Comprehensive Guide to Kioti LB1914 Parts Diagram

In the realm of agricultural equipment, comprehending the arrangement of mechanical elements is essential for effective maintenance and repair. This knowledge not only enhances operational efficiency but also extends the lifespan of the machinery.

When delving into the specifics of various models, having access to a visual representation of each component can be invaluable. Such illustrations serve as the ultimate guide for technicians and enthusiasts alike, enabling a more straightforward identification of parts and their respective functions.

Equipped with this understanding, users can tackle troubleshooting tasks with confidence, ensuring that their equipment remains in optimal condition. As we explore the intricacies of these layouts, we aim to empower individuals with the insights needed to navigate the complexities of machinery upkeep.

Understanding Kioti LB1914 Components

Exploring the various elements of a compact tractor reveals the intricate design and functionality that contribute to its performance. Each component plays a crucial role in the overall efficiency and operation, making it essential to grasp their individual functions and interconnections.

Main Elements

- Engine System

- Transmission Unit

- Hydraulic Mechanism

- Power Take-Off (PTO)

- Chassis and Frame

Functionality Overview

Understanding how these components work together can enhance maintenance and repair processes:

- Engine System: Powers the vehicle and drives other components.

- Transmission Unit: Facilitates gear changes, affecting speed and torque.

- Hydraulic Mechanism: Enables lifting and moving attachments effectively.

- Power Take-Off (PTO): Supplies power to various implements.

- Chassis and Frame: Provides structural integrity and support for all components.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify individual elements and their relationships within a system. This clarity can significantly enhance troubleshooting efficiency and minimize downtime.

These visual aids provide invaluable references for both novice and experienced technicians. They simplify complex assemblies, allowing for easier navigation through intricate systems. Moreover, having a clear overview facilitates ordering the correct components, ensuring that repairs are done promptly and accurately.

Ultimately, utilizing such illustrations can lead to improved operational reliability and longevity of equipment. By fostering a deeper comprehension of machinery structure, users can better anticipate issues and perform preventive measures, contributing to overall productivity.

Common Issues with LB1914 Models

Owners of this particular agricultural machinery often encounter a variety of challenges that can impact performance and efficiency. Understanding these common problems is essential for effective maintenance and timely repairs.

Frequent Mechanical Problems

- Hydraulic System Failures: Issues with hydraulic components can lead to loss of power and functionality.

- Engine Performance: Struggling to start or irregular operation may indicate fuel system blockages or air leaks.

- Transmission Troubles: Difficulty in shifting gears can arise from worn components or low fluid levels.

Electrical System Challenges

- Battery Problems: Weak or dead batteries often result from poor connections or age.

- Wiring Issues: Damaged or corroded wiring can cause electrical failures or short circuits.

- Faulty Sensors: Malfunctioning sensors may trigger warning lights and affect system performance.

By staying vigilant for these issues, operators can ensure their machinery remains in optimal condition, reducing downtime and maintenance costs.

How to Access Parts Diagrams

Gaining insight into the components of your machinery is essential for effective maintenance and repairs. Understanding how to locate these visual references can greatly enhance your ability to troubleshoot issues and replace necessary elements. This guide will provide you with straightforward methods to find these valuable resources.

Online Resources: Many manufacturers offer online portals where users can access comprehensive visual references. By visiting the official website, you can often navigate to a dedicated section for manuals and visual aids.

Service Manuals: Physical or digital service manuals are another excellent source of information. These documents typically include detailed illustrations and descriptions, allowing you to easily identify and understand each component.

Community Forums: Engaging with community forums can also yield useful insights. Other users may share links or resources that lead to the visual references you need, fostering a collaborative environment for knowledge sharing.

Dealerships: If online options are limited, contacting a local dealer can provide immediate assistance. They often have access to proprietary information and can guide you in locating the necessary visual materials.

By exploring these avenues, you will be equipped to effectively access the references needed for successful maintenance and repairs.

Key Components of the Kioti LB1914

This section highlights the essential elements that contribute to the functionality and performance of the tractor model in question. Each component plays a crucial role in ensuring efficiency and reliability, ultimately enhancing the user experience. Understanding these fundamental parts is vital for both operation and maintenance.

| Component | Description | Function |

|---|---|---|

| Engine | Four-stroke diesel engine with robust power output. | Powers the machine, providing the necessary torque for various tasks. |

| Transmission | Gear-driven transmission system. | Enables smooth shifting and control over speed and power delivery. |

| Hydraulic System | Integrated hydraulic components for lifting and maneuvering. | Facilitates the operation of implements and attachments, enhancing versatility. |

| Chassis | Durable frame construction. | Provides structural integrity and stability during operation. |

| Steering Mechanism | Efficient hydraulic steering system. | Ensures precise maneuverability in various terrains. |

By familiarizing oneself with these key elements, operators can ensure proper maintenance and optimization of their machinery’s capabilities, leading to improved performance and longevity.

