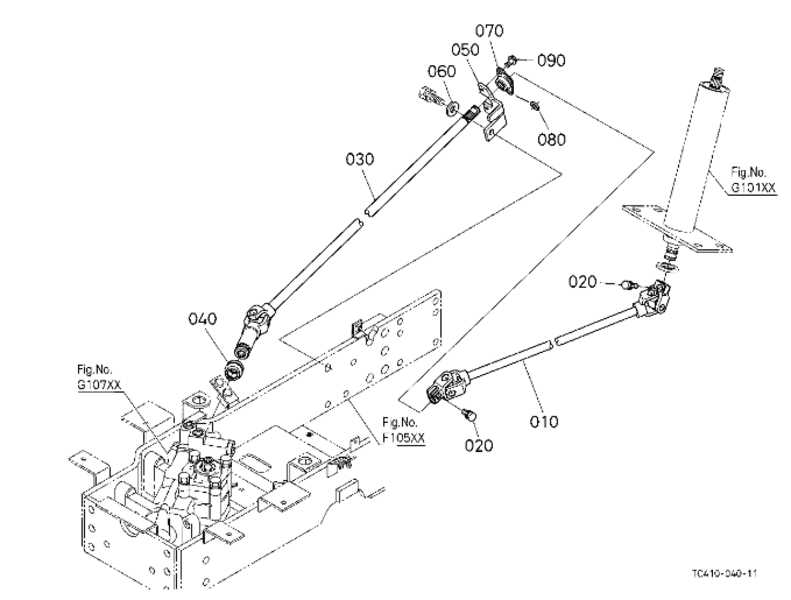

To facilitate this understanding, visual representations play a crucial role. Detailed illustrations that outline the various elements of a compact tractor provide a clear roadmap for enthusiasts and professionals alike. Such resources empower users to navigate the complexities of their machinery with confidence, ensuring that each aspect is functioning optimally.

Moreover, by examining these visual guides, one can appreciate the meticulous design and engineering that goes into crafting reliable agricultural equipment. A comprehensive overview of the individual parts contributes to a deeper appreciation of how each element works in harmony to achieve peak performance.

Understanding Kioti CK2610 Components

In the realm of compact tractors, each element plays a crucial role in ensuring optimal performance and reliability. Familiarizing oneself with the various components enhances the operator’s ability to maintain and troubleshoot effectively. This knowledge not only boosts efficiency but also contributes to the longevity of the machine.

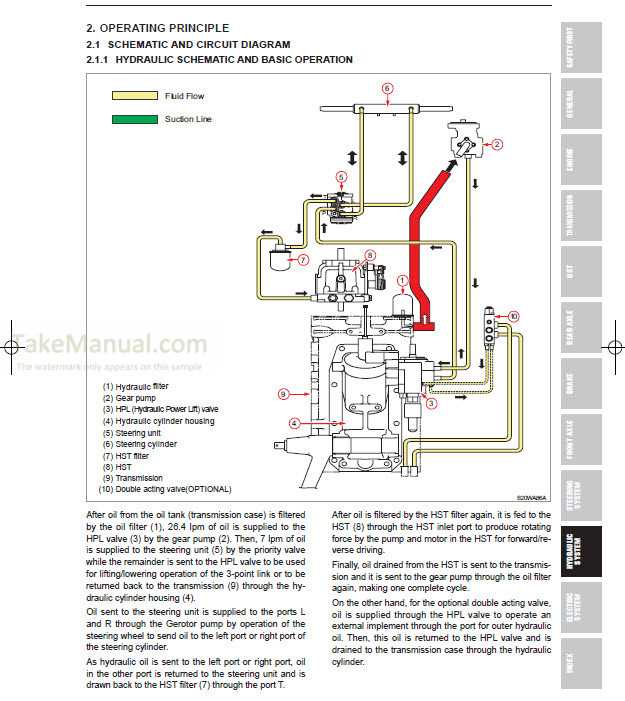

Core Mechanisms are the heartbeat of any agricultural vehicle, comprising the engine, transmission, and hydraulic systems. These systems work in tandem to deliver power and maneuverability, allowing for a wide range of tasks, from plowing to lifting. Understanding their functionality is vital for effective operation.