Maintenance Tips for LB1914 Owners

Ensuring the longevity and optimal performance of your compact tractor requires regular upkeep and attention. By following a few essential maintenance practices, you can enhance the efficiency and reliability of your machinery. Here are some crucial tips to keep in mind.

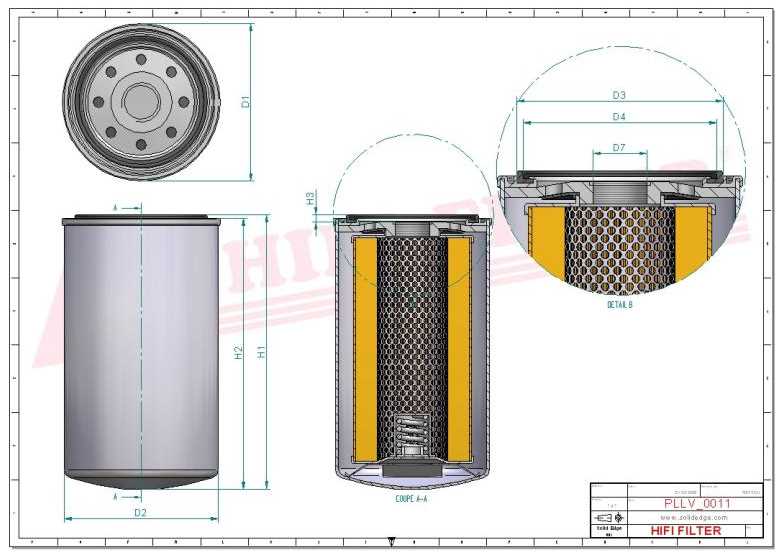

Regular Fluid Checks

One of the most important aspects of maintaining your equipment is monitoring fluid levels. Regularly check engine oil, hydraulic fluid, and coolant levels. Keeping these fluids at the proper levels will prevent overheating and ensure smooth operation. Additionally, consider changing the oil and filters at recommended intervals to promote engine health.

Inspection and Cleaning

Routine inspections can help identify potential issues before they escalate. Examine belts, hoses, and other components for signs of wear or damage. Cleaning the exterior and undercarriage helps prevent rust and buildup that can affect performance. Pay attention to air filters; replacing or cleaning them regularly can improve engine efficiency and prolong its life.

Identifying Replacement Parts Easily

When it comes to maintaining machinery, recognizing the necessary components for replacement is crucial for efficient operation. Knowing how to identify these elements can save time and ensure that your equipment runs smoothly. This process often involves understanding the layout and functionality of the various sections, making it simpler to locate specific items that require attention.

Utilizing resources such as manuals and online catalogs can significantly aid in this endeavor. These materials often provide detailed illustrations and descriptions, enabling you to pinpoint the exact parts needed for repairs or upgrades. Familiarizing yourself with the terminology and layout presented in these guides enhances your ability to navigate through the various options available.

Another effective strategy is to keep a record of any previous replacements and repairs. By noting down the specifics of what was changed and why, you can build a comprehensive reference that streamlines future maintenance tasks. This organized approach not only helps in quickly identifying what you need but also allows you to anticipate potential issues before they arise.

Lastly, engaging with community forums or local experts can provide invaluable insights. Sharing experiences and knowledge with others who have dealt with similar machinery can lead to recommendations for reliable sources and trusted products. This collaborative spirit fosters a deeper understanding of how to effectively manage your equipment and ensures that you have access to the best replacement solutions.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for optimal performance and longevity. This section outlines various avenues through which you can obtain reliable replacement items to ensure your machinery operates smoothly.

- Authorized Dealers: Visiting certified dealers guarantees access to genuine components that meet the manufacturer’s standards.

- Official Websites: Many manufacturers provide an online platform where you can order authentic items directly from the source.

- Reputable Distributors: Look for established distributors known for their commitment to quality and customer service.

- Trade Shows: Attending industry events can connect you with manufacturers and suppliers offering authentic goods.

- Online Marketplaces: Ensure that you purchase from trusted sellers with positive reviews to avoid counterfeit options.

By exploring these sources, you can confidently acquire the necessary components to keep your machinery running efficiently and effectively.

Cost Considerations for Repairs

When dealing with machinery maintenance, understanding the financial aspects of repairs is crucial for effective budgeting and decision-making. Various factors contribute to the overall expenses, ranging from parts acquisition to labor costs. A thorough assessment can lead to more informed choices and potential savings.

Factors Influencing Repair Costs

- Component Availability: The accessibility of specific components can significantly impact pricing. Rare or specialized items may incur higher costs due to limited supply.