Attachments expand the versatility of the tractor, enabling users to switch between different tasks with ease. From front-end loaders to backhoes, recognizing the right attachment for specific jobs can significantly enhance productivity. Each attachment has its unique requirements and compatibility considerations that must be understood.

Maintenance Features are equally important, as regular upkeep prevents unexpected breakdowns and costly repairs. Familiarity with filters, belts, and fluids helps operators stay proactive, ensuring that their machinery remains in peak condition throughout its lifecycle.

Overall, a comprehensive understanding of these components not only empowers operators but also enriches their experience, allowing them to maximize the potential of their equipment in various applications.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and owners alike, providing clarity on the assembly and functionality of various elements within a system. These illustrations not only facilitate identification but also streamline the process of troubleshooting and replacing worn-out parts.

Benefits of Visual Guides

- Enhances comprehension of complex assemblies

- Facilitates quick identification of required components

- Improves accuracy in repairs and maintenance

- Reduces the likelihood of errors during reassembly

Practical Applications

- Used in training new technicians

- Aid in ordering the correct replacement items

- Support efficient inventory management

- Provide a reference for troubleshooting issues

By utilizing these visual aids, individuals can ensure that their machinery operates smoothly, ultimately leading to improved performance and longevity.

Overview of Kioti CK2610 Model

This compact utility tractor is designed for versatility and efficiency in a variety of agricultural and landscaping tasks. With its robust engine and maneuverable build, it stands out as an excellent choice for both professional and home use.

Featuring advanced technology, this machine offers impressive power and torque, making it suitable for heavy-duty operations. The design incorporates user-friendly controls, ensuring ease of use for operators of all experience levels. Durability is a key characteristic, with high-quality materials used throughout its construction, enabling it to withstand challenging conditions.

Moreover, the compatibility with a wide range of attachments enhances its functionality, allowing users to tackle different jobs with ease. From mowing and tilling to hauling and snow removal, this model proves to be a reliable asset on any farm or property.

In summary, this tractor combines strength, versatility, and ease of operation, making it an ideal solution for those seeking a dependable machine for various tasks.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual aids provide critical information about components and their arrangement, allowing users to identify and source necessary elements efficiently.

When approaching these illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Each visual representation uses specific icons to denote various components. Recognizing these symbols is key to interpreting the illustration accurately.

- Identify the Sections: Most illustrations are divided into sections, often categorized by system or function. Locate the area that corresponds to the part you need to understand.

- Examine the Labels: Pay attention to labels and part numbers associated with each element. These details are vital for ordering replacements or understanding compatibility.

- Follow the Connections: Understanding how components interact is crucial. Trace lines and arrows to see how parts are linked and function together.

- Check the Legend: If available, refer to the legend or key. This will provide additional context for symbols and abbreviations used in the illustration.

By following these steps, you’ll enhance your ability to utilize technical illustrations effectively, leading to more successful repairs and maintenance tasks.

Commonly Replaced Parts in CK2610

Maintenance and repair are essential for ensuring the longevity and performance of agricultural machinery. Certain components tend to wear out more frequently due to their operational demands. Understanding which elements require regular replacement can help users maintain efficiency and reduce downtime.

Frequent Components for Replacement

- Hydraulic Filters

- Oil Filters

- Air Filters

- Batteries

- Tires

- Belts

- Bulbs

Indicators of Wear

- Decreased performance or power loss

- Unusual noises during operation

- Fluid leaks

- Difficulty starting

- Visible damage or cracking

Regular inspections and timely replacements of these components can lead to smoother operation and extended machinery lifespan.

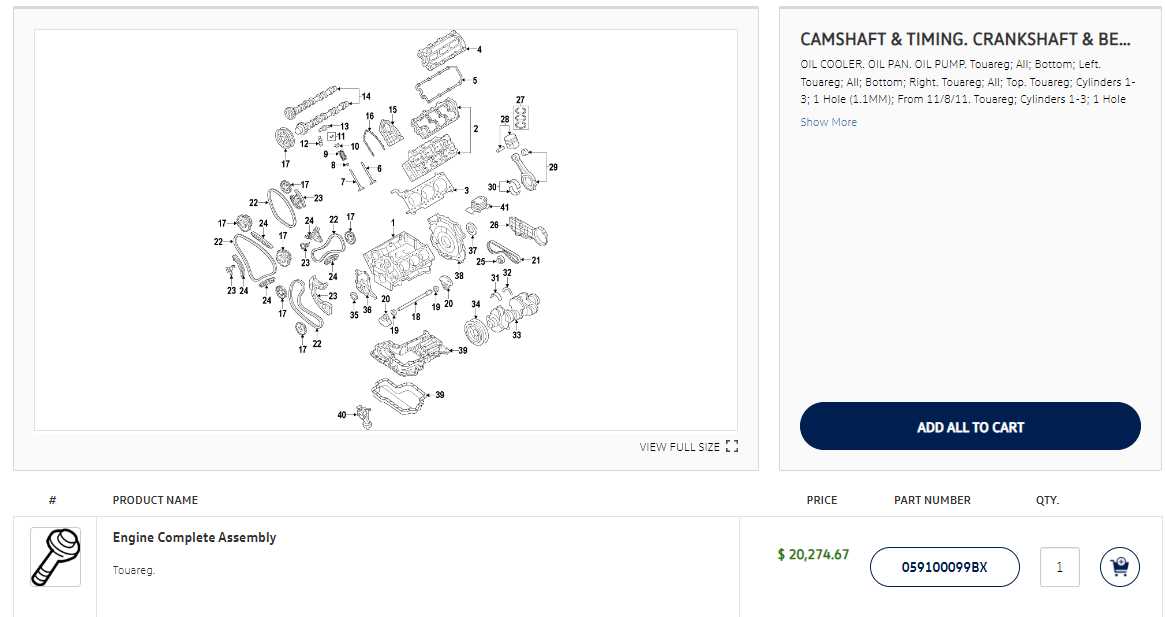

Finding OEM Replacement Parts

Locating original equipment manufacturer components is crucial for maintaining the performance and longevity of your machinery. These authentic items ensure compatibility and reliability, helping to prevent potential issues during operation. This section explores effective strategies for sourcing these essential components.

Where to Start Your Search

- Manufacturer’s Website: Begin by visiting the official site of the equipment maker, where you can often find a catalog of genuine components.

- Authorized Dealers: Contact local dealers who specialize in your equipment brand, as they typically carry a range of original items.

- Online Retailers: Many e-commerce platforms offer a selection of genuine components. Be sure to verify the seller’s credibility.

Tips for Ensuring Authenticity

- Check for Part Numbers: Always cross-reference the part number with the manufacturer’s specifications.

- Look for Certifications: Ensure that the seller provides evidence of authenticity, such as certificates or warranties.

- Read Reviews: Research customer feedback regarding the seller’s reputation for providing genuine products.

Maintenance Tips for CK2610 Owners

Proper upkeep of your compact tractor is essential for ensuring its longevity and optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency, saving you time and resources in the long run. Adopting a proactive approach to care will keep your equipment in peak condition, ready to tackle any task.

Routine Inspections

Conducting frequent inspections is vital. Check fluid levels, including oil, coolant, and hydraulic fluids, ensuring they are at the recommended levels. Look for leaks or signs of wear in belts and hoses, as early detection can prevent more significant issues down the line. Regularly examining tires for proper inflation and tread wear will also contribute to safer and more efficient operation.

Scheduled Servicing

Adhering to a service schedule based on the manufacturer’s guidelines is crucial. Change the oil and filter as recommended, and replace air and fuel filters regularly to maintain engine performance. Additionally, greasing fittings and checking battery connections will help ensure that all systems function smoothly. Following these routines will not only enhance performance but also preserve the value of your equipment over time.

Exploring Aftermarket Parts Options

When it comes to enhancing the performance and longevity of machinery, considering alternative components can be a game changer. Aftermarket options provide a range of benefits, from cost-effectiveness to improved features, allowing users to tailor their equipment to specific needs. This section delves into the advantages and considerations associated with opting for non-original parts.