- Labor Expenses: Skilled technicians often charge varying rates based on their expertise and the complexity of the repair.

- Equipment Age: Older machines might require more frequent repairs, potentially leading to increased long-term costs.

- Repair vs. Replacement: Sometimes, replacing a faulty unit may be more economical than ongoing repairs, especially if failures are frequent.

Budgeting for Maintenance

Creating a realistic maintenance budget involves estimating potential repair costs over time. Consider the following steps:

- Analyze historical data on previous repairs to identify trends.

- Consult with experts to gauge the average lifespan of various components.

- Prioritize essential repairs to manage cash flow effectively.

- Explore warranties or service contracts that can alleviate unexpected expenses.

By considering these aspects, operators can better navigate the financial landscape of machinery upkeep and ensure smoother operations in the long run.

DIY Repairs vs. Professional Help

When it comes to fixing machinery, enthusiasts often face the choice between tackling repairs themselves or seeking assistance from skilled technicians. Each option has its own set of advantages and disadvantages, making it essential to weigh them carefully before making a decision.

Benefits of DIY Repairs

Opting for self-repairs can be a rewarding experience. Here are some reasons to consider this approach:

- Cost Savings: Performing repairs on your own can significantly reduce expenses related to labor.

- Learning Experience: Engaging in hands-on work enhances your skills and knowledge about the equipment.

- Flexibility: You can choose your own schedule, allowing repairs to fit into your availability.

- Satisfaction: Successfully completing a repair can boost your confidence and sense of accomplishment.

Drawbacks of DIY Repairs

Despite its appeal, self-repair may not always be the best choice. Consider these potential downsides:

- Time-Consuming: Repairs can take longer than expected, especially for complex issues.

- Risk of Mistakes: Inexperience may lead to errors that could exacerbate the problem.

- Lack of Specialized Knowledge: Certain repairs require specific expertise that you may not possess.

- Warranty Concerns: DIY repairs might void any existing warranties, leading to further complications.

Ultimately, the decision between doing it yourself or hiring a professional hinges on your skills, the complexity of the repair, and your budget. Careful consideration of both options will help ensure the best outcome for your equipment.

Understanding Warranty and Coverage

Warranty and coverage are essential components when acquiring any machinery or equipment, as they provide peace of mind and financial protection against unforeseen issues. Understanding the terms and conditions associated with these agreements helps users make informed decisions and ensures they are aware of their rights and responsibilities.

Types of Coverage

There are various types of protection plans available, ranging from basic warranties that cover specific components to comprehensive packages that include additional services. Basic coverage often protects against manufacturing defects, while extended options may encompass routine maintenance and other essential services, enhancing the overall value of the investment.

Claim Process and Requirements

Filing a claim typically requires adherence to certain procedures, including documentation of the issue and proof of purchase. Users should familiarize themselves with the specific requirements outlined in the warranty documentation to ensure a smooth process when seeking repairs or replacements. Being proactive in understanding these guidelines can significantly streamline the experience.

Community Resources for Kioti Owners

For enthusiasts and operators of compact tractors, finding reliable support and information is essential. Engaging with a community of fellow owners can provide invaluable insights, tips, and resources that enhance the overall experience of ownership.

Here are some key resources to consider:

- Online Forums: Join discussions with other owners to share experiences and seek advice.

- Social Media Groups: Platforms like Facebook host groups dedicated to tractor enthusiasts, offering a space for interaction and information exchange.

- Local Clubs: Many areas have clubs that meet regularly, providing opportunities for networking and knowledge sharing.

- YouTube Channels: Numerous content creators focus on maintenance tips, repair tutorials, and product reviews relevant to compact tractors.

- Manufacturer Support: Check official resources for manuals, FAQs, and customer service options.

By leveraging these resources, owners can improve their understanding and maintenance of their machines, ensuring they remain in top condition for years to come.

Latest Upgrades for LB1914 Models

Recent advancements in technology have led to significant enhancements in specific tractor models, aiming to improve performance, efficiency, and user experience. These updates address common issues and introduce features that cater to modern agricultural demands.

The latest improvements include:

- Enhanced Engine Efficiency: New tuning options for the engine that optimize fuel consumption while maintaining power output.

- Improved Hydraulics: Upgraded hydraulic systems that increase lifting capacity and responsiveness.

- Advanced Transmission Options: Introduction of more gears and smoother shifting for better handling across various terrains.

- Upgraded Safety Features: Enhanced safety systems including roll-over protection and better visibility with new design elements.

- Ergonomic Operator Controls: Redesigned cab layout providing more comfort and accessibility for the operator.

These enhancements not only improve functionality but also contribute to a more enjoyable operating experience. Owners can look forward to greater reliability and performance from their machinery, reflecting the latest innovations in the field.