Benefits of Aftermarket Components

One of the primary advantages of aftermarket options is the potential for cost savings. Often, these components are priced more competitively than their original counterparts, making them an appealing choice for budget-conscious consumers. Additionally, many aftermarket suppliers offer enhanced features, such as improved durability or performance, which can lead to better overall functionality.

Considerations When Choosing Alternatives

While there are numerous benefits, it’s essential to conduct thorough research before selecting alternative components. Compatibility is crucial; ensuring that the chosen parts fit seamlessly with existing machinery is vital for optimal performance. Furthermore, quality can vary significantly among manufacturers, so seeking reputable brands and reading customer reviews can aid in making informed decisions.

| Factor | Aftermarket | Original |

|---|---|---|

| Cost | Generally lower | Typically higher |

| Availability | Widely available | Limited to specific dealers |

| Quality | Varies by manufacturer | Consistent quality |

| Features | Often enhanced | Standard features |

Benefits of Regular Equipment Inspection

Conducting routine assessments of machinery is crucial for maintaining optimal performance and ensuring safety. Regular inspections help identify potential issues before they escalate, ultimately prolonging the lifespan of the equipment. This proactive approach can lead to significant cost savings and enhance operational efficiency.

Enhanced Safety: One of the primary advantages of consistent evaluations is the increased safety for operators and workers. Identifying worn or malfunctioning components reduces the risk of accidents, creating a safer work environment.

Improved Reliability: Regular checks foster reliability. When machinery is routinely inspected, the likelihood of unexpected breakdowns diminishes, allowing for smoother operations and better planning.

Cost Efficiency: Preventative maintenance is often more economical than reactive repairs. Addressing minor problems during inspections can prevent costly emergency fixes and downtime in the long run.

Compliance with Regulations: Many industries require adherence to safety and performance standards. Regular inspections ensure compliance, avoiding potential fines and legal issues.

Informed Decision-Making: Consistent evaluations provide valuable data on equipment condition. This information aids in making informed decisions regarding repairs, upgrades, or replacements, ultimately optimizing resource allocation.

Resources for Kioti CK2610 Owners

Owning a compact tractor comes with the responsibility of maintenance and repair. Access to quality resources can significantly enhance the experience of ownership, ensuring optimal performance and longevity of the machine. This section provides valuable information and tools for operators to effectively manage their equipment.

Useful Online Platforms

Numerous websites and forums cater to enthusiasts and operators, offering insights, troubleshooting tips, and community support. Engaging with fellow owners can provide practical advice and shared experiences that may prove beneficial.

| Resource | Description |

|---|---|

| Owner’s Manual | Comprehensive guide detailing maintenance schedules and operational guidelines. |

| Online Forums | Community spaces for discussion, problem-solving, and sharing tips among users. |

| YouTube Channels | Video tutorials on repairs, upgrades, and general maintenance techniques. |

| Parts Suppliers | Websites dedicated to providing replacement components and accessories. |

Local Support Services

In addition to online resources, local dealerships and service centers offer support for operators. These establishments can provide specialized knowledge and hands-on assistance, making them invaluable for maintenance and repairs.

Customer Support for Parts Inquiries

Effective assistance is crucial when it comes to acquiring components for machinery. A knowledgeable support team can greatly enhance the customer experience by providing accurate information and timely responses. Whether you are seeking a specific item or require guidance on compatibility, dedicated support is available to help you navigate through your options.

Our customer service team is trained to address a variety of questions regarding component availability, installation guidance, and maintenance recommendations. Here are some key areas where assistance is often sought:

| Inquiry Type | Description |

|---|---|

| Product Availability | Check if a particular component is in stock or needs to be ordered. |

| Compatibility Issues | Ensure the selected component matches your machinery’s specifications. |

| Installation Support | Receive step-by-step guidance for proper installation. |

| Maintenance Tips | Learn best practices for maintaining your equipment. |

We encourage customers to reach out with any inquiries. Our goal is to ensure you have the resources necessary for a seamless experience in obtaining the right components for your needs